Articles

What Causes A Water Pump To Go Bad

Modified: January 8, 2024

Learn about the common causes of water pump failure with our informative articles. Expert insights and tips to prevent and diagnose issues.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A water pump is a critical component in a vehicle’s cooling system. Its primary function is to circulate coolant, also known as antifreeze, through the engine to regulate its temperature. Without a properly functioning water pump, the engine can overheat, leading to severe damage and potentially costly repairs.

In this article, we will explore the common signs of a failing water pump, the causes of water pump failure, and provide some maintenance tips to help prevent this issue from occurring.

Whether you’re a car enthusiast or a casual driver, understanding the role of a water pump and being able to identify potential problems can help you take proactive measures to keep your vehicle running smoothly.

Key Takeaways:

- Regular coolant flushes are essential to remove impurities, prevent corrosion, and extend the lifespan of the water pump, ensuring optimal cooling system performance and reducing the risk of costly repairs.

- Using OE or OEM parts, proper installation, and regular maintenance are crucial for preserving the water pump’s performance, preventing leaks, and minimizing the risk of premature failure, ultimately ensuring a reliable and efficient cooling system.

Read more: Does Water Pump Make Noise When Going Bad

Definition of a Water Pump

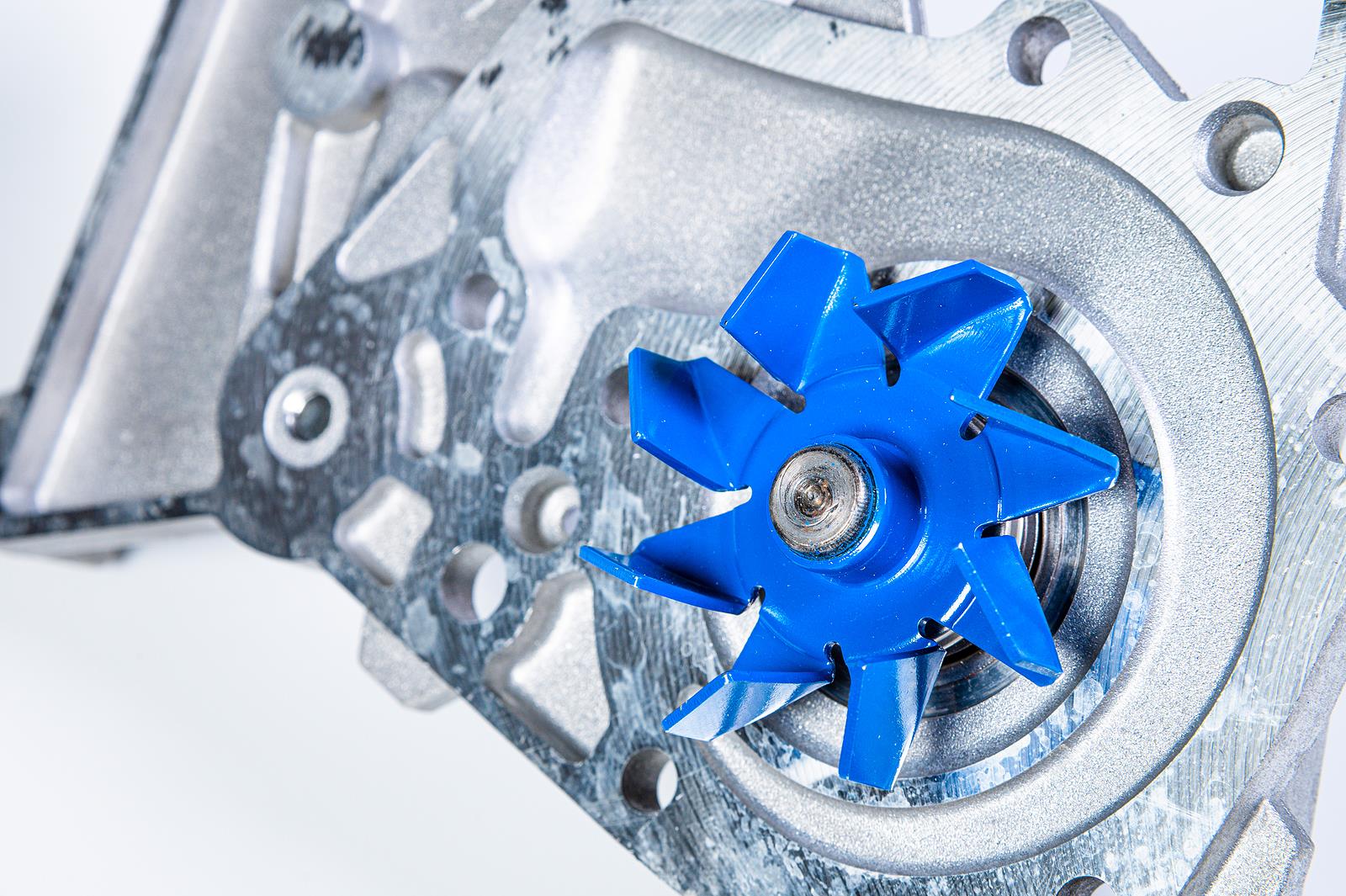

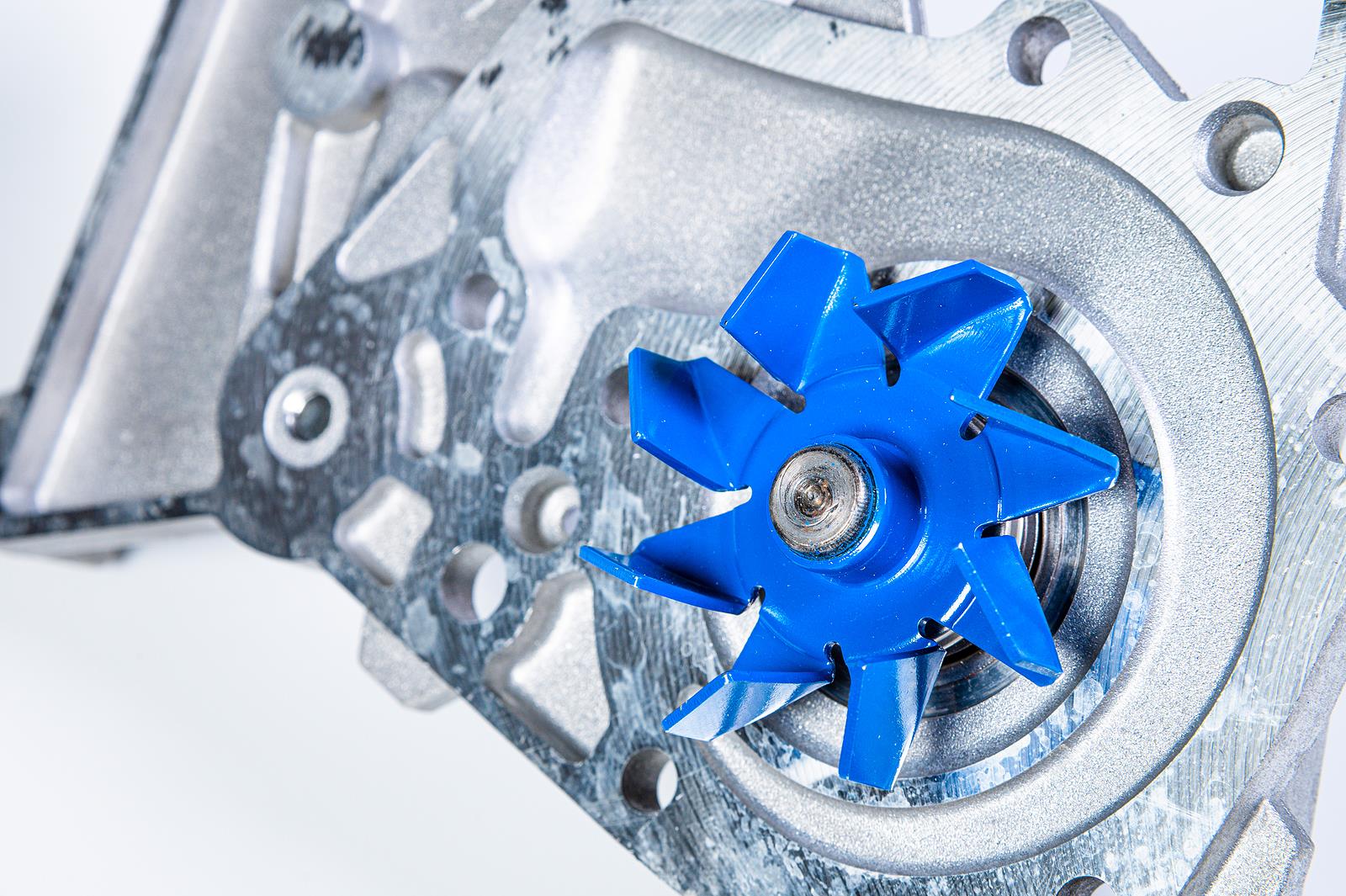

