Articles

What Are Water Pumps with Electronic Controls

Modified: December 7, 2023

Looking for articles on water pumps with electronic controls that circulate coolant when needed? Find out which type of water pump fits your needs here.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Water pumps play a crucial role in various industries and applications, from residential plumbing systems to commercial irrigation systems. They are responsible for circulating water and ensuring its efficient distribution. In recent years, the advancement of technology has introduced electronic controls in water pumps, revolutionizing their functionality and performance.

Electronic controls in water pumps allow for precise and automated operations, optimizing efficiency and reducing energy consumption. These advanced systems detect and respond to changing conditions, ensuring that the pump operates only when necessary. This results in significant cost savings, improved reliability, and reduced maintenance requirements.

In this article, we will explore the benefits of electronic control in water pumps and delve into the various types that are available in the market. Specifically, we will focus on the type of water pump that is run by electronic controls and circulates coolant only when needed. So, let’s dive in and discover the advantages of this innovative technology.

Key Takeaways:

- Electronic control systems in water pumps optimize energy consumption, extend lifespan, and enhance reliability, revolutionizing water distribution across industries and applications.

- Water pumps with electronic controls circulate coolant only when needed, providing precise temperature control, energy efficiency, and improved engine performance, contributing to environmental sustainability.

Read more: What Is A Water Pump

Electronic Controls in Water Pumps

Traditional water pumps are usually operated by manual switches or pressure sensors. While these systems have served their purpose for many years, they lack the precision and efficiency that electronic controls can offer. Electronic controls in water pumps bring automation and optimization to the forefront, allowing for precise control over the pump’s operation.

Electronic control systems utilize various sensors and algorithms to monitor and respond to changing conditions. These sensors can detect factors such as water pressure, flow rate, temperature, and even ambient conditions. Based on the input received, the electronic control system adjusts the pump’s speed, output, and on/off cycles to match the exact requirements.

One of the primary advantages of electronic controls in water pumps is their ability to modulate the pump’s performance based on demand. Rather than running at a constant speed, electronic control systems can vary the pump’s output to meet the specific needs at any given time. This eliminates wasteful energy consumption and reduces wear and tear on the pump, leading to extended lifespan and lower maintenance costs.

Additionally, electronic control systems offer enhanced safety features. These systems can detect irregularities or malfunctions in the pump’s operation and automatically shut it down to prevent damage. This proactive approach helps prevent accidents and costly repairs, providing peace of mind to users.

Furthermore, electronic control systems enable remote monitoring and control of the water pump. With the integration of advanced communication technologies, users can access and control the pump’s operation from anywhere, using their smartphones or computers. This remote functionality allows for efficient management of water systems, especially in large-scale applications where multiple pumps are involved.

Overall, electronic controls in water pumps bring a new level of efficiency, precision, and convenience to operations. Whether it’s for residential or industrial use, the integration of electronic control systems can greatly enhance the performance and reliability of water pumps, ultimately leading to energy savings, cost reductions, and improved sustainability.

Benefits of Electronic Control in Water Pumps

The implementation of electronic control in water pumps offers a wide range of benefits that contribute to improved efficiency, cost savings, and overall performance. Let’s explore some of the key advantages of using electronic control systems in water pumps:

- Energy Efficiency: Electronic control systems allow pumps to operate at variable speeds based on demand, ensuring that energy consumption is optimized. By running the pump only when needed and adjusting its output accordingly, energy wastage is minimized, resulting in substantial energy savings.

- Cost Savings: The energy efficiency achieved through electronic control systems directly translates into cost savings. By reducing energy consumption, businesses and homeowners can lower their utility bills significantly, making electronic control water pumps a financially favorable investment in the long run.

- Extended Lifespan: Traditional water pumps that operate at a constant speed can experience excessive wear and tear. In contrast, electronic control systems allow pumps to operate at lower speeds when demand is lower, reducing the strain on the equipment. This extends the lifespan of the pump, reducing the need for frequent repairs and replacement.

