Home>Articles>What Is The Advantage Of Brushless Motors For Hand Tools

Articles

What Is The Advantage Of Brushless Motors For Hand Tools

Modified: December 7, 2023

Discover the benefits of brushless motors for hand tools in this informative article. Learn why professionals prefer these efficient and long-lasting tools for their projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Hand tools are indispensable for a wide range of tasks, from DIY projects to professional construction work. When it comes to choosing the right hand tools, one crucial factor to consider is the type of motor powering them. Traditional hand tools often utilize brushed motors, but in recent years, there has been a shift towards brushless motors due to their numerous advantages.

In this article, we will delve into the world of brushless motors for hand tools and explore the various advantages they offer over their brushed counterparts. Understanding these benefits will enable you to make an informed decision when selecting hand tools for your projects.

Key Takeaways:

- Brushless motors offer increased efficiency, power, and control for hand tools, resulting in improved performance, longer battery life, and precise speed modulation. Their durability and quieter operation enhance user comfort and productivity.

- The absence of brushes in brushless motors leads to a longer lifespan, reduced maintenance, and quieter operation. Their resistance to dust and moisture makes them suitable for demanding environments, while their precise control and consistent torque ensure optimal results for various tasks.

How Brushless Motors Work

To understand the advantages of brushless motors for hand tools, it is essential first to grasp the functioning of these motors. Unlike brushed motors, which rely on brushes and a commutator to create the electromagnetic field needed for rotation, brushless motors operate using electronic commutation.

