Articles

What Does AC CapACitor Do

Modified: February 26, 2024

Discover the importance of AC capacitors in this informative article. Learn how they function and why they are crucial for your HVAC system's performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to keeping our homes cool and comfortable, air conditioning (AC) systems play a vital role. These systems are complex and consist of several components that work together to regulate temperature. One such component is the AC capacitor, which plays a crucial role in the proper functioning of the AC system.

In this article, we will explore the functionality of an AC capacitor and its importance in the AC system. We will also discuss the different types of AC capacitors, common symptoms of a faulty capacitor, how to test and replace it, and the safety precautions that should be taken.

Whether you’re a homeowner trying to understand the basics of your AC system or an AC technician looking to expand your knowledge, this article will provide you with a comprehensive understanding of AC capacitors and their role in maintaining a cool and comfortable living environment.

Key Takeaways:

- AC capacitors are crucial for starting and running air conditioning systems, maintaining voltage stability, improving motor performance, and correcting power factor. Recognizing symptoms of a faulty capacitor and following safety precautions are essential for optimal AC system performance.

- Understanding the types and roles of AC capacitors, along with the importance of professional testing and replacement, ensures a comfortable and reliable cooling experience. Regular maintenance and prompt attention to faulty capacitors contribute to the longevity and efficiency of AC systems.

Read more: How Long Does AC CapACitor Last

What is an AC Capacitor?

An AC capacitor is an electrical component that stores and releases electrical energy in an AC system. It is a key part of the AC system’s starting and running mechanisms. The capacitor functions as a temporary energy storage unit, providing the necessary power for the AC system to start and run smoothly.

AC capacitors are typically cylindrical in shape and made up of two metal plates separated by an insulating material called a dielectric. The dielectric material can be made of various substances, such as ceramic, paper, or plastic, depending on the capacitor’s type and purpose.

AC capacitors come in different sizes and capacitance ratings, measured in microfarads (μF). The capacitance rating indicates the capacitor’s ability to store electrical charge. Higher capacitance values indicate a larger storage capacity and, therefore, a greater ability to deliver electrical energy when required.

Capacitors used in AC systems are designed to handle high voltage and current levels. They are built to withstand the specific requirements of AC operation, such as the alternating current waveform and the voltage fluctuations that occur during operation.

Overall, an AC capacitor acts as an essential component in an AC system, providing the necessary electrical energy for the system’s operation and ensuring smooth and efficient functioning.

How Does an AC Capacitor Work?

To understand how an AC capacitor works, it’s important to grasp the concept of capacitance. Capacitance is the ability of a capacitor to store electrical charge. It is determined by the surface area of the capacitor’s plates, the distance between them, and the properties of the dielectric material.

When an AC system is turned on, the AC capacitor begins its role in the startup process. The capacitor is connected to both the compressor and the fan motor. As the system receives power, the capacitor stores electrical energy.

During the startup phase, the AC capacitor releases this stored energy to provide the initial power boost required by the compressor and fan motor to start running. The capacitor acts as a temporary power source, compensating for the high demand for power during the system’s startup.

Once the AC system is running, the capacitor continues to function by maintaining a stable voltage across the motor. It helps to create a phase shift between the electrical current and voltage, which helps in the efficient operation of the motor. This phase shift enables the motor to receive the necessary power to operate optimally, improving performance and reducing strain on the electrical system.

Essentially, the AC capacitor acts as a buffer and stabilizer, ensuring that the AC system has a consistent and reliable source of electrical energy. Without a functioning capacitor, the AC system may struggle to start, experience power issues, or fail to operate efficiently.

In summary, an AC capacitor works by storing and releasing electrical energy to help the AC system start up and run smoothly. It plays a vital role in the startup process and the efficient operation of the AC system by maintaining a stable voltage and compensating for power fluctuations.

Role of AC Capacitor in the AC System

The AC capacitor plays a crucial role in the functioning of an AC system. It serves multiple purposes, ensuring that the system operates efficiently and effectively. Let’s explore the key roles of an AC capacitor in an AC system:

- Starting the AC System: The capacitor provides an initial power boost during the startup phase of the AC system. When the system is turned on, it requires a significant amount of power to initiate the compressor and the fan motor. The capacitor stores electrical energy and releases it quickly, enabling the system to start running smoothly.

