Articles

What Is An EMT Conduit

Modified: October 20, 2024

Discover everything you need to know about EMT conduit in our informative articles. Explore the benefits, uses, and installation tips for EMT conduit.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

The world of electrical installations and wiring is vast, with numerous components and materials that play a crucial role in ensuring the safe and efficient transmission of electricity. One such component is the EMT conduit, which stands for Electrical Metallic Tubing. EMT conduit is commonly used in various industries and applications due to its durability, versatility, and ease of installation.

In this article, we will explore what EMT conduit is, its uses and applications, the advantages it offers, installation requirements, common types and sizes, comparisons with other conduit types, as well as maintenance and safety considerations. By the end of this article, you will have a comprehensive understanding of EMT conduit and its significance in the world of electrical systems.

Key Takeaways:

- EMT conduit, or Electrical Metallic Tubing, is a versatile and cost-effective solution for protecting and routing electrical wiring in various applications, offering durability, flexibility, and ease of installation.

- When compared to other conduit types, EMT conduit stands out for its affordability, ease of installation, and flexibility, making it a preferred choice for many electrical projects in commercial, residential, and industrial settings.

Read more: How To Connect EMT Conduit

Definition of EMT Conduit

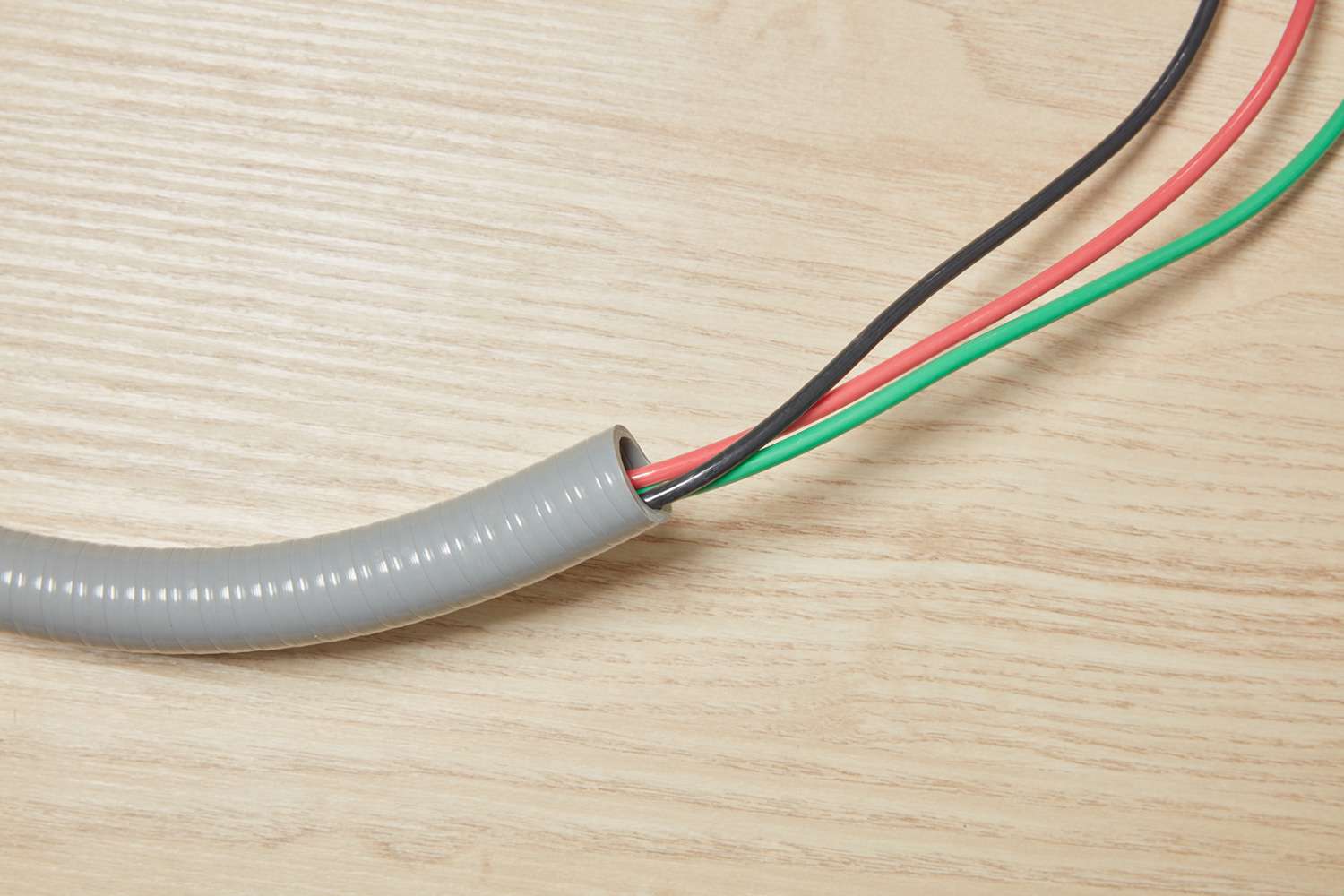

EMT conduit, also known as electrical metallic tubing, is a type of tubing used to protect and route electrical wiring in a wide range of applications. It is made of thin-walled galvanized steel or aluminum, which provides strength and durability while remaining lightweight. The walls of EMT conduit are smooth and allow for easy pulling and pushing of wires through the conduit.

EMT conduit is designed to meet the National Electrical Code (NEC) standards and comes in various sizes ranging from 1/2 inch to 4 inches in diameter. It is typically available in 10-foot lengths and can be easily cut and threaded to fit specific project requirements.

This type of conduit is commonly used in commercial, industrial, and residential applications where exposed conduit is acceptable. It is often installed in dry locations, such as interior walls, ceilings, and exteriors where it is protected from moisture. However, it is not suitable for wet or corrosive environments, as it may rust or degrade over time.

EMT conduit is recognized for its ease of installation and cost-effectiveness. It can be bent using special tools or by hand to navigate around obstacles and follow the desired path. Additionally, EMT conduit allows for the use of regular fittings and connectors, making it compatible with various electrical devices and junction boxes.

Uses and Applications of EMT Conduit

EMT conduit is widely used in a variety of industries and applications due to its versatility and durability. Here are some common uses and applications of EMT conduit:

