Articles

What Is Blue Conduit Used For

Modified: February 26, 2024

Discover the many uses of blue conduit in our informative articles. From electrical wiring to plumbing installations, explore the versatility of blue conduit today.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of blue conduit – a versatile and highly efficient solution for cable management. In order to understand the various applications and benefits of blue conduit, it is important to first grasp the concept and purpose behind this innovative technology.

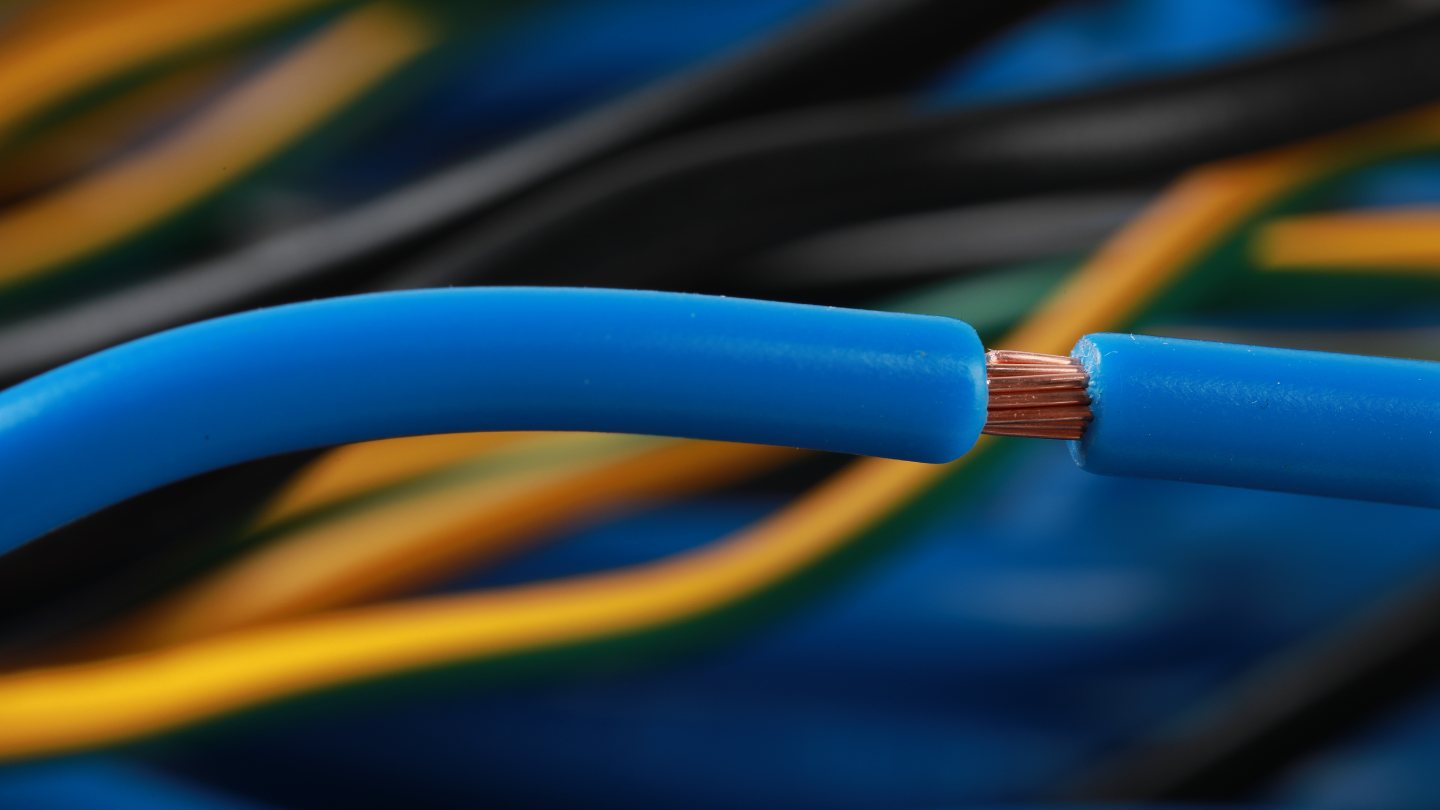

Blue conduit, also known as HDPE (High-Density Polyethylene) conduit, is a type of tubing used for protecting and organizing electrical cables and wiring. It is a reliable and cost-effective alternative to traditional metal conduits, offering a multitude of advantages in terms of durability, flexibility, and ease of installation.

