Home>Home Maintenance>Why Do Capacitors Fail In An Air Conditioner

Home Maintenance

Why Do Capacitors Fail In An Air Conditioner

Modified: March 7, 2024

Learn about the common reasons why capacitors fail in an air conditioner and how proper home maintenance can prevent such issues.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of home maintenance, where we strive to keep our living spaces comfortable and functional. One essential component in our quest for comfort is the air conditioner. Whether it’s a sweltering summer day or a muggy evening, we rely on our air conditioners to keep us cool and refreshed. But what happens when our trusty AC unit starts acting up and fails to deliver the cool air we crave?

In many cases, the culprit behind air conditioner malfunctions is a failed capacitor. Capacitors play a vital role in the operation of air conditioning systems, and their failure can have a significant impact on the performance and efficiency of your unit. Understanding why capacitors fail and how to recognize the signs of a failing capacitor can empower you as a homeowner to take proactive measures to keep your air conditioner running smoothly.

In this article, we will delve into the world of air conditioner capacitors, exploring common causes of failure and the telltale signs that indicate your capacitor may be on its last legs. Additionally, we will discuss the importance of regular maintenance and how to diagnose and replace a failed capacitor to ensure the longevity of your air conditioning unit.

So, grab a refreshing beverage, sit back, and let’s dive into the world of air conditioner capacitors!

Key Takeaways:

- Regular maintenance and timely replacement of capacitors are crucial for keeping your air conditioner running smoothly. Look out for signs of capacitor failure, such as reduced cooling capacity and frequent circuit breaker tripping.

- Overheating, age, power surges, and poor quality components can cause capacitor failure. Addressing these issues promptly and seeking professional help for diagnosis and replacement is essential for maintaining a reliable air conditioning system.

Read more: Why Do Coils Freeze On An Air Conditioner

Overview of Air Conditioner Capacitors

Before we delve into the common causes of capacitor failure, let’s gain a basic understanding of what an air conditioner capacitor is and its role in the functioning of your AC unit.

