Articles

What Is A Metal Conduit Made Of

Modified: October 20, 2024

Learn about the composition of metal conduit and its various materials in this informative article.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Metal conduit is a crucial component in electrical wiring systems, providing a protective pathway for electrical cables and wires. It is widely used in both residential and commercial construction projects to ensure the safety and reliability of electrical installations. But have you ever wondered what metal conduit is made of? In this article, we will explore the various types of metal conduit and delve into the materials used to manufacture them.

Metal conduit is a crucial component in electrical wiring systems, providing a protective pathway for electrical cables and wires. It is widely used in both residential and commercial construction projects to ensure the safety and reliability of electrical installations. But have you ever wondered what metal conduit is made of? In this article, we will explore the various types of metal conduit and delve into the materials used to manufacture them.

Metal conduit is a crucial component in electrical wiring systems, providing a protective pathway for electrical cables and wires. It is widely used in both residential and commercial construction projects to ensure the safety and reliability of electrical installations. But have you ever wondered what metal conduit is made of? In this article, we will explore the various types of metal conduit and delve into the materials used to manufacture them.

Metal conduit is a crucial component in electrical wiring systems, providing a protective pathway for electrical cables and wires. It is widely used in both residential and commercial construction projects to ensure the safety and reliability of electrical installations. But have you ever wondered what metal conduit is made of? In this article, we will explore the various types of metal conduit and delve into the materials used to manufacture them.

Metal conduit is a crucial component in electrical wiring systems, providing a protective pathway for electrical cables and wires. It is widely used in both residential and commercial construction projects to ensure the safety and reliability of electrical installations. But have you ever wondered what metal conduit is made of? In this article, we will explore the various types of metal conduit and delve into the materials used to manufacture them.

Key Takeaways:

- Metal conduit, including steel, aluminum, galvanized, stainless steel, and copper, offers physical and environmental protection, fire resistance, and versatility for electrical wiring systems in various applications.

- Proper installation and maintenance of metal conduit are crucial for ensuring the safety, functionality, and longevity of the electrical wiring system. Consult with professionals and follow industry best practices for optimal results.

Read more: What Is Rigid Metal Conduit

Overview of Metal Conduit

Metal conduit is a robust and durable type of tubing used for protecting and organizing electrical wires. It plays a crucial role in keeping electrical circuits safe by shielding them from environmental factors and preventing accidental damage. Metal conduit is available in various sizes, shapes, and materials, making it versatile for a wide range of applications.

One of the primary functions of metal conduit is to protect electrical wires from physical damage. It provides a rigid and secure pathway for the wires, safeguarding them from impact, compression, and abrasion. This is especially important in industries or locations where there is a higher risk of mechanical damage, such as manufacturing plants or construction sites.

Additionally, metal conduit offers protection against moisture, chemicals, and other hazardous substances. It acts as a barrier, preventing the infiltration of water, dust, and corrosive materials that could potentially damage the electrical wiring system. This is particularly critical in outdoor or harsh environments where the electrical cables may be exposed to the elements.

Metal conduit also helps in organizing and managing electrical cables, making it easier to trace and troubleshoot electrical issues. With proper installation, it allows for the neat and orderly arrangement of wires, reducing the risk of tangled or disorganized cabling. This not only improves the efficiency of maintenance and repairs but also enhances overall safety.

Furthermore, metal conduit provides an extra level of fire protection. In the event of a fire, metal conduit can help to contain and prevent the spread of flames by confining them to a specific area. This is crucial in buildings or facilities where fire safety is a top priority, such as hospitals, schools, and industrial complexes.

Metal conduit is available in a variety of types, each with its own unique characteristics. The choice of conduit depends on factors such as the application, environment, and specific requirements. The most commonly used types of metal conduit include steel conduit, aluminum conduit, galvanized conduit, stainless steel conduit, and copper conduit.

In the following sections, we will discuss each type of metal conduit in more detail, exploring the materials used in their construction, their features, and their applications. By understanding the different types of metal conduit, you can make an informed decision about which one is most suitable for your specific electrical wiring needs.

