Home>Home Maintenance>What Does A Capacitor Do In An Air Conditioning Unit

Home Maintenance

What Does A Capacitor Do In An Air Conditioning Unit

Modified: March 6, 2024

Discover the importance of capacitors in air conditioning units and how they contribute to effective home maintenance. Learn more about their role and function.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on the role of a capacitor in an air conditioning unit! In this article, we will take a deep dive into the world of home maintenance, specifically focusing on the importance of capacitors in keeping your air conditioner running smoothly. Whether you are a homeowner looking to better understand how your air conditioning unit works or an HVAC professional seeking to expand your knowledge, this article is here to provide you with all the information you need.

An air conditioning unit is an essential component of any home. It provides comfort during hot summer months, allowing us to escape the scorching heat and enjoy a cool and pleasant indoor environment. However, have you ever wondered how this magical device operates? Behind the scenes, there are several intricate parts that work together to create the ideal indoor climate, and one of these crucial components is the capacitor.

The basic principles of air conditioning involve the extraction of heat from the indoor air and the circulation of cool air back into the room. This process is achieved through a combination of mechanical, electrical, and chemical reactions within the air conditioning unit. Among these processes, the role of the capacitor cannot be underestimated.

So, what exactly is a capacitor? In simple terms, the capacitor is an electronic component that stores and releases electrical energy. It acts as a temporary reservoir, storing an electrical charge and then discharging it when needed. In the context of an air conditioning unit, the capacitor is responsible for providing the necessary jolt of power to the motor that drives the compressor and fan, allowing them to start and run efficiently.

Without a properly functioning capacitor, the air conditioning unit may struggle to start or fail to run at all. Therefore, it is crucial to understand the function of a capacitor in an air conditioning unit and the signs that indicate a faulty or failing capacitor. Additionally, we will explore the different types of capacitors used in air conditioning units and provide some maintenance tips to ensure the longevity and optimal performance of this essential component.

So, let’s dive into the world of capacitors in air conditioning units and discover why they are vital in creating a comfortable living environment in our homes.

Key Takeaways:

- Capacitors in air conditioning units store and release electrical energy to start and maintain the motor, ensuring efficient cooling. Regular maintenance and prompt repairs can prevent issues and extend the system’s lifespan.

- Signs of a faulty capacitor include slow startup, frequent circuit breaker tripping, and loud buzzing sounds. Professional inspections and cleaning can help identify and address capacitor problems, ensuring reliable performance.

Read more: What Does AC CapACitor Do

Overview of Air Conditioning Units

Before we delve into the details of capacitors in air conditioning units, let’s first gain a basic understanding of how air conditioning systems work. Air conditioning units are designed to regulate temperature, humidity, and air quality in indoor spaces, providing a comfortable environment regardless of external weather conditions.

Typically, an air conditioning system consists of four main components: the compressor, the condenser, the evaporator, and the expansion valve. These components work together to facilitate the heat transfer process, extracting heat from the air inside the room and transferring it outside.

The compressor plays a crucial role in the air conditioning system. It is responsible for compressing low-pressure refrigerant gas into a high-pressure gas, increasing its temperature in the process. This high-pressure gas then flows to the condenser, where it releases heat to the surrounding environment, cooling down and transforming into a high-pressure liquid.

From the condenser, the high-pressure liquid refrigerant moves to the expansion valve. The expansion valve reduces the pressure of the refrigerant, causing it to evaporate into a low-pressure gas. This evaporation process absorbs heat from the surrounding air, cooling it down in the process. The cooled air is then distributed throughout the room via the evaporator, providing a comfortable indoor climate.

It is important to note that the compressor and fan motors in an air conditioning unit require a significant amount of electrical energy to start and operate. This is where the capacitor comes into play, supplying the electrical jolt needed to initiate the motor’s movement and keep it running smoothly.

Now that we have a general understanding of how an air conditioning unit works, we can delve deeper into the role of the capacitor in this intricate system. Understanding the function and importance of capacitors will help us identify capacitor-related issues and take the necessary steps to maintain and repair them.

Basic Principles of Air Conditioning

Before we dive into the specifics of capacitors in air conditioning units, it is important to grasp the fundamental principles behind air conditioning. This knowledge will provide a solid foundation for understanding the role of capacitors in this cooling process.

At its core, air conditioning involves the transfer of heat from one location to another, resulting in a temperature difference between the two areas. This temperature difference is achieved through the use of refrigerants, substances that are capable of absorbing and releasing heat energy at different temperatures.

The air conditioning process starts with the refrigerant being compressed by the compressor, increasing its pressure and temperature. This hot, high-pressure gas then flows to the condenser, where it releases heat to the surrounding environment, cooling down and transforming into a high-pressure liquid.