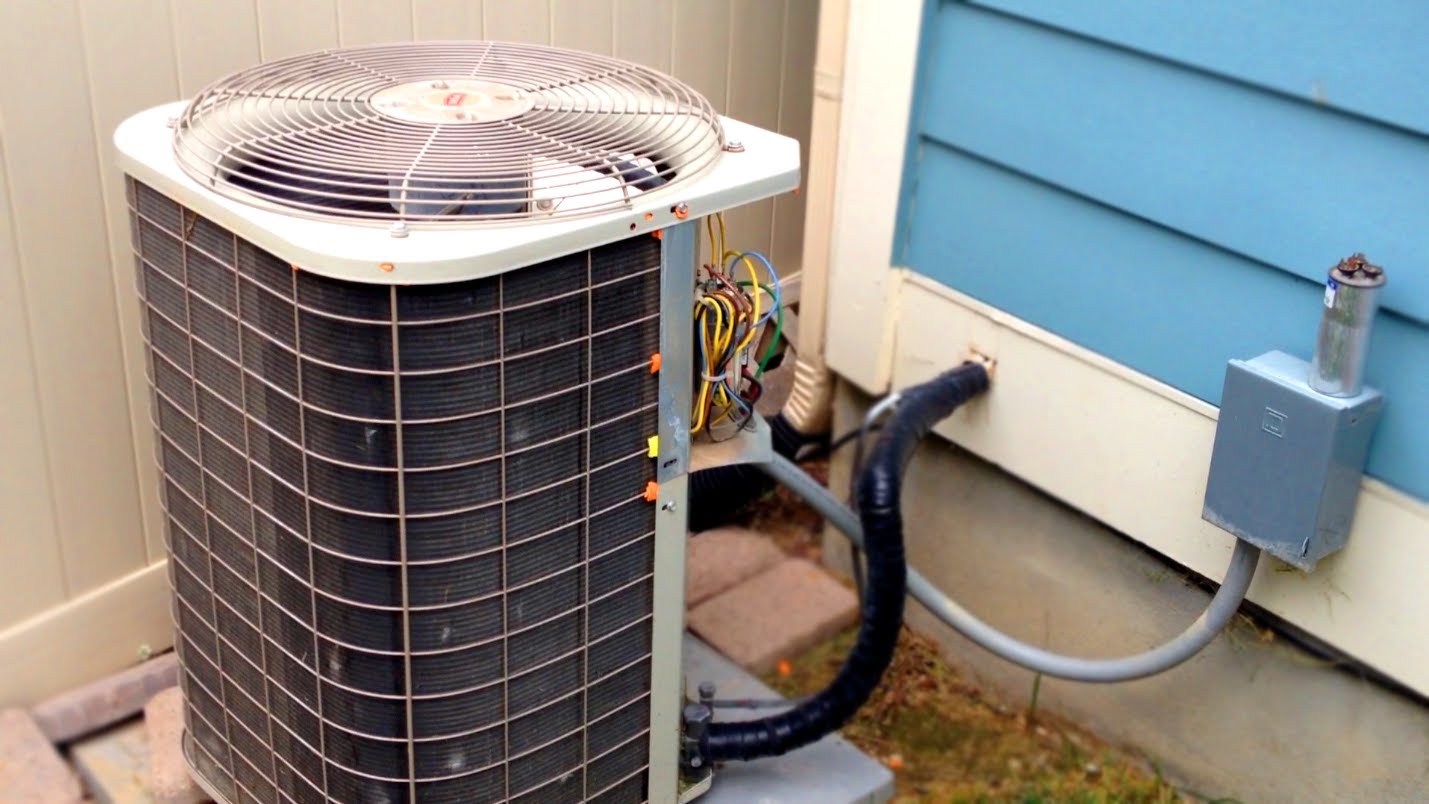

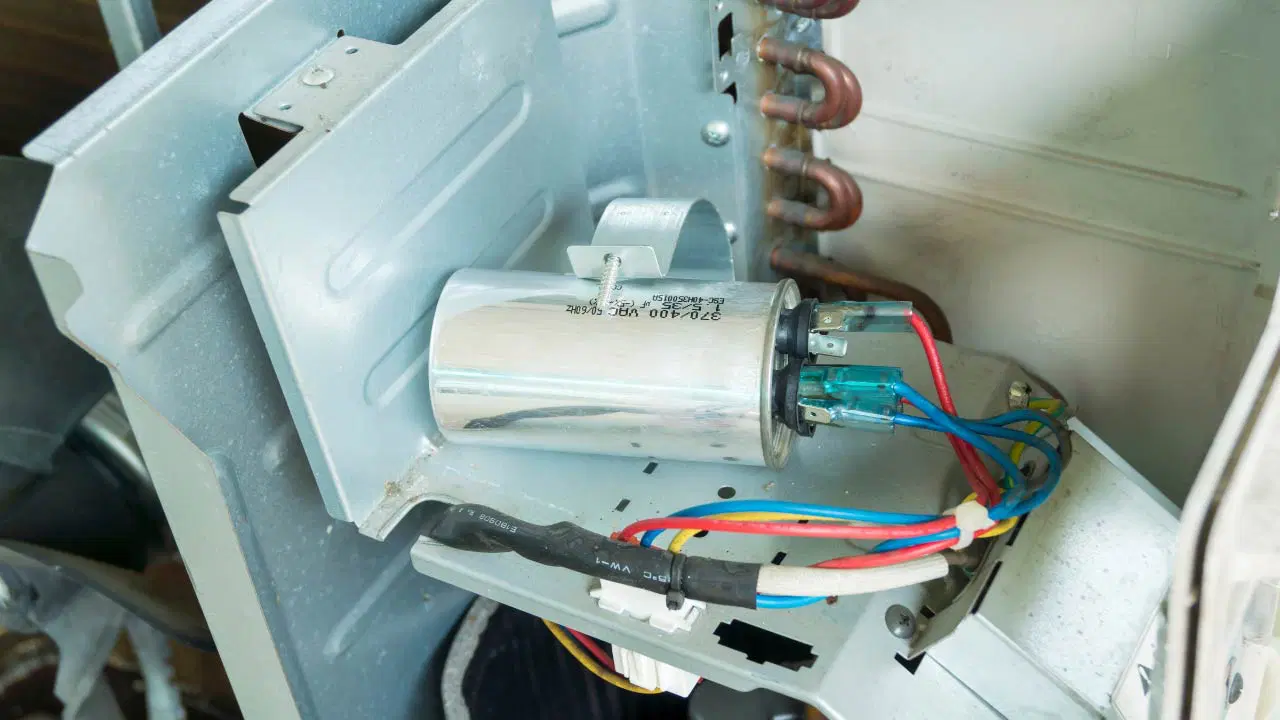

An air conditioner capacitor is an electrical component that stores and releases electrical energy to help start the motor or compressor in your air conditioning system. It acts as a temporary battery, providing an extra power boost when the motor or compressor needs to start up. Capacitors come in various sizes and types, with the most common ones being run capacitors and start capacitors.

Run capacitors are designed to provide a steady stream of electrical energy to keep the motor running smoothly. They are typically found in the condenser unit of your air conditioner. Start capacitors, on the other hand, provide an extra boost of power during the start-up phase to help the motor overcome inertia and start rotating. They are usually found in the outdoor condenser unit.

Both run and start capacitors play crucial roles in the efficient operation of your air conditioning system. Without them, your air conditioner would struggle to start, resulting in reduced performance, increased energy consumption, and potential damage to the motor or compressor.

Since capacitors are constantly subjected to electrical currents and heat, they are susceptible to wear and tear over time. Various factors can contribute to their failure, and it’s essential to be aware of these to prevent sudden breakdowns and costly repairs.

Now that we have a general understanding of air conditioner capacitors, let’s explore the common causes of capacitor failure.

Common Causes of Capacitor Failure

Capacitors, like any other electrical component, are prone to failure due to various factors. Understanding these common causes can help you take preventative measures to extend the lifespan of your capacitors. Let’s take a closer look at the main culprits behind capacitor failure in air conditioning systems:

- Overheating: Excessive heat is one of the primary reasons for capacitor failure. Air conditioners operate in harsh outdoor environments and are exposed to high temperatures. Over time, the continuous heat can cause the capacitor to deteriorate, leading to performance issues or complete failure.

