Articles

What Is A Hydrostatic Plumbing Test

Modified: December 7, 2023

Learn about hydrostatic plumbing tests in this informative article. Discover the importance of these tests and how they are conducted in the plumbing industry.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A hydrostatic plumbing test is a critical procedure that is conducted to ensure the integrity and functionality of a plumbing system. It involves using water to test the pipes, fittings, valves, and connections for any leaks or defects. This test is commonly performed during the construction or renovation of a building to ensure that the plumbing system meets the required standards and does not pose any risks of water damage or contamination.

In this article, we will delve deeper into the process of a hydrostatic plumbing test, its importance, and the benefits it offers. We will also discuss the preparation and execution of the test, as well as the evaluation of the results. Additionally, we will explore the potential issues that can be identified through a hydrostatic plumbing test and highlight the value it brings to plumbing systems.

Whether you are a homeowner, a building contractor, or a plumbing professional, understanding the concept and significance of a hydrostatic plumbing test can be invaluable. It allows you to ensure the reliability and longevity of your plumbing system, thereby avoiding potential problems and costly repairs in the future.

Key Takeaways:

- Hydrostatic plumbing tests are crucial for identifying leaks, ensuring compliance with regulations, and preventing water contamination. Conducting these tests can save homeowners and contractors from costly repairs and legal issues.

- By detecting leaks, faulty connections, and pressure issues, hydrostatic plumbing tests help maintain system integrity and prevent water-related emergencies. Regular testing contributes to long-term durability and reliability of plumbing systems.

Read more: What Is A Smoke Test For Plumbing

Understanding Hydrostatic Plumbing Test

A hydrostatic plumbing test involves pressurizing the plumbing system with water to determine its overall strength, durability, and ability to withstand pressure. The test is conducted by filling the plumbing system with water and applying a set amount of pressure for a specific duration. The pressure is maintained for a certain period to assess if there are any leaks or failures in the system.

This type of test is commonly used in residential, commercial, and industrial buildings to ensure the quality and functionality of the plumbing system. It is especially important during the construction phase or when significant plumbing modifications are made.

