Articles

What Is A Conduit Body Used For

Modified: March 1, 2024

Find out what a conduit body is used for and learn more in our informative articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of electrical installations, it is essential to have proper conduits to protect and organize wiring systems. Conduits serve as a pathway for electrical cables, ensuring safety and preventing damage. However, in certain situations, it becomes necessary to change the direction of the conduit or connect multiple conduits together. This is where a conduit body comes into play.

A conduit body, also known as a junction or access fitting, is a crucial component in electrical systems. It provides a means for making turns, pulls, or splices in conduit runs. By offering flexibility and versatility, conduit bodies help electricians navigate through challenging wiring configurations and ensure the smooth flow of electrical power.

This article aims to delve deeper into the concept of conduit bodies, exploring their definition, purpose, types, installation process, and the benefits of their usage. Additionally, it will highlight the common applications where conduit bodies are commonly employed.

So, let’s dive in and discover what conduit bodies are all about and why they are an integral part of electrical installations!

Key Takeaways:

- Conduit bodies provide flexibility, protection, and accessibility in electrical installations, ensuring efficient wire routing and easy maintenance while safeguarding wiring systems from environmental factors.

- From residential to industrial applications, conduit bodies offer versatile solutions for navigating conduit paths, facilitating wire connections, and ensuring the safety and performance of electrical systems.

Read more: Which Types Of Conduit Bodies Are Used To Provide A Pull Point On A Straight Conduit Run?

Definition of a Conduit Body

A conduit body can be defined as a device used in electrical installations to facilitate the connection, redirection, or branching of conduits. It acts as an access point for wires to enter or exit the conduit, enabling electricians to make changes in the direction of the conduit run or access the wiring for maintenance or troubleshooting purposes.

