Home>Articles>How To Cut Flexible Metal Conduit With Wires Inside

Articles

How To Cut Flexible Metal Conduit With Wires Inside

Modified: August 28, 2024

Learn the best technique for cutting flexible metal conduit with wires inside in this informative article. Discover step-by-step instructions and helpful tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

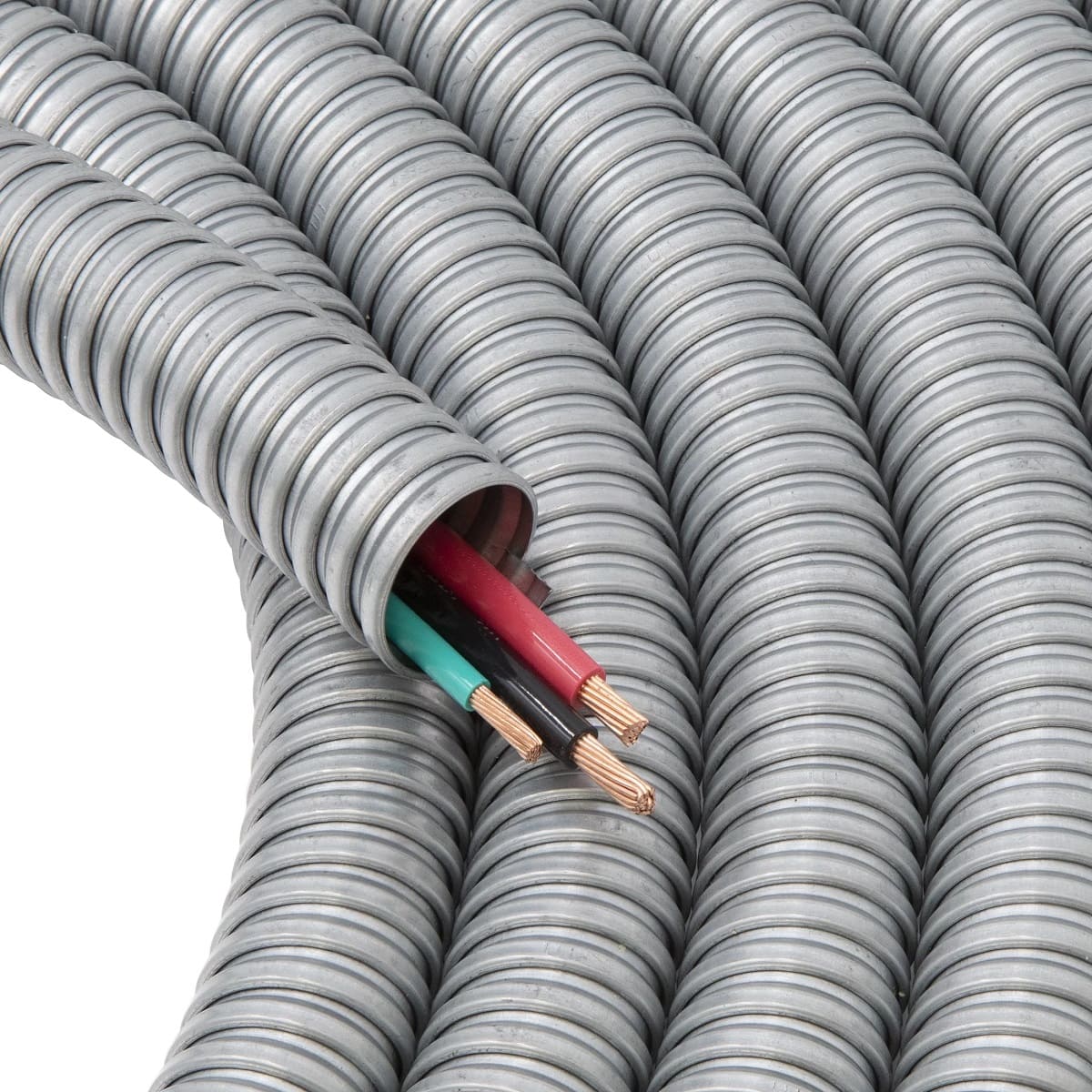

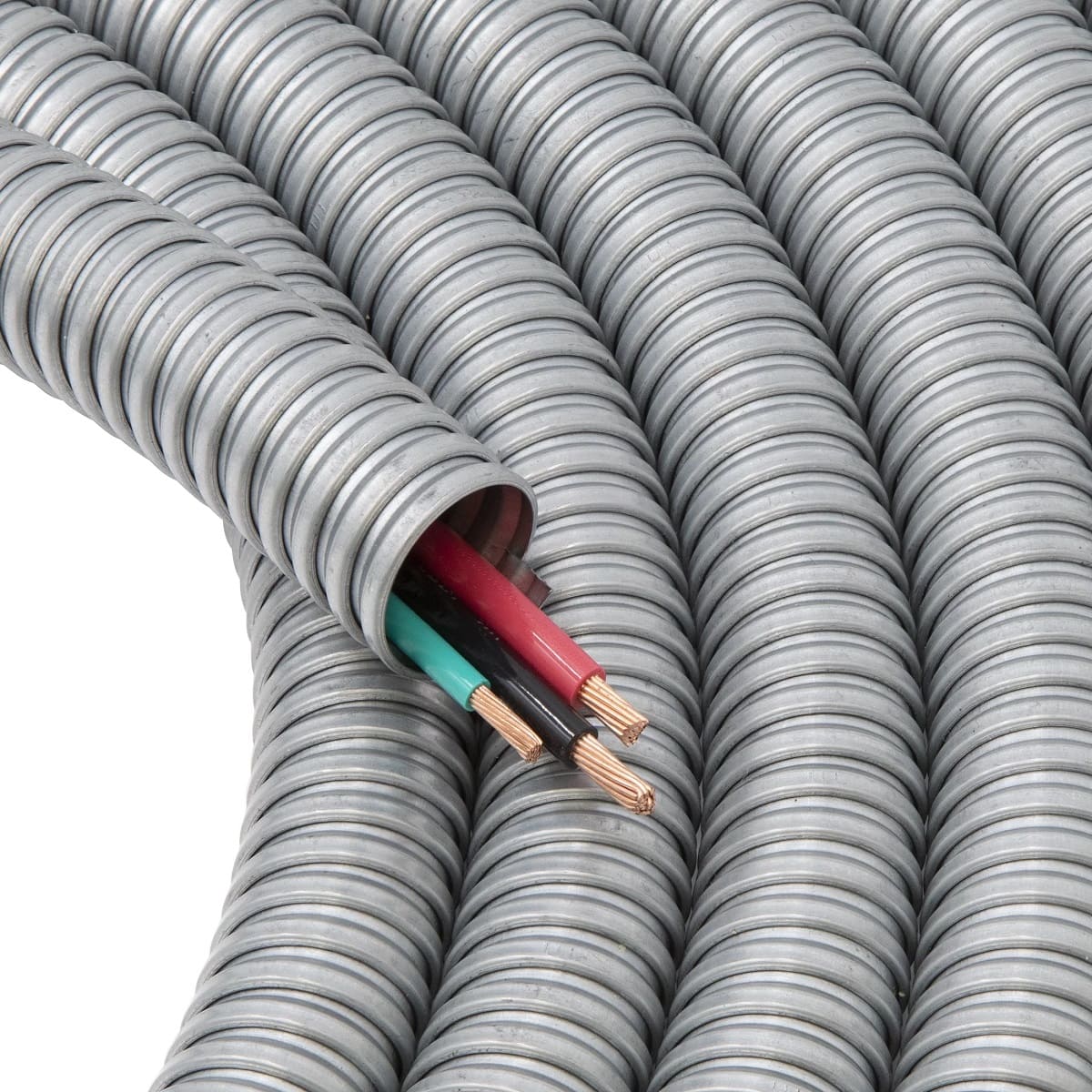

Cutting flexible metal conduit with wires inside can be a challenging task, but with the right tools and techniques, it can be done safely and effectively. Flexible metal conduit, also known as FMC or “Greenfield,” is a popular choice for wiring installations that require flexibility, such as in tight spaces or areas that may require frequent adjustments. However, when it comes time to trim or adjust the conduit, it’s important to follow the proper procedures to avoid damaging the wires inside or risking personal injury.

In this article, we will guide you through different methods for cutting flexible metal conduit with wires inside. We will discuss the tools and materials needed for each method, provide step-by-step instructions, and highlight safety precautions to ensure a successful and safe cutting process.