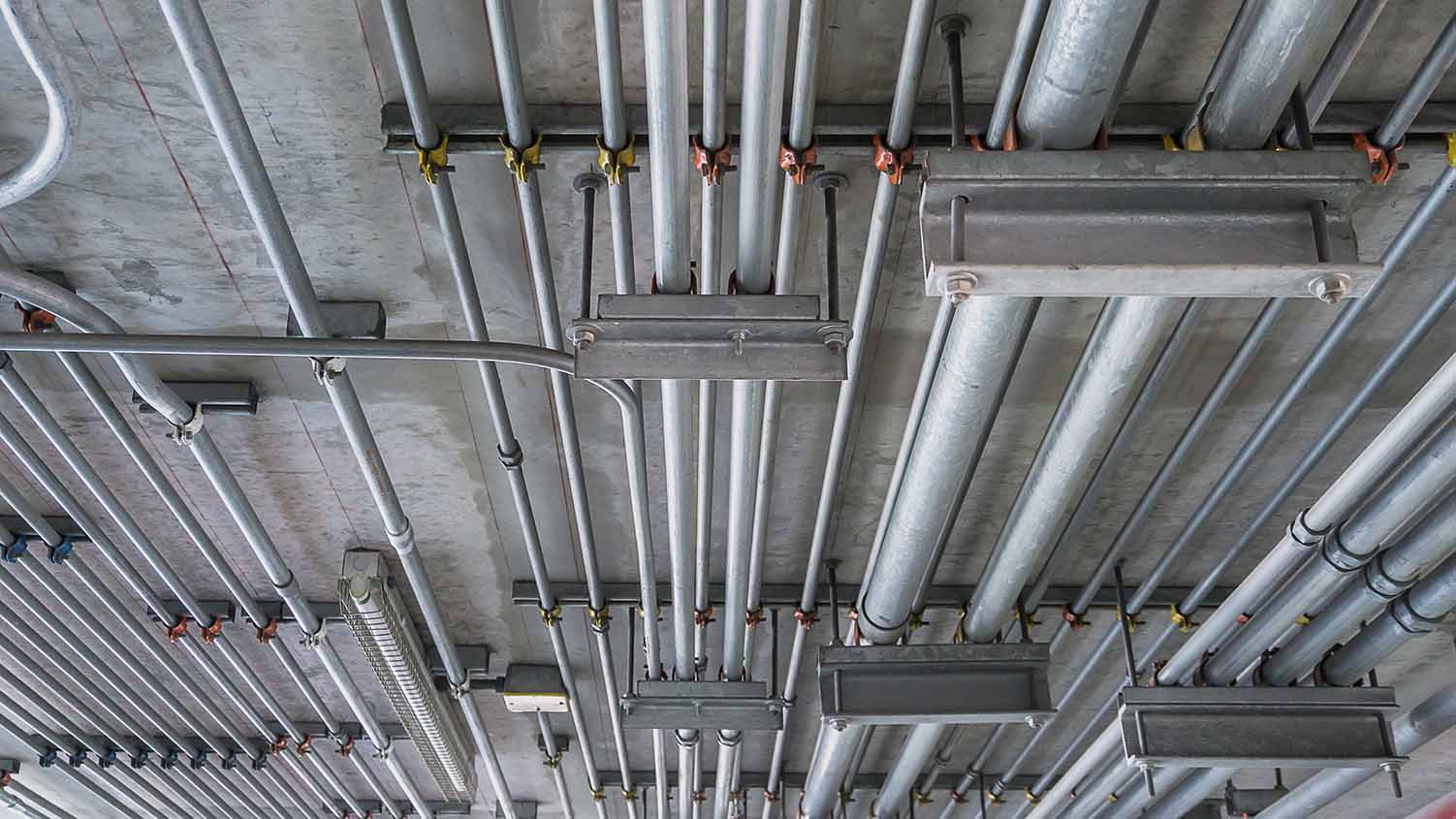

- Commercial buildings: EMT conduit is frequently used in commercial buildings, such as offices, retail stores, and restaurants, to provide a reliable and safe electrical wiring solution. It can be surface mounted or concealed within walls, ceilings, or floors.

- Residential buildings: In residential settings, EMT conduit is often used to protect and route electrical wiring in homes, apartments, and condominiums. It is commonly found in basements, attics, and crawl spaces.

- Industrial facilities: EMT conduit is suitable for use in industrial settings, including factories, warehouses, and manufacturing plants. Its robust construction ensures the protection of electrical wiring in demanding environments.

- Outdoor installations: EMT conduit is ideal for outdoor installations where electrical wiring needs to be protected from the elements. It can be used for street lighting, landscape lighting, and outdoor signage.

- Data centers: EMT conduit is commonly employed in data centers to provide a sturdy and reliable means of routing power and data cables. Its excellent grounding properties help minimize electromagnetic interference.

- Renewable energy projects: EMT conduit is often used in renewable energy projects, such as solar power systems and wind farms, to protect and route electrical wiring from the energy source to the distribution points.

These are just a few examples of the many applications where EMT conduit is utilized. Its flexibility, ease of installation, and compatibility with various fittings and connectors make it a popular choice for electrical wiring projects of all sizes.

Advantages and Benefits of EMT Conduit

EMT conduit offers several advantages and benefits that make it a preferred choice for electrical installations. Here are some of the key advantages:

- Durability: EMT conduit is made of sturdy galvanized steel or aluminum, providing excellent durability and resistance against physical damage. It can withstand impacts, vibrations, and other external forces, ensuring the long-term protection of the electrical wiring.

- Flexibility: EMT conduit can be easily bent and shaped to navigate around obstacles, corners, and tight spaces. This flexibility allows for efficient routing of electrical wiring, reducing the need for additional fittings or complex installation procedures.

- Easy to install: The lightweight nature of EMT conduit, combined with its smooth walls, makes it easy to handle and install. It can be cut to the desired length using simple tools and requires minimal effort to pull or push wires through the conduit.

- Cost-effective: EMT conduit is an economical choice compared to other types of conduit. Its lower cost per foot, combined with the ease of installation, results in significant cost savings in both material and labor expenses.

- Compatibility: EMT conduit is compatible with a wide range of fittings and connectors, allowing for seamless integration with electrical devices, junction boxes, and outlets. This compatibility makes it versatile and adaptable to different installation requirements.

- Grounding properties: EMT conduit provides excellent grounding capabilities, which helps mitigate the risk of electrical shocks and prevents electromagnetic interference. The metallic construction of the conduit allows for efficient grounding of electrical systems.