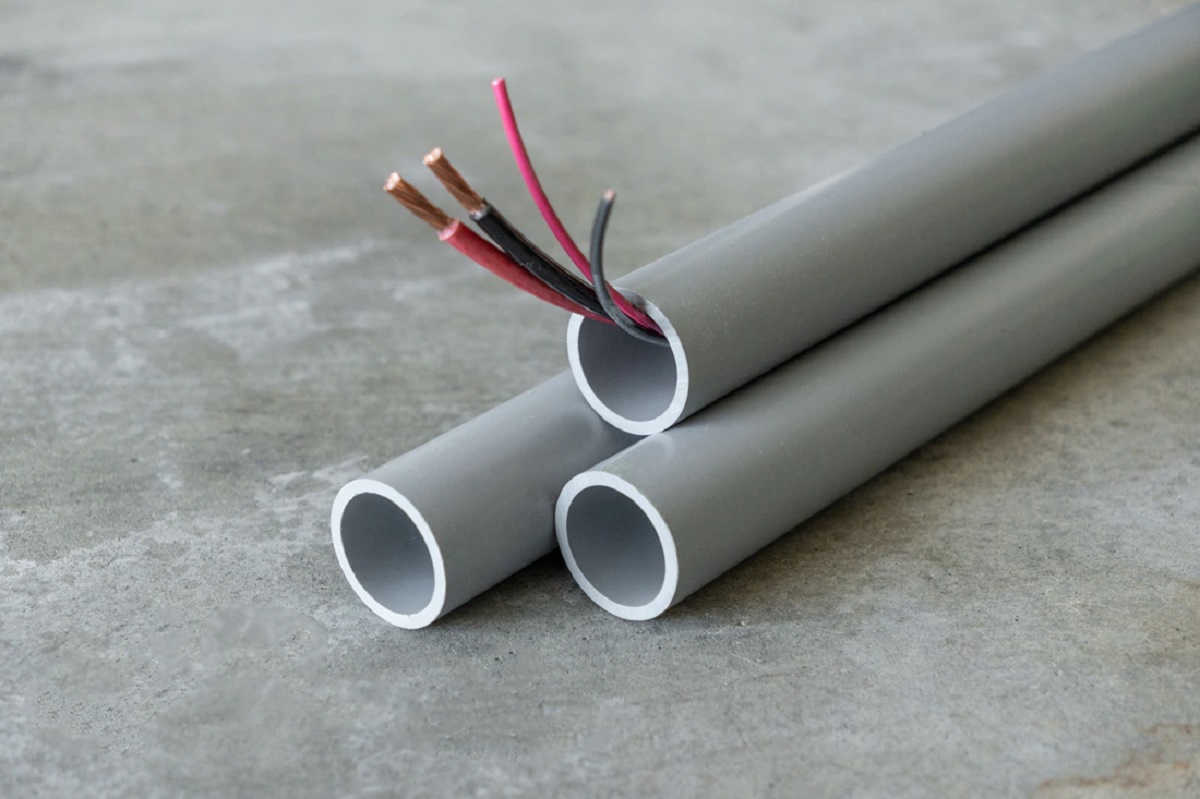

Conduit bodies are typically made of rugged materials such as durable metals or non-metallic substances that are resistant to corrosion, moisture, and extreme temperatures. They are designed to provide a secure and protected enclosure for the electrical connections within.

Unlike standard conduit fittings, such as elbows or couplings, which only allow for straight runs or limited bending angles, a conduit body offers greater flexibility by allowing multiple conduit connections and various bending options.

Conduit bodies come in different shapes and sizes, with various access points and configurations to accommodate the specific needs of different wiring setups. They may have removable or hinged covers, providing easy access to the wiring inside while ensuring the safety and integrity of the electrical connections.

Overall, a conduit body serves as a critical component in electrical installations, offering a practical and flexible solution for achieving desired changes in the conduit path and maintaining the integrity of the wiring system.