With the ever-increasing demands for efficient and secure cable management, the use of blue conduit has become a popular choice across a wide range of industries. From residential and commercial buildings to infrastructure projects, blue conduit is revolutionizing the way we manage and safeguard our electrical systems.

This article will provide you with a comprehensive overview of blue conduit, exploring its definition, benefits, applications, installation process, maintenance, and cost comparison with traditional conduit options. By the end, you will have a thorough understanding of why blue conduit is the go-to solution for effective cable management.

Key Takeaways:

- Blue conduit, also known as HDPE conduit, offers durability, flexibility, and cost-effectiveness for cable management. Its vibrant blue color and resistance to environmental factors make it a standout choice for various industries.

- The installation process of blue conduit is straightforward, and its maintenance requirements are minimal. With its versatility and long-term cost savings, blue conduit provides a reliable and efficient solution for cable management needs.

Read more: What Is Conduit Used For

Definition of Blue Conduit

Blue conduit, also referred to as HDPE (High-Density Polyethylene) conduit, is a type of tubing that is specifically designed to protect and route electrical cables and wiring. It is made from a high-density polyethylene material that provides exceptional strength and flexibility.

One of the distinguishing features of blue conduit is its vibrant blue color, which makes it easily identifiable and differentiates it from other types of conduits. The blue color is not just for aesthetics; it serves a functional purpose, as it indicates that the conduit contains electrical wiring.

Blue conduit is available in different sizes and configurations to accommodate various cable diameters and installation requirements. It is commonly available in diameters ranging from ½ inch to 6 inches, catering to both residential and commercial applications.

What sets blue conduit apart from traditional metal conduits is its inherent flexibility. Unlike metal conduits, which can be rigid and difficult to bend, blue conduit is highly flexible and can be easily maneuvered around corners, obstacles, and tight spaces. This flexibility allows for easier installation and reduces the time and effort required to route cables.

Moreover, blue conduit offers excellent resistance to corrosion, moisture, and chemicals. It is designed to withstand harsh environmental conditions, making it suitable for both indoor and outdoor installations. The durable nature of blue conduit ensures that the cables within it remain well-protected and insulated, minimizing the risk of damage or disruption to electrical systems.

Overall, blue conduit offers a reliable and efficient solution for cable management, combining strength, flexibility, and durability. Its unique color and design features make it a standout choice in the industry, setting it apart from other types of conduits.

Benefits of Blue Conduit

Blue conduit offers a wide range of benefits that make it a preferred choice for cable management in various industries. Let’s explore some of the key advantages of using blue conduit:

- Durability: Blue conduit is constructed from high-density polyethylene, which provides excellent durability and resistance to corrosion and impact. It can withstand extreme weather conditions, UV radiation, and chemicals, ensuring long-term protection for the cables inside.

- Flexibility: Unlike rigid metal conduits, blue conduit is highly flexible. It can be easily bent, twisted, and maneuvered around obstacles, making the installation process faster and more efficient. The flexibility of blue conduit also allows for easier cable routing in tight spaces.

- Cost-effective: Blue conduit offers cost-effectiveness over traditional metal conduits. It is more affordable to purchase and install, and the flexibility of blue conduit reduces the need for additional fittings and connectors, further reducing installation costs.

- Easy installation: Blue conduit is lightweight and easy to handle, making it simple to transport and install. Its flexibility allows installers to quickly and easily route cables, saving time and effort during the installation process.

- Improved cable protection: The high-density polyethylene material of blue conduit provides superior protection for electrical cables. It shields the cables from physical damage, moisture, chemicals, and UV radiation, ensuring optimal performance and longevity of the electrical system.

