Articles

What Is The Function Of A Water Pump

Modified: January 8, 2024

Discover the important function of a water pump in our informative articles. Learn how water pumps work and why they are essential for various applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Water pumps play a crucial role in various industries and applications, from providing clean water for households to facilitating the operations of large-scale agricultural, commercial, and industrial systems. These devices are essential for maintaining a steady flow of water and ensuring efficient water distribution.

In simple terms, a water pump is a mechanical device designed to move or transfer water from one location to another. It operates by creating a pressure difference that pushes water through a system of pipes or hoses. This pressure difference is typically generated by the rotation of an impeller or a piston within the pump.

Water pumps are primarily used in situations where natural water flow is inadequate or unavailable. They are employed in a wide range of settings, including residential buildings, irrigation systems, sewage treatment plants, and industrial processes. Without the existence and proper functioning of water pumps, many essential activities would come to a halt.

This article will delve into the function, types, and components of water pumps, as well as how they work, common applications, and maintenance tips for optimal performance. By understanding the role and importance of water pumps, you’ll gain a deeper appreciation for the vital role they play in our day-to-day lives.

Key Takeaways:

- Water pumps are essential for maintaining water supply, supporting agriculture, and enabling industrial processes. Understanding their function and importance is crucial for appreciating their vital role in our daily lives.

- Regular maintenance and troubleshooting are key to ensuring the longevity and efficiency of water pumps. By implementing proper care, we can prevent potential issues and ensure reliable operation for years to come.

Read more: What Is A Water Pump

Definition of a Water Pump

A water pump is a mechanical device designed to transport fluids, specifically water, from one location to another. It is commonly used to increase the pressure of the water, enabling it to flow more efficiently through pipes or hoses. Water pumps come in various sizes, capacities, and configurations to suit different applications and requirements.

These pumps work by converting mechanical energy into hydraulic energy. This is achieved through the use of an impeller, which is a rotating component within the pump. As the impeller spins, it creates a centrifugal force that propels the water outwards and pushes it through the pump’s outlet.

Water pumps can be powered by diverse energy sources, including electric motors, gasoline or diesel engines, hydraulic systems, or even manual operation. The choice of power source depends on the pump’s intended use and the available resources.

It is important to note that water pumps are not limited to moving water. They can also be used to transport other fluids, such as chemicals, oils, and fuels, depending on the design and specifications of the pump.

Overall, a water pump serves as a crucial tool for efficient water management and distribution. It enables us to access clean water for everyday use, supports agricultural practices by providing irrigation systems, and facilitates various industrial operations that rely on water circulation and supply.

Importance of Water Pumps

Water pumps are integral to a wide range of industries and applications, playing a vital role in maintaining water supply, managing drainage, and facilitating fluid movement. Here are some key reasons why water pumps are important:

1. Water Supply: Water pumps ensure a consistent and reliable water supply to households, commercial buildings, and industries. They are often used to draw water from wells, rivers, or reservoirs and deliver it to areas where natural water flow is insufficient.

2. Irrigation and Agriculture: In agriculture, water pumps are essential for irrigation systems, supplying water to crops and ensuring their healthy growth. They help optimize water usage, improve crop yields, and support sustainable farming practices.

3. Industrial Processes: Many industrial operations rely on water pumps to facilitate the movement of fluids. From manufacturing processes to cooling systems, water pumps play a critical role in various sectors, including chemical production, power generation, and mining.

4. Wastewater Management: Water pumps are used in sewage treatment plants to transport wastewater through treatment processes. They help maintain proper sanitation standards, prevent water contamination, and ensure the safe disposal or reuse of wastewater.

5. Fire Protection: Firefighting systems utilize water pumps to supply water at high pressure, enabling efficient firefighting and extinguishing of fires. They are a crucial component in the safety infrastructure of buildings, warehouses, and public spaces.

6. Fountain and Water Feature Installation: Water pumps are commonly employed in the installation of fountains, waterfalls, and decorative water features. They create visually appealing water displays by pumping water through intricate piping systems.

7. Swimming Pool Maintenance: Water pumps are essential for circulating and filtering water in swimming pools. They help maintain water clarity, prevent the growth of algae and bacteria, and ensure a safe and enjoyable swimming environment.