Whether you are a professional electrician or a DIY enthusiast, having the knowledge and skills to cut flexible metal conduit with wires inside is an essential skill to have. By learning the proper techniques, you can confidently tackle wiring projects and achieve a clean and precise cut every time.

Key Takeaways:

- Mastering the art of cutting flexible metal conduit with wires inside requires the right tools, safety precautions, and techniques. Whether using a hacksaw, rotary tubing cutter, reciprocating saw, or conduit cutter, prioritizing safety and precision is essential for successful electrical projects.

- Prioritizing safety, proper tool selection, and meticulous attention to detail are crucial when cutting flexible metal conduit with wires inside. By following safety precautions, using the correct tools, and maintaining precision, DIY enthusiasts and professional electricians can confidently achieve clean and precise cuts while safeguarding the integrity of the electrical installation.

Read more: How To Cut Conduit With Wires Inside

Tools and Materials Needed

Before you begin cutting flexible metal conduit with wires inside, it’s important to gather the necessary tools and materials. Here is a list of items you will need:

- Hacksaw or reciprocating saw

- Rotary tubing cutter

- Conduit cutter

- Safety goggles

- Gloves

- Measuring tape

- Pencil or marker

- Deburring tool

These tools are essential for different cutting methods and will ensure that you have the right equipment to safely and effectively cut the flexible metal conduit without damaging the wires inside.

When selecting a hacksaw or reciprocating saw, choose one with a fine-tooth blade to ensure a smooth and clean cut. A rotary tubing cutter is specifically designed for cutting conduit and is an excellent option for clean and precise cuts. A conduit cutter is another tool dedicated to cutting conduit and provides a convenient and easy solution for straight cutting.

Additionally, it’s crucial to prioritize safety while working with electrical wiring. Therefore, it is essential to wear safety goggles to protect your eyes from any potential flying debris and gloves to safeguard your hands.

Having a measuring tape, pencil, or marker is essential for marking the desired length of the conduit before cutting. This will help ensure accuracy and precision throughout the cutting process.

Lastly, a deburring tool is useful for removing any burrs or sharp edges created during the cutting process. This step is essential to maintain the integrity of the wires inside and prevent potential damage to the insulation or accidental injury.

By having the right tools and materials on hand, you’ll be well-prepared to tackle cutting flexible metal conduit with wires inside safely and efficiently.

Preparation

Before you start cutting flexible metal conduit with wires inside, it’s important to take a few preparatory steps to ensure a smooth and successful cutting process. Here are the key preparation steps:

- Turn off the power: It is crucial to turn off the power to the area where you’ll be working. This will prevent any electrical shock or damage to the wires during the cutting process. Locate the appropriate circuit breaker and switch it off.

- Clear the workspace: Ensure that the area where you’ll be cutting the conduit is clear of any obstacles or debris that could interfere with the process. This will provide you with a safe and unobstructed workspace.

- Measure and mark: Use a measuring tape to determine the desired length of the conduit, taking into account any bends or turns that may be required. Mark the measurement with a pencil or marker directly on the conduit.

- Secure the conduit: If necessary, secure the conduit in place using clamps or a vise grip. This will prevent it from moving or shifting during the cutting process, ensuring a more precise cut.

By following these preparation steps, you’ll create a safe and organized working environment, allowing you to focus on cutting the flexible metal conduit with wires inside accurately and without any unnecessary complications. Taking the time to properly prepare will ultimately result in a more efficient and successful cutting process.

Method 1: Using a Hacksaw

Using a hacksaw is a popular and versatile method for cutting flexible metal conduit with wires inside. Follow these step-by-step instructions to successfully cut the conduit using a hacksaw:

- Put on safety gear: Before starting, put on your safety goggles and gloves to protect your eyes and hands.

- Secure the conduit: If needed, secure the conduit in place using clamps or a vise grip to prevent it from moving during the cutting process.

- Measure and mark: Use a measuring tape to determine the desired length of the conduit. Mark the measurement with a pencil or marker directly on the conduit.

- Position the hacksaw: Place the hacksaw blade against the marked line on the conduit, making sure the blade is perpendicular to the conduit.

- Start cutting: Apply moderate pressure and begin sawing through the conduit using a back-and-forth motion. Let the saw do the work and avoid applying excessive force.

- Maintain control: Keep a firm grip on the hacksaw handle and ensure that the blade stays aligned with the marked line as you continue cutting.