Types of Metal Conduit

Metal conduit comes in various materials and configurations to suit different applications and environments. The choice of metal conduit depends on factors such as the level of protection required, the type of wiring system, and the specific installation conditions. Let’s take a closer look at some of the most commonly used types of metal conduit:

1. Steel Conduit: Steel conduit is the most popular and widely used type of metal conduit. It is highly durable and provides excellent protection against physical damage. Steel conduit is available in two main forms: rigid and flexible. Rigid steel conduit is used in applications where a high level of rigidity is required, such as in commercial and industrial settings. Flexible steel conduit, also known as Greenfield or flex conduit, offers more versatility and is commonly used in applications where there is a need for flexibility, such as in tight or curved spaces.

2. Aluminum Conduit: Aluminum conduit is lightweight and corrosion-resistant, making it an ideal choice for outdoor applications. It is commonly used in electrical installations where weight is a concern, such as in suspended or overhead wiring. Aluminum conduit is also suitable for use in areas where corrosive substances are present.

3. Galvanized Conduit: Galvanized conduit is made from steel that has been coated with a layer of zinc. This coating provides excellent corrosion resistance, making galvanized conduit suitable for outdoor and wet environments. It is commonly used in applications where added protection against moisture and corrosive elements is required.

4. Stainless Steel Conduit: Stainless steel conduit is highly resistant to corrosion, making it an excellent choice for installations in extreme environments or areas with high humidity or chemical exposure. It is commonly used in industries such as food processing, pharmaceuticals, and petrochemicals, where hygiene and durability are essential.

5. Copper Conduit: Copper conduit offers superior conductivity and is commonly used for grounding applications or to shield sensitive electrical circuits from electromagnetic interference (EMI). It is also commonly used in electrical installations where aesthetic appeal is important, as copper has an attractive appearance.

These are just a few examples of the types of metal conduit available in the market. It is important to consult with a professional electrician or electrical engineer to determine the most suitable type of conduit for your specific application, as different environments and requirements may necessitate different types of conduit. The proper selection of metal conduit ensures the safety and efficiency of your electrical wiring system.

Steel Conduit

Steel conduit is one of the most commonly used types of metal conduit in electrical installations. It is known for its durability, strength, and high level of protection it provides to electrical wiring systems. Steel conduit is available in two main forms: rigid steel conduit (RSC) and flexible steel conduit.

Rigid steel conduit (RSC) is the most commonly used type, especially in commercial and industrial settings. It is a thick-walled pipe that provides a high level of rigidity and protection against physical damage, making it suitable for applications where wiring needs to be securely protected. RSC is typically used in exposed locations where wiring is subject to impact or heavy-duty installations such as machinery or equipment.