- Ease of identification: The vibrant blue color of the conduit makes it easily distinguishable from other types of conduits, reducing the chance of confusion during installation or maintenance. The blue color serves as a visual indicator that the conduit contains electrical wiring.

- Longevity: Blue conduit has a long lifespan, requiring minimal maintenance over its lifetime. It does not rust or corrode like metal conduits, eliminating the need for regular inspections or replacements.

Overall, the benefits of blue conduit make it an attractive option for cable management. Its durability, flexibility, cost-effectiveness, and ease of installation ensure efficient and reliable protection for electrical cables in various applications.

Applications of Blue Conduit

Blue conduit finds wide-ranging applications in numerous industries and settings. Its versatility and durability make it an ideal solution for various cable management needs. Let’s explore some of the common applications of blue conduit:

- Residential Buildings: Blue conduit is extensively used in residential buildings for wiring applications. It is commonly employed for routing electrical cables in walls, ceilings, and floors, ensuring safe and organized wiring throughout the house.

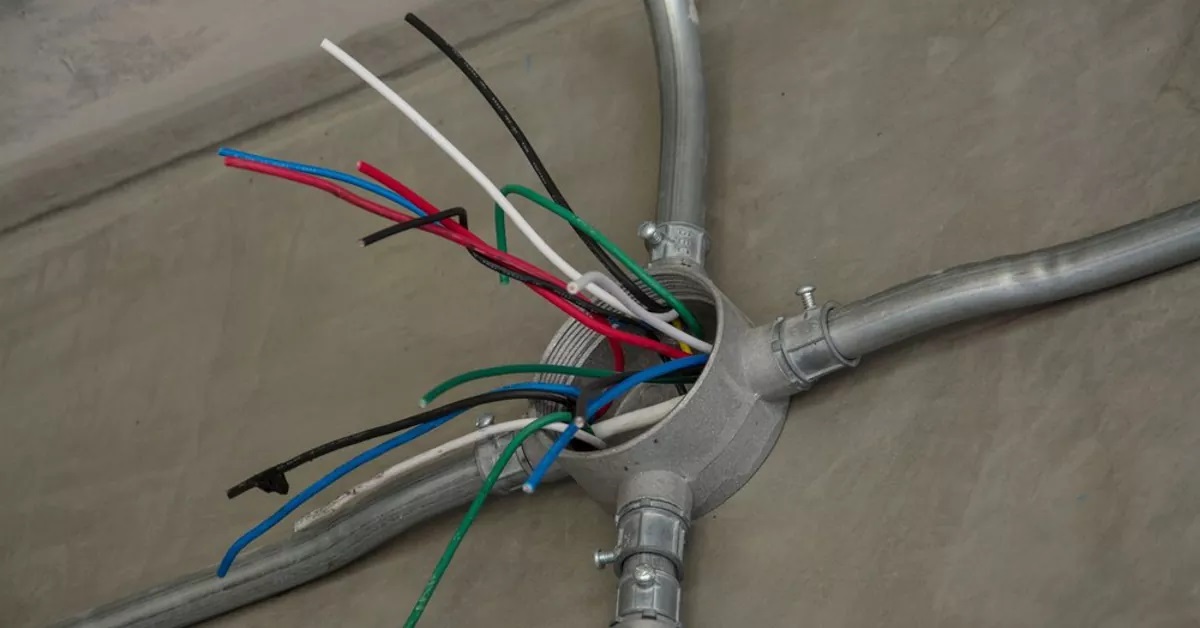

- Commercial Buildings: In commercial buildings, blue conduit is used for cable management in offices, retail spaces, and industrial facilities. It provides a reliable solution for routing power and data cables, telecommunication lines, and security system wiring.

- Infrastructure Projects: Blue conduit plays a crucial role in infrastructure projects such as highways, bridges, and tunnels. It is used to protect and route communication lines, fiber optic cables, and electrical wiring, ensuring the efficient and reliable functioning of these critical systems.