- Precision Operation: Electronic control systems enable precise control over the operation of water pumps. With sensors that monitor various factors such as flow rate, pressure, and temperature, the system can adjust the pump’s performance to match the specific requirements at any given time. This ensures optimal performance and prevents overworking the pump unnecessarily.

- Improved Reliability: The integration of electronic control systems enhances the reliability of water pumps. These systems can detect malfunctions or irregularities in the pump’s operation and automatically shut it down, preventing further damage. By detecting and addressing issues promptly, electronic control systems help prevent costly repairs and downtime.

- Remote Monitoring and Control: Electronic control systems enable remote monitoring and control of water pumps. Through advanced communication technologies, users can access real-time data and control the pump’s operation from anywhere. This feature is particularly beneficial for large-scale applications with multiple pumps, as it allows for centralized management and efficient troubleshooting.

- Environmental Sustainability: By reducing energy consumption and optimizing pump performance, electronic control systems contribute to environmental sustainability. The lower energy demand helps to reduce carbon emissions and conserve natural resources, making electronic control water pumps a greener choice for both residential and commercial applications.

Overall, the implementation of electronic control in water pumps offers numerous benefits that enhance efficiency, reliability, and cost-effectiveness. With the ability to optimize energy consumption and provide precise control over pump performance, electronic control systems are revolutionizing the water pump industry, providing sustainable and efficient solutions for various applications.

Look for a variable speed electronic water pump, which can adjust the coolant flow based on engine temperature, reducing energy consumption and improving efficiency.

Types of Water Pumps with Electronic Controls

Electronic controls have become increasingly popular in the water pump industry, with various types of pumps incorporating this advanced technology. Let’s take a look at some of the different types of water pumps that utilize electronic controls:

- Centrifugal Pumps: Centrifugal pumps are widely used in applications that require high flow rates. With electronic controls, these pumps can adjust their speed and output based on demand, ensuring optimal performance and energy efficiency. Electronic control systems also provide protection against dry run, overheating, and other potential issues.

- Submersible Pumps: Submersible pumps are designed to operate underwater and are commonly used in deep wells, sump pits, and sewage systems. With electronic controls, these pumps can monitor water levels and adjust their operation accordingly. This ensures efficient pumping while preventing damage caused by running dry or excessive flooding.

- Booster Pumps: Booster pumps are used to increase water pressure in residential and commercial applications. Electronic control systems allow booster pumps to adjust their operation based on variations in demand, maintaining a consistent water pressure throughout the system. This ensures optimal performance while conserving energy.

- Variable Speed Pumps: Variable speed pumps, as the name suggests, allow for adjustable speeds based on demand. These pumps utilize electronic control systems to modulate their speed and output, resulting in significant energy savings. By operating at lower speeds when demand is low, variable speed pumps can achieve greater efficiency and extend the lifespan of the pump.

- Effluent Pumps: Effluent pumps are specifically designed for wastewater and sewage applications. Electronic control systems in effluent pumps can monitor water levels, flow rates, and other factors to ensure efficient pumping and prevent issues such as overflow or blockages. These controls also provide protection against motor overheating and other malfunctions.

- Recirculation Pumps: Recirculation pumps are often used in heating and cooling systems to circulate water through the system and maintain a consistent temperature. With electronic controls, these pumps can adjust their speed and operation based on temperature differentials, ensuring energy-efficient and precise circulation.

- Jet Pumps: Jet pumps are commonly used in residential water supply systems. Electronic control systems in jet pumps can adjust the pump’s speed and operation based on the water demand, providing a constant and reliable water supply. These controls also offer protection against dry-run and operate more quietly than traditional jet pumps.

These are just a few examples of the types of water pumps that incorporate electronic controls. The integration of electronic control systems in these pumps enhances their efficiency, performance, and reliability, making them ideal choices for a wide range of applications.