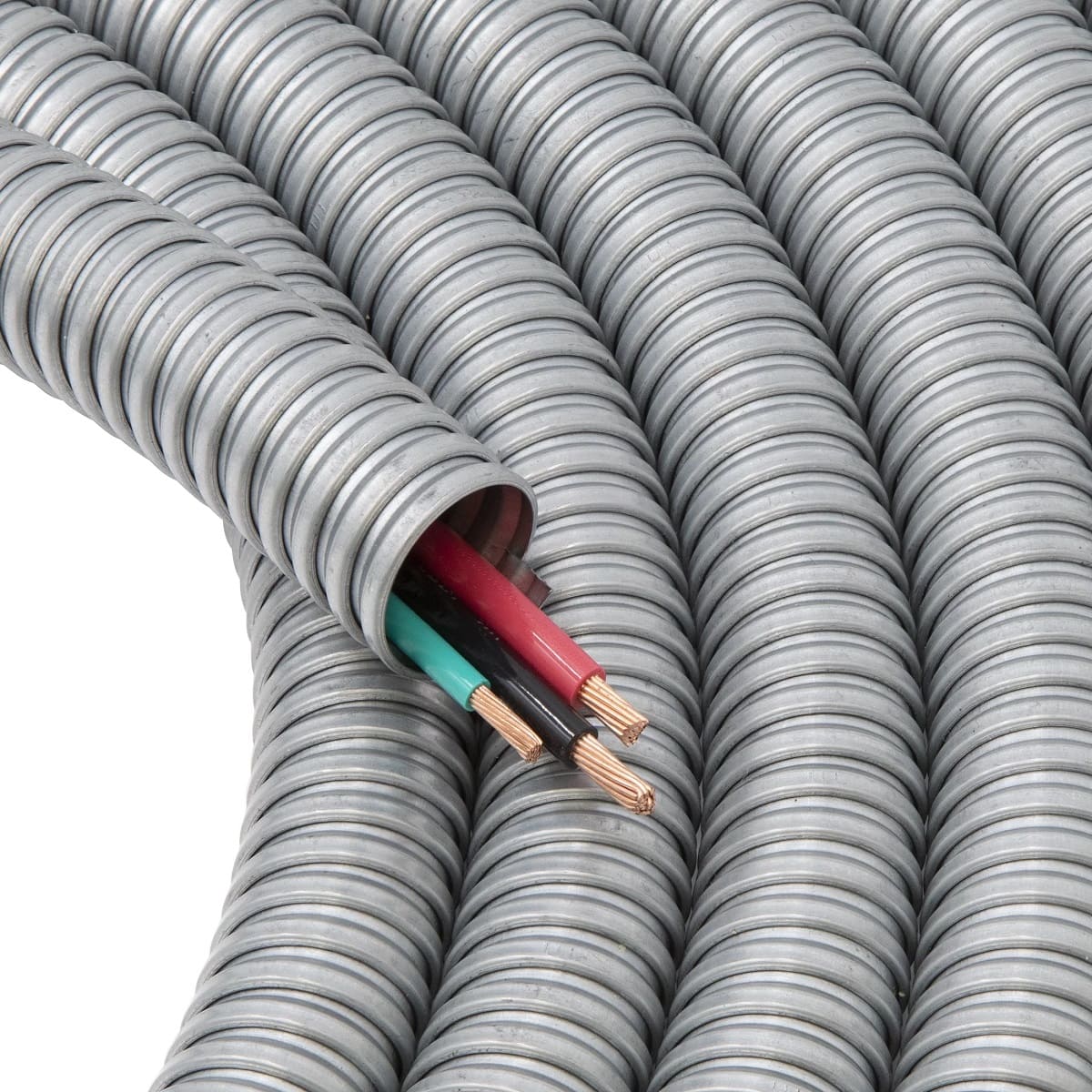

Flexible steel conduit, also known as Greenfield or flex conduit, offers more versatility and ease of installation in areas where a certain level of flexibility is required. It is made up of a galvanized steel strip wound in a helical pattern, allowing for bending and shaping around corners or obstacles. Flexible steel conduit is commonly used in areas where rigid conduit installation is difficult or impractical, such as in tight or curved spaces.

Steel conduit is known for its ability to withstand harsh environments and provide excellent protection to electrical wiring. It is highly resistant to impact, crushing, and corrosion, ensuring the integrity and longevity of the wiring system. Steel conduit is suitable for both indoor and outdoor applications and can withstand exposure to moisture, chemicals, and extreme temperatures.

Installation of steel conduit requires careful planning and adherence to local electrical codes and regulations. The conduit is typically installed using couplings, connectors, and fittings to ensure a secure and proper connection between conduit sections. It should be properly grounded to ensure electrical safety.

Steel conduit offers several benefits, including:

1. Rigid protection: Steel conduit provides a strong and rigid pathway for electrical wiring, protecting it from physical damage, including impact, crushing, and abrasion.

2. Fire resistance: Steel is non-combustible and can help contain and prevent the spread of fire, making it a safe choice for installations where fire resistance is important.

3. Durability: Steel conduit is highly durable and can withstand harsh environmental conditions, making it suitable for long-term use.

4. EMI shielding: Steel conduit can provide electromagnetic interference (EMI) shielding, protecting sensitive electrical circuits from outside interference.

In summary, steel conduit is a reliable and durable choice for electrical wiring installations. Its ability to withstand environmental factors, provide physical protection, and offer versatility in installation makes it a preferred choice in many applications. By using steel conduit, you can ensure the safety and longevity of your electrical wiring system.

Aluminum Conduit

Aluminum conduit is a lightweight and corrosion-resistant type of metal conduit that is commonly used in electrical installations. It offers several advantages over other types of conduit, making it a popular choice in certain applications and environments.

One of the key benefits of aluminum conduit is its lightweight nature. Compared to steel conduit, aluminum conduit is significantly lighter, which makes it easier to handle and install. This can be particularly beneficial in situations where weight is a concern, such as in suspended or overhead wiring.