From the condenser, the high-pressure liquid refrigerant moves to the expansion valve, where its pressure is reduced, causing it to vaporize and evaporate into a low-pressure gas. This evaporation process absorbs heat energy from the surrounding environment, resulting in a lower temperature.

The cooled gas then enters the evaporator, where a fan blows air across the evaporator coils. As the warm indoor air comes into contact with the cold evaporator coils, heat is transferred from the air to the refrigerant, causing the air to become cooler. The now-warmed refrigerant gas returns to the compressor, and the cycle repeats.

It is important to note that in order for the air conditioning system to operate efficiently, the compressor and fan motors need a surge of electrical power to start and maintain their functions. This is where the capacitor comes into play.

The capacitor acts as a temporary power storage device, providing the necessary electrical jolt to kickstart the motor and keep it running smoothly. It stores electrical energy when the air conditioning unit is idle and releases it when needed, ensuring a consistent and reliable power supply to the motors.

Now that we have a basic understanding of how air conditioning works and the role of capacitors in this process, let’s explore in more detail what exactly a capacitor is and how it functions in an air conditioning unit.

What is a Capacitor?

A capacitor is an electronic component that plays a vital role in various electrical systems, including air conditioning units. It is designed to store and release electrical energy, acting as a temporary reservoir or “capacitance” in the circuit.

The basic structure of a capacitor consists of two metallic plates separated by an insulating material known as a dielectric. The plates are typically made of conducting materials such as aluminum or tantalum, while the dielectric can be made of materials like ceramic, plastic, or electrolyte.

When a voltage is applied across the plates, an electrical field is created within the dielectric. The field causes electrons to accumulate on one plate and be repelled from the other plate. This accumulation of charge, also known as an electric potential difference or voltage, is responsible for storing electrical energy within the capacitor.

The unit of measurement for capacitance is the farad (F), named after the renowned physicist Michael Faraday. However, capacitors used in air conditioning units typically have capacitance values measured in microfarads (μF) or picofarads (pF).

Capacitors used in air conditioning units are primarily of two types: start capacitors and run capacitors. Start capacitors are designed to provide the initial boost of energy needed to start the motor. They have a large capacitance and are only engaged during the startup phase of the air conditioning unit.

Run capacitors, on the other hand, have a smaller capacitance and are continuously active once the motor is running. They help to maintain a steady flow of electrical energy to the motor, ensuring its smooth operation. Run capacitors also assist in improving the power factor of the motor, enhancing its efficiency.

In summary, a capacitor is an essential component in an air conditioning unit that stores and releases electrical energy to initiate and maintain the operation of the motor. Understanding the function of capacitors is crucial in diagnosing and resolving issues related to motor failures or problems in air conditioning units.

Now that we have covered the basics of capacitors, let’s explore in more detail the specific function of a capacitor in an air conditioning unit.

Function of a Capacitor in an Air Conditioning Unit

The function of a capacitor in an air conditioning unit is crucial to the overall operation and performance of the system. It plays a vital role in providing the necessary electrical jolt to start and maintain the motor that drives the compressor and fan.

When the air conditioning unit is turned on, the compressor and fan motors require an initial surge of electrical energy to overcome the inertia and start rotating. This surge is provided by the start capacitor, which has a high capacitance value and can store a significant amount of energy.

As the start capacitor receives power, it charges up and stores electrical energy. When the air conditioning unit is switched on or the thermostat signals the need for cooling, the start capacitor rapidly discharges its stored energy, providing a powerful jolt to the motor. This jolt helps kickstart the motor into motion, overcoming the resistance and allowing it to start running.

Once the motor is in motion, it is supported by the run capacitor. The run capacitor is responsible for maintaining the flow of electrical energy to the motor, ensuring its continuous and efficient operation. It helps stabilize the motor’s voltage and current, improving its performance and preventing voltage drops that may lead to motor stalls or damage.

In addition to starting and maintaining the motor, capacitors also assist in improving the power factor of the motor. Power factor is a measure of the efficiency with which electrical power is utilized. A low power factor can result in energy wastage and increased utility costs, so capacitors help to optimize the power factor, reducing energy consumption and improving overall efficiency.

Capacitors in air conditioning units are subjected to continuous electrical stress and can deteriorate over time due to factors like temperature fluctuations, humidity, voltage spikes, and age. It is essential to regularly inspect and maintain the capacitors to ensure their proper functioning. Faulty or failing capacitors can lead to motor failures, inefficient operation, and ultimately, system breakdowns.

In the next sections, we will delve deeper into the different types of capacitors used in air conditioning units, discuss the signs indicating a faulty capacitor, and provide some maintenance tips to help keep your air conditioning system running smoothly.

A capacitor in an air conditioning unit stores and releases electrical energy to help start the compressor and fan motors. It also helps maintain a consistent voltage for the system to operate efficiently. Regular maintenance and inspection of the capacitor can help prevent system breakdowns.