- Age and Wear: Like most components, capacitors have a limited lifespan. Over the years, capacitors will naturally wear out and lose their ability to store and release energy effectively. Aging capacitors are more susceptible to failure, so it’s important to keep track of their age and plan for replacements as needed.

- Power Surges: Electrical power surges, whether from lightning strikes or problems with the electrical grid, can cause damage to electronic components, including capacitors. Surges can overload the capacitor and cause it to fail instantly or shorten its lifespan.

- Poor Quality Components: In some cases, capacitor failure can be attributed to the use of subpar or counterfeit components. Low-quality capacitors may not be able to withstand the demands of the air conditioning system, leading to premature failure.

It’s important to note that these causes of capacitor failure are not exhaustive, and other factors, such as improper installation or manufacturing defects, can also contribute to failure. Nonetheless, understanding these common causes can help you identify potential issues and take appropriate actions to prevent capacitor failure in your air conditioning system.

Overheating

One of the primary causes of capacitor failure in air conditioning systems is overheating. Air conditioners operate in harsh outdoor environments, especially during summer months, where temperatures can soar. As a result, the capacitors are constantly exposed to high levels of heat, which can take a toll on their performance and longevity.

Capacitors are designed to withstand a certain level of heat, but prolonged exposure to excessive temperatures can cause them to deteriorate and eventually fail. When a capacitor overheats, its internal components, such as the dielectric material or the electrolyte, can degrade or evaporate. This can lead to a loss of capacitance or a short circuit, rendering the capacitor ineffective.

There are several factors that can contribute to capacitor overheating:

- Improper air circulation: Proper airflow is crucial for dissipating heat and maintaining optimal temperatures. If the air conditioning unit is installed in a confined space or if the vents are blocked, the capacitor may not receive adequate airflow, which can cause it to overheat.

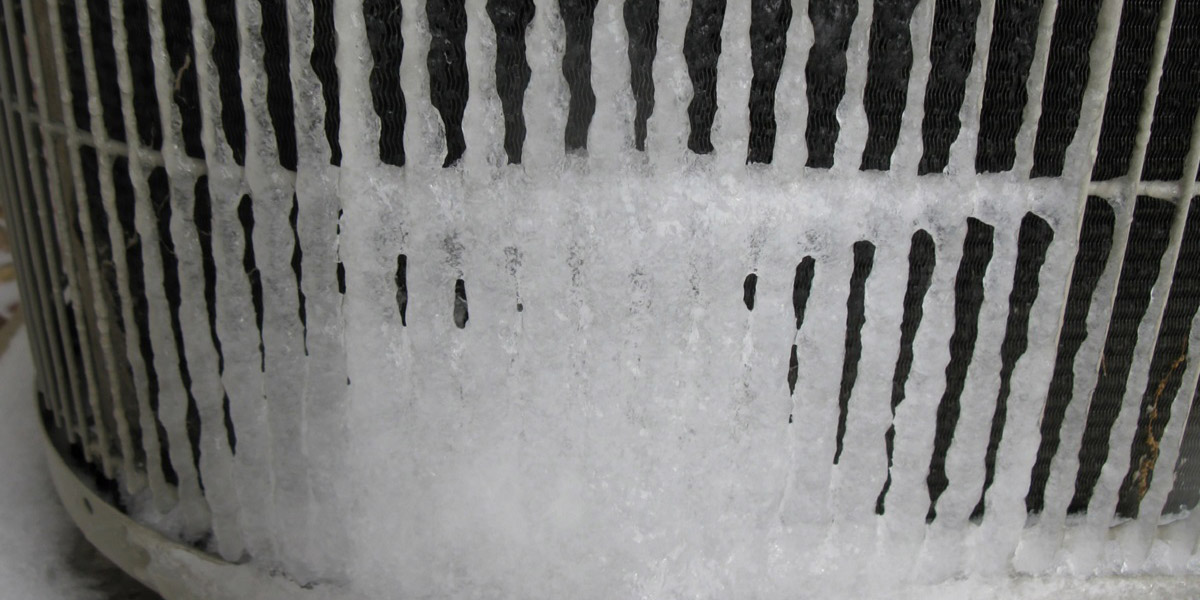

- Dirty or clogged condenser coils: Over time, dirt, dust, and debris can accumulate on the condenser coils, obstructing heat dissipation and causing the system to work harder. This extra strain can result in an increase in temperature, potentially causing the capacitor to overheat.

- Faulty fan motor: The fan motor plays a vital role in circulating air over the condenser coils. If the fan motor malfunctions or operates at a lower speed, it can disrupt the normal airflow and contribute to capacitor overheating.

- Electrical issues: Voltage fluctuations or irregularities in the electrical supply can also lead to capacitor overheating. High voltages can cause excessive current flow through the capacitor, generating excess heat and potentially damaging the internal components.

To prevent capacitor overheating, it is essential to ensure proper ventilation and airflow around the air conditioning unit. Regular maintenance, such as cleaning the condenser coils and ensuring the fan motor is in good working condition, can also help mitigate the risk of overheating. Additionally, using surge protectors or investing in a voltage stabilizer can help protect the capacitor from damage caused by electrical issues.

By addressing the issue of overheating, you can significantly extend the lifespan of your capacitors and maintain the efficient operation of your air conditioning system.