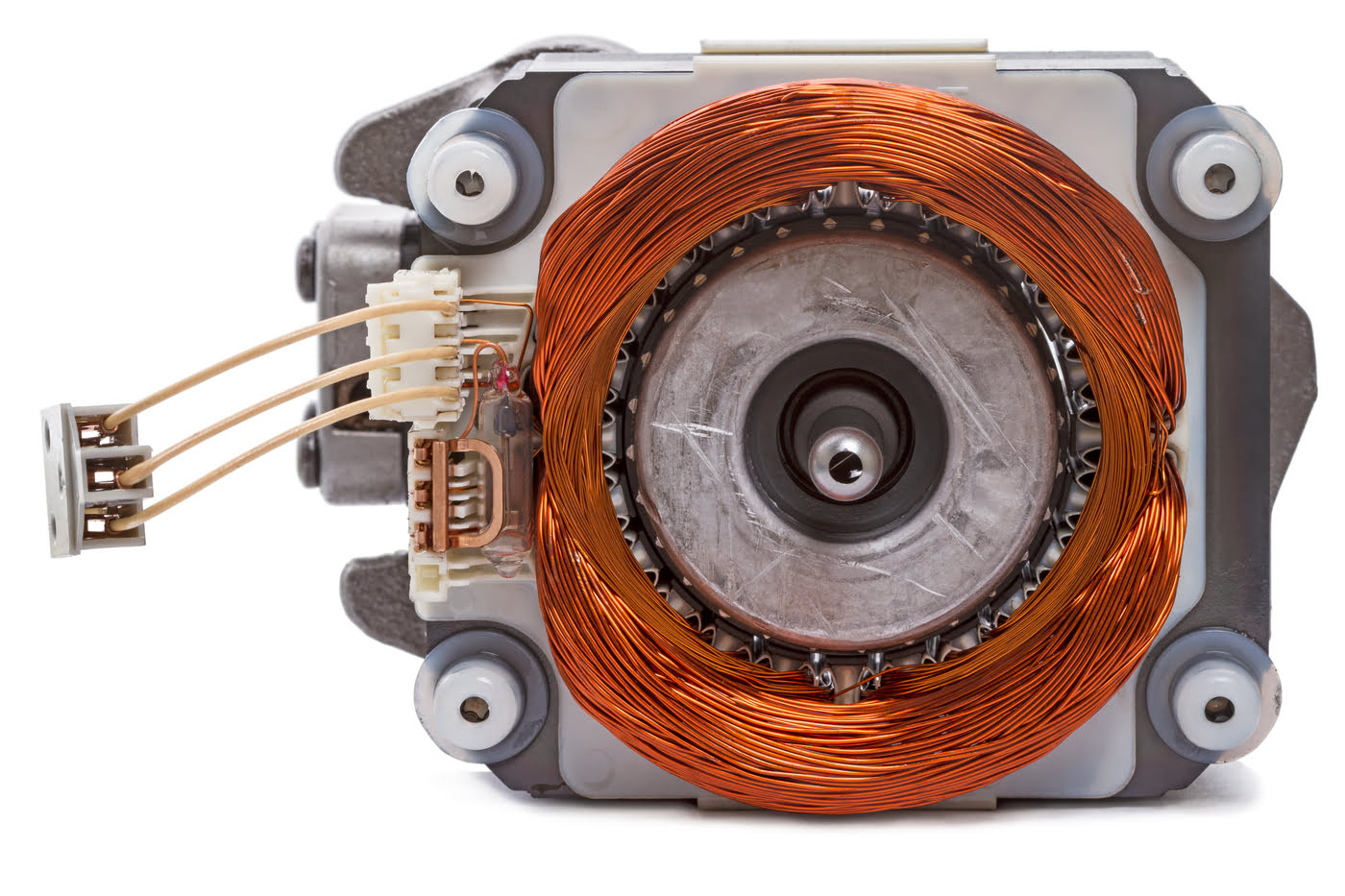

A brushless motor consists of three main components: the rotor (or armature), the stator (containing the windings), and the electronic controller. The rotor contains permanent magnets, while the stator contains electromagnetic windings arranged in a specific pattern.

When an electric current flows through the stator windings, it creates a magnetic field that interacts with the permanent magnets on the rotor. This interaction causes the rotor to rotate, generating motion in the hand tool.

What sets brushless motors apart is the role of the electronic controller. It plays a crucial role in determining the speed and direction of the motor by precisely modulating the current supplied to the stator windings. This electronic control eliminates the need for brushes and commutators, resulting in a more efficient and reliable motor.

Increased Efficiency and Power

One of the primary advantages of brushless motors for hand tools is their increased efficiency and power. The absence of brushes and commutators translates into reduced energy loss and improved overall performance.

Brushless motors are more efficient because there is no friction from brushes rubbing against the commutator, which leads to less heat generation and energy wastage. This efficiency means that more of the electrical energy is converted into mechanical power, resulting in higher torque and better performance.

Furthermore, brushless motors can operate at higher speeds without the risk of overheating. The electronic controller allows for precise control of the motor’s speed, ensuring optimal performance for various tasks. This increased efficiency and power make brushless motors suitable for demanding applications that require consistent and reliable performance.

Another aspect worth mentioning is that brushless motors can adjust their power output based on the demand. This feature, known as electronic speed control, enables the motor to adapt to different working conditions, providing the right amount of power for each task. This not only enhances efficiency but also extends the battery life of cordless hand tools.

Overall, the increased efficiency and power of brushless motors make them a superior choice for hand tools, allowing for better performance and improved productivity.

Longer Lifespan

Another significant advantage of brushless motors for hand tools is their longer lifespan compared to brushed motors. The absence of brushes means there is no friction or wear on the motor components, resulting in less mechanical stress and increased durability.

Brushes in traditional motors, due to constant contact with the rotating commutator, tend to wear down over time and require regular replacement. This wear and tear can lead to a decrease in performance and eventual motor failure. In contrast, brushless motors have no brushes to wear out, providing a longer lifespan and reducing the need for frequent maintenance.

Furthermore, the electronic commutation system in brushless motors results in smoother and more precise operation. Without the mechanical components of traditional motors, there is less vibration, noise, and potential for mechanical failure. The absence of physical contact between parts also reduces the risk of internal damage, such as sparks or electrical arcing, which can occur in brushes and commutators.

Additionally, since brushless motors generate less heat, they can operate at cooler temperatures compared to traditional motors. Overheating is a common cause of motor failure, but with brushless motors, the risk is significantly minimized. This thermal advantage further contributes to their longer lifespan and reliability.

Overall, the absence of brushes and the smoother operation of brushless motors result in a longer lifespan, reducing the need for frequent motor replacements and saving money in the long run.

Brushless motors for hand tools offer longer lifespan, higher efficiency, and more power compared to brushed motors. They also require less maintenance and provide better control for precision work.

Greater Control and Precision

Brushless motors offer greater control and precision, making them an ideal choice for tasks that require accuracy and finesse. The electronic controller in brushless motors allows for precise modulation of the motor’s speed and torque, providing optimal control over the tool’s performance.

With brushless motors, you can easily adjust the speed and power output to match the specific requirements of your task. This level of control enables you to work with delicate materials or perform intricate tasks without the risk of damaging the workpiece.