Types of Capacitors Used in Air Conditioning Units

There are different types of capacitors used in air conditioning units, each designed for specific purposes and applications. The two main types of capacitors commonly found in these systems are start capacitors and run capacitors.

1. Start Capacitors: Start capacitors are high capacitance capacitors that are primarily responsible for providing the initial boost of electrical energy needed to start the motor. They are designed to handle the high current draw during motor startup. Start capacitors are typically larger in size and have a higher capacitance value, ranging from around 70 to 1,200 microfarads (μF).

2. Run Capacitors: Run capacitors, as the name suggests, are capacitors that continuously operate once the motor is running. They provide a steady flow of electrical energy to the motor, ensuring its smooth and efficient operation. Run capacitors have a smaller capacitance value compared to start capacitors, typically ranging from 1 to 100 microfarads (μF).

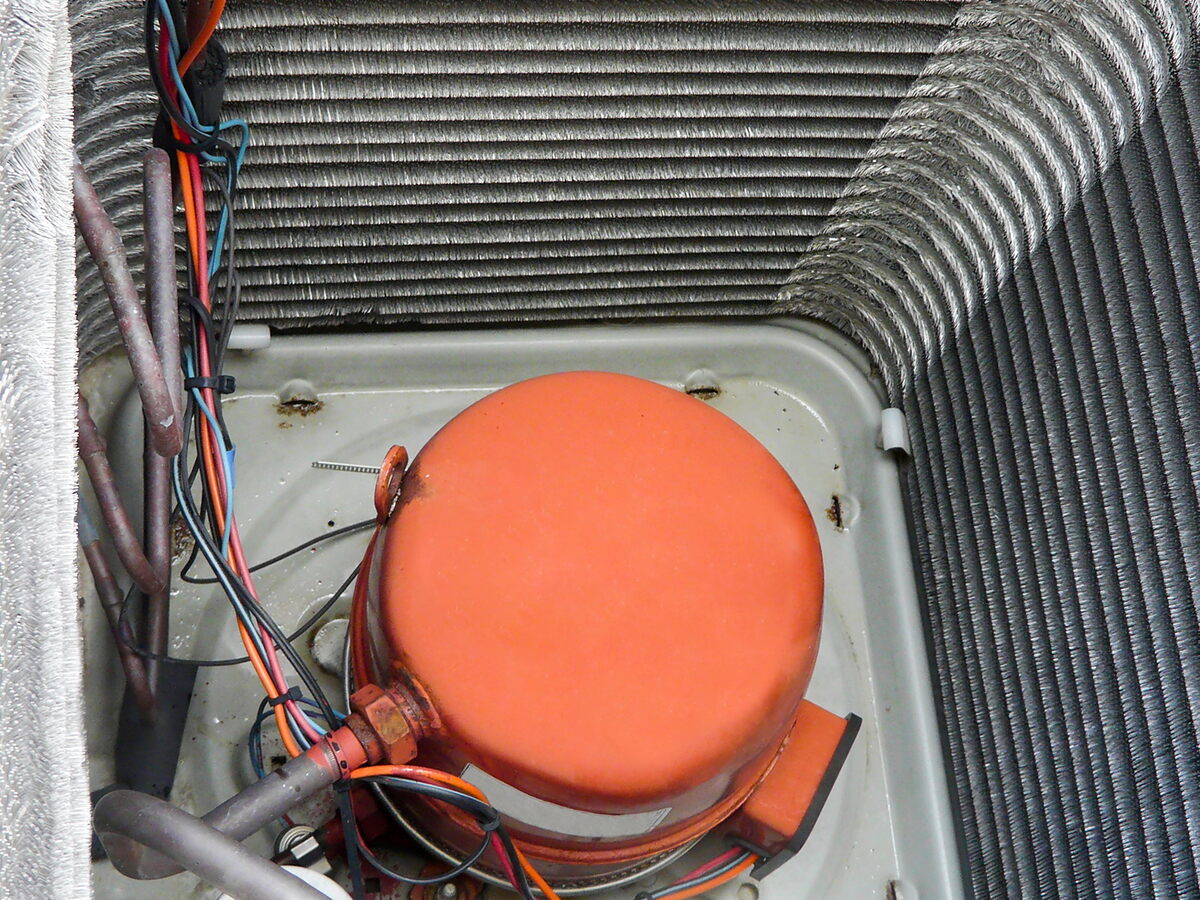

Both start and run capacitors are essential components in an air conditioning unit and work in conjunction to support the motor. They are usually located within the condenser unit, near the motor, although their exact placement may vary depending on the specific air conditioning system.

In addition to these common capacitors, there are also dual-run capacitors that combine the functions of both start and run capacitors into a single component. Dual-run capacitors are often found in newer air conditioning units and are designed to simplify the overall capacitor layout and reduce the number of components within the system. They typically have multiple sets of terminals, allowing for the connection of both the start and run circuits.