- Finish the cut: Continue sawing until you have completely cut through the conduit. Take your time and maintain a steady pace to achieve a smooth and clean cut.

- Remove any burrs: Once the cut is complete, use a deburring tool to remove any sharp edges or burrs from the cut end of the conduit.

Using a hacksaw requires some manual effort, but it provides a reliable and accessible way to cut flexible metal conduit with wires inside. Take caution to maintain control of the saw and follow all safety precautions throughout the cutting process.

Note: When using a hacksaw, it’s common for the cutting process to create metal shavings. Ensure you remove any debris from the conduit and workspace to avoid potential hazards.

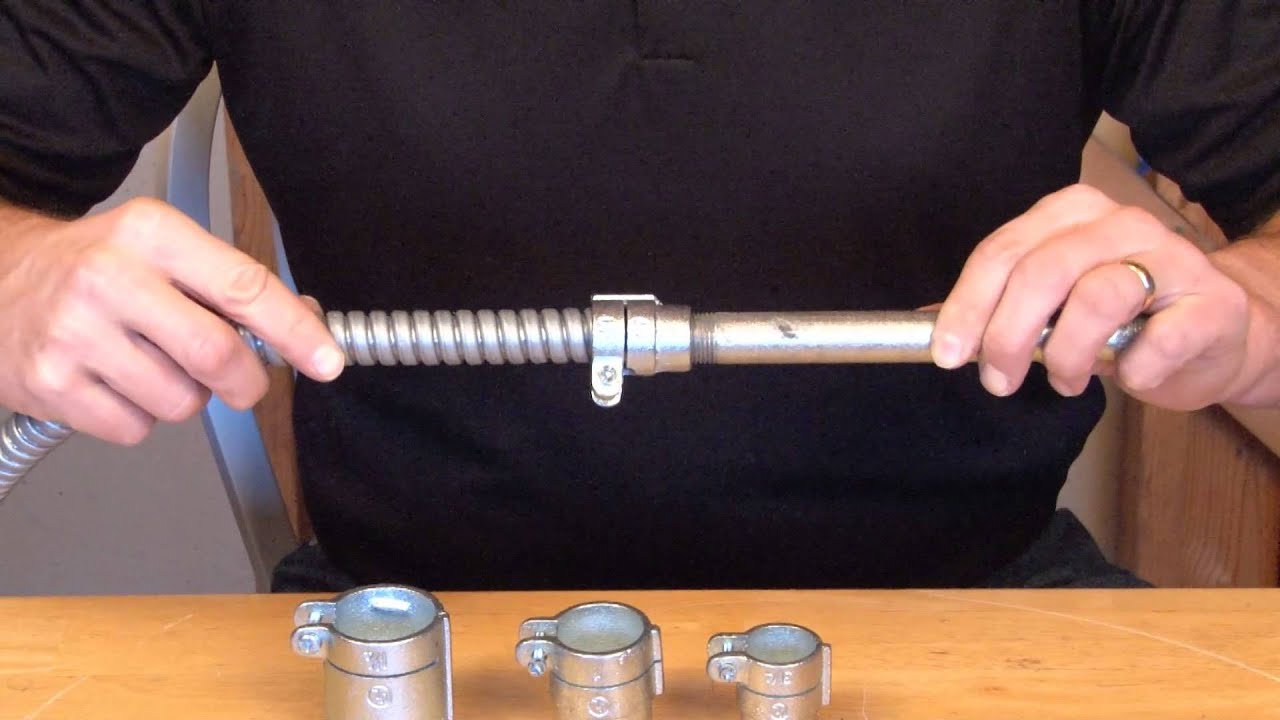

Method 2: Using a Rotary Tubing Cutter

The rotary tubing cutter is a specialized tool designed specifically for cutting conduit. It provides a clean and precise cut without damaging the wires inside. Follow these step-by-step instructions to cut flexible metal conduit with wires inside using a rotary tubing cutter:

- Put on safety gear: Before you begin, put on your safety goggles and gloves to protect your eyes and hands.

- Secure the conduit: If necessary, secure the conduit in place using clamps or a vise grip to prevent it from moving during the cutting process.

- Measure and mark: Use a measuring tape to determine the desired length of the conduit. Mark the measurement with a pencil or marker directly on the conduit.

- Position the tubing cutter: Place the rotary tubing cutter around the conduit, aligning the blade with the marked line. Make sure the cutter is perpendicular to the conduit.