8. Emergency Situations: During floods or natural disasters, water pumps are used to remove excess water and prevent property damage. They help with dewatering flooded areas, keeping infrastructure intact, and protecting lives and livelihoods.

In summary, the importance of water pumps cannot be overstated. They are essential for maintaining water supply, managing wastewater, supporting agricultural practices, and enabling various industrial processes. Water pumps contribute to our everyday lives, ensuring access to clean water and facilitating the proper functioning of numerous systems and industries.

Types of Water Pumps

Water pumps are available in a variety of types, each designed for specific applications and operating conditions. Here are some common types of water pumps:

1. Centrifugal Pumps: Centrifugal pumps are the most widely used type of water pump. They work by utilizing the centrifugal force generated by an impeller to move water. These pumps are efficient, versatile, and suitable for a wide range of applications, including residential, commercial, and industrial use.

2. Submersible Pumps: Submersible pumps are designed to be fully immersed in water. They are commonly used for deep well pumping, drainage, and sewage applications. Submersible pumps are compact, efficient, and can handle high volumes of water.

3. Diaphragm Pumps: Diaphragm pumps use a flexible diaphragm that moves back and forth to pump water. They are known for their ability to handle fluids with high solids content and are commonly used in wastewater treatment, mining, and chemical industries.

4. Jet Pumps: Jet pumps work by creating a vacuum in a chamber, which draws water from a well or reservoir. These pumps are commonly used in residential water supply systems. They can be shallow well jet pumps or deep well jet pumps, depending on the depth of the water source.

5. Gear Pumps: Gear pumps use tightly meshed gears to move water. They are known for their smooth and constant flow. Gear pumps are commonly used in hydraulic systems, as well as in applications that require precise and controlled fluid movement.

6. Peristaltic Pumps: Peristaltic pumps are also known as hose pumps. They use a flexible tube or hose squeezed by rollers or shoes to move water. These pumps are ideal for handling corrosive or abrasive fluids and are commonly used in chemical dosing, food processing, and pharmaceutical industries.

7. Axial Flow Pumps: Axial flow pumps are designed to move water parallel to the pump axis. They are commonly used in irrigation systems, flood control, and water circulation in large bodies of water such as lakes or ponds.

8. Reciprocating Pumps: Reciprocating pumps use pistons or plungers to move water in back-and-forth motion. They are commonly used in high-pressure applications, such as car wash systems, firefighting, and oil and gas operations.

These are just a few examples of the types of water pumps available. Each type has its own advantages and is suited for specific applications and operating conditions. When selecting a water pump, it’s important to consider factors such as flow rate, pressure requirements, power source, and the characteristics of the fluid being pumped.