It is essential to choose capacitors that are compatible with the specific air conditioning unit. Capacitors come in different voltage ratings, and using a capacitor with a lower voltage rating than required can lead to premature failure or damage to the capacitor and the motor. It is always recommended to consult the manufacturer’s specifications or seek professional advice when replacing or selecting capacitors for an air conditioning unit.

Now that we have explored the different types of capacitors used in air conditioning units, let’s move on to the next section, where we will discuss the signs that indicate a faulty capacitor.

Signs of a Faulty Capacitor in an Air Conditioning Unit

A faulty capacitor in an air conditioning unit can cause various issues and negatively impact the system’s performance. It is important to be aware of the signs that indicate a faulty capacitor so that you can address the problem promptly and prevent further damage to the unit.

Here are some common signs to watch out for:

- Slow or weak startup: If your air conditioning unit takes a long time to start or struggles to start, it could be a sign of a faulty start capacitor. The capacitor may have decreased capacitance or failed completely, preventing the motor from receiving the necessary jolt of energy to initiate rotation.

- Frequent tripping of circuit breaker: A malfunctioning capacitor can cause excessive electrical stress on the motor, leading to frequent tripping of the circuit breaker. This is often accompanied by a sudden loss of power to the air conditioning unit, requiring manual resetting of the breaker.

- Intermittent cooling or airflow issues: Capacitor-related issues can result in inconsistent cooling performance or reduced airflow from the air conditioning unit. The capacitor’s inability to provide the required electrical power to the motor can cause the unit to function at suboptimal levels, resulting in insufficient cooling or inadequate airflow throughout the space.

- Loud humming or buzzing sounds: Faulty capacitors can produce audible humming or buzzing sounds, particularly when the air conditioning unit is operating. These noises are often indicative of electrical issues within the capacitor or the associated motor, and they require immediate attention to prevent further damage.