- Utilities and Energy Sector: Blue conduit finds extensive use in utilities and the energy sector for cable management in power distribution networks, substations, and renewable energy projects. It provides a robust and durable solution for protecting electrical cables and wiring, thereby ensuring the safe and efficient transmission of power.

- Transportation: Blue conduit is employed in transportation infrastructure, including airports, train stations, and seaports. It is used for cable management in lighting systems, security systems, control and monitoring systems, and communication networks.

- Data Centers: Blue conduit is a popular choice for cable management in data centers. It allows for the efficient organization and routing of networking cables, fiber optic cables, and power cables, ensuring reliable and scalable connectivity within the data center environment.

- Renewable Energy Projects: With the growing focus on renewable energy, blue conduit is extensively used in solar and wind energy projects. It provides a durable and weather-resistant solution for protecting and routing cables in solar panels, wind turbines, and energy storage systems.

These are just a few examples of the diverse applications of blue conduit. Its versatility, durability, and ease of installation make it suitable for a wide range of industries and settings where effective cable management is essential.

Blue conduit is typically used for carrying electrical wires in residential and commercial buildings. It provides protection for the wires and makes it easier to identify electrical systems. Always follow local building codes and regulations when using blue conduit.

Installation Process of Blue Conduit

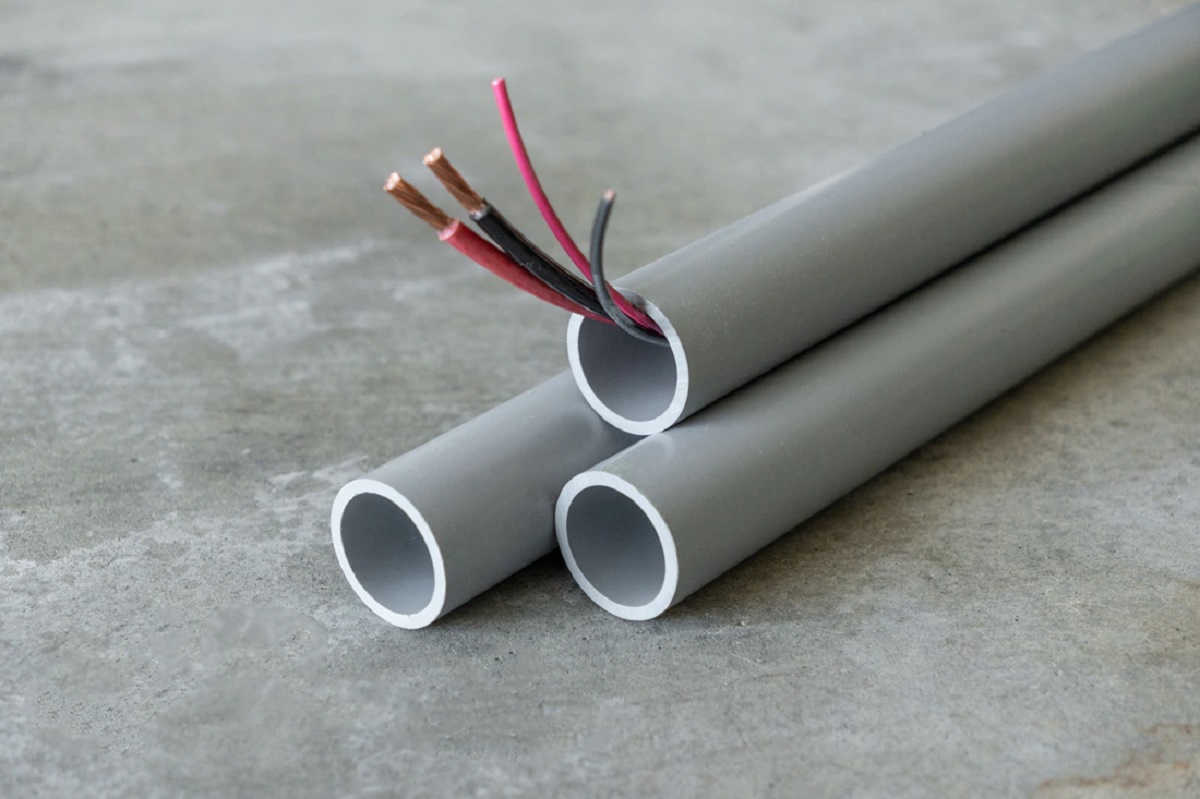

The installation process for blue conduit is straightforward and can be completed with basic tools and equipment. Here are the general steps involved:

- Planning: Start by assessing the cable management requirements and determining the route for the conduit. Take into consideration any obstacles, corners, or areas where the conduit needs to be flexible or joined with fittings.