Age and Wear

As with any electrical component, capacitors have a finite lifespan. Over time, they naturally experience wear and tear, which can lead to their eventual failure. The age of a capacitor is a key factor to consider when assessing its performance and reliability.

Capacitors are subject to constant electrical stress as they receive and release energy during the operation of an air conditioning system. This continuous cycle of charging and discharging can cause the capacitor’s internal components to deteriorate over time. The dielectric material, which plays a crucial role in storing electrical energy, may break down, resulting in reduced capacitance or even a complete loss of functionality.

Similarly, the electrolyte within the capacitor can evaporate or leak, affecting its ability to store and release energy effectively. As a capacitor ages, its effectiveness in supporting the motor or compressor in an air conditioner diminishes, leading to decreased performance and potential system malfunctions.

The lifespan of a capacitor can vary depending on various factors, including its quality, usage patterns, and environmental conditions. On average, capacitors in air conditioners tend to last around 10 to 20 years, but this can vary significantly.

It’s important to keep track of the age of your capacitors and make plans for replacements as needed. Regular maintenance and inspections by a qualified technician can help assess the condition of the capacitors and determine if they are approaching the end of their service life. Proactive replacement of aging capacitors can help prevent unexpected failures and potential damage to the air conditioning system.

In addition to age, it’s worth noting that capacitors can also experience premature wear due to factors such as voltage spikes, excessive heat, or poor quality components. Therefore, even if a capacitor is relatively new, it is essential to monitor its performance and be aware of any signs of failure.

By being proactive and replacing aging capacitors in a timely manner, you can ensure the efficient and reliable operation of your air conditioning system, and minimize the risk of costly repairs or replacements down the line.

Read more: What Is A Capacitor On An Air Conditioner

Power Surges

Power surges can be detrimental to electronic components, including capacitors in air conditioning systems. A power surge occurs when there is a sudden spike in electrical voltage, typically caused by lightning strikes, faulty wiring, or problems with the electrical grid.

These voltage spikes can overload the capacitor, causing it to receive an excessive amount of electrical current. The capacitor may not be able to handle this sudden surge of power, leading to various issues, such as overheating, component breakdown, or complete failure.

Power surges can occur both internally and externally. Internal power surges are usually caused by fluctuations within the air conditioning system itself, such as when the compressor or motor cycles on and off. External power surges, on the other hand, are caused by factors outside the control of the air conditioner, such as lightning strikes or problems with the electrical supply.

To protect capacitors from power surges, it is important to take preventive measures:

- Surge protectors: Installing surge protectors or power surge suppressors can help divert excess electrical energy away from sensitive components, such as capacitors. These devices are designed to absorb and dissipate excessive voltage, protecting the capacitor from damage.

- Voltage regulators or stabilizers: Voltage regulators or stabilizers are electrical devices that maintain a steady and consistent voltage supply to the air conditioning system. By regulating the voltage, they prevent sudden spikes or drops that could potentially harm the capacitors.

- Proper grounding: Ensuring that your home’s electrical system is properly grounded can help redirect excess electrical energy, such as from lightning strikes or power surges, into the ground, protecting your air conditioning system and its components.

By implementing these protective measures, you can significantly reduce the risk of capacitor failure due to power surges. It is essential to consult with a qualified electrician to assess your home’s electrical system and recommend the appropriate surge protection devices for your air conditioning system.

Remember, prevention is key when it comes to protecting capacitors from power surges. By doing so, you can ensure the smooth operation and longevity of your air conditioning system.

Poor Quality Components

The quality of the components used in air conditioning systems can have a significant impact on their overall performance and durability. When it comes to capacitors, using poor quality or counterfeit components can lead to premature failure and potential system malfunctions.

In an effort to cut costs, some manufacturers may opt for cheap, low-quality capacitors that are not designed to withstand the demands of an air conditioning system. These capacitors may lack the necessary materials and construction standards needed for reliable and long-lasting performance.

Low-quality capacitors may experience issues such as leakage, loss of capacitance, or even short circuits, which can result in the complete failure of the capacitor. In some cases, these components may not meet safety standards or be properly tested, posing a risk to the overall operation of the air conditioning system.

In addition to using poor quality capacitors, counterfeit components are also a concern in the HVAC industry. Counterfeit capacitors are often marketed as genuine, high-quality products, but they are actually cheap imitations that can fail prematurely or cause damage to the air conditioning system.

To ensure the reliability and performance of your air conditioning system, it is important to work with reputable manufacturers and trusted suppliers. When replacing capacitors, make sure to choose components that meet industry standards and have been tested for quality and performance.

Working with a qualified technician or HVAC professional can help ensure that you are using genuine components and avoiding counterfeit or low-quality products. These experts have the knowledge and experience to identify and source reliable capacitors that are suitable for your specific air conditioning system.

Investing in high-quality components may come with a slightly higher price tag, but it is a worthwhile investment in the long run. By using reliable capacitors, you can minimize the risk of premature failure, enhance the overall performance of your air conditioning system, and potentially save money on repairs and replacements in the future.