In addition to being lightweight, aluminum conduit is also highly resistant to corrosion. It naturally forms a thin layer of oxide on its surface, which acts as a protective barrier against environmental elements. This makes aluminum conduit suitable for outdoor installations and areas where corrosive substances are present.

Another advantage of aluminum conduit is its excellent conductivity. Aluminum is a highly efficient conductor of electricity, allowing for the seamless flow of current through the conduit. This makes it an ideal choice for applications where electrical conductivity is crucial, such as in power distribution systems.

It is important to note that aluminum conduit should only be used with compatible aluminum fittings and connectors. This ensures proper electrical continuity and prevents potential issues that may arise from dissimilar metals coming into contact with each other. Following the manufacturer’s recommendations and guidelines for installation is essential to ensure a safe and reliable electrical wiring system.

While aluminum conduit offers many benefits, there are also some considerations to keep in mind. Aluminum is softer than steel, which means it may not provide the same level of physical protection against impact and crushing as steel conduit. Therefore, aluminum conduit is generally not recommended for applications where high levels of mechanical protection are required.

Furthermore, aluminum conduit may require additional precautions when used in areas with high temperatures or where a high degree of electrical grounding is necessary. Special attention must be paid to thermal expansion and contraction, as well as proper grounding techniques to ensure safety and functionality.

In summary, aluminum conduit is a lightweight, corrosion-resistant, and highly conductive option for electrical wiring installations. Its advantages make it suitable for specific applications where weight, corrosion resistance, and electrical conductivity are important factors. However, it is essential to consider the specific requirements of the installation and consult with professionals to determine the most appropriate type of conduit to use.

Galvanized Conduit

Galvanized conduit is a type of metal conduit that provides excellent protection against corrosion. It is made from steel that has been coated with a layer of zinc through a process called galvanization. This protective zinc coating helps to prevent rust and corrosion, making galvanized conduit a popular choice for outdoor and wet environments.

The galvanization process involves immersing the steel conduit in a bath of molten zinc. This creates a metallurgical bond between the zinc and the steel, resulting in a durable and corrosion-resistant coating. Galvanized conduit can withstand exposure to moisture, chemicals, and extreme outdoor conditions, making it suitable for a wide range of applications.

One of the main advantages of galvanized conduit is its ability to resist corrosion. The zinc coating acts as a sacrificial layer, protecting the underlying steel from oxidation and corrosion. Even if the zinc coating is scratched or damaged, the steel is still shielded from corrosion due to the cathodic protection provided by the zinc. This makes galvanized conduit a reliable choice for areas with high humidity, corrosive substances, or saltwater exposure.

Another benefit of galvanized conduit is its durability and strength. The steel core of the conduit provides rigidity and impact resistance, while the zinc coating enhances its resistance to corrosion. This combination of strength and corrosion resistance makes galvanized conduit suitable for demanding applications where protection and longevity are essential.

Galvanized conduit is commonly used in a variety of applications, including electrical wiring systems for outdoor lighting, irrigation systems, underground installations, and industrial settings. Its resistance to corrosion makes it ideal for environments such as construction sites, agricultural facilities, or areas exposed to harsh weather conditions.

Installation of galvanized conduit follows similar principles to other types of conduit. It should be properly secured and fastened using suitable connectors and fittings to ensure a robust and reliable electrical wiring system. Proper grounding techniques should also be employed to ensure electrical safety and compliance with local codes and regulations.

While galvanized conduit offers excellent corrosion resistance, it is important to note that over time, the zinc coating may naturally wear off or deteriorate in certain conditions. Regular inspection and maintenance are essential to identify any signs of damage or deterioration, and necessary repairs or replacements should be carried out promptly.

In summary, galvanized conduit provides exceptional protection against corrosion, making it a practical and durable choice for outdoor and wet environments. Its resistance to rust and ability to withstand harsh conditions make it suitable for a wide range of applications. By choosing galvanized conduit, you can ensure the longevity and reliability of your electrical wiring system.

Stainless Steel Conduit

Stainless steel conduit is a versatile and highly durable type of metal conduit that offers superior corrosion resistance. It is made from steel alloyed with chromium, which provides excellent resistance to corrosion, rust, and oxidation. Stainless steel conduit is commonly used in industries and applications where hygiene, durability, and resistance to harsh environments are paramount.