Moreover, brushless motors provide consistent torque across a wide range of speeds. This feature ensures that the tool maintains a steady and controlled rotation even under varying loads. This stability allows for smoother operation, reducing the chance of jerky movements or sudden changes in speed.

Additionally, the absence of brushes in brushless motors eliminates the phenomenon of brush sparking, which can cause electrical interference and interfere with wireless communication devices. This reduction in electromagnetic interference ensures a cleaner and more precise operation, especially in sensitive work environments.

Whether you are using a brushless drill for drilling precise holes or a brushless jigsaw for intricate cuts, the greater control and precision of brushless motors make them the preferred choice for tasks where accuracy is paramount.

Read more: What Are Brushless Power Tools

Reduced Maintenance and Durability

One of the notable advantages of brushless motors for hand tools is their reduced maintenance requirements and improved durability. The absence of brushes and commutators eliminates the need for regular brush replacements, reducing both cost and downtime.

Traditional brushed motors require periodic brush replacement to ensure optimal performance. Brushes wear out over time due to friction and constant contact with the commutator. In contrast, brushless motors eliminate this maintenance task altogether, saving time and effort.

Furthermore, brushless motors are more resistant to dust, debris, and moisture. The absence of physical contact between parts reduces the accumulation of debris, minimizing the risk of clogging or motor damage. This resilience makes brushless motors suitable for use in challenging environments, such as construction sites or workshops.

The durability of brushless motors also stems from their ability to handle higher current and power loads. The electronic controller efficiently regulates the flow of electricity, preventing overheating and excessive strain on the motor. This capability enhances the overall durability and reliability of the motor, ensuring it can withstand rigorous use without compromising performance.

Additionally, brushless motors are often designed with rugged and robust construction to withstand the demands of heavy-duty applications. The high-quality materials and craftsmanship contribute to their long lifespan and ability to withstand impacts and vibrations.

Overall, the reduced maintenance requirements and improved durability of brushless motors make them a cost-effective choice for hand tools, resulting in less downtime and longer-lasting performance.

Quieter Operation

One of the often overlooked benefits of brushless motors for hand tools is their quieter operation. The absence of brushes and commutators eliminates the mechanical friction and sparking noise commonly associated with traditional brushed motors.

Brushless motors rely on electronic commutation, which results in smoother and more seamless operation. The precise control of the motor’s speed and torque, facilitated by the electronic controller, minimizes vibrations and reduces noise levels. This quiet operation is especially advantageous when working in noise-sensitive environments or when performing tasks that require concentration.

Furthermore, the elimination of brushes and commutators removes the possibility of brush sparking, which can produce electrical noise and interfere with nearby electronic devices or communication systems. The reduced electromagnetic interference results in a cleaner electrical output, contributing to a quieter overall operation.

In addition to the noise reduction, quieter operation also leads to a more comfortable working experience. The absence of loud motor sounds allows for better communication and less fatigue during prolonged use of hand tools.

Whether you are working at home on a DIY project or in a professional setting, the quiet operation of brushless motors improves the overall workplace environment and enhances user comfort.

Conclusion

Brushless motors have revolutionized the world of hand tools, providing numerous advantages over traditional brushed motors. The elimination of brushes and commutators allows for increased efficiency, power, and control, making brushless motors the preferred choice for both DIY enthusiasts and professionals.

The increased efficiency and power of brushless motors result in improved performance and productivity, delivering more torque and longer battery life for cordless tools. Their precise speed modulation and consistent torque offer greater control and precision, perfect for tasks that require accuracy and finesse.

Furthermore, brushless motors have a longer lifespan and reduced maintenance requirements. The absence of brushes eliminates the need for regular replacements and reduces the risk of component wear and motor failure. Their durability and resistance to dust, debris, and moisture make brushless motors suitable for use in demanding environments.

Another advantage of brushless motors is their quieter operation, resulting in a more comfortable and less disruptive working experience. The absence of mechanical friction and sparking noise enhances productivity and reduces fatigue during extended tool use.

In conclusion, brushless motors for hand tools offer a myriad of benefits, including increased efficiency, power, control, durability, reduced maintenance, and quieter operation. With their superior performance, longevity, and precision, brushless motors are undoubtedly the future of hand tools, ensuring optimal results for a wide range of applications.

Frequently Asked Questions about What Is The Advantage Of Brushless Motors For Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Advantage Of Brushless Motors For Hand Tools”