Purpose and Function of a Conduit Body

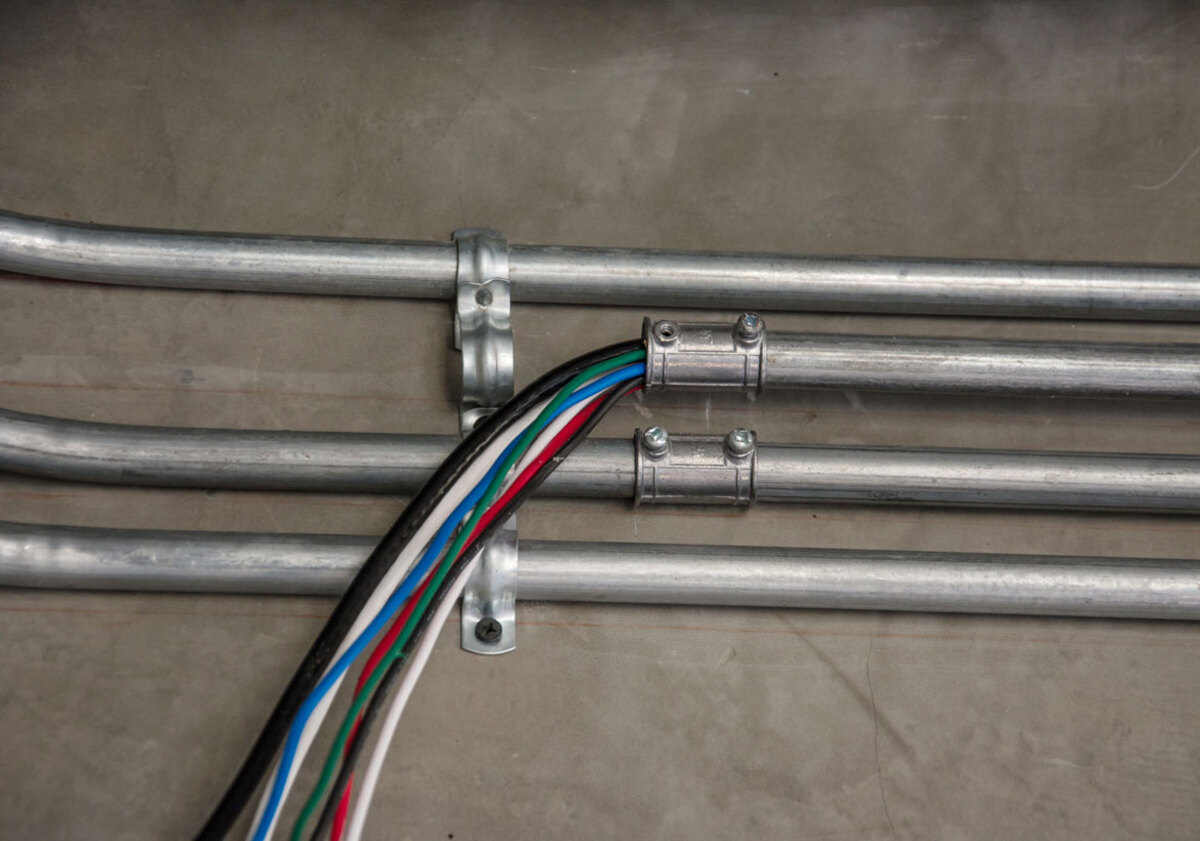

The primary purpose of a conduit body is to provide a means for changing the direction of a conduit or connecting multiple conduits together. It serves as a versatile junction point that allows for the smooth continuation of the electrical wiring system.

Here are some key functions of a conduit body:

- Change in Conduit Direction: One of the main functions of a conduit body is to facilitate changes in the direction of the conduit run. It allows electricians to make turns or bends in the conduit system without impeding the flow of electrical power. This is particularly useful when working around obstacles, corners, or irregular surfaces where a straight conduit run is not feasible.

- Access Point: A conduit body serves as an access point for wires to enter or exit the conduit. It provides a secure and protected enclosure that allows easy access for making connections, pulling wires, or performing maintenance tasks. The removable or hinged covers on conduit bodies enable convenient access to the wiring inside, ensuring efficient installation and troubleshooting processes.

- Branching or Splicing: Another important function of a conduit body is to facilitate branching or splicing of conduits. It enables electricians to split the conduit system into multiple paths or join conduits together to create a unified wiring system. This is particularly useful when expanding an existing electrical infrastructure or connecting different sections of a building or facility.

- Protection and Safety: Conduit bodies play a crucial role in safeguarding electrical connections and wiring systems. They provide a secure and enclosed environment that protects the wires from external factors such as moisture, dust, debris, and physical damage. Additionally, conduit bodies help prevent the accidental contact of live wires by keeping them concealed and inaccessible.

Overall, the purpose and function of a conduit body are to enhance the flexibility, accessibility, and protection of electrical conduit systems. They allow for changes in direction, facilitate wiring connections, and ensure the integrity and safety of the electrical infrastructure.

Types of Conduit Bodies

Conduit bodies come in various types, each designed for specific purposes and applications. Here are some common types of conduit bodies:

- Conduit Body with Threaded Openings: This is the most basic type of conduit body, featuring threaded openings on one or more sides. It allows for the connection of conduits with standard threaded fittings, such as couplings or connectors.

- Tapped Conduit Body: A tapped conduit body is similar to a conduit body with threaded openings, but with pre-tapped holes instead of threads. It enables the direct insertion of conduit connectors, eliminating the need for additional threaded fittings.

- Pull Box Conduit Body: A pull box conduit body is designed to provide extra space for pulling or splicing wires. It features larger dimensions compared to standard conduit bodies and may have multiple conduit openings, allowing for easy access and maneuverability during installation or maintenance.

- Weatherproof Conduit Body: Weatherproof conduit bodies are specifically designed to resist moisture, dust, and other environmental elements. They feature gaskets or sealing mechanisms to ensure a watertight and corrosion-resistant enclosure, making them suitable for outdoor or damp locations.

- Conduit Body with Integral Cover: This type of conduit body has a built-in cover that is permanently attached or hinged. It provides a secure and protected enclosure for electrical connections while offering easy access to the wiring inside. The integral cover eliminates the need for separate covers or accessories.

- Conduit Body with Expansion Space: Some conduit bodies are designed with additional space, often referred to as expansion space. This allows for the installation of connectors, splices, or other accessories within the same enclosure, providing a compact and integrated solution for complex conduit configurations.

These are just a few examples of the numerous types of conduit bodies available in the market. The choice of conduit body depends on the specific requirements of the electrical installation, such as the number of conduits, the size of the wires, the environment, and the desired functionality.