- Code compliance: EMT conduit meets the standards set by the National Electrical Code (NEC), ensuring compliance with electrical safety regulations. Using EMT conduit in your installations helps maintain code compliance and ensures the safety of the electrical system.

These advantages make EMT conduit a preferred choice for many electrical projects. Whether in residential, commercial, or industrial settings, EMT conduit provides a reliable, durable, and cost-effective solution for protecting and routing electrical wiring.

Installation and Requirements for EMT Conduit

Installing EMT conduit requires careful planning and adherence to certain requirements to ensure a safe and efficient electrical system. Here are the key steps and considerations for installing EMT conduit:

- Planning: Before beginning the installation process, it is important to plan the route of the conduit to ensure it meets the requirements of the project. Consider factors such as the location, distance, number of bends, and any obstacles that need to be navigated.

- Tools and materials: Gather all the necessary tools and materials for the installation, including EMT conduit, connectors, straps, conduit benders, a hacksaw or conduit cutter, screwdrivers, and a hammer. Ensure you have the appropriate sizes and types of fittings for the project.

- Marking and measuring: Use a tape measure and a pencil or marker to mark the locations where the conduit will be installed. Measure and mark the points where the conduit will be cut and bent to fit the layout of the electrical system.

- Cutting and bending: Use a hacksaw or conduit cutter to make clean cuts on the conduit at the marked points. For bends, utilize a conduit bender to achieve the desired angle. Follow the manufacturer’s guidelines for proper bending techniques and ensure that the conduit is not overstressed or kinked.