- Running the AC System: Once the AC system is up and running, the capacitor continues to play a vital role. It helps to stabilize and maintain a consistent electrical voltage across the motor, ensuring its smooth and efficient operation. By creating a phase shift between the current and voltage, the capacitor helps the motor receive the right amount of power to operate optimally.

- Improving Motor Performance: The capacitor also improves the performance of the AC system’s motor. By providing the necessary power boost during startup and maintaining a stable voltage, the capacitor helps prevent motor overheating and reduces strain on the electrical system. This, in turn, extends the lifespan of the motor and enhances the overall performance and efficiency of the AC system.

- Power Factor Correction: In addition to its starting and running functions, the AC capacitor helps correct the power factor of the AC system. Power factor is a measure of how effectively the AC system utilizes the available electrical power. A low power factor can result in increased energy consumption and reduced system efficiency. The capacitor helps offset the reactive power in the system, improving the power factor and reducing energy wastage.

Overall, the AC capacitor plays a critical role in the AC system, starting the system, maintaining voltage stability, improving motor performance, and correcting the power factor. Without a properly functioning capacitor, the AC system may struggle to start, experience power issues, and operate inefficiently. Regular maintenance and monitoring of the capacitor are essential to ensure the smooth operation of the AC system and optimize its performance.

Types of AC Capacitors

AC capacitors come in various types, each designed for specific purposes and applications within the AC system. Let’s explore the most common types of AC capacitors:

- Run Capacitors: Run capacitors are the most commonly used capacitors in AC systems. They are primarily responsible for providing constant voltage and phase shift to the motor during its operation. Run capacitors are typically connected to the motor’s auxiliary winding and contribute to the motor’s smooth running and efficient performance.

- Start Capacitors: Start capacitors are specifically designed to provide high starting torque to the AC motor during the startup phase. They deliver an extra burst of power to overcome the initial inertia and help the motor reach its operating speed efficiently. Start capacitors are often used in motors with high starting loads, such as air conditioner compressors.

- Dual Run Capacitors: Dual run capacitors combine the functionality of both run and start capacitors into a single unit. They are commonly used in AC systems that require both starting torque for the motor and continuous voltage regulation during operation.

- Motor Run Capacitors: Motor run capacitors are specialized capacitors used specifically for single-phase AC motors. They are responsible for improving the motor’s power factor and providing the necessary voltage stabilization during motor operation. Motor run capacitors are typically connected to the motor’s main winding and contribute to its efficient performance and extended lifespan.

- Oil-Filled Capacitors: Oil-filled capacitors are designed for high-voltage applications, commonly found in heavy-duty industrial AC systems. They are filled with a dielectric oil, which provides excellent insulation properties and helps dissipate heat generated during operation. These capacitors are known for their durability and reliability in harsh environments.

It’s important to note that AC capacitors vary in capacitance ratings, voltage ratings, and physical dimensions. It’s essential to refer to the AC system’s specifications and guidelines to determine the appropriate type and size of capacitor required for replacement or installation.

Understanding the different types of AC capacitors helps ensure that the correct capacitor is chosen for a specific AC system, contributing to its optimal performance and longevity.

A tip for understanding what an AC capacitor does is to remember that it stores and releases electrical energy to help start and run the motor in an air conditioning system. It helps maintain a consistent voltage and can improve the efficiency of the system.

Read more: How Do I Know If My AC CapACitor Is Bad?

Common Symptoms of a Faulty AC Capacitor

A faulty AC capacitor can disrupt the proper functioning of an AC system and lead to various issues. It’s important to be able to recognize the common symptoms of a faulty capacitor to address the problem promptly. Here are some signs to look out for:

- Failure to Start: If the AC system fails to start or experiences difficulty in starting, it could be a sign of a faulty capacitor. A capacitor that is unable to provide the necessary power boost during the startup phase can prevent the system from initiating.