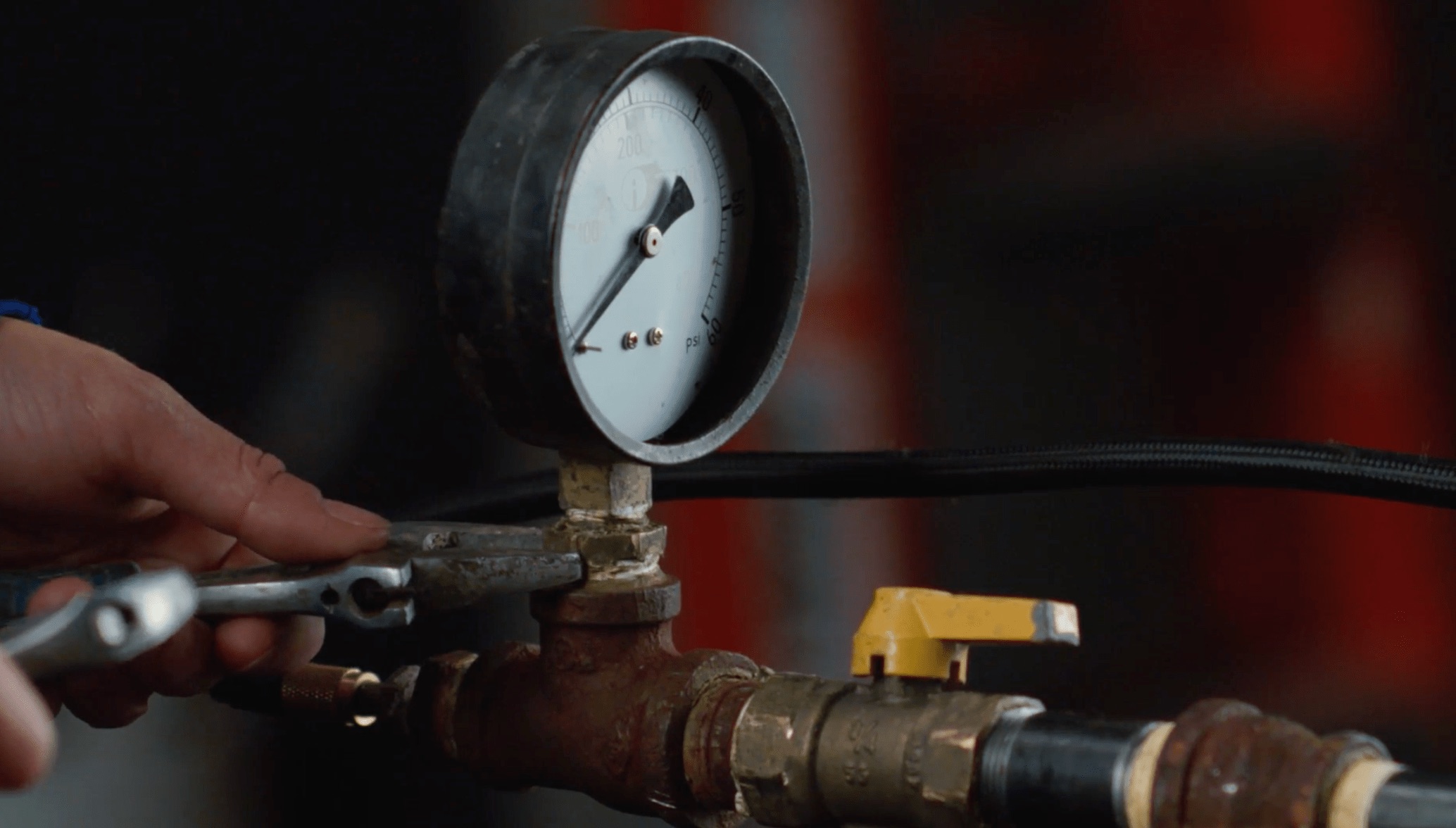

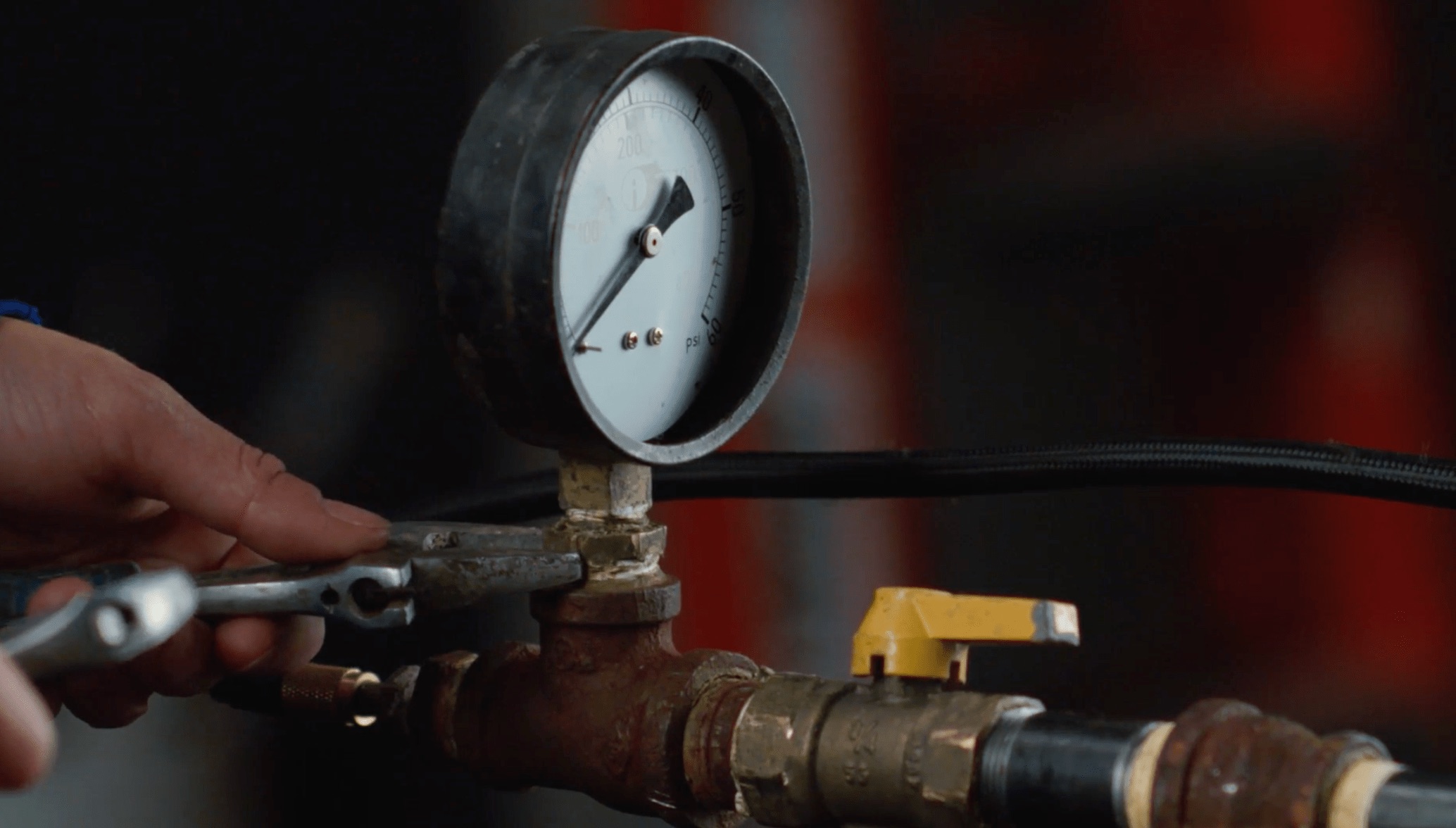

During a hydrostatic plumbing test, a specialized gauge is attached to the system to monitor and adjust the pressure. The water level is carefully measured, and any drop in the water level indicates a potential leak in the system. This test allows plumbers to identify weak points, faulty connections, or damaged pipes that may cause leaks or water damage in the future.

In addition to identifying leaks, a hydrostatic plumbing test can also help determine if the system can handle the required water pressure. This is particularly important in industrial settings where high-pressure systems are commonly used. By conducting this test, potential problems and weak points can be detected and addressed before they become major issues.

It is worth noting that a hydrostatic plumbing test is typically performed on closed systems. This means that the water supply to the building is shut off during the test to prevent any external water pressure from affecting the results. Only the plumbing system within the building is subjected to pressure to determine its integrity.

Overall, a hydrostatic plumbing test is a reliable and effective method for assessing the condition of a plumbing system. By understanding the purpose and methodology behind this test, homeowners and professionals can make informed decisions and take proactive measures to ensure the optimal performance of their plumbing systems.

Importance of Hydrostatic Plumbing Test

A hydrostatic plumbing test is a crucial step in ensuring the safety, functionality, and efficiency of a plumbing system. Here are some key reasons why conducting this test is of utmost importance:

- Identifying leaks and weaknesses: One of the primary purposes of a hydrostatic plumbing test is to detect any leaks or weaknesses in the system. By pressurizing the plumbing system with water, any potential leaks or faulty connections can be identified. Addressing these issues early on can prevent water damage, mold growth, and costly repairs down the line.

- Ensuring compliance with building codes and regulations: Hydrostatic plumbing tests are often mandated by building codes and regulations to ensure that plumbing systems meet the required standards. By conducting this test, homeowners, contractors, and inspectors can verify that the plumbing system is in compliance, ensuring the safety and well-being of the occupants.

- Preventing water contamination: A hydrostatic plumbing test can help identify any points in the system where water may be at risk of contamination. Whether it’s due to leaks in sewage lines or cross-connections, detecting and addressing these issues is crucial for maintaining the quality and safety of the water supply.

- Testing system durability: Pressurizing the plumbing system simulates the everyday stresses and demands it will endure. By subjecting the system to the required pressure for a specific duration, weaknesses in pipes, fittings, or valves can be exposed. This helps ensure the long-term durability and reliability of the system.

- Preventing future emergencies: At some point, plumbing emergencies are almost inevitable. However, a hydrostatic plumbing test can minimize the risk of unexpected issues by identifying potential problems before they escalate. By proactively addressing weaknesses in the system, you can avoid sudden bursts, floods, and disruptions in the water supply.