- Marking and Measurement: Use a pencil or marker to mark the desired locations for the conduit. Measure and cut the conduit into required lengths, ensuring sufficient length for connections and bends.

- Drilling Holes: If necessary, drill holes in walls, ceilings, or floors to accommodate the conduit. Ensure that the holes are aligned and sized appropriately to allow for easy passage of the conduit.

- Attaching Fittings: Attach fittings such as couplings, elbows, and connectors to the conduit as needed. These fittings will allow for smooth routing and connection of the conduit in different directions and angles.

- Securing the Conduit: Attach conduit straps or clamps at regular intervals to secure the conduit in place. This will prevent the conduit from shifting or sagging over time.

- Routing the Cables: Insert the electrical cables into the conduit and carefully route them along the desired path. Ensure that the cables are not tightly packed and have sufficient space for movement and future maintenance.

- Connecting Conduit Sections: When joining multiple sections of conduit, use appropriate connectors or couplings. Make sure the connection is tight and secure to maintain proper cable protection and conductivity.

- Sealing Joints: If needed, apply sealant or tape to seal the joints and prevent the entry of moisture, dust, or debris. This step is particularly important for outdoor installations or areas prone to moisture.

- Final Checks: Inspect the installation to ensure that the conduit is properly aligned, the cables are secure, and there are no visible defects. Test the functionality of the cables and conduct a thorough visual inspection before completing the installation.

Note that the specific steps and techniques used may vary depending on the installation requirements and local building codes. It is always recommended to consult industry standards and guidelines, as well as seek professional assistance if needed, to ensure a proper and compliant installation of blue conduit.

Read more: What Is Red Conduit Used For

Maintenance and Durability of Blue Conduit

Blue conduit is known for its durability, requiring minimal maintenance over its lifespan. However, a few maintenance considerations can help ensure the longevity and performance of the conduit:

Regular Inspections: Periodically inspect the blue conduit for any signs of damage or wear. Look for cracks, breaks, or exposed cables. Check the fittings and connections to ensure they are secure and intact. Promptly address any issues to prevent further damage or potential safety hazards.

Cleaning: Keep the blue conduit clean and free from dust, debris, and moisture. Use a soft cloth or brush to gently remove any dirt or particles that may have accumulated on the surface. Avoid using harsh chemicals or abrasive cleaners that may damage the conduit.

Protection from UV Radiation: Although blue conduit is designed to be UV-resistant, prolonged exposure to intense sunlight can still cause degradation over time. If the conduit is installed in an outdoor or exposed area, consider applying a UV-protective coating or using conduit covers to shield it from direct sunlight.

Ensure Proper Connections: Regularly check the connections and fittings to ensure they are tight and secure. Loose connections can lead to cable damage or disruption of electrical systems. Tighten any loose fittings as needed.

Proper Cable Routing: Ensure that the cables within the blue conduit are properly routed and organized. Avoid overcrowding the conduit, as it can put unnecessary strain on the cables and reduce airflow for better heat dissipation. Proper cable organization helps maintain optimal performance and reduces the chances of cable failure.

Protect from Chemical Exposure: If the blue conduit is installed in environments where it may come into contact with corrosive chemicals, take measures to protect it. Apply appropriate chemical-resistant coatings or consider using alternative conduit materials optimized for chemical exposure to ensure long-term durability.

Overall, blue conduit is designed to provide long-lasting performance and durability. By performing routine inspections, keeping it clean, protecting it from UV radiation and chemicals, and ensuring proper cable routing, you can maximize the lifespan and reliability of the blue conduit installation.