- Intermittent Operation: A capacitor that is malfunctioning may cause the AC system to work inconsistently. The system may turn on and off frequently, leading to inadequate cooling or heating and an overall unstable performance.

- Weak Airflow: A faulty capacitor can impact the fan motor’s performance, resulting in weakened airflow from the vents. If you notice reduced airflow or weak circulation of cool or warm air, the capacitor could be at fault.

- Increased Energy Consumption: A defective capacitor can cause the AC system to draw more power to compensate for its inefficiency. This can result in higher energy bills without a noticeable improvement in the system’s performance or cooling/heating capacity.

- Strange Noises: A malfunctioning capacitor may produce abnormal sounds during operation. You may hear buzzing, humming, or clicking noises coming from the AC system. These sounds can be an indication that the capacitor is failing and requires attention.

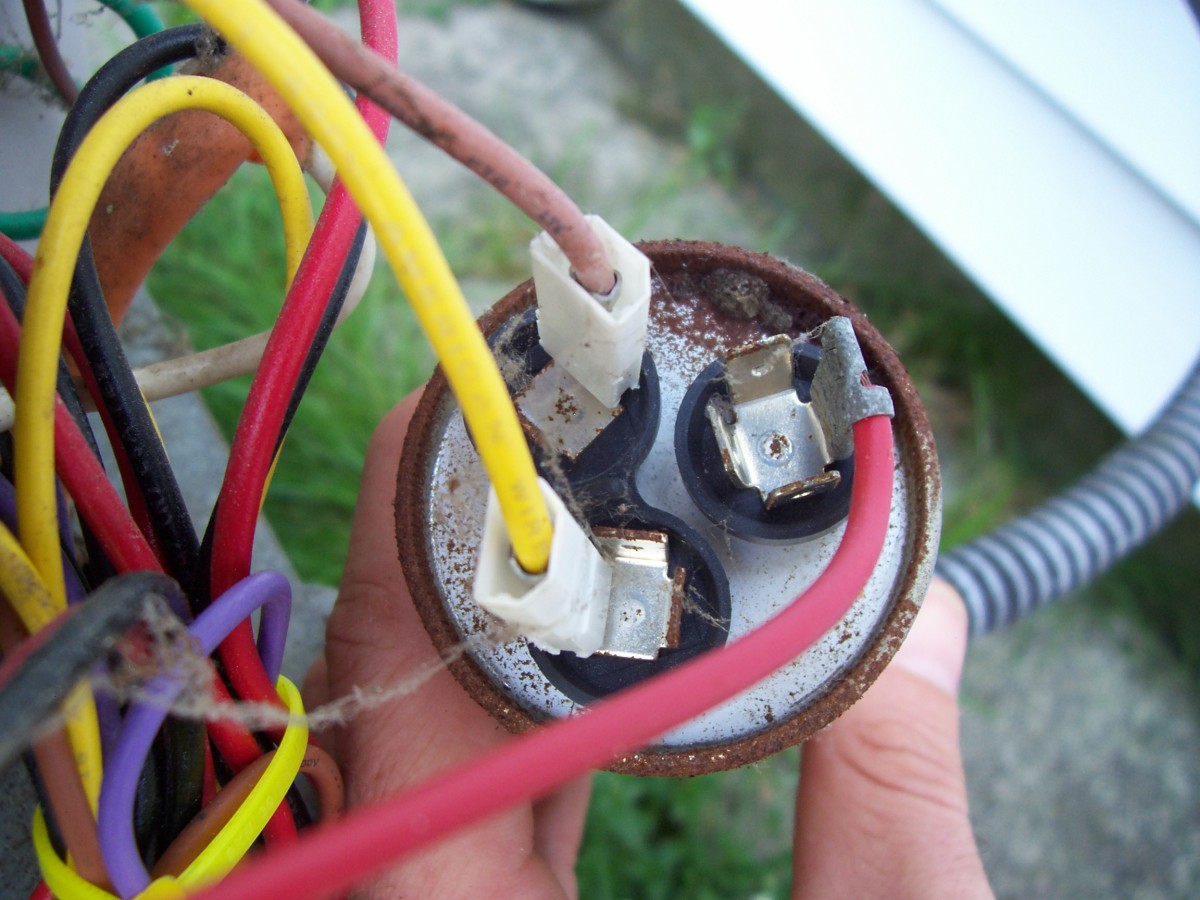

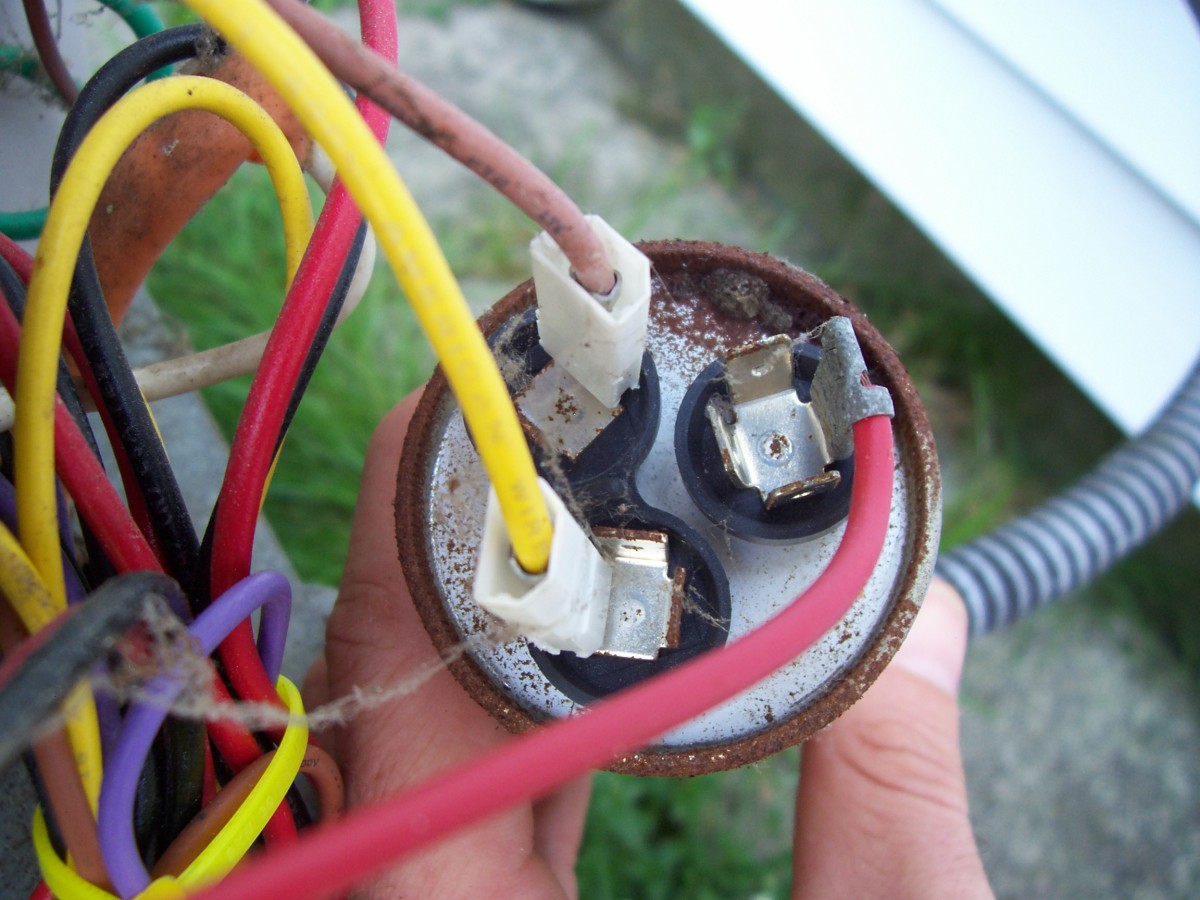

- Visual Signs of Damage: Physically inspecting the capacitor can sometimes reveal visible signs of damage. Look for bulging or leaking on the capacitor’s exterior. If you notice any signs of swelling, corrosion, or fluid leakage, it’s a clear indication that the capacitor is faulty and needs to be replaced.