One of the primary advantages of stainless steel conduit is its exceptional corrosion resistance. The chromium content in stainless steel forms a thin, protective layer of chromium oxide on the surface, which acts as a barrier against corrosive elements and prevents rusting. This makes stainless steel conduit suitable for installations in environments with high humidity, exposure to chemicals, or extreme temperatures.

In addition to corrosion resistance, stainless steel conduit is highly durable and can withstand harsh conditions. It is resistant to impact, abrasion, and mechanical stress, making it suitable for industrial applications where the conduit may be subject to heavy use or potential damage. Stainless steel conduit is commonly used in industries such as food processing, pharmaceuticals, petrochemicals, and wastewater treatment plants.

Stainless steel conduit is also known for its hygienic properties. Its smooth surface makes it easy to clean and maintain, making it an ideal choice for installations that require strict cleanliness standards, such as in food manufacturing facilities or hospitals. Additionally, stainless steel is non-porous, which means it is resistant to bacterial growth and can withstand frequent cleaning with disinfectants.

Another advantage of stainless steel conduit is its high strength-to-weight ratio. It provides excellent rigidity and structural integrity, even in demanding applications. This allows for secure cable routing and protection of electrical wiring systems. Stainless steel conduit is available in various sizes and types, including rigid and flexible options, to accommodate different installation requirements.

Installation of stainless steel conduit follows similar principles as other types of conduit. It should be properly secured, fastened, and grounded according to local electrical codes and regulations. Stainless steel conduit can be connected using fittings specifically designed for stainless steel applications, ensuring a reliable and consistent electrical wiring system.

While stainless steel conduit offers numerous benefits, it is worth noting that it is generally more expensive than other types of conduit due to the material’s properties and manufacturing process. However, the long-term cost-effectiveness and durability of stainless steel conduit may outweigh its initial expense, particularly in applications where corrosion resistance and hygiene are critical factors.

In summary, stainless steel conduit is a durable, corrosion-resistant, and hygienic choice for electrical wiring installations. Its exceptional resistance to corrosion, strength, and cleanliness make it suitable for various industries and installations where durability and reliability are paramount. By selecting stainless steel conduit, you can ensure the longevity and performance of your electrical wiring system, especially in challenging environments.

Metal conduit is typically made of steel or aluminum. Steel conduit is strong and durable, while aluminum conduit is lightweight and corrosion-resistant. When choosing between the two, consider the specific needs of your project.

Copper Conduit

Copper conduit is a type of metal conduit that is known for its excellent electrical conductivity and corrosion resistance. It is commonly used in electrical installations where efficient electrical performance and aesthetic appeal are important factors.

One of the primary advantages of copper conduit is its superior electrical conductivity. Copper is one of the most conductive materials, allowing for efficient flow of electrical current through the conduit. This makes it an ideal choice for grounding applications or to shield sensitive electrical circuits from electromagnetic interference (EMI). Copper conduit ensures reliable electrical connections and minimizes voltage drops, enhancing overall system performance.

In addition to its conductivity, copper conduit offers excellent corrosion resistance. Copper is naturally resistant to corrosion, making it suitable for both indoor and outdoor installations. It does not rust or degrade over time, ensuring long-term durability and reliability. This makes copper conduit a popular choice in areas with high humidity or corrosive environments.

Another benefit of copper conduit is its aesthetic appeal. Copper has a distinctive reddish-gold color that adds an attractive and unique visual element to electrical installations. It is often used in architectural or design-centric projects where the conduit is left exposed or visible. Copper conduit can lend a touch of elegance and sophistication to residential, commercial, or historical buildings.

Copper conduit is available in different forms, including rigid and flexible options, to accommodate various installation requirements. Rigid copper conduit provides a sturdy and protective pathway for electrical wiring, ensuring reliable and secure cable routing. Flexible copper conduit, commonly known as copper tubing, offers versatility and ease of installation in areas where a certain degree of flexibility is needed.

When working with copper conduit, it is important to ensure proper installation and grounding techniques. Copper conduit should be securely fastened and connected using appropriate fittings and connectors to maintain electrical continuity and prevent potential issues. Proper grounding is crucial to ensure safety and compliance with local electrical codes and regulations.