Cost Comparison of Blue Conduit vs. Traditional Conduit

When it comes to selecting the right conduit for your cable management needs, cost is an important factor to consider. Let’s compare the costs of blue conduit and traditional conduit options:

Material Cost: Blue conduit is generally more affordable than traditional conduit options like metal conduits. High-density polyethylene, the material used for blue conduit, is cost-effective to manufacture, making it a budget-friendly choice for cable management projects.

Installation Cost: Blue conduit offers advantages in terms of installation costs. Its lightweight and flexible nature make it easier and faster to install compared to rigid metal conduits. This can reduce labor costs, as less time and effort are required for routing and connecting the conduit.

Additional Fittings and Connectors: Traditional conduit options often require additional fittings, connectors, and tools for installation. This can add to the overall project cost. In contrast, blue conduit’s flexibility reduces the need for additional fittings, thus potentially lowering the total cost of the installation.

Maintenance Cost: Blue conduit generally has lower maintenance costs compared to traditional conduit options. Its durability and resistance to corrosion and impact reduce the need for regular maintenance and replacements. This can translate into long-term cost savings for the cable management system.

Durability and Longevity: Blue conduit’s durability translates into long-term cost savings. Traditional conduit options, particularly those made of metal, may be prone to rust, corrosion, and damage over time, requiring frequent replacements. In contrast, blue conduit’s resistance to environmental factors and wear ensures a longer lifespan, reducing the need for frequent replacements and associated costs.

Overall Project Cost: When considering the overall cost of a cable management project, including material, installation, and maintenance costs, blue conduit often offers a more cost-effective solution compared to traditional conduit options. Its affordability, ease of installation, and long-term durability contribute to lower overall project expenses.

While blue conduit may have a higher upfront material cost than some of the traditional conduit options, the benefits it provides in terms of installation efficiency, reduced maintenance, and long-term durability often outweigh the initial investment. The cost-effectiveness of blue conduit makes it an attractive choice for various cable management applications.

Conclusion

Blue conduit, also known as HDPE conduit, is a versatile and highly efficient solution for cable management. Its durability, flexibility, and cost-effectiveness make it a preferred choice across various industries and settings.

In this article, we explored the definition and key features of blue conduit. We discussed its vibrant blue color, which serves as a visual indicator that the conduit contains electrical wiring. The high-density polyethylene material provides exceptional strength, flexibility, and resistance to corrosion and impact.

We also highlighted the numerous benefits of blue conduit. Its durability ensures long-term protection for electrical cables, while its flexibility allows for easy installation and routing in tight spaces. Blue conduit is cost-effective, easy to identify, and requires minimal maintenance, making it an attractive choice for cable management projects.

Furthermore, we explored the various applications of blue conduit, including residential and commercial buildings, infrastructure projects, utilities, transportation, data centers, and renewable energy projects. Its versatility and reliability make it suitable for a wide range of cable management needs.

The installation process of blue conduit was outlined, emphasizing the steps involved in planning, measuring, drilling, attaching fittings, securing the conduit, routing the cables, and final inspections. Proper installation techniques ensure a safe and efficient cable management system.

We also discussed the maintenance and durability of blue conduit, emphasizing the importance of regular inspections, cleaning, and protection from UV radiation and chemicals. By following these maintenance practices, the longevity and performance of the conduit can be maximized.

Finally, we compared the cost of blue conduit versus traditional conduit options, highlighting the cost-effectiveness of blue conduit in terms of material cost, installation cost, additional fittings, maintenance cost, and overall project cost. While the upfront material cost may be slightly higher, the long-term savings due to efficiency, durability, and reduced maintenance make blue conduit a cost-effective choice.

In conclusion, blue conduit offers a reliable, efficient, and cost-effective solution for cable management. Its durability, flexibility, and versatility make it ideal for a wide range of applications. Whether in residential, commercial, or infrastructure projects, blue conduit ensures secure and organized cable routing, protecting electrical systems and promoting optimal performance.

Frequently Asked Questions about What Is Blue Conduit Used For

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Blue Conduit Used For”