If you observe any of these symptoms in your AC system, it’s recommended to consult an AC technician for a thorough inspection and capacitor replacement, if necessary. Prompt attention to a faulty capacitor can prevent further damage to the system and ensure optimal performance and energy efficiency.

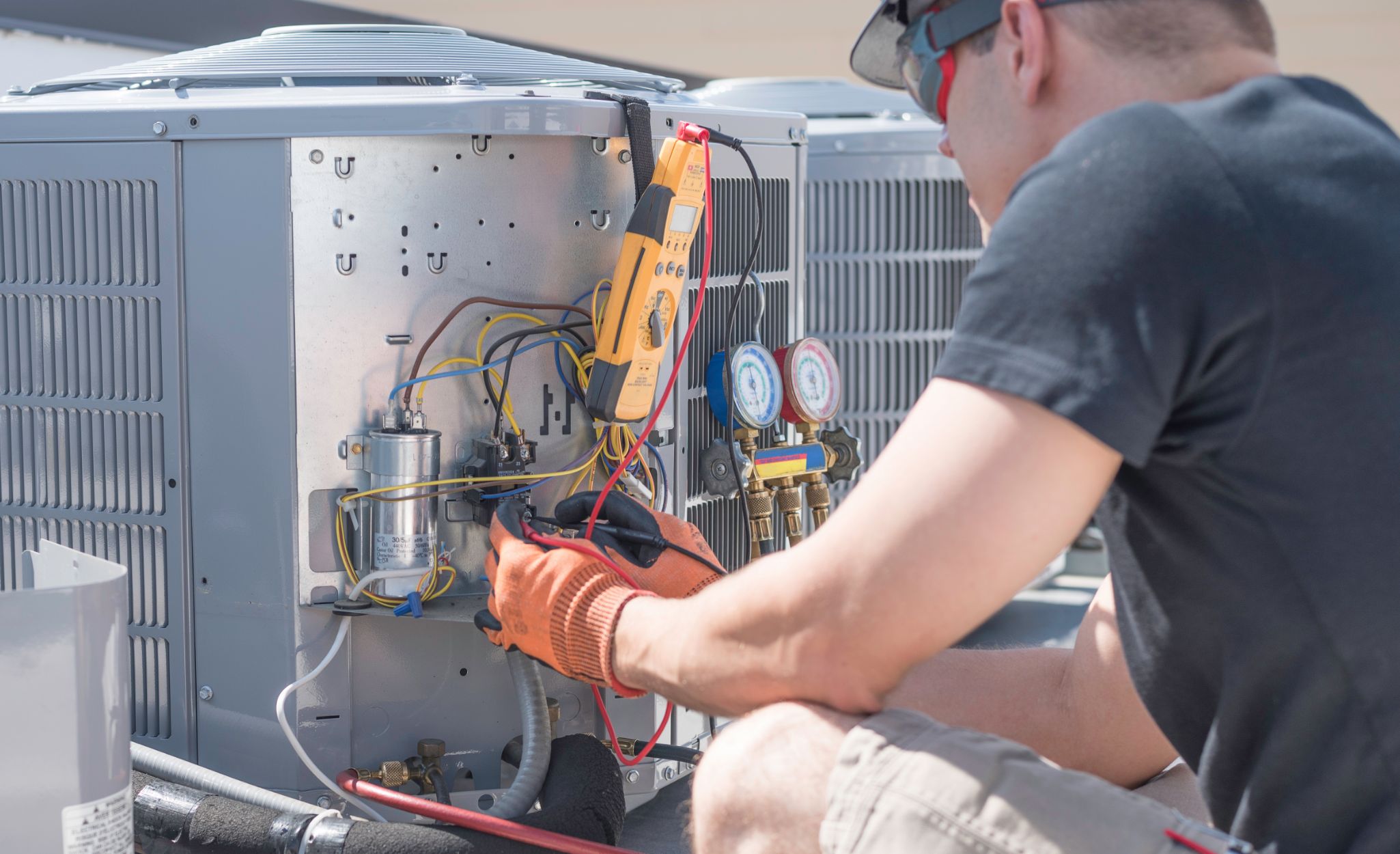

How to Test and Replace an AC Capacitor

Testing and replacing an AC capacitor should be done by a qualified AC technician. However, it’s helpful to have an understanding of the process involved. Here are the general steps taken for testing and replacing an AC capacitor:

- Turn Off Power: Before starting any work on the AC system, ensure that the power supply is turned off. This is important for safety reasons and to prevent any electrical mishaps.