Components of a Water Pump

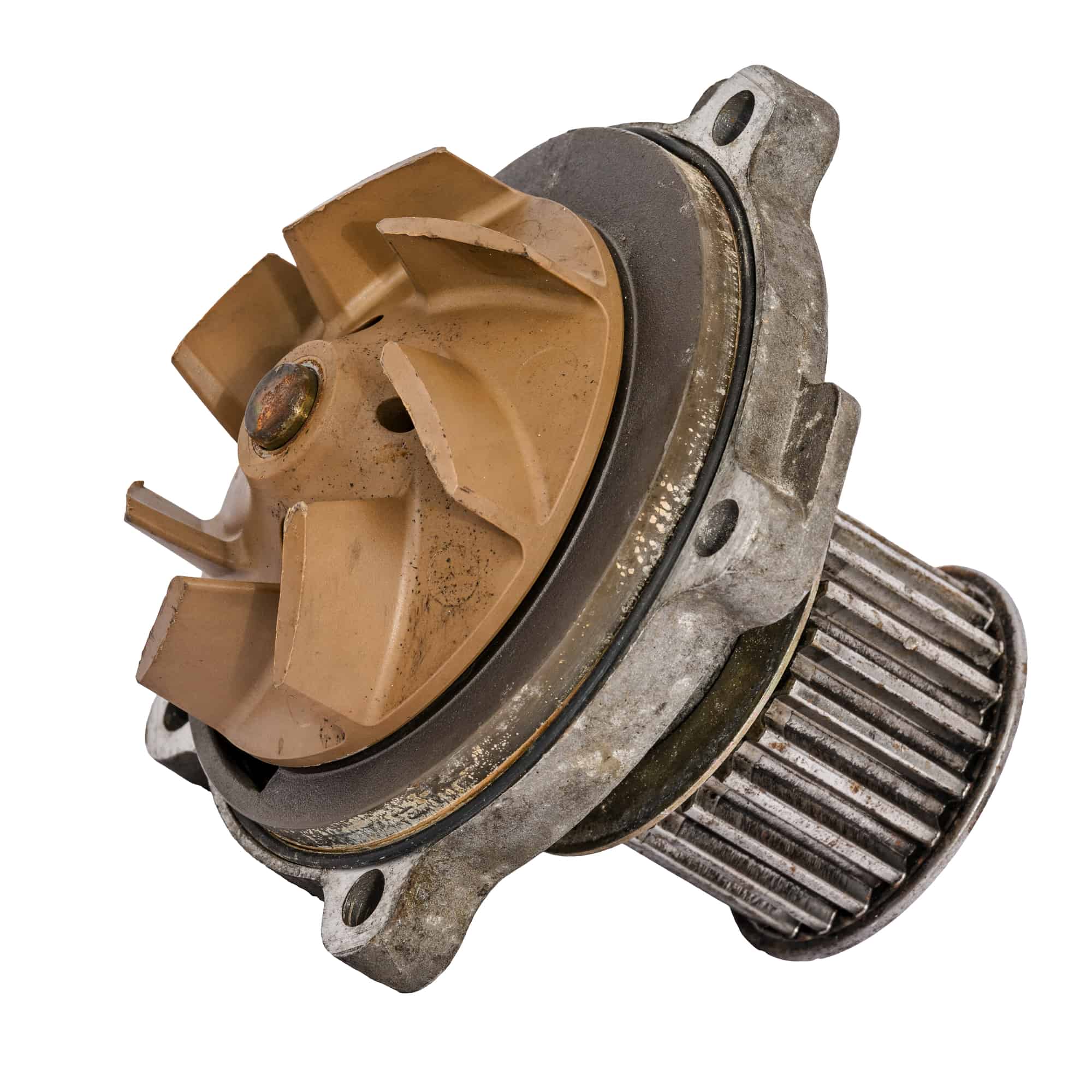

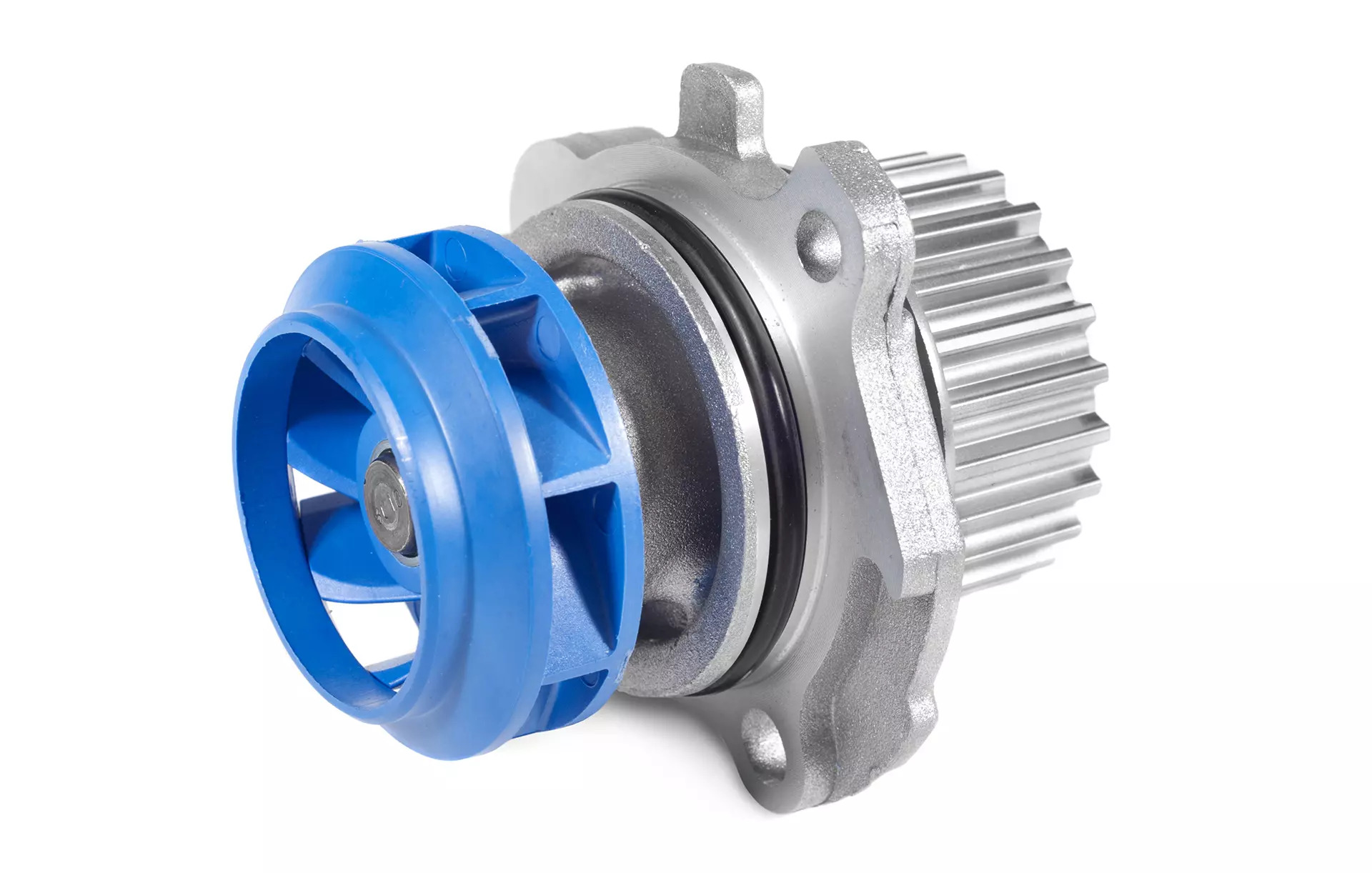

A water pump consists of various components that work together to efficiently move water from one location to another. Understanding the different parts of a water pump can help provide insight into how it functions. Here are the main components:

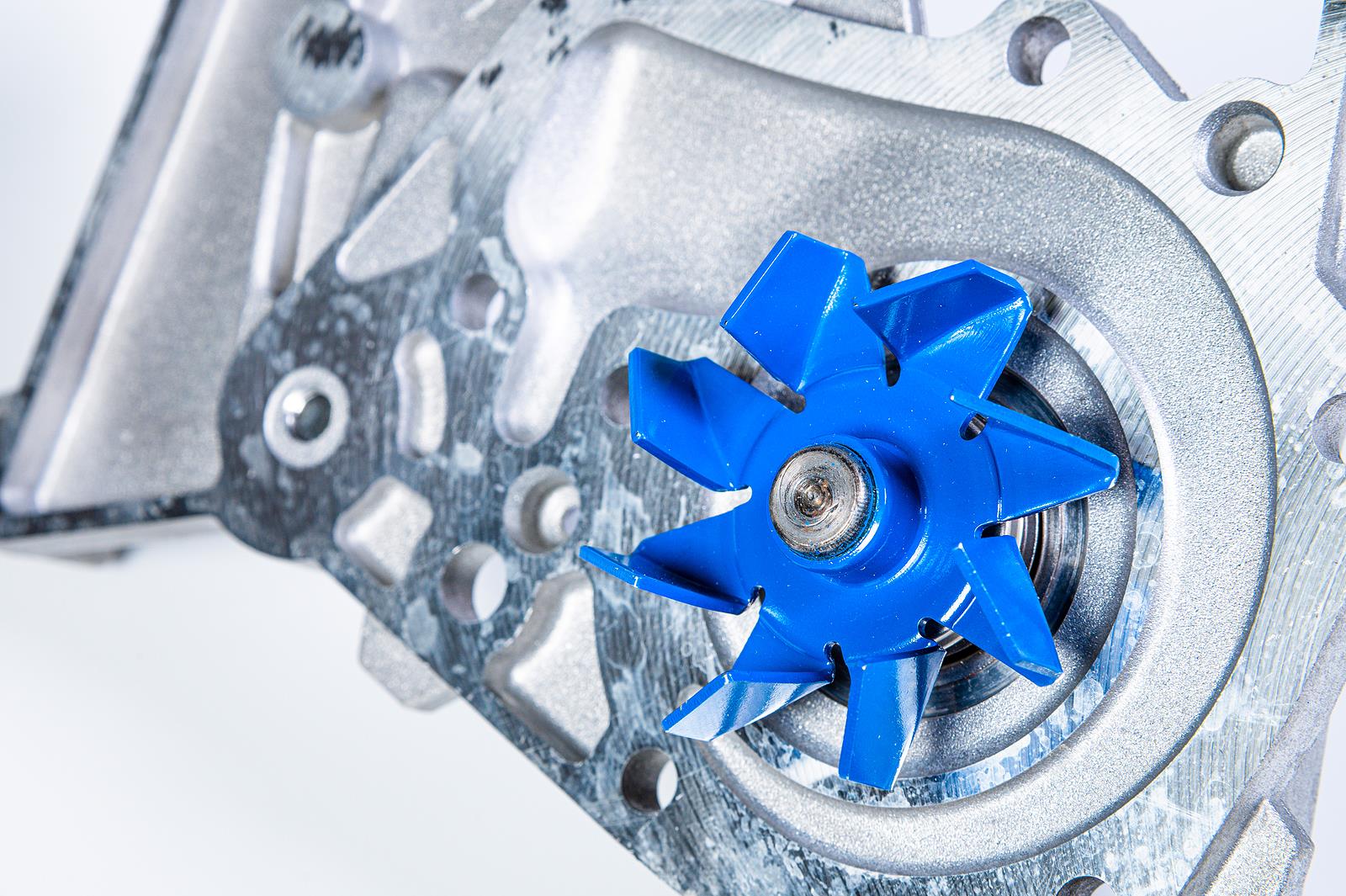

1. Impeller: The impeller is a rotating component inside the pump. Its primary function is to generate centrifugal force, which propels the water through the pump. The impeller blades are carefully designed to create a specific flow pattern and increase the pressure of the water.

2. Casing: The casing, also known as the volute, is the housing that surrounds the impeller. It is designed to guide the water flow and direct it towards the outlet of the pump. The shape of the casing influences the pump’s efficiency and performance.

3. Inlet and Outlet Ports: The inlet port is the opening through which water enters the pump, while the outlet port is where the water is discharged. These ports are strategically positioned to optimize the flow of water and maximize efficiency.

4. Seal or Packing: Seals or packing help prevent water leakage around the rotating shaft of the pump. They ensure a watertight seal, minimizing the risk of damage to the pump and maintaining efficient operation.

5. Motor or Power Source: The motor or power source is responsible for driving the rotation of the impeller. In electric water pumps, an electric motor is used, while gasoline or diesel engines power portable and irrigation pumps. Hydraulic pumps may be powered directly by hydraulic systems, and manual pumps are operated manually by hand or foot.

6. Shaft: The shaft connects the impeller to the motor or power source, transmitting the rotational motion. It needs to be sturdy and properly aligned for smooth operation and minimal vibration.

7. Bearings: Bearings support the rotating components of the water pump, such as the shaft and impeller. They reduce friction and allow for smooth and efficient rotation.

8. Strainer or Filter: Some water pumps come equipped with a strainer or filter to prevent debris, particles, or large objects from entering the pump. These components help protect the impeller and other crucial parts from damage.

These are the main components found in most water pumps. However, depending on the specific design and purpose of the pump, additional components such as check valves, pressure gauges, control panels, and flow sensors may also be included.

Regular maintenance of your water pump is essential to ensure it continues to function properly. This includes checking for leaks, inspecting the drive belt, and replacing the pump if it shows signs of wear.