Signs of Capacitor Failure in an Air Conditioner

Capacitors play a crucial role in the efficient operation of an air conditioning system. When a capacitor starts to fail, it can have a noticeable impact on the performance of your AC unit. Recognizing the signs of capacitor failure can help you address the issue early on and prevent further damage or system breakdown. Here are some common signs to watch out for:

- Reduced Cooling Capacity: One of the primary signs of a failing capacitor is a decrease in the cooling capacity of your air conditioning system. If you notice that your AC is no longer providing the same level of cool air as before or is struggling to reach the desired temperature, it could be a sign that the capacitor is unable to support the motor or compressor adequately.

- Frequent Tripping of Circuit Breaker: A failing capacitor can cause the motor or compressor to work harder than usual, resulting in an increased electrical load. This additional strain may cause the circuit breaker to trip frequently as a safety measure to prevent electrical damage. If you find that the circuit breaker associated with your air conditioner is constantly tripping, it’s worth investigating the condition of the capacitor.

- Clicking or Buzzing Noises: Unusual clicking or buzzing noises coming from your air conditioning system can indicate a malfunctioning capacitor. These sounds often occur when the capacitor is struggling to start the motor or compressor, or when its internal components are deteriorating. If you notice any strange noises, it’s advisable to have a professional inspect the capacitor.

- Failure to Start or Frequent Cycling: Capacitor failure can result in difficulties starting the motor or compressor. You may notice that your air conditioner takes longer than usual to start up or that it cycles on and off frequently. This erratic behavior is a potential indication that the capacitor is not providing the necessary power boost to initiate proper operation.

If you observe any of these signs, it’s crucial to address the capacitor issue promptly. Continuing to run an air conditioning system with a failing capacitor can put additional strain on other components and may eventually lead to extensive damage or complete system failure.

It’s recommended to consult with a professional HVAC technician who can diagnose the capacitor’s condition and determine whether it needs to be repaired or replaced. They have the expertise and necessary equipment to assess and address the capacitor issue effectively, ensuring the optimal performance of your air conditioning system.

Regular maintenance and cleaning of the air conditioner can help prevent capacitor failure. Dust and debris can cause overheating and damage the capacitor, so keeping the unit clean can extend its lifespan.

Reduced Cooling Capacity

One of the telltale signs of a failing capacitor in an air conditioner is a decrease in the cooling capacity of the system. If you notice that your AC unit is no longer providing the same level of cool air as before or is struggling to reach the desired temperature, it could be indicative of capacitor failure.

Capacitors are responsible for providing an extra power boost to the motor or compressor during startup. They store and release electrical energy to help initiate the cooling process. However, when a capacitor starts to fail, its ability to provide this extra power diminishes. As a result, the motor or compressor may not receive the necessary electrical boost, leading to reduced cooling capacity.

You may notice that your air conditioning system takes longer to cool down your space or fails to reach the set temperature. Rooms that were once comfortably cool may now feel warm and stuffy. This decrease in cooling performance can be particularly noticeable on hot summer days when your air conditioner is under higher demand.

If you experience reduced cooling capacity from your air conditioning system, it’s important to have the capacitor examined by a professional technician. They can diagnose the issue and determine if the capacitor requires repair or replacement.

Ignoring a failing capacitor can result in more significant problems down the line. The strain on the motor or compressor can lead to additional wear and tear on these components, potentially causing further damage. By addressing the capacitor issue promptly, you can ensure the continued effectiveness and efficiency of your air conditioning system.

Remember that regular maintenance and inspections by a qualified technician can help identify capacitor problems early on. If you notice a decrease in cooling capacity or any other signs of capacitor failure, don’t delay in seeking professional assistance to rectify the issue and restore the optimal performance of your air conditioner.

Frequent Tripping of Circuit Breaker

If your air conditioning system is causing the circuit breaker to trip frequently, it could be a sign of a failing capacitor. A circuit breaker is designed to protect your electrical system from excessive current flow, and when it detects an overload, it will automatically shut off the power to prevent electrical damage or fire hazards.

When a capacitor begins to fail, it may cause the motor or compressor in your air conditioner to work harder than usual. This increased electrical load can lead to a surge in current, triggering the circuit breaker to trip as a safety precaution.

If you find that the circuit breaker associated with your air conditioner is tripping frequently, it is essential to investigate the condition of the capacitor. A failing capacitor may not be providing the necessary power boost to start the motor or compressor efficiently, resulting in an increased electrical demand that exceeds the circuit breaker’s capacity.

It’s worth noting that there could be other factors contributing to the tripping of the circuit breaker, such as a faulty motor or compressor. However, a failing capacitor is a common culprit in such situations. Consulting with a professional HVAC technician is crucial to accurately diagnose the issue and identify the root cause.

Attempting to reset the circuit breaker repeatedly without addressing the underlying problem can lead to further electrical issues and potential damage to the air conditioning system. It’s important to have a qualified technician inspect and assess the condition of the capacitor. They will be able to determine whether the capacitor needs to be repaired or replaced to restore proper functioning.

Remember, safety should be your top priority. If you notice frequent tripping of the circuit breaker associated with your air conditioner, contact a professional to address the issue promptly. They can provide the necessary expertise to diagnose and resolve the capacitor problem and ensure the safe and reliable operation of your air conditioning system.

Clicking or Buzzing Noises

Unusual clicking or buzzing noises coming from your air conditioning system can be indicative of a malfunctioning capacitor. These sounds often occur when the capacitor is struggling to start the motor or compressor or when its internal components are deteriorating.