- Discharge Capacitor: Capacitors store electrical energy even when the power is turned off. To discharge the capacitor, use an insulated screwdriver with a rubber handle. Carefully touch the metal contacts of the capacitor with the screwdriver to release any stored charge.

- Testing: To determine if a capacitor is faulty, an AC technician will use a multimeter or a capacitance tester. These tools measure the capacitance value and can identify if it falls outside the acceptable range. Additionally, the technician may also check for other signs of capacitor damage, such as bulging or leaking.

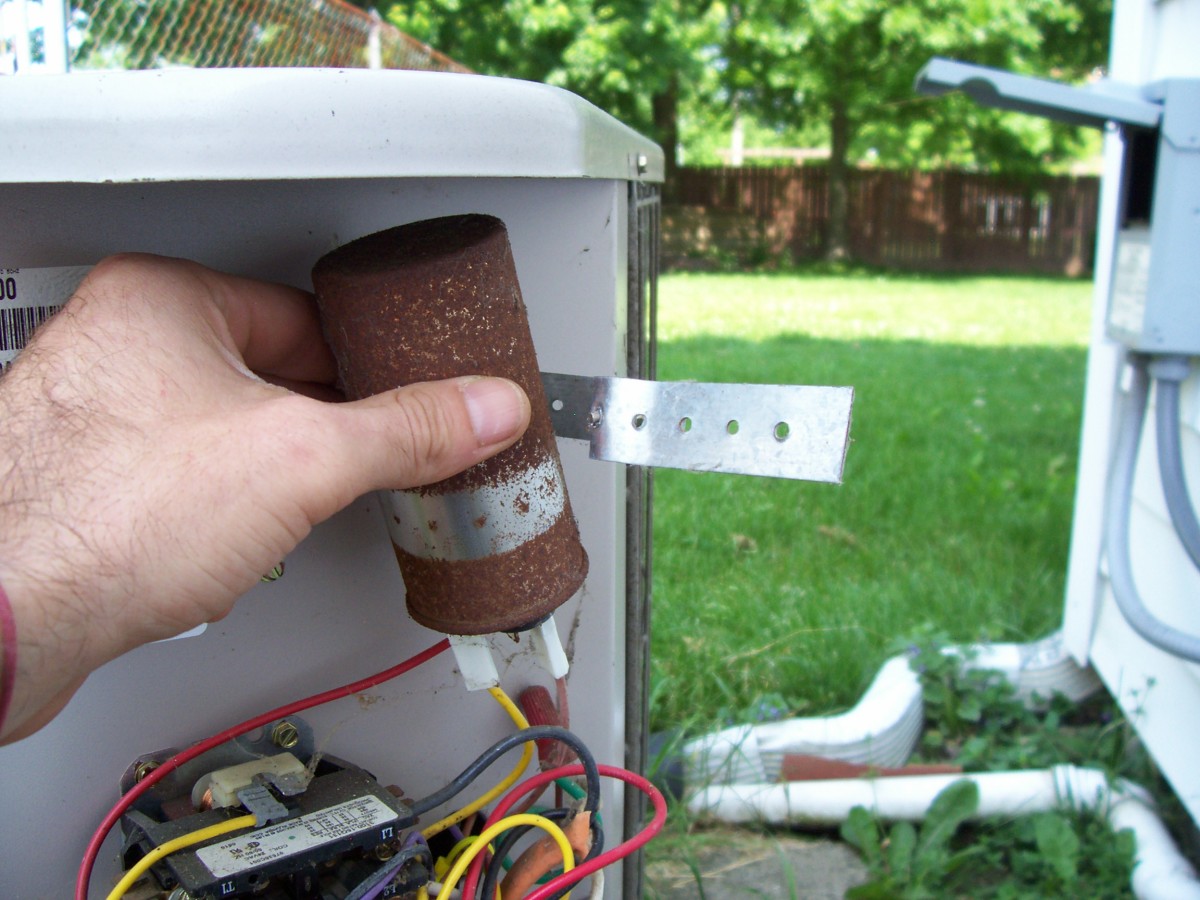

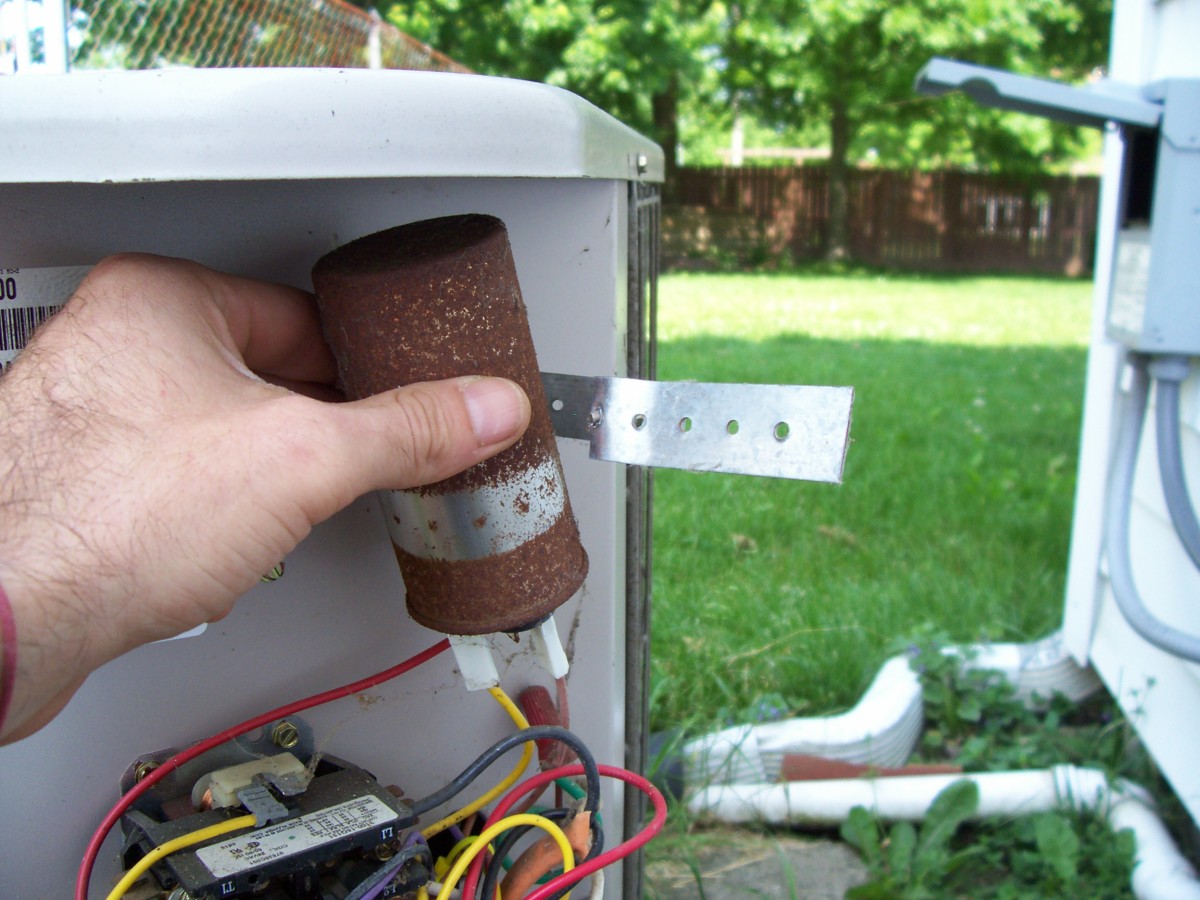

- Replacing the Capacitor: If the capacitor is found to be faulty, replacement is necessary. The technician will first ensure the correct capacitor type, capacitance rating, and voltage rating are identified. They will then disconnect the wiring harness or terminals connected to the capacitor. The defective capacitor will be carefully removed from its mounting bracket or strap. The new capacitor will be securely installed in its place, and the wiring connections will be reattached.