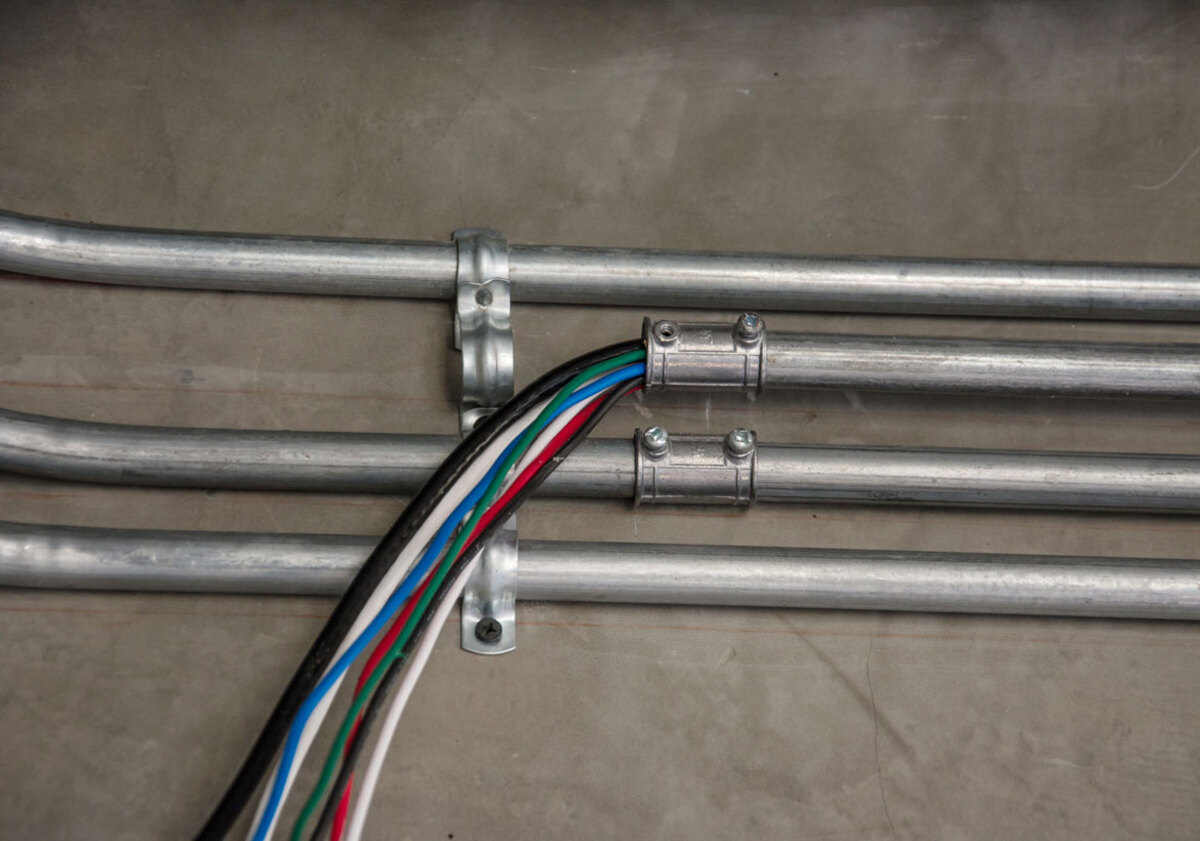

- Securing the conduit: Attach conduit straps or clamps at regular intervals to secure the conduit to walls, ceilings, or other surfaces. The spacing between straps should adhere to local building codes and the manufacturer’s recommendations.

- Connecting to devices and junction boxes: Install appropriate connectors to attach the conduit to electrical devices, junction boxes, or panels. Ensure that the connectors are tight and secure to maintain proper electrical continuity.

- Grounding: Properly ground the EMT conduit by using grounding bushings or fittings at both ends. Connect the grounding wire to the grounding bushing and ensure that it is securely fastened.

- NEC requirements: Follow the guidelines outlined by the National Electrical Code (NEC) for the installation of EMT conduit. Familiarize yourself with local electrical codes and obtain any necessary permits before beginning the installation process.

It is important to consult with a qualified electrician or refer to the NEC and local codes for specific installation requirements and guidelines. Proper installation of EMT conduit ensures the longevity, safety, and functionality of the electrical system.

When working with EMT conduit, always use the appropriate connectors and fittings to ensure a secure and code-compliant installation. This will help to protect the electrical wiring and ensure safety.

Read more: How To Successfully Install An EMT Conduit

Common Types and Sizes of EMT Conduit

EMT conduit is available in various types and sizes to accommodate different electrical installations. Here are the most common types and sizes of EMT conduit:

- Galvanized steel EMT conduit: This is the most common type of EMT conduit and is widely used in a variety of applications. It is made of zinc-coated steel, which provides excellent corrosion resistance and durability.

- Aluminum EMT conduit: Aluminum EMT conduit is lightweight and offers good corrosion resistance. It is commonly used in areas where weight is a concern or in locations where corrosion may be an issue, such as outdoor installations.

EMT conduit is available in a range of sizes, typically measured by the diameter of the conduit. Here are the most common sizes:

- 1/2 inch EMT conduit: This is the smallest size of EMT conduit and is commonly used for residential electrical wiring and light-duty commercial applications.

- 3/4 inch EMT conduit: This size is frequently used for general electrical installations, including residential and commercial applications.

- 1 inch EMT conduit: This size is suitable for larger electrical installations that require a higher capacity for wiring and conduit bends.

- 1-1/4 inch EMT conduit: This size is commonly used for heavy-duty applications, such as industrial and commercial installations that require larger wiring or conduit bends.

- 1-1/2 inch and larger EMT conduit: These sizes are often employed in larger-scale electrical installations, where the capacity for multiple wires and larger conduit bends is necessary.

It is important to select the appropriate type and size of EMT conduit based on the specific requirements of the electrical project. Consulting with an electrician or referring to local codes and regulations can help determine the correct type and size of EMT conduit to use.

Comparisons between EMT Conduit and Other Conduit Types

When it comes to electrical wiring, there are various types of conduit available, each with its own advantages and considerations. Here are some key comparisons between EMT conduit and other common conduit types:

- Rigid Metal Conduit (RMC): RMC is a heavy-duty conduit made of galvanized steel or stainless steel. It provides superior protection and is suitable for demanding environments. However, compared to EMT conduit, RMC is more difficult to bend and shape, making it less flexible for installations that require intricate routing.

- Intermediate Metal Conduit (IMC): IMC is a medium-weight conduit that offers a balance between RMC and EMT conduit. It is made of galvanized steel and provides good protection against physical damage. IMC is relatively easier to bend than RMC and provides better corrosion resistance compared to EMT conduit.

- Flexible Metal Conduit (FMC): FMC, also known as “greenfield” or “flex conduit,” is a flexible conduit made of a spiral-wound metal strip. It is commonly used for short runs and applications that require flexibility. Unlike EMT conduit, FMC can easily curve and bend around obstacles, making it ideal for installations that require frequent movements or changes.