When a capacitor starts to fail, it may struggle to provide the necessary electrical boost to initiate proper operation. As a result, you may hear clicking or buzzing noises as the compressor tries to start but fails to do so successfully.

These sounds can be particularly prominent when you first turn on your air conditioner or during the cycle of the cooling process. The clicking noise may resemble a repetitive clicking sound, while the buzzing noise may be more continuous and persistent.

It’s important not to ignore these unusual sounds, as they can be a clear indication of capacitor failure. Continuing to run your air conditioning system with a malfunctioning capacitor can put additional strain on other components, potentially leading to further damage or system breakdown.

If you hear clicking or buzzing noises from your air conditioner, it’s advisable to have a professional HVAC technician inspect the capacitor. They have the expertise and necessary equipment to diagnose the issue accurately.

The technician will assess the condition of the capacitor and determine if it needs to be repaired or replaced. In some cases, a faulty capacitor can be repaired by replacing the faulty components, while in other cases, a complete replacement may be necessary.

By addressing the clicking or buzzing noises promptly, you can prevent further damage to your air conditioning system and ensure its continued smooth and efficient operation. Trust the expertise of a qualified technician to identify and resolve the capacitor issue, restoring peace and quiet to your cooling system.

Failure to Start or Frequent Cycling

If your air conditioning system fails to start or frequently cycles on and off, it could be a sign of a failing capacitor. Capacitors play a crucial role in providing the necessary electrical boost to start the motor or compressor in your AC unit.

When a capacitor begins to deteriorate or lose its effectiveness, it may struggle to initiate the starting process. As a result, your air conditioner may fail to start altogether or experience frequent cycling, where it turns on and off repeatedly in short intervals.

If you notice that your air conditioner doesn’t kick on when it should or if it starts but quickly shuts off again, it’s likely that the capacitor is unable to provide the required electrical jolt to keep the motor or compressor running smoothly.

Frequent cycling can also occur as a result of the capacitor’s inconsistent performance. It may provide enough power to start the system initially, but fail to sustain the required electrical boost to keep the motor or compressor running. This can lead to constant on-off cycles, disrupting the cooling process and causing discomfort in your living space.

It’s important to have a professional HVAC technician assess the capacitor in such cases. They can determine whether the capacitor needs to be repaired or replaced to restore proper functionality.

Attempting to troubleshoot the issue yourself without the necessary expertise can lead to further complications and potential damage to the air conditioning system. A qualified technician will have the skills and knowledge to accurately diagnose the capacitor’s condition and take appropriate action.

By addressing the failure to start or frequent cycling promptly, you can avoid the inconvenience of an unreliable air conditioning system, prevent additional strain on other components, and ensure a comfortable and consistent indoor climate.

Diagnosing and Replacing a Failed Capacitor

When you suspect that a capacitor in your air conditioning system has failed, it is crucial to diagnose the issue accurately and take the necessary steps to replace the faulty component. Here’s a general guide on how to diagnose and replace a failed capacitor:

Step 1: Safety First: Before attempting any diagnosis or replacement, ensure that the power to your air conditioning system is completely turned off. This is to prevent any electrical accidents or injuries.