It’s important to consult with electrical professionals or review the manufacturer’s guidelines to select the appropriate conduit body type for your specific project to ensure optimal performance and safety.

A conduit body is used to provide access to conductors for maintenance or pulling in new wires. It also helps to make bends in the conduit system.

Installation of Conduit Bodies

The installation of conduit bodies is a critical step in electrical wiring systems. Proper installation ensures the seamless flow of electrical power and the protection of the wiring connections. Here are the general steps for installing conduit bodies:

- Plan the Conduit Configuration: Before installing conduit bodies, it is essential to plan the conduit configuration. Determine the desired direction changes, branching points, or splices in the conduit system. Measure and mark the locations where the conduit bodies will be installed.

- Cut and Thread Conduits: Prepare the conduits by cutting them to the required length and threading the ends. Ensure that the conduit ends are clean and free from burrs or sharp edges that may damage the wires or interfere with the installation process.

- Select the Appropriate Conduit Body Type: Choose the conduit body type that suits your installation needs. Consider factors such as the number of conduit openings, the desired functionality, the environment, and any specific codes or regulations that may apply.

- Insert the Conduits: Insert the conduits into the appropriate openings of the conduit body. Make sure they fit snugly and securely. Use locknuts or bushings to secure the conduits and provide strain relief.

- Make Electrical Connections: Strip the insulation from the wires and make the necessary electrical connections within the conduit body. Follow the appropriate wiring methods and techniques, ensuring proper grounding and insulation. Use wire connectors, terminal blocks, or other approved devices for secure and reliable connections.

- Secure the Conduit Body: Once the connections are made, secure the conduit body in place. Tighten the locknuts or fasteners to ensure a firm and stable installation. Avoid over-tightening, which can damage the conduit or compromise the electrical connections.

- Test and Inspect: After installing the conduit bodies, thoroughly test the electrical connections and conduct a visual inspection to ensure proper installation. Check for any loose connections, exposed wires, or signs of damage or corrosion. Make any necessary adjustments or repairs before proceeding.

It is important to follow all applicable electrical codes, regulations, and safety precautions during the installation process. If you are unsure or inexperienced in electrical installations, it is recommended to consult a licensed electrician or professional for guidance and assistance.

By following these installation guidelines, you can ensure a reliable and efficient conduit body installation, promoting the longevity and functionality of your electrical wiring system.

Read more: How To Attach Conduit Body To House

Benefits and Advantages of Using Conduit Bodies

Using conduit bodies in electrical installations offers several benefits and advantages. Here are some of the key reasons why electricians and professionals prefer the use of conduit bodies:

- Flexibility and Versatility: Conduit bodies provide flexibility in navigating the conduit system. They allow for changes in direction, making turns, and branching conduits, which is especially useful in complex wiring configurations or when working around obstacles. Conduit bodies offer versatile solutions to adapt the conduit path according to various installation requirements.

- Accessible Wire Connections: One of the primary advantages of conduit bodies is that they provide easy access to wire connections. The removable or hinged covers allow electricians to access the wiring inside the conduit body, facilitating easier installation, inspection, maintenance, or troubleshooting. This accessibility reduces the time and effort required to work with the wiring connections.

- Protection and Safety: Conduit bodies offer a protective enclosure for the electrical connections. They shield the wires from environmental factors such as moisture, dust, debris, and physical damage. Additionally, conduit bodies help prevent accidental contact with live wires, enhancing safety for both the occupants and the electrical system.

- Efficient Wire Pulling: Pulling wires through a conduit system can be a challenging task. Conduit bodies, especially those designed as pull boxes, provide extra space for wire pulling. This additional room allows for smoother and more efficient wire installations, reducing the risk of damaging the wires or causing unnecessary strain on the conduits.

- Code Compliance: The use of conduit bodies helps ensure compliance with electrical codes and regulations. Conduit bodies are designed to meet specific standards for electrical installations. By incorporating conduit bodies into the wiring system, electricians can adhere to the required guidelines, ensuring a safe and efficient electrical infrastructure.