While copper conduit offers numerous benefits, it is worth noting that it is generally more expensive than other types of conduit due to the cost of copper as a raw material. However, the long-term advantages of its conductivity, corrosion resistance, and aesthetic appeal may justify its higher investment.

In summary, copper conduit is a reliable and aesthetically pleasing choice for electrical wiring installations. Its superior electrical conductivity, corrosion resistance, and attractive appearance make it suitable for a wide range of applications. By using copper conduit, you can ensure efficient electrical performance, long-lasting durability, and a touch of elegance in your electrical systems.

Benefits of Metal Conduit

Metal conduit offers a wide range of benefits, making it a preferred choice for electrical wiring installations in both residential and commercial settings. Let’s explore some of the key advantages of using metal conduit:

1. Physical Protection: One of the primary benefits of metal conduit is its ability to provide robust physical protection to electrical wiring. Metal conduit offers a rigid and secure pathway for cables, shielding them from impact, crushing, and abrasion. This is particularly important in areas where wiring may be exposed to mechanical stress, such as industrial settings or construction sites. Metal conduit helps ensure the integrity and longevity of the electrical wires, reducing the risk of damage or electrical faults.

2. Environmental Protection: Metal conduit acts as a barrier, offering protection against moisture, chemicals, and other hazardous substances. It prevents the infiltration of water, dust, and corrosive materials that could potentially damage the electrical wiring system. This is particularly crucial in outdoor installations or areas where the wiring may be exposed to harsh environmental conditions. Metal conduit helps maintain the reliability and safety of the electrical system, even in challenging environments.

3. Fire Resistance: Metal conduit provides an additional layer of fire protection. In the event of a fire, metal conduit can help contain and prevent the spread of flames by confining them to a specific area. This is especially important in buildings or facilities where fire safety is a top priority, such as hospitals, schools, or industrial complexes. Metal conduit contributes to the overall fire resistance of the electrical system, enhancing the safety of the occupants and minimizing potential damage.

4. EMI Shielding: Metal conduit, especially when properly grounded, can offer electromagnetic interference (EMI) shielding. It helps protect sensitive electrical circuits from external sources of electromagnetic interference, ensuring the integrity and reliability of the signals. This is particularly important in applications where precise and accurate transmission of electrical signals is required, such as data centers or industrial automation systems.

5. Durability and Longevity: Metal conduit is known for its durability and long lifespan. It is designed to withstand harsh conditions and resist factors that can lead to degradation or failure. Metal conduit is highly resistant to corrosion, impact, and extreme temperatures, ensuring its reliability even in demanding environments. By using metal conduit, you can enjoy a robust and long-lasting electrical wiring system, reducing the need for frequent repairs or replacements.

6. Versatility: Metal conduit is available in various types, sizes, and shapes, providing versatility to suit different applications and installation requirements. It can be used for both indoor and outdoor installations and is compatible with a wide range of electrical wiring systems. The flexibility of metal conduit allows for easy adaptation to various configurations and layouts, making it a practical choice for diverse projects.

In summary, metal conduit offers numerous benefits, including physical and environmental protection, fire resistance, EMI shielding, durability, and versatility. By using metal conduit in electrical wiring installations, you can ensure the safety, reliability, and longevity of the electrical system. Metal conduit provides peace of mind and safeguards against potential hazards, making it an essential component in electrical infrastructure.

Read also: 15 Best Non Metalic Conduit for 2025

Installation and Maintenance of Metal Conduit

Proper installation and maintenance of metal conduit are crucial for ensuring the safety, reliability, and longevity of the electrical wiring system. Here are some important considerations for the installation and maintenance of metal conduit:

Installation:

1. Plan and Design: Before starting the installation, it is essential to carefully plan and design the electrical wiring system. Consider factors such as the type and size of conduit needed, the route and layout of the conduit, and compliance with local electrical codes and regulations.

2. Select the Right Conduit: Choose the appropriate type of metal conduit for your specific application. Consider factors such as the level of physical protection required, environmental conditions, and compatibility with the electrical wiring system.

3. Prepare the Installation Area: Ensure that the installation area is clean, free from debris, and adequately prepared. Remove any obstacles or obstructions that may hinder the installation process. If required, mark and secure the desired pathway for the conduit.