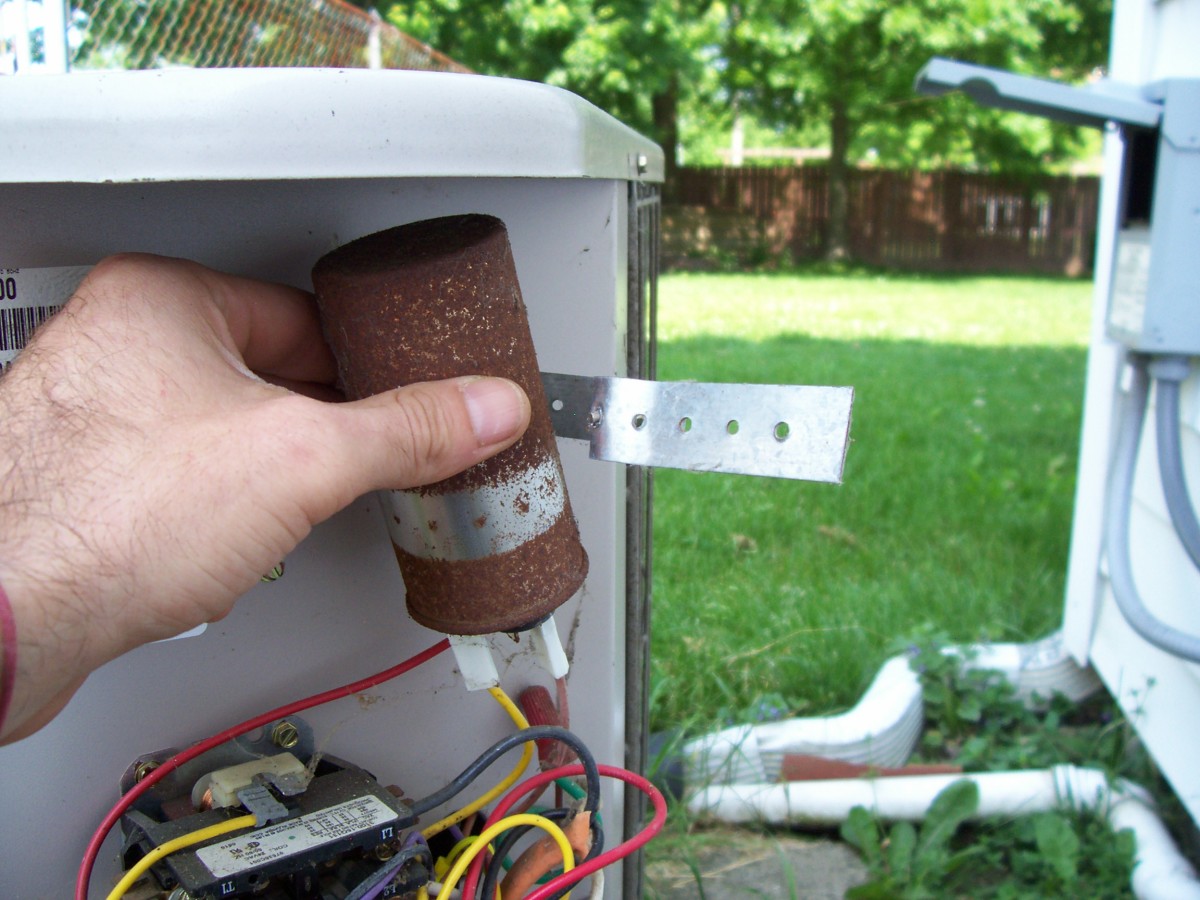

- Swollen or bulging capacitor: Physical signs of a faulty capacitor include visible swelling or bulging of the capacitor casing. This is typically caused by the buildup of internal pressure due to a failure within the capacitor. Swollen capacitors should be replaced promptly to avoid the risk of rupture or leakage.

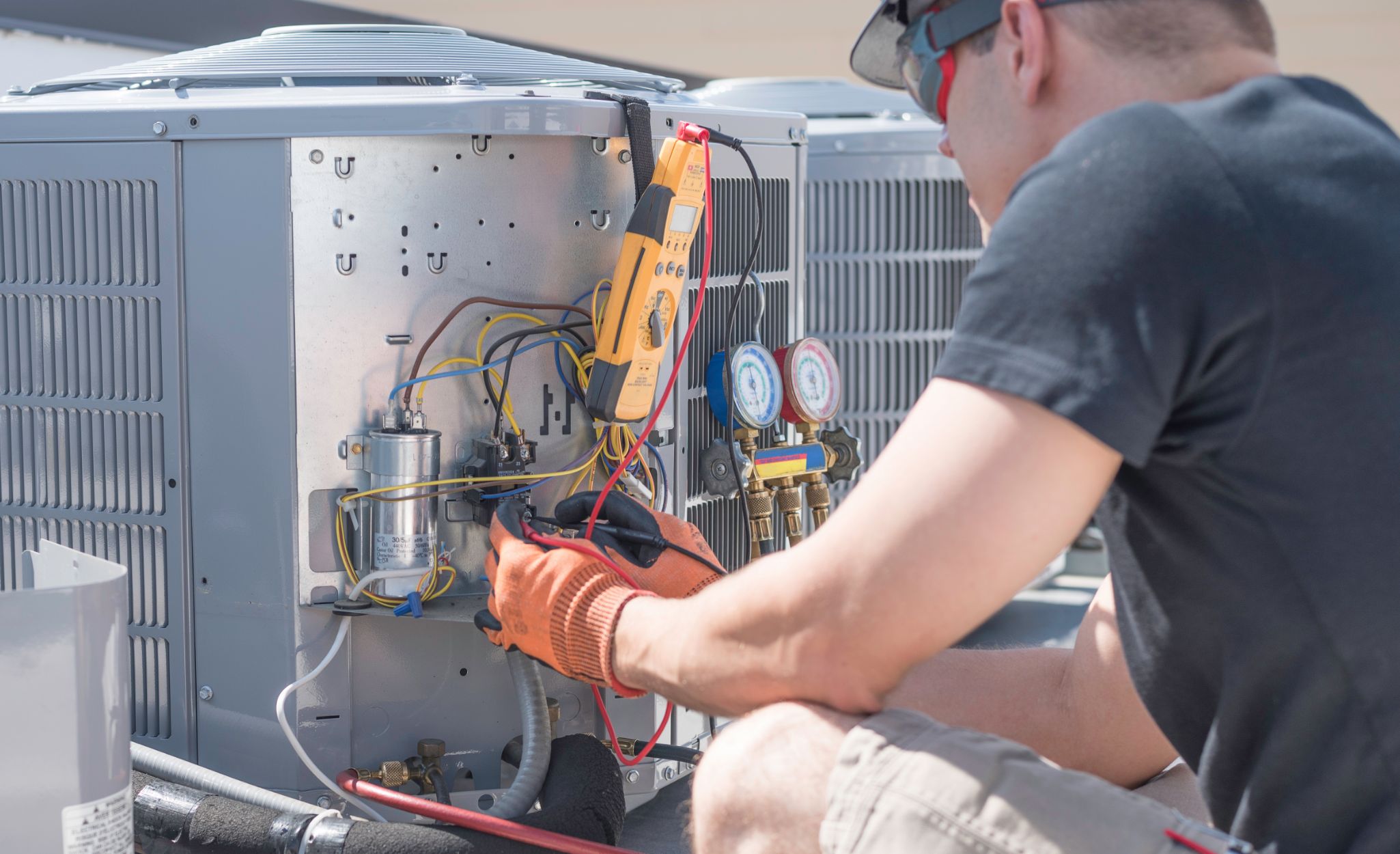

If you notice any of these signs or suspect a faulty capacitor in your air conditioning unit, it is advisable to contact a professional HVAC technician for inspection and repair. Attempting to handle capacitor replacement or repair without proper knowledge and expertise can be dangerous and may lead to further damage to the unit or electrical risks.