Read more: What Is A Water Pump Settlement

How Water Pumps Work

Water pumps operate based on fluid dynamics and the principle of converting mechanical energy into hydraulic energy. Understanding how water pumps work can help demystify their operation. Here is a simplified explanation of the process:

1. Prime the Pump: Before a water pump can function, it needs to be primed. This involves filling the pump and the intake pipe with water to create an airtight seal and remove any air pockets. Priming ensures that water can flow smoothly through the pump and prevents airlock.

2. Inlet and Outlet: Water enters the pump through the inlet port, usually located at the bottom or side of the pump body. The inlet pipe is connected to a water source such as a well or reservoir. The water is then guided to the impeller.

3. Impeller Rotation: The main rotating component of the water pump is the impeller. As the impeller spins, it creates centrifugal force, which pushes water away from the center and towards the outer edges. The impeller blades are curved, creating a low-pressure area at the center and a high-pressure area at the edges.

4. Pressure Increase: When water enters the impeller, it is subjected to the centrifugal force and forced outward. As it moves from the low-pressure center to the high-pressure edges, the water gains velocity and pressure. This pressure increase causes the water to be forcibly expelled from the impeller.

5. Casing and Outlet Flow: The casing or volute of the pump is designed to guide the water flow from the impeller to the outlet port. The shape of the casing helps convert the velocity of the water into pressure. The water exits the pump through the outlet port, ready for its intended application, such as irrigation or water supply.

6. Continuous Operation: Water pumps are designed to operate continuously, maintaining a steady flow of water. The rotation of the impeller, coupled with the design of the casing, ensures a constant supply of water, even when the demand varies.

7. Power Source: The rotation of the impeller is driven by a power source, such as an electric motor, internal combustion engine, hydraulic system, or manual operation. The power source provides the mechanical energy needed to spin the impeller and create the pressure difference.

It’s important to note that water pumps may require periodic maintenance, such as checking for clogs or blockages, ensuring proper lubrication, and monitoring for any signs of wear. Regular maintenance helps to prolong the lifespan of the pump and ensures optimal performance.

By harnessing fluid dynamics and mechanical energy, water pumps play a critical role in various industries and applications, providing a reliable and efficient means of transporting water from one location to another.

Common Applications of Water Pumps

Water pumps are utilized in a wide array of applications across various industries due to their ability to efficiently move and manage water. Here are some common applications where water pumps are essential:

1. Residential Water Supply: Water pumps are used in residential buildings to ensure a consistent water supply for everyday use. They help draw water from wells, storage tanks, or municipal water lines and deliver it to faucets, showers, and appliances throughout the house.

2. Irrigation Systems: Water pumps play a vital role in agricultural practices by supplying water to irrigation systems. They help distribute water to crops, ensuring proper hydration for healthy growth and maximizing crop yields.

3. Industrial Processes: Many industries rely on water pumps for various manufacturing and processing operations. Water pumps facilitate the movement of fluids in cooling systems, chemical processes, power generation, and wastewater treatment plants.

4. Construction Sites: Water pumps are used in construction projects for dewatering, especially in areas prone to flooding or where excavation requires water removal. They help maintain dry and safe working conditions.

5. Swimming Pools and Spas: Water pumps are essential for maintaining the cleanliness and circulation of water in swimming pools and spas. They help filter and circulate water, ensuring safe and hygienic swimming conditions.

6. Fountains and Water Features: Water pumps are used to create decorative water displays in parks, gardens, and public spaces. They circulate water through intricate piping systems, powering fountains, waterfalls, and ornamental water features.

7. Sewage and Wastewater Management: Water pumps are crucial in sewage treatment plants to transport wastewater through various treatment processes, including filtration and disinfection. They aid in the safe disposal or reuse of wastewater while preventing contamination.

8. Fire Protection Systems: Water pumps are integral to fire protection systems in residential, commercial, and industrial buildings. They provide the required water pressure to firefighting equipment, such as sprinklers and fire hydrants, ensuring prompt and effective fire suppression.

9. Groundwater Management: Water pumps are utilized for groundwater management, including the extraction of water for domestic, agricultural, or industrial use. They help access water from wells and maintain water levels in underground aquifers.