4. Cut and Assemble the Conduit: Measure and cut the metal conduit to the desired lengths, using appropriate tools such as a conduit cutter or hacksaw. Assemble the conduit sections using couplings, connectors, and fittings, ensuring a secure and proper connection.

5. Secure and Support the Conduit: Properly secure the conduit to walls, ceilings, or other structures using suitable straps, clamps, or hangers. Ensure that the conduit is adequately supported to prevent sagging or excessive movement that may lead to damage or strain on the electrical wires.

6. Electrical Connections: Properly connect and secure the electrical wires to the conduit using suitable connectors and fittings. Follow proper grounding techniques to ensure electrical safety and compliance with local codes and regulations.

Maintenance:

1. Regular Inspections: Conduct regular inspections of the metal conduit system to identify any signs of damage, corrosion, or wear. Look for dents, bends, cracks, or loose fittings that may affect the integrity of the conduit or the electrical wiring.

2. Repair or Replace Damaged Sections: Promptly repair or replace any damaged or deteriorated sections of the metal conduit. This may involve replacing damaged conduit sections, fittings, or connectors to ensure the continued protection and functionality of the electrical wiring system.

3. Clean the Conduit: Periodically clean the metal conduit to remove dirt, dust, or debris that may accumulate over time. Use a soft cloth, brush, or compressed air to clean both the external and internal surfaces of the conduit. Avoid using abrasive materials or harsh chemicals that may damage or corrode the conduit.

4. Maintain Grounding: Monitor and maintain proper grounding of the metal conduit system to ensure electrical safety and reduce the risk of electrical problems. Inspect grounding connections regularly to verify their integrity and effectiveness.

5. Follow Manufacturer Recommendations: Refer to the manufacturer’s guidelines and recommendations for any specific maintenance requirements or considerations for the specific type of metal conduit being used.

By following proper installation practices and regularly maintaining the metal conduit system, you can ensure the safety, functionality, and longevity of the electrical wiring system. It is important to consult with a professional electrician or electrical engineer for specific guidance and to comply with local codes and regulations.

Conclusion

Metal conduit is a critical component in electrical wiring systems, providing a protective pathway for electrical cables and ensuring the safety and reliability of electrical installations. We explored the various types of metal conduit, including steel conduit, aluminum conduit, galvanized conduit, stainless steel conduit, and copper conduit, each with its own unique characteristics and applications.

Steel conduit offers durability and physical protection, making it ideal for commercial and industrial settings. Aluminum conduit provides lightweight and corrosion-resistant properties, suitable for outdoor and weight-sensitive applications. Galvanized conduit offers excellent corrosion resistance, making it reliable in outdoor and wet environments. Stainless steel conduit provides superior corrosion resistance and hygienic properties, ideal for harsh or clean environments. Copper conduit offers excellent electrical conductivity and aesthetic appeal.

The benefits of using metal conduit in electrical wiring systems are numerous. It provides physical protection against impact, fire resistance, shielding against electromagnetic interference, and durability. Metal conduit also offers environmental protection, with resistance against moisture, chemicals, and other hazardous substances. Its versatility and compatibility with various wiring systems make metal conduit a reliable choice for different applications.

Proper installation and maintenance of metal conduit are vital for ensuring the safety and longevity of the electrical wiring system. Following industry best practices, planning, selecting the appropriate conduit, secure installation, and periodic maintenance are essential. Inspecting, repairing, cleaning, and maintaining proper grounding ensures the continued functionality and protection of the metal conduit system.

By understanding the different types of metal conduit and their benefits, you can make informed decisions when selecting the most suitable conduit for your specific electrical wiring needs. Always consult with a professional electrician or electrical engineer for guidance and to comply with local codes and regulations.

In conclusion, metal conduit offers a reliable and versatile solution for protecting electrical wiring systems. From physical and environmental protection to enhanced conductivity and corrosion resistance, metal conduit plays a crucial role in maintaining the integrity and safety of electrical installations. By choosing the right type of metal conduit and following proper installation and maintenance practices, you can ensure the efficiency, reliability, and durability of your electrical wiring system for years to come.

Frequently Asked Questions about What Is A Metal Conduit Made Of

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Metal Conduit Made Of”