- Non-Metallic Conduit (NMC): NMC, also known as PVC conduit, is made of a non-metallic material, typically PVC (polyvinyl chloride). It is lightweight, cost-effective, and resistant to moisture, corrosion, and chemicals. NMC is commonly used in residential and outdoor applications. However, it does not provide the same level of physical protection as metal conduits like EMT.

When deciding which conduit type to use, consider factors such as the installation environment, level of physical protection required, flexibility needs, and cost. EMT conduit is often the go-to choice for many applications due to its versatility, ease of installation, and cost-effectiveness. However, it is essential to evaluate specific project requirements and consult with professionals to choose the most suitable conduit type.

Maintenance and Safety Considerations for EMT Conduit

Maintaining EMT conduit and ensuring its safety is crucial to ensure the proper functioning of electrical systems and mitigate potential risks. Here are some important maintenance and safety considerations for EMT conduit:

- Regular inspections: Conduct routine inspections of the EMT conduit to check for any signs of damage, such as dents, corrosion, or loose connections. Inspect the conduit for any electrical or physical hazards that may compromise its integrity.

- Protection from moisture: Although EMT conduit provides some level of moisture resistance, it is not recommended for use in wet or corrosive environments. Ensure that the conduit is properly sealed and protected from moisture ingress, especially at connection points and entry/exit locations.

- Proper grounding: Ensure that the EMT conduit is properly grounded to minimize the risk of electrical shocks and to provide a reliable path for excess electrical current. Use grounding bushings or fittings at both ends of the conduit and connect them to the grounding system as per local electrical codes.

- Avoid overfilling: Do not overload the EMT conduit by introducing more wires than its designated capacity. Overfilling can lead to overheating, reduced airflow, and potential system failure. Follow the manufacturer’s recommendations and local codes regarding fill capacity.

- Secure and support the conduit: Ensure that the EMT conduit is securely fastened and supported using appropriate straps or clamps. This helps prevent sagging, excessive movement, and potential damage to the conduit or the wiring inside it. Follow local building codes and manufacturer’s guidelines for proper spacing and support.

- Proper wire pulling techniques: When pulling or pushing wires through EMT conduit, use proper techniques to avoid damaging the conduit or the wires themselves. Avoid excessive force or sharp bending that may result in kinks or breaks. Use lubricants or wire pulling compound to aid in the process if necessary.

- Keep access points clear: Ensure that access points to the EMT conduit, such as junction boxes or panels, are kept clear and easily accessible for maintenance and troubleshooting purposes. Avoid blocking or obstructing access to these points with equipment, furniture, or other objects.

- Follow electrical codes and regulations: Adhere to the requirements set forth by the National Electrical Code (NEC) and local electrical regulations when installing and maintaining EMT conduit. This ensures compliance with safety standards and minimizes potential hazards.

It is important to consult with a qualified electrician or electrical engineer to address any specific maintenance or safety concerns related to the EMT conduit within your electrical system. Regular maintenance and adherence to safety guidelines will help ensure a reliable and safe electrical installation.

Conclusion

EMT conduit, also known as Electrical Metallic Tubing, provides a reliable, durable, and cost-effective solution for protecting and routing electrical wiring in various applications. It offers several advantages, including its durability, flexibility, easy installation, cost-effectiveness, and compatibility with various fittings.

EMT conduit is widely used in commercial buildings, residential structures, industrial facilities, outdoor installations, data centers, and renewable energy projects. Its versatility makes it suitable for a wide range of electrical wiring applications.

When compared to other conduit types, such as Rigid Metal Conduit (RMC), Intermediate Metal Conduit (IMC), Flexible Metal Conduit (FMC), and Non-Metallic Conduit (NMC), EMT conduit stands out for its ease of installation, flexibility, and affordability.

To ensure the safety and proper functioning of the electrical system, it is important to follow proper installation practices, conduct regular inspections, protect the conduit from moisture, ensure proper grounding, and adhere to electrical codes and regulations.

In conclusion, EMT conduit plays a vital role in electrical installations by providing a secure and efficient means of protecting and routing electrical wiring. Its durability, flexibility, and ease of installation make it a preferred choice for many professionals in the electrical industry. By considering the specific needs of your project and following proper maintenance and safety practices, you can ensure the longevity and reliability of your electrical system with EMT conduit.

Frequently Asked Questions about What Is An EMT Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is An EMT Conduit”