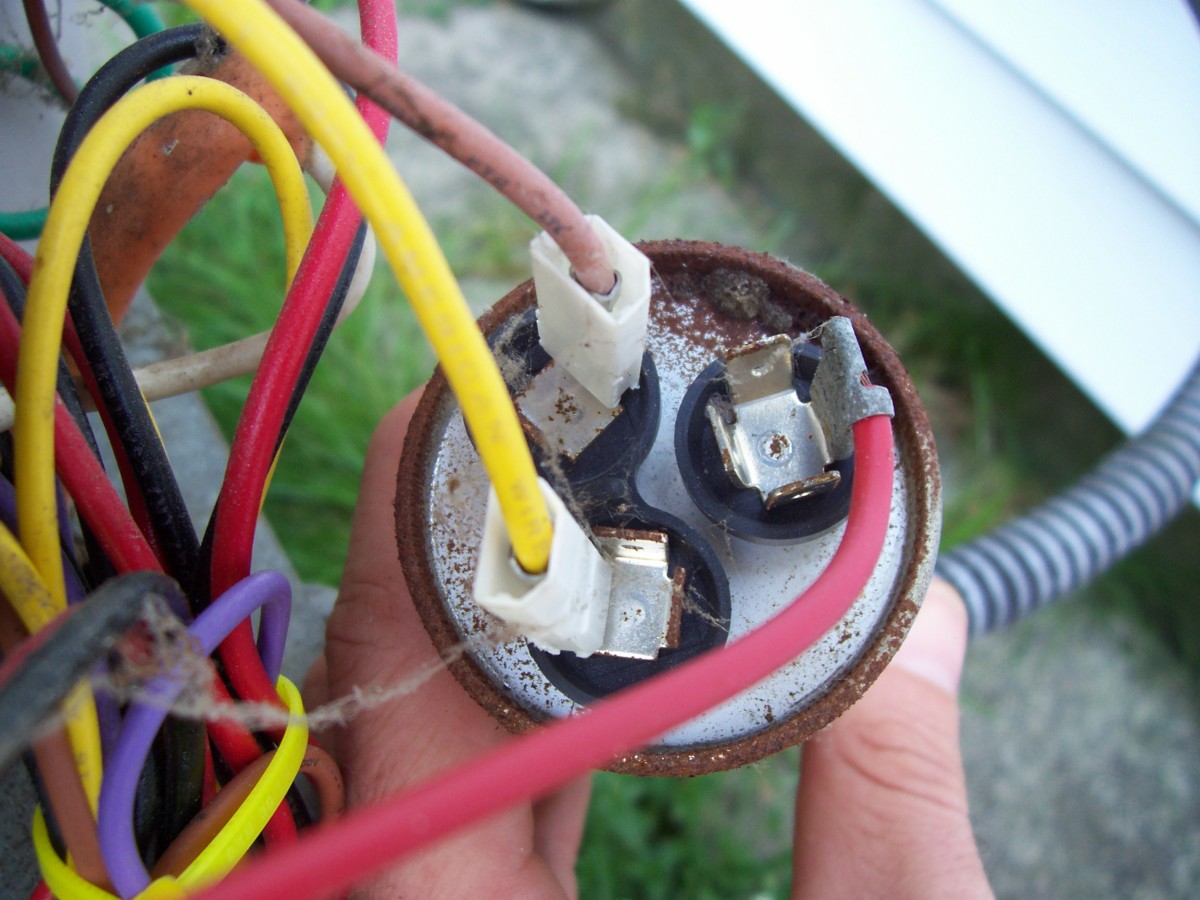

Step 2: Visual Inspection: Start by visually inspecting the capacitor. Look for any noticeable signs of damage, such as bulging, leaking, or a melted appearance. These visual indications often suggest a failed or faulty capacitor.

Step 3: Capacitance Testing: Use a multimeter to test the capacitance of the capacitor. Set the multimeter to the capacitance measurement setting and touch the leads to the corresponding terminals on the capacitor. The meter should display a capacitance reading that is within the specified range for that particular capacitor. If the reading is significantly lower than expected or shows an open circuit, it confirms that the capacitor has failed.

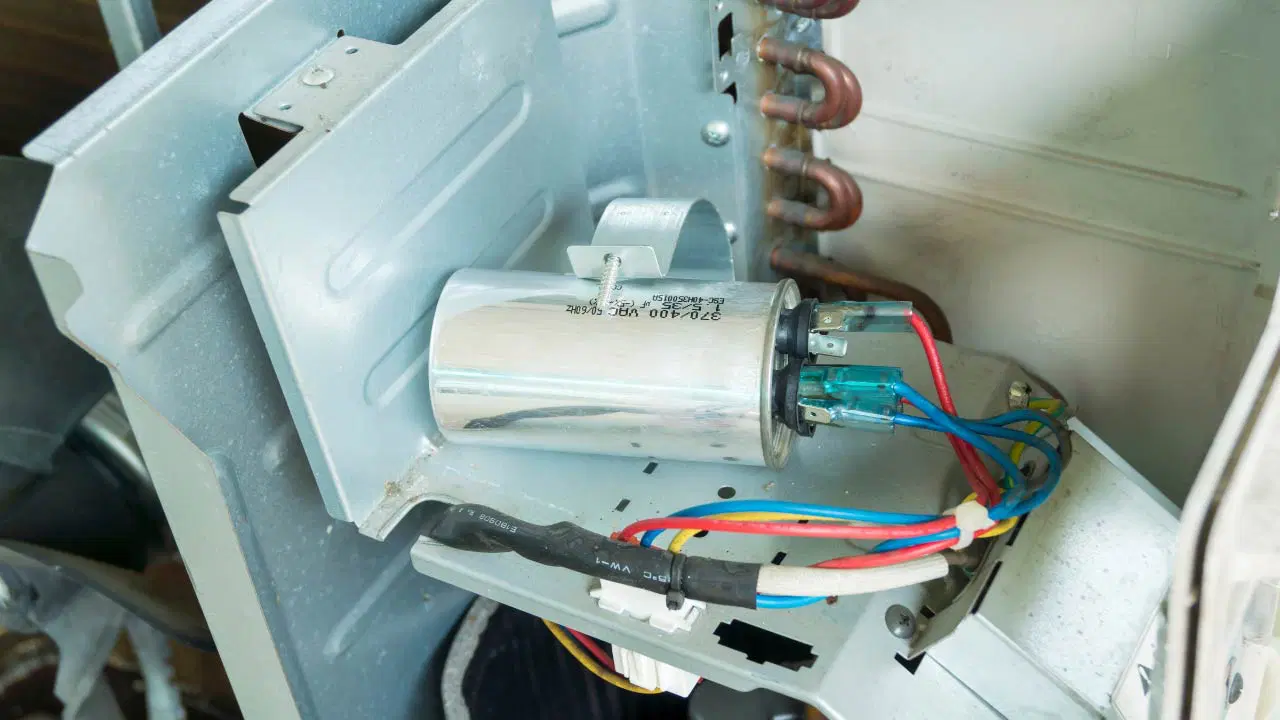

Step 4: Replacement: If the capacitor is determined to be defective, it’s time to replace it. Start by identifying the correct replacement capacitor with the same specifications (i.e., capacitance, voltage rating, and type) as the original. Make sure to turn off power to the system before removing the old capacitor.