- Testing Again: After the replacement, the technician will perform a final test to ensure the new capacitor is functioning correctly. This may involve checking the capacitance readings and verifying the stable operation of the AC system.

It’s important to note that testing and replacing capacitors require technical expertise and knowledge of AC systems. Attempting to do it yourself without proper training can be dangerous and may cause further damage to the system. It’s best to consult a qualified AC technician who can accurately test and replace the capacitor to ensure safe and proper operation of the AC system.

AC Capacitor Safety Precautions

Working with AC capacitors involves dealing with electrical components, which can be hazardous if not handled properly. Here are some essential safety precautions to keep in mind when working with AC capacitors:

- Turn Off Power: Before working on the AC system, always ensure that the power supply is turned off. This will prevent the risk of electric shock and other electrical accidents. It is recommended to turn off the AC unit at the circuit breaker or disconnect the power source completely.

- Discharge Capacitor: Capacitors store electrical energy even when the power is turned off. To avoid any potential electrical shocks, discharge the capacitor using an insulated screwdriver or a discharge tool. Make sure to follow proper safety procedures and guidelines while discharging the capacitor.

- Use Protective Gear: When handling AC capacitors, wear the appropriate protective gear, such as insulated gloves, safety glasses, and insulated footwear. This will provide an extra layer of protection against electrical hazards.

- Handle with Care: Capacitors are delicate components, and mishandling them can cause damage or injury. Avoid dropping or forcefully impacting the capacitor, as it can result in internal damage or rupture. Handle the capacitor with care and ensure it is securely installed to prevent any accidents.

- Follow Manufacturer Instructions: Always refer to the manufacturer’s instructions and guidelines when testing or replacing capacitors. Each brand and model may have specific instructions that should be followed to ensure safe and proper installation.

- Consult a Professional: While basic troubleshooting can be done by homeowners, it is recommended to consult a qualified AC technician for testing and replacing capacitors. They have the necessary knowledge, training, and equipment to safely handle AC capacitors and address any electrical issues in the AC system.

- Regular Maintenance: To ensure the safety and longevity of the AC capacitor, schedule regular maintenance and inspections by a licensed technician. This will help detect any potential issues early on and prevent safety hazards.

Adhering to these safety precautions will help minimize the risks associated with working on AC capacitors. Remember, if you are unsure or uncomfortable with performing any AC system maintenance or repairs, it is always best to seek professional assistance to ensure the safety of yourself and your AC system.

Conclusion

AC capacitors are essential components of air conditioning systems, playing a crucial role in their proper functioning. Understanding how capacitors work and their importance in the AC system can help homeowners and AC technicians identify and address issues effectively.

In this article, we explored what AC capacitors are and how they function. We discussed their role in starting and running the AC system, as well as their impact on motor performance and power factor correction. We also covered the different types of AC capacitors commonly used in AC systems.

Additionally, we discussed the common symptoms of a faulty AC capacitor, including failure to start, intermittent operation, weak airflow, increased energy consumption, strange noises, and visible signs of damage. Recognizing these signs can help prompt diagnosis and timely replacement of the faulty capacitor.

We also covered the general process of testing and replacing AC capacitors, emphasizing the importance of hiring a qualified AC technician to ensure safe and proper handling of electrical components. Safety precautions, such as turning off power, discharging the capacitor, wearing protective gear, and following manufacturer instructions, were highlighted to avoid electrical hazards.

Regular maintenance, including professional inspections, will help maintain the longevity and efficiency of AC capacitors and the overall performance of the AC system.

In conclusion, AC capacitors play a critical role in the smooth and efficient functioning of air conditioning systems. Understanding their functionality, types, and importance, along with recognizing signs of capacitor failure and following safety precautions, will contribute to a comfortable and reliable cooling experience in homes and commercial spaces. Remember to seek professional assistance when needed to ensure the safety and optimal performance of your AC system.

Frequently Asked Questions about What Does AC CapACitor Do

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does AC CapACitor Do”