By recognizing the importance of a hydrostatic plumbing test, homeowners, contractors, and plumbing professionals can prioritize the safety and functionality of their plumbing systems. Regularly conducting this test not only helps maintain the quality of the system but also offers peace of mind to occupants and ensures compliance with building codes and regulations.

Preparation for a Hydrostatic Plumbing Test

Before conducting a hydrostatic plumbing test, proper preparation is essential to ensure accurate results and a smooth testing process. Here are some key steps to take when preparing for a hydrostatic plumbing test:

- Review building codes and regulations: Familiarize yourself with the local building codes and regulations that govern plumbing systems. Understand the requirements and standards for conducting a hydrostatic plumbing test and ensure compliance.

- Gather necessary equipment: Collect all the required equipment for the test, including a pressure gauge, hoses, plugs, and a water source. Ensure that the equipment is in good working condition to prevent any issues during the test.

- Shut off the water supply: Before conducting the test, shut off the main water supply to the building. This is necessary to isolate the plumbing system and prevent external water pressure from affecting the results.

- Drain the plumbing system: To ensure accurate results, drain the plumbing system completely. Open all faucets, drains, and fixtures to remove any residual water from the system before the test begins.

- Inspect the plumbing system: Thoroughly inspect the plumbing system for any visible signs of leaks, corrosion, or damage. Address any noticeable issues before proceeding with the test to avoid potential complications.

- Seal all openings: Close all openings and fixtures in the plumbing system, including faucets, drains, and fixtures. Ensure that all connections and access points are properly sealed to prevent water from escaping during the test.

- Fill the plumbing system: Once the system is drained and sealed, slowly fill it with water. Start from the lowest level of the building, gradually moving upwards to allow air to escape. Make sure the water fills all pipes, fittings, and valves.

- Apply pressure: Attach a pressure gauge to the plumbing system and adjust it to the required test pressure. Maintain the pressure for the specified duration, monitoring the system for any signs of leaks or drops in pressure.

- Evaluate the results: After completing the test, carefully inspect the system for any visible leaks, water damage, or abnormal pressure drops. Record the results and address any issues that are identified during the evaluation.

By following these preparation steps, you can ensure that the hydrostatic plumbing test is conducted accurately and effectively. Adequate preparation helps in obtaining reliable results and identifying any potential issues in the plumbing system.

Conducting a Hydrostatic Plumbing Test

Conducting a hydrostatic plumbing test requires careful execution to obtain accurate results and ensure the integrity of the plumbing system. Here are the key steps involved in conducting a hydrostatic plumbing test:

- Prepare the plumbing system: Before starting the test, ensure that the plumbing system is properly prepared. This includes closing all fixtures and openings, draining the system of any residual water, and inspecting for visible leaks or damage.

- Attach the pressure gauge: Attach a pressure gauge to the plumbing system to monitor and adjust the pressure during the test. The gauge should be properly calibrated and securely attached to provide accurate readings.

- Fill the system with water: Slowly fill the plumbing system with water, starting from the lowest point and working your way up. This allows air to escape and ensures that all pipes, fittings, and valves are filled with water.

- Pressurize the system: Once the system is filled with water, gradually apply pressure to the desired level using a pump or a specialized pressure testing device. Ensure that the pressure does not exceed the system’s maximum allowable limit.

- Maintain pressure for the specified duration: Once the desired pressure is reached, maintain it for the specified duration. This duration may vary depending on the building codes, regulations, or project requirements. Monitor the pressure gauge throughout the test to ensure stability.

- Monitor for leaks: While the system is under pressure, closely monitor the pressure gauge for any signs of pressure drops, indicating potential leaks. Inspect the entire plumbing system, including connections, fittings, and valves, for visible leaks or water seepage.

- Record observations and measurements: During the test, keep detailed records of observations, measurements, and any issues detected. Document the pressure readings, duration of the test, and any visible leaks or abnormalities for reference and evaluation.

- Evaluate the results: After the specified duration, carefully inspect the system for any visible leaks, water damage, or abnormal pressure drops. Compare the recorded observations with the expected results to identify any potential issues or areas of concern.