Regular maintenance and inspection of capacitors in air conditioning units can help identify potential issues before they escalate. It is recommended to schedule routine check-ups with a qualified technician to ensure the optimal performance and longevity of your air conditioning system.

Now that we have covered the signs of a faulty capacitor, let’s move on to the importance of maintaining a capacitor in an air conditioning unit.

Importance of Maintaining a Capacitor in an Air Conditioning Unit

Maintaining a capacitor in an air conditioning unit is crucial for the overall performance and longevity of the system. Capacitors play a vital role in starting and running the motor that drives the compressor and fan, ensuring the proper functioning of the unit. Neglecting capacitor maintenance can lead to a range of issues and potentially expensive repairs.

Here are some reasons why maintaining a capacitor is essential:

- Reliable motor operation: The capacitor provides the necessary electrical jolt to start the motor and keep it running smoothly. Regular maintenance ensures that the capacitor is in optimal condition, supplying the required power to the motor. This results in reliable motor operation and prevents issues like slow startup, motor stalls, or complete motor failure.

- Efficient energy consumption: Faulty capacitors can cause the motor to operate at suboptimal levels, leading to increased energy consumption. A well-maintained capacitor helps ensure that the motor runs efficiently, reducing energy waste and lowering utility costs. It improves the power factor of the motor, thereby maximizing its energy efficiency.

- Extended system lifespan: Capacitor failure can lead to excessive stress on the motor and other components of the air conditioning system. This can result in premature wear and tear and potentially shorten the system’s overall lifespan. By properly maintaining the capacitor, you can help prolong the life of the air conditioning unit, saving you from costly replacements or repairs.

- Prevention of motor damage: Malfunctioning capacitors can cause voltage spikes or fluctuations that can damage the motor. Unstable power supply can overheat the motor, leading to irreversible damage. Regular maintenance and inspection of the capacitor can detect any potential issues early on, preventing motor damage and avoiding costly motor replacements.

- Improved system performance: A well-maintained capacitor ensures the smooth operation of the air conditioning unit. It helps maintain consistent cooling performance, adequate airflow, and proper temperature control. By addressing capacitor-related issues promptly, you can enjoy optimal comfort and performance from your air conditioning system.

To maintain a capacitor, it is recommended to schedule routine professional inspections and maintenance. Qualified HVAC technicians can check the capacitance, voltage rating, and overall condition of the capacitor. They can also perform capacitor replacements or repairs as necessary, ensuring that the air conditioning unit operates reliably and efficiently.

Regular cleaning of the air conditioning unit, including the capacitor, is also essential to prevent dust, debris, or moisture buildup, which can affect its performance. Always follow manufacturer guidelines and consult professionals for any specific maintenance requirements for your particular air conditioning unit.

By prioritizing the maintenance of the capacitor in your air conditioning unit, you can optimize its performance, extend its lifespan, and enjoy reliable and efficient cooling for years to come.

Next, let’s explore some common capacitor problems and their solutions to help you troubleshoot any potential issues.

Common Capacitor Problems and Solutions

Capacitors in air conditioning units can experience various issues over time, ranging from minor glitches to complete failure. Understanding these common problems and their solutions can help you troubleshoot and address capacitor-related issues in your air conditioning system.

Here are some of the most common capacitor problems and their possible solutions:

- Capacitor failure: Capacitors can fail due to age, electrical stress, or other factors. If the capacitor is completely non-functional, it will need to be replaced with a new one. It is crucial to choose a replacement capacitor with the correct capacitance (μF) and voltage rating (V) for your specific air conditioning unit. Consult a professional HVAC technician for guidance and assistance in selecting and installing the proper capacitor.

- Reduced capacitance: Over time, capacitors can lose their capacitance value due to aging or degradation. Reduced capacitance can lead to motor startup issues or inefficient motor operation. If the capacitance is significantly lower than the rated value, the capacitor should be replaced to restore the proper operation of the air conditioning unit.