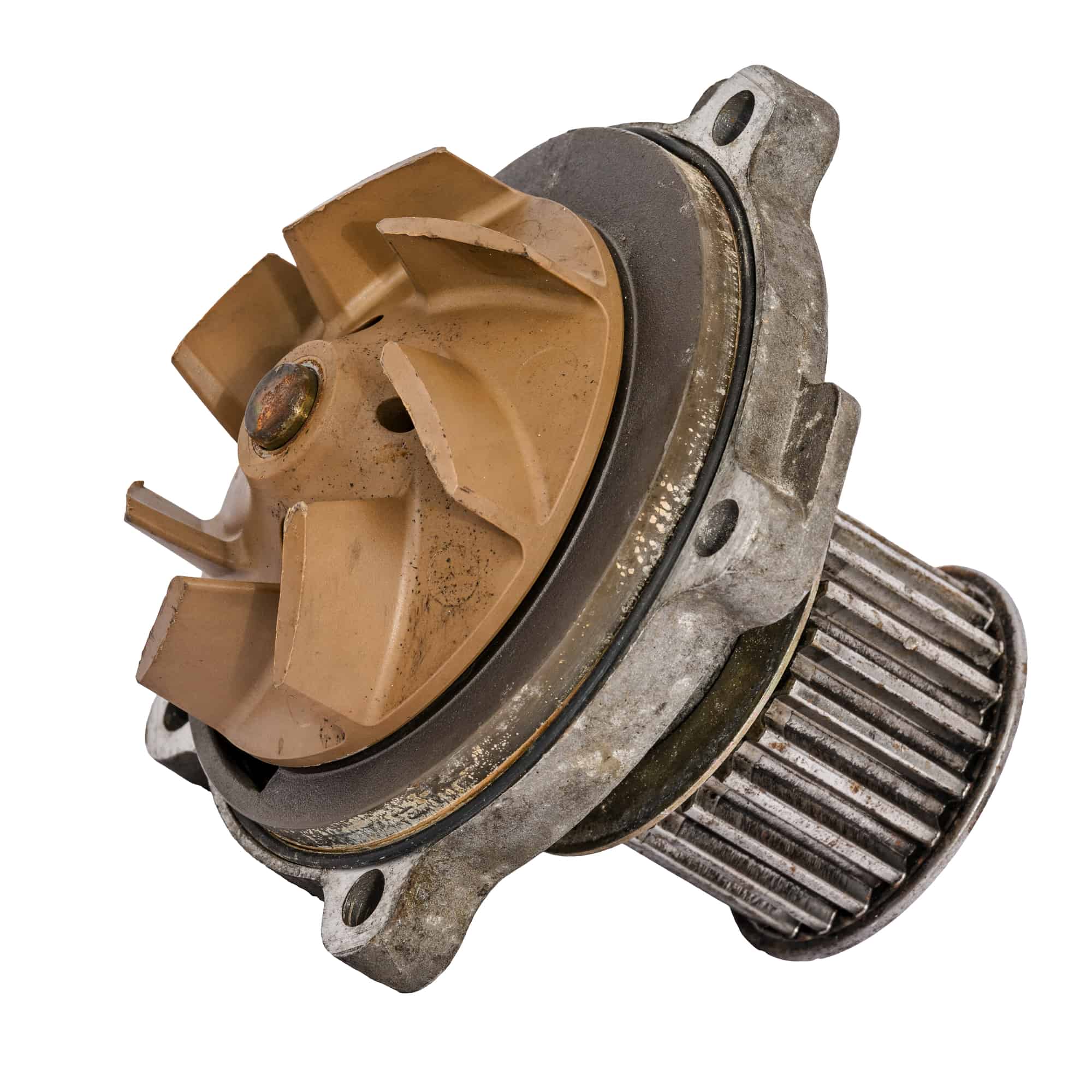

Water Pumps That Circulate Coolant When Needed

In certain applications, such as automotive engines, it is crucial to circulate coolant to prevent overheating and maintain optimal operating temperatures. Traditional water pumps in these systems operate continuously, circulating coolant regardless of the actual need. However, with the advancement of electronic control systems, water pumps that circulate coolant only when needed have emerged, providing more efficient and precise cooling.