Step 5: Wiring: Take note of the existing wiring connections, or take a photo, to ensure proper reconnection of the new capacitor. Carefully disconnect the wires from the old capacitor, and attach them to the corresponding terminals on the new capacitor. Double-check that all connections are secure and tightly fastened.

Step 6: Mounting: Secure the new capacitor in its designated location. Ensure that it is properly mounted and positioned to avoid movement or vibration that may cause wire disconnection or damage.

Step 7: Testing: Once the new capacitor is installed, turn on the power to your air conditioning system and test its operation. Ensure that the motor or compressor starts smoothly and that the system is cooling effectively. Listen for any abnormal sounds or irregularities that could indicate further issues.

Step 8: Professional Assistance: While the above steps provide a general guide, it is always recommended to seek the assistance of a qualified HVAC technician for diagnosing and replacing a failed capacitor. They have the necessary experience, tools, and expertise to handle the process safely and efficiently.

Remember, working with electrical components can be dangerous, so exercise caution. If you are uncertain about any aspect of the diagnosis or replacement, it’s best to rely on professional help to ensure the proper functioning of your air conditioning system.

Importance of Regular Maintenance

Regular maintenance is essential for the proper functioning and longevity of your air conditioning system, including its capacitors. Here are some key reasons why regular maintenance is important:

- Preventative Maintenance: Regular maintenance allows for the early detection of potential issues, including capacitor failure. By identifying and addressing problems before they escalate, you can avoid costly repairs or replacements in the future.

- Optimal Performance: Well-maintained capacitors contribute to the efficient operation of your air conditioning system. Capacitors that are clean, properly connected, and in good working condition can provide the necessary electrical boost, leading to improved performance and energy efficiency.

- Extended Lifespan: Regular maintenance helps prolong the lifespan of your capacitors. By keeping them clean, ensuring proper airflow, and addressing any issues promptly, you can prevent premature failure and enjoy the full potential of your air conditioning system for years to come.

- Energy Savings: Properly maintained capacitors help your air conditioning system operate more efficiently, which translates into energy savings. When capacitors are in good condition, the system requires less energy to start and run, resulting in lower energy consumption and lower utility bills.

- Improved Indoor Air Quality: Regular maintenance involves cleaning and replacing air filters, which can improve indoor air quality. Dirty filters not only reduce the effectiveness of your air conditioning system but can also contribute to poor air circulation and increased allergens and dust particles in the air.

- System Reliability: Maintaining your air conditioning system, including the capacitors, ensures its reliability when you need it most. Regular inspections and maintenance help identify and address potential issues, reducing the risk of sudden breakdowns or malfunctions during hot summer days.

- Manufacturer Requirements: Some warranties or guarantees for air conditioning systems may stipulate regular maintenance as a requirement. Failing to maintain your system properly could void the warranty, leaving you responsible for any repairs or replacements.

It’s recommended to schedule professional maintenance at least once a year, ideally before the start of the cooling season. A qualified HVAC technician will thoroughly inspect and service your air conditioning system, including cleaning and checking the condition of the capacitors. They can identify any potential issues, make necessary adjustments, and ensure the overall efficiency and performance of your system.

Additionally, regular maintenance should include simple tasks that you can do yourself, such as regularly cleaning or replacing air filters, clearing debris around the outdoor unit, and ensuring proper ventilation and airflow around the system.

By investing in regular maintenance, you not only prolong the life of your air conditioning system, but you also enjoy peace of mind knowing that your system is operating optimally, providing comfort and energy savings throughout the year.

Conclusion

Air conditioner capacitors are vital components in the smooth operation of your cooling system. Understanding why capacitors fail and being able to recognize the signs of a failing capacitor are crucial for maintaining the efficiency and longevity of your air conditioning system.

In this comprehensive guide, we have explored the common causes of capacitor failure, including overheating, age and wear, power surges, and poor quality components. We have also discussed the signs of capacitor failure, such as reduced cooling capacity, frequent tripping of the circuit breaker, clicking or buzzing noises, and failure to start or frequent cycling.

To diagnose and replace a failed capacitor, it’s important to follow the correct steps, ensuring safety and accuracy in the process. However, it is always advisable to seek the assistance of a qualified HVAC technician to handle the diagnosis and replacement of capacitors to ensure the proper functioning of your air conditioning system.

Regular maintenance is paramount in maintaining the performance and reliability of your air conditioning system, including capacitors. By conducting routine inspections, cleaning or replacing air filters, and addressing issues promptly, you can prevent potential failures and extend the lifespan of your capacitors.

Remember, when it comes to your air conditioning system, prevention is key. Regular maintenance, professional inspections, and timely repairs or replacements of capacitors can save you from unexpected breakdowns, costly repairs, and uncomfortable living conditions.

Investing in the well-being of your air conditioner and its capacitors will not only enhance the efficiency of your cooling system but also result in energy savings and a more comfortable indoor environment for you and your family.

So, don’t forget to schedule regular maintenance, be attentive to the signs of capacitor failure, and seek professional assistance when needed. With proper care and maintenance, you can ensure that your air conditioning system stays cool, reliable, and efficient for years to come.

Frequently Asked Questions about Why Do Capacitors Fail In An Air Conditioner

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.