- Tighten the cutter: Adjust the cutter’s wheel so that it applies light pressure to the conduit. Rotate the cutter around the conduit, tightening the cutter’s wheel periodically to gradually deepen the groove.

- Continue rotating: Keep rotating the cutter around the conduit, tightening the cutter’s wheel as necessary, until you have completely cut through the conduit.

- Check the cut: Once the cut is complete, inspect the cut end of the conduit to ensure it is clean and free of any burrs.

The rotary tubing cutter offers a convenient and precise method for cutting flexible metal conduit with wires inside. It minimizes the risk of damaging the wires and provides a clean cut, making it a preferred choice for many electricians and DIY enthusiasts.

Remember to take your time and apply steady pressure when using the rotary tubing cutter. This will help in achieving a smooth and accurate cut. Follow all safety precautions provided by the manufacturer and be cautious while handling the tool.

Before cutting flexible metal conduit with wires inside, make sure to turn off the power to the circuit to avoid any electrical hazards. Use a conduit cutter to make a clean and precise cut without damaging the wires inside.

Read more: How To Cut Flexible Electrical Conduit

Method 3: Using a Reciprocating Saw

Another effective method for cutting flexible metal conduit with wires inside is using a reciprocating saw. This power tool provides a rapid and efficient cutting process. Follow these step-by-step instructions to cut the conduit using a reciprocating saw:

- Put on safety gear: Before starting, put on your safety goggles and gloves to protect your eyes and hands.

- Secure the conduit: If necessary, secure the conduit in place using clamps or a vise grip to prevent it from moving during the cutting process.

- Measure and mark: Use a measuring tape to determine the desired length of the conduit. Mark the measurement with a pencil or marker directly on the conduit.

- Select the appropriate blade: Choose a fine-toothed blade suitable for cutting metal. Ensure the blade is sharp and in good condition.

- Position the reciprocating saw: Align the blade with the marked line on the conduit, ensuring it is perpendicular to the conduit.

- Start cutting: Turn on the saw and slowly guide the reciprocating saw along the marked line, allowing the blade to do the work. Apply moderate pressure, but avoid excessive force to prevent damage to the wires inside.

- Maintain control: Keep a firm grip on the saw’s handle and maintain control as you continue cutting. Follow the marked line closely for a clean and accurate cut.

- Finish the cut: Continue sawing until you have completely cut through the conduit. Take your time and maintain a steady pace for a smooth and precise cut.

- Remove any burrs: After completing the cut, use a deburring tool to remove any sharp edges or burrs from the cut end of the conduit.

A reciprocating saw offers speed and power for cutting flexible metal conduit with wires inside. It is particularly useful when dealing with thicker or more rigid conduit. However, it is essential to exercise caution and proper handling while using this power tool.

Always follow the manufacturer’s instructions for your specific reciprocating saw model and use a blade designed for cutting metal. By doing so, you can achieve clean and precise cuts while minimizing the risk of damaging the wires inside the conduit.

Method 4: Using a Conduit Cutter

The conduit cutter is a specialized tool designed specifically for cutting flexible metal conduit with wires inside. It provides a precise and clean cut, making it an excellent choice for professional electricians and DIY enthusiasts. Follow these step-by-step instructions to cut flexible metal conduit using a conduit cutter:

- Put on safety gear: Ensure you are wearing safety goggles and gloves before starting the cutting process.

- Secure the conduit: If necessary, secure the conduit in place using clamps or a vise grip to prevent it from moving during the cutting process.

- Measure and mark: Use a measuring tape to determine the desired length of the conduit. Mark the measurement with a pencil or marker directly on the conduit.

- Open the cutter: Depending on the design of your conduit cutter, open it enough to fit around the conduit.

- Position the cutter: Place the conduit cutter’s blade around the marked line on the conduit, ensuring it is aligned and perpendicular to the conduit.

- Close the cutter: Squeeze the handles of the conduit cutter together to close the blade onto the conduit. Apply firm and even pressure to keep the cut controlled.

- Rotate the cutter: Rotate the conduit cutter around the conduit while maintaining constant pressure. This will gradually cut through the conduit as you turn.

- Finish the cut: Continue rotating the cutter until you have completed the cut. Take your time and ensure a smooth and clean cut.

- Inspect the cut: After completing the cut, check the cut end of the conduit to ensure it is free of burrs or sharp edges. If needed, use a deburring tool to remove any rough spots.