10. Flood Prevention and Drainage: Water pumps are deployed in flood-prone areas to prevent or mitigate flooding. They can be used to remove excess water from low-lying areas or to redirect water away from properties and infrastructure.

These are just a few examples of the diverse applications of water pumps. The versatility and reliability of water pumps make them indispensable in numerous industries and essential for our daily lives, ensuring access to clean water, supporting agriculture, and playing a pivotal role in various processes and systems.

Maintenance and Troubleshooting of Water Pumps

Proper maintenance of water pumps is essential to ensure their longevity, efficiency, and reliable operation. Regular maintenance can help prevent potential issues and ensure optimal performance. Here are some maintenance tips and troubleshooting techniques for water pumps:

1. Regular Inspection: Perform routine visual inspections of the pump, checking for any signs of leaks, corrosion, or damage. Inspect the motor, impeller, and seals for wear and tear. Address any issues promptly to prevent further damage.

2. Clean and Clear Intake: Regularly check and clean the intake or strainer of the pump to remove debris, leaves, or other foreign objects that may hinder water flow. A clogged intake can decrease pump performance and efficiency.

3. Lubrication: If the pump has bearings, ensure they are properly lubricated as per the manufacturer’s recommendations. Proper lubrication helps reduce friction and extends the life of the pump.

4. Check and Test Seals: Inspect the seals or packing around the shaft for any signs of leakage. Replace worn or damaged seals promptly to prevent water leakage and maintain a watertight seal.

5. Monitor Pump Pressure and Flow: Regularly check the pressure and flow rate of the pump to ensure it is operating within the recommended range. Adjustments may be required to maintain optimal performance.

6. Verify Power Source: If the pump is not operating, check the power source to ensure it is connected and functioning properly. Inspect electrical connections and fuses, and ensure fuel levels are adequate for gasoline or diesel-powered pumps.

7. Listen for Unusual Noises: Unusual noises, such as grinding or vibrating sounds, may indicate a problem with the pump. Investigate the source of the noise and address it promptly to prevent further damage.

8. Consider Seasonal Maintenance: Depending on the usage and climate, some pumps may require specific maintenance during different seasons. For instance, winterize the pump in colder climates to prevent freezing or corrosion.

9. Refer to Manufacturer Guidelines: Follow the specific maintenance guidelines provided by the manufacturer for your pump model. This includes recommended maintenance tasks, intervals, and any specific requirements.

10. Consult a Professional: If you encounter complex issues or are unsure about a particular problem, it is advisable to consult a professional or the manufacturer’s customer support for assistance. They can provide expert guidance and troubleshooting tips.

By implementing regular maintenance practices and promptly addressing any issues that arise, you can ensure the longevity and efficiency of your water pump. Remember that proper maintenance not only extends the life of the pump but also helps prevent costly repairs and downtime.

Conclusion

Water pumps play a crucial role in our everyday lives and are essential for a wide range of applications. Whether it’s providing water for residential use, supporting agricultural practices, or enabling industrial operations, water pumps are the backbone of efficient water management and distribution.

From centrifugal pumps to submersible pumps, each type of water pump serves a specific purpose and offers unique advantages. The impeller, casing, power source, and other components work together to create pressure, propel water, and ensure a steady flow to our homes, farms, and industries.

Understanding how water pumps work and learning about their common applications allows us to appreciate their significance. They provide us with clean water, support agricultural productivity, assist in waste management, help protect against fires, and bring beauty to our surroundings through decorative water features.

Regular maintenance and troubleshooting are vital to the optimal performance and longevity of water pumps. By inspecting, cleaning, lubricating, and addressing any issues promptly, we can prevent potential problems and ensure that the pump operates reliably and efficiently.

In conclusion, water pumps are a fundamental part of our lives, enabling us to access water easily and efficiently. Their importance cannot be overstated, as they contribute to our well-being, support agriculture and industry, and help in various vital applications. By understanding their function, types, components, and maintenance, we can ensure that water pumps continue to serve us effectively in the years to come.

Frequently Asked Questions about What Is The Function Of A Water Pump

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Function Of A Water Pump”