- Enhanced Aesthetic Appeal: Conduit bodies can contribute to the overall aesthetic appeal of an electrical installation. With different shapes, sizes, and cover options, conduit bodies can blend seamlessly into the surrounding environment, providing a neat and organized appearance. This can be particularly beneficial in commercial or residential settings where aesthetics are important.

Overall, the use of conduit bodies offers flexibility, accessibility, protection, and compliance in electrical installations. Their advantages contribute to the functionality, efficiency, and safety of the wiring system, making them an essential component in both residential and commercial electrical projects.

Common Applications of Conduit Bodies

Conduit bodies find applications in various electrical installations across different industries. Here are some of the common applications where conduit bodies are commonly employed:

- Commercial Buildings: Conduit bodies are extensively used in commercial buildings for electrical installations. They are often used in wiring systems for offices, retail spaces, warehouses, and other commercial establishments. Conduit bodies help route electrical cables, make changes in direction, and provide access points for wire connections, ensuring a reliable and flexible wiring infrastructure.

- Residential Buildings: In residential buildings, conduit bodies play a crucial role in electrical installations. They are used in various applications such as wiring systems for houses, condominiums, apartments, or townhouses. Conduit bodies enable the connection of conduits, navigate around corners or obstructions, and provide access points for wire connections in a way that ensures the safety and efficiency of the electrical system.

- Industrial Facilities: Conduit bodies have vital applications in industrial facilities, including manufacturing plants, factories, and warehouses. These environments often have complex electrical systems that require flexibility and durability. Conduit bodies are used to accommodate different conduit runs, make changes in direction, connect multiple conduits, and facilitate wire pulling, ensuring the smooth and efficient flow of electrical power.

- Outdoor Installations: Conduit bodies designed for outdoor use are commonly employed in applications where wiring systems are exposed to harsh weather conditions. They are frequently used in outdoor lighting installations, signage, landscape lighting, security systems, and other outdoor electrical setups. Weatherproof conduit bodies protect the wiring connections from moisture, dust, and other environmental elements, ensuring their longevity and performance.

- Data and Communication Networks: Conduit bodies are also utilized in data and communication networks, such as telecommunication systems or computer networks. They provide a secure and accessible pathway for running network cables, fiber optic cables, or other communication wiring. Conduit bodies assist in making directional changes, branching cables, and providing access points for maintenance or expansion of the network infrastructure.

- Renovation or Retrofit Projects: During renovation or retrofit projects, where existing electrical systems need to be modified or expanded, conduit bodies are the go-to solution. They offer a convenient means to integrate new conduits into the existing system, make changes in the conduit path, and ensure the compatibility and integrity of the wiring connections.

These are just a few examples of the applications where conduit bodies are commonly used. The versatility and functionality of conduit bodies make them essential components in a wide range of electrical installations, providing reliable and flexible solutions for various wiring requirements.

Conclusion

Conduit bodies play a vital role in electrical installations by providing flexibility, protection, and accessibility to wiring systems. They serve as junctions that enable changes in the direction of conduits, facilitate wire connections, and ensure the efficient flow of electrical power. Throughout this article, we have explored the definition, purpose, types, installation process, benefits, and common applications of conduit bodies.

Conduit bodies offer several advantages, including flexibility in navigating conduit paths, easy access to wire connections for installation and maintenance, protection against environmental factors, efficient wire pulling, compliance with electrical codes, and enhanced aesthetics. These benefits make conduit bodies an integral component in residential, commercial, industrial, and outdoor electrical applications.

Whether it’s a simple residential wiring project or a complex industrial installation, conduit bodies provide the necessary flexibility, durability, and protection to ensure the safety and performance of the electrical system. By utilizing conduit bodies, electricians and professionals can create reliable and efficient installations that meet the required standards and regulations.

In conclusion, conduit bodies offer a versatile solution for managing conduit runs, facilitating wire connections, and protecting the integrity of electrical systems. Their flexibility, accessibility, and adaptability make them indispensable in the world of electrical installations. When working on any electrical project, consider the use of conduit bodies to ensure a reliable, organized, and efficient wiring infrastructure.

Frequently Asked Questions about What Is A Conduit Body Used For

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Conduit Body Used For”