- Address identified issues: If any leaks or weaknesses are detected during the test, address them promptly. Repair or replace the faulty components, connections, or fittings to ensure the integrity and functionality of the plumbing system.

By following these steps and conducting the hydrostatic plumbing test with precision, you can assess the performance and reliability of the plumbing system, identify any weaknesses or leaks, and take necessary measures to ensure the system’s longevity and functionality.

When conducting a hydrostatic plumbing test, make sure to fill the system with water and pressurize it to the specified level for a set period of time to check for leaks and ensure the integrity of the pipes.

Read more: How To Remove A Plumbing Test Ball

Evaluation of Results

After conducting a hydrostatic plumbing test, the evaluation of the results is a crucial step in determining the overall condition of the plumbing system. Here are key aspects to consider during the evaluation:

- Pressure stability: During the test, monitor the pressure gauge for stability. If there were no significant pressure drops or fluctuations indicating leaks, it suggests that the plumbing system is in good condition and able to withstand the required pressure.

- Visible leaks: Inspect the entire plumbing system for any visible leaks or water seepage. Even minor leaks should not be overlooked, as they can potentially lead to significant water damage if left unattended.

- Water level change: Measure the water level before and after the test to assess if there has been any notable change. A significant drop in the water level during the test may indicate the presence of leaks in the system.

- Recorded observations: Review the detailed records of observations and measurements taken during the test. Compare them to the expected results and evaluate if any abnormalities or deviations were detected.

- Compliance with codes and regulations: Ensure that the results of the hydrostatic plumbing test meet the requirements of local building codes and regulations. If any issues or non-compliance are identified, take appropriate actions to rectify them.

- Documentation: Maintain comprehensive documentation of the test results, including pressure readings, duration, and any identified issues. This documentation serves as a reference for future inspections and helps track the maintenance history of the plumbing system.

Based on the evaluation of the results, appropriate actions should be taken to address any identified issues. This may include repairing or replacing faulty components, sealing leaks, or strengthening weak points. By promptly addressing these issues, you can ensure the optimal performance and longevity of the plumbing system.

It’s important to note that a hydrostatic plumbing test provides valuable insights into the condition of the system at the time of testing. Regular maintenance and ongoing monitoring are necessary to ensure that the plumbing system continues to function properly and remains in good condition.

Benefits of a Hydrostatic Plumbing Test

A hydrostatic plumbing test offers several benefits to homeowners, building contractors, and plumbing professionals. Here are some key advantages of conducting a hydrostatic plumbing test:

- Detection of leaks and weaknesses: By pressurizing the plumbing system with water, a hydrostatic plumbing test can identify any leaks, faulty connections, or weaknesses in the system. This early detection allows for timely repairs, preventing water damage and potential plumbing emergencies.

- Ensuring system integrity: Conducting a hydrostatic plumbing test ensures that the plumbing system is built to withstand the required pressure and meet the necessary standards. Knowing that the system is structurally sound provides peace of mind and confidence in its longevity and reliability.

- Compliance with regulations: Many building codes and regulations require hydrostatic plumbing tests to ensure that the plumbing system meets the required standards for safety and functionality. By conducting this test, homeowners and contractors can ensure compliance and avoid potential legal issues or penalties.

- Prevention of water contamination: Hydrostatic plumbing tests help identify plumbing system vulnerabilities that could lead to water contamination. By addressing these issues early on, the risk of cross-connections, leaks in sewage lines, or other sources of water contamination can be minimized, safeguarding the health and well-being of occupants.

- Predictive maintenance: By regularly conducting hydrostatic plumbing tests, potential problems can be detected before they escalate into major issues. This allows for proactive maintenance and repairs, preventing costly emergency repairs or replacements in the future.

- Improved system performance: A properly functioning plumbing system enhances water efficiency, reduces water waste, and ensures efficient water distribution throughout the building. Hydrostatic plumbing tests help identify areas where the system might be underperforming, allowing for adjustments or repairs that optimize its overall efficiency.

- Increased property value: Having a plumbing system that has undergone a hydrostatic plumbing test and has a clean bill of health can increase the value of a property. Prospective buyers are more likely to be attracted to a home or building with a well-maintained and reliable plumbing system.