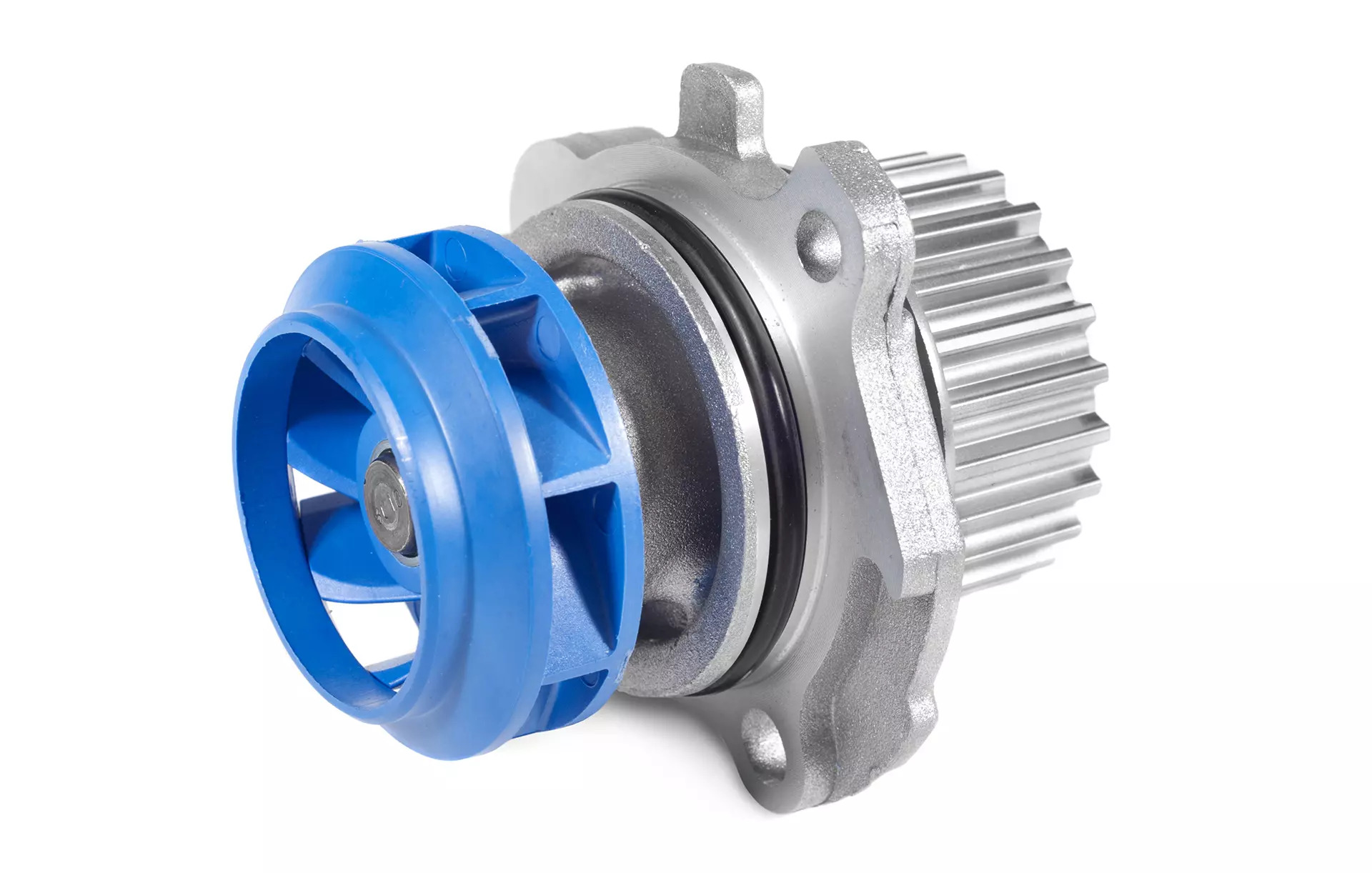

These electronic-controlled water pumps utilize sensors and algorithms to monitor the engine’s temperature and coolant flow. When the engine reaches a specific temperature threshold, the electronic control system activates the pump to circulate coolant through the system. This strategic cooling approach ensures that the engine is cooled down when necessary, without wasting energy on unnecessary coolant circulation during normal operating conditions.

By circulating coolant only when needed, these electronic-controlled water pumps offer several advantages:

- Energy Efficiency: By eliminating continuous coolant circulation, these pumps reduce energy consumption, resulting in increased fuel efficiency in automotive applications. This is especially beneficial during idle or low-load conditions, where the cooling demand is minimal and continuous coolant circulation becomes unnecessary.

- Temperature Control: Electronic-controlled water pumps provide precise temperature control by circulating coolant based on the engine’s actual temperature. This ensures that the engine remains within the optimal operating temperature range, preventing overheating and improving overall performance and longevity.

- Reduced Wear and Tear: Continuous coolant circulation can lead to increased wear and tear on the pump and other cooling system components. By operating the water pump only when needed, electronic controls reduce unnecessary strain and prolong the lifespan of these components, resulting in lower maintenance and replacement costs.

- Quick Response: The integration of electronic control systems enables quick response to temperature changes. As soon as the engine reaches the temperature threshold, the pump can start circulating coolant immediately, ensuring efficient and timely cooling for optimal engine performance.

- Improved Engine Efficiency: By maintaining the engine’s optimal operating temperature, electronic-controlled water pumps contribute to improved engine efficiency. When an engine operates at the right temperature, it can achieve better fuel combustion, reduce emissions, and optimize power output.

- Enhanced Environmental Sustainability: The energy savings achieved by electronic-controlled water pumps contribute to reduced fuel consumption and lower carbon emissions, making them more environmentally friendly. This is particularly important in automotive applications, where reducing fuel consumption and emissions is a key concern.