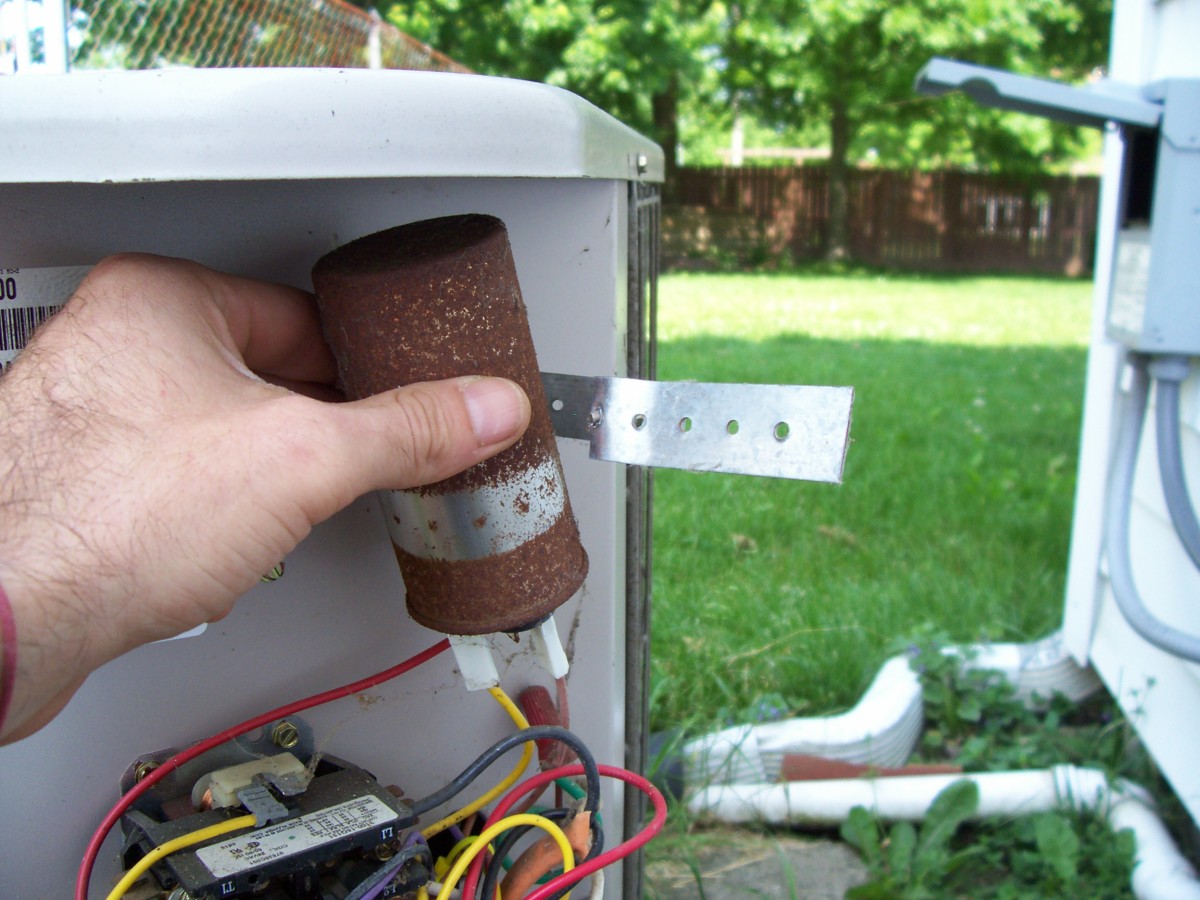

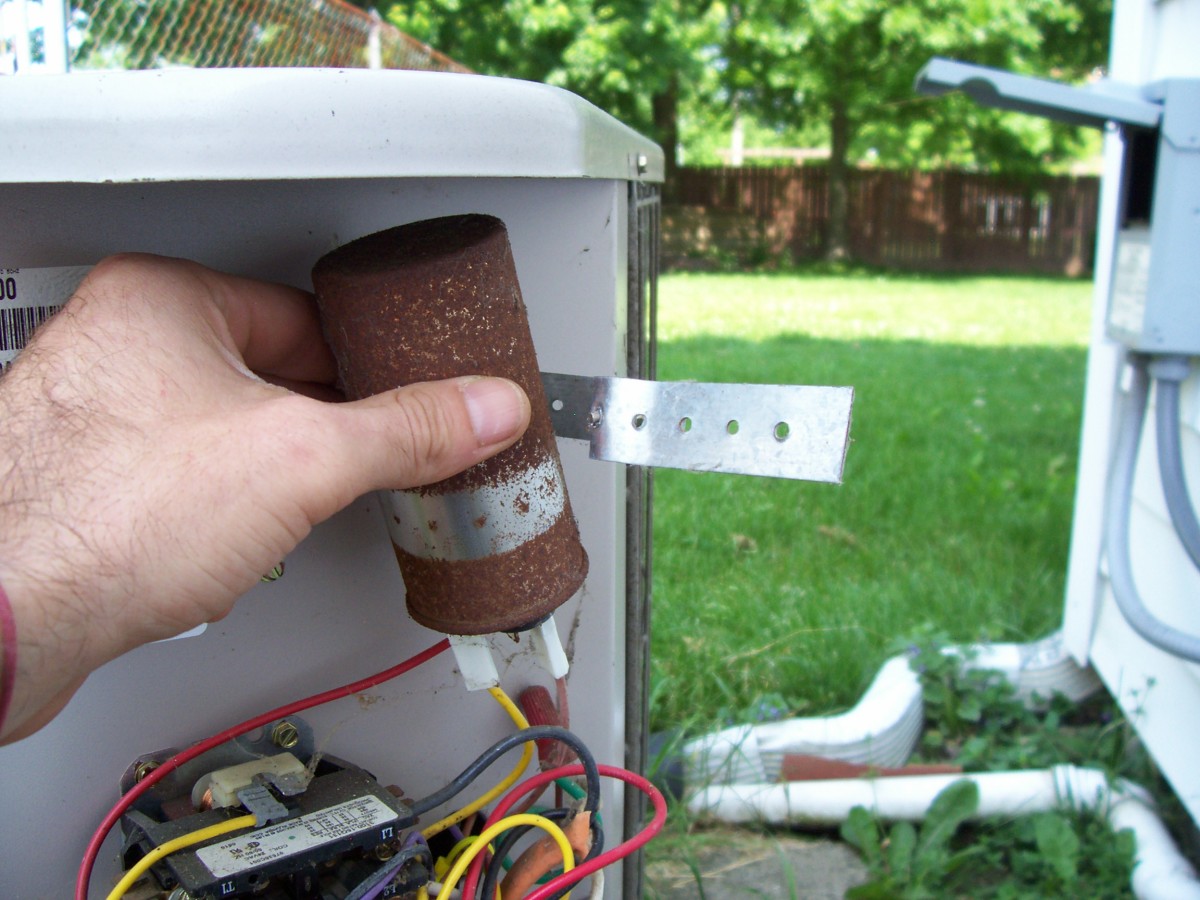

- Weak or swollen capacitor: A weak or swollen capacitor is often a sign of internal damage or an impending failure. If you notice a capacitor that appears weak or swollen, it is best to have it replaced as soon as possible. Swollen capacitors can be potentially dangerous and may rupture or leak, causing damage to the surrounding components.

- Loose or corroded connections: Capacitors rely on proper electrical connections to function effectively. Loose or corroded connections can hinder the flow of electricity and affect the capacitor’s performance. Regularly inspect the capacitor’s terminals for any signs of looseness or corrosion. If necessary, clean the terminals and tighten any loose connections to ensure a secure electrical connection.

- Overheating: Excessive heat can cause capacitors to degrade and fail prematurely. Poor ventilation or high ambient temperatures in the air conditioning unit can contribute to capacitor overheating. Ensure proper airflow around the capacitor by keeping the surrounding area clean and free of debris. Additionally, consider installing a capacitor with a higher temperature rating to withstand the heat generated during operation.

When dealing with capacitor problems, it is important to prioritize safety. Always disconnect the power supply and discharge the capacitor before inspecting or performing any maintenance on it. If you are unsure or uncomfortable with capacitor repairs, it is best to seek the assistance of a qualified HVAC technician.

Regular maintenance and inspections are crucial for detecting and addressing capacitor problems early on. By staying proactive and addressing capacitor issues promptly, you can avoid more severe damage to the air conditioning unit and ensure its optimal performance throughout its lifespan.

Now that we have explored common capacitor problems and solutions, let’s conclude our comprehensive guide on capacitors in air conditioning units with a summary.

Read more: How Long Does AC CapACitor Last

Conclusion