By recognizing the benefits of a hydrostatic plumbing test, homeowners, contractors, and plumbing professionals can prioritize the maintenance and performance of their plumbing systems. Investing in this testing process can save individuals time, money, and stress by preventing major issues and ensuring the long-term durability of the plumbing system.

Potential Issues Detected by a Hydrostatic Plumbing Test

A hydrostatic plumbing test is a valuable tool for identifying various potential issues in a plumbing system. Here are several common problems that can be detected through this type of testing:

- Leaks: The primary purpose of a hydrostatic plumbing test is to identify leaks in the system. Whether it’s a small pinhole leak or a significant rupture, a hydrostatic test can expose any points of weakness where water is escaping.

- Cracked or broken pipes: Over time, pipes can develop cracks or break due to corrosion, shifting foundations, or excessive pressure. A hydrostatic plumbing test can reveal these issues and indicate the need for pipe repairs or replacements.

- Faulty connections: Connections between pipes, fittings, and fixtures can become loose or faulty, leading to leaks or reduced water flow. A hydrostatic test can pinpoint these weak connections and prompt proper repairs.

- Inadequate sealant: Improper sealant application or aged sealant can result in water seepage. During a hydrostatic plumbing test, any signs of water escaping through seams or joints can indicate the need for resealing.

- Corrosion and rust: Metal pipes in plumbing systems can be susceptible to rust and corrosion over time. A hydrostatic test can reveal areas where corrosion has weakened the pipes, necessitating repairs or replacements.

- Blockages or clogs: A hydrostatic test may highlight areas of blockage or clogs in the plumbing system. Whether it’s a buildup of debris, mineral deposits, or tree roots infiltrating the pipes, this testing method can identify the need for drain clearing or pipe cleaning.

- Pressure issues: Hydrostatic testing can detect pressure-related problems within the plumbing system. Whether it’s excessive pressure that may cause pipe bursts or inadequate pressure that affects water flow, this test can help identify and rectify these issues.

- Backflow prevention failures: A hydrostatic test can reveal issues with backflow preventers, which are crucial for preventing contaminated water from flowing back into the main water supply. Problems with backflow prevention devices can put the water supply at risk of contamination, making their detection crucial for maintaining water quality.

By identifying these potential issues through a hydrostatic plumbing test, timely repairs and necessary maintenance can be carried out, ensuring the overall performance, safety, and reliability of the plumbing system. Regular testing can help prevent more extensive damage, higher repair costs, and potential water-related emergencies.

Conclusion

A hydrostatic plumbing test is an essential procedure for assessing the integrity and functionality of a plumbing system. Through the use of water pressure, this test allows for the detection of leaks, weaknesses, and potential issues that could compromise the system’s performance and safety.

By conducting a hydrostatic plumbing test, homeowners, contractors, and plumbing professionals can ensure compliance with building codes and regulations, prevent water contamination, and identify and address problems before they escalate. From detecting leaks and faulty connections to assessing pressure stability and system durability, this test provides valuable insights into the condition of the plumbing system.

Proper preparation and execution are essential for a successful hydrostatic plumbing test. Adequate equipment, shutting off the water supply, draining the system, and sealing openings are necessary steps to ensure accurate results. Careful evaluation of the test results and addressing any identified issues in a timely manner are crucial to maintaining the optimal performance of the plumbing system.

The benefits of a hydrostatic plumbing test are significant. It allows for the prevention of water damage, potential emergencies, and contamination, while also improving system efficiency and increasing property value. Regular testing contributes to the long-term durability and reliability of the plumbing system, saving homeowners and building owners from costly repairs and ensuring the safety and well-being of occupants.

To safeguard your plumbing system, consider scheduling a hydrostatic plumbing test during the construction or renovation phase, as well as periodically for maintenance purposes. Consulting with a professional plumber is recommended to ensure the test is conducted accurately and effectively.

By recognizing the importance of a hydrostatic plumbing test and taking proactive measures to assess and maintain the plumbing system, you can enjoy a reliable and efficient water supply while minimizing the risks of water damage and costly repairs in the future.

Frequently Asked Questions about What Is A Hydrostatic Plumbing Test

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Hydrostatic Plumbing Test”