Water pumps that circulate coolant only when needed demonstrate the power of electronic control systems in optimizing cooling operations. By providing precise temperature control, energy efficiency, and reduced wear and tear, these pumps contribute to improved performance, longevity, and environmental sustainability in various applications.

Read more: What Is The Function Of A Water Pump

Conclusion

The integration of electronic control systems in water pumps has transformed the way we approach water distribution and coolant circulation. These advanced systems provide precise control, energy efficiency, and improved performance in various applications. From residential plumbing to automotive cooling systems, electronic controls have revolutionized the way we manage and optimize water pump operations.

Electronic control systems offer several key benefits. They optimize energy consumption by adjusting the pump’s speed and output based on demand, resulting in significant cost savings and reduced environmental impact. These systems also provide enhanced safety features, detecting and responding to malfunctions or irregularities to prevent damage and improve reliability.

Various types of water pumps utilize electronic controls to deliver optimal performance. From centrifugal pumps to submersible and booster pumps, each type incorporates electronic control systems to maximize efficiency and meet specific application requirements. Additionally, water pumps that circulate coolant only when needed offer precise temperature control, reduced wear and tear, and improved engine efficiency in automotive applications.

In conclusion, electronic control systems have significantly enhanced the functionality, efficiency, and reliability of water pumps. Whether it’s through energy savings, extended lifespan, or improved performance, these systems provide innovative solutions for diverse industries and applications. As technology continues to advance, we can expect further developments in electronic control systems, paving the way for even more efficient and intelligent water pump operations.

Frequently Asked Questions about What Are Water Pumps With Electronic Controls

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Water Pumps with Electronic Controls”