The conduit cutter offers a straightforward and precise method for cutting flexible metal conduit with wires inside. It reduces the risk of damaging the wires and provides a clean cut, ensuring the integrity of the electrical installation.

Always follow the instructions provided by the manufacturer for your specific conduit cutter model. Take care to maintain a firm grip on the handles while cutting and follow all safety precautions to prevent any accidents or injuries.

Safety Precautions

When working with electrical wiring and cutting flexible metal conduit with wires inside, it is essential to prioritize safety. Follow these safety precautions to ensure a safe cutting process:

- Turn off the power: Before starting any work, locate and turn off the power to the area where you’ll be cutting the conduit. This step will minimize the risk of electrical shock and protect both you and the wires inside the conduit.

- Wear safety gear: Always wear appropriate safety gear, including safety goggles to protect your eyes from flying debris and gloves to safeguard your hands from cuts or injuries. Consider wearing ear protection if using power tools that generate significant noise.

- Secure the conduit: If necessary, secure the conduit in place using clamps or a vise grip. This will prevent it from moving or shifting during the cutting process, ensuring accurate and precise cuts.

- Proper tool selection: Use the correct tools for the job. Make sure your saw blades or cutters are specifically designed for cutting metal conduit. Using the right tools will result in cleaner cuts and minimize the risk of accidents.

- Follow manufacturer instructions: Always follow the manufacturer’s instructions and guidelines for your specific cutting tools. This includes proper operation, maintenance, and any safety recommendations specific to the tool.

- Work in a well-ventilated area: Ensure there is proper ventilation in the workspace to disperse any fumes generated during the cutting process, particularly when using power tools. This will help maintain good air quality and reduce the risk of respiratory irritation.

- Take breaks if needed: If the cutting process is time-consuming or physically demanding, take breaks regularly to prevent fatigue, which could lead to mistakes or accidents.

- Dispose of waste properly: Dispose of any waste material, such as metal shavings or debris, in a safe and responsible manner. Keep the work area clean and free from tripping hazards.

Remember, your safety and the safety of others should always be a top priority when working with electrical wiring and cutting flexible metal conduit with wires inside. By following these safety precautions and using caution throughout the cutting process, you can complete the task effectively and minimize the risk of accidents or injuries.

Conclusion

Cutting flexible metal conduit with wires inside may seem like a daunting task, but with the right tools, techniques, and safety precautions, it can be successfully accomplished. Whether you are a professional electrician or a DIY enthusiast, having the knowledge and skills to cut flexible metal conduit is essential for various wiring projects.

In this article, we explored different methods for cutting flexible metal conduit with wires inside. We discussed the use of a hacksaw, rotary tubing cutter, reciprocating saw, and conduit cutter, outlining the step-by-step instructions for each method. Each of these methods has its own advantages and suits different preferences and requirements.

Throughout the cutting process, it is crucial to prioritize safety. This includes wearing the appropriate safety gear, turning off the power, securing the conduit, and using the right tools for the job. Following safety precautions such as these will help ensure a safe working environment and protect both you and the integrity of the electrical installation.

Remember to take your time, follow the proper steps for measurement and marking, and apply steady pressure during the cutting process. Inspect the cut end of the conduit and remove any burrs or sharp edges using a deburring tool to maintain the integrity of the wires inside.

By gaining the necessary skills and knowledge to cut flexible metal conduit with wires inside, you can confidently tackle wiring projects, make adjustments as needed, and achieve clean and precise cuts. Always refer to the manufacturer’s instructions and guidelines for your specific tools and equipment to ensure proper usage and safety.

With practice, patience, and adherence to safety measures, you can master the art of cutting flexible metal conduit with wires inside, and successfully complete your electrical projects with confidence.

Excited to tackle more home improvement projects? If mastering your electrical setup intrigues you, our guide on how to run overhead electrical wire to your garage offers practical tips. Prefer rolling up your sleeves for hands-on activities? Our insights into the benefits of DIY projects could spark your next weekend endeavor. For those continuing with wiring tasks, our techniques on effective conduit cutting ensure your next steps are smooth and precise. Dive into these articles for deeper knowledge and confidence in taking on new challenges around your home.

Frequently Asked Questions about How To Cut Flexible Metal Conduit With Wires Inside

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Cut Flexible Metal Conduit With Wires Inside”