Understanding the role and importance of capacitors in air conditioning units is essential for homeowners and HVAC professionals alike. Capacitors are critical components that provide the necessary electrical energy to start and maintain the motors that drive the compressor and fan, ensuring the proper functioning of the air conditioning system.

In this comprehensive guide, we have covered the basic principles of air conditioning and delved into the function and types of capacitors used in air conditioning units. We have also discussed the signs of a faulty capacitor and the importance of maintaining capacitors in air conditioning systems.

By maintaining capacitors in optimal condition, you can ensure reliable motor operation, efficient energy consumption, and extended system lifespan. Regular inspections, cleaning, and professional maintenance can help detect issues early and prevent costly repairs or replacements.

Common capacitor problems, such as capacitor failure, reduced capacitance, weak or swollen capacitors, loose connections, and overheating, can be addressed with appropriate solutions. It is crucial to follow safety protocols and consult professionals when dealing with capacitor repairs or replacements.

In conclusion, capacitors play a crucial role in the proper functioning of air conditioning units. Understanding their function, maintaining their condition, and addressing any issues promptly can contribute to the longevity and optimal performance of your air conditioning system.

We hope that this guide has provided you with valuable insights and practical knowledge about capacitors in air conditioning units. By applying this knowledge, you can ensure a cool and comfortable environment in your home while maximizing the efficiency and lifespan of your air conditioning unit.

Remember, when in doubt or if you encounter complex issues, it is always recommended to seek the assistance of qualified HVAC professionals who have the expertise and experience to address any specific problems with your air conditioning unit’s capacitors.

Frequently Asked Questions about What Does A Capacitor Do In An Air Conditioning Unit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.