A water pump is a mechanical device that helps circulate coolant through the engine to regulate its temperature. It is typically driven by the engine’s belt or timing chain and is responsible for moving the coolant from the radiator to the engine block and back.

The water pump consists of several key components, including an impeller, a housing, and a shaft. The impeller is a fan-like device that spins rapidly, creating a centrifugal force that propels the coolant through the system. The housing encloses the impeller and guides the flow of coolant. The shaft connects the impeller to the engine’s driving mechanism, allowing it to rotate.

Water pumps can vary in design depending on the type of engine and cooling system used. In modern vehicles, electric water pumps are becoming more common, replacing traditional belt-driven pumps. Electric water pumps offer greater control over coolant flow, allowing for improved cooling efficiency.

Overall, the water pump plays a crucial role in maintaining the engine’s optimal operating temperature. By constantly circulating coolant, it helps dissipate excess heat and prevents the engine from overheating.

Common Signs of a Failing Water Pump

A failing water pump can cause various issues in a vehicle’s cooling system. Recognizing the common signs of water pump failure can help you address the problem before it leads to further damage. Here are some warning signs to look out for:

- Overheating Issues: One of the primary indicators of a failing water pump is the engine constantly running hot or overheating. If the water pump is unable to circulate coolant effectively, the engine will not be properly cooled down, leading to rising temperatures. This can result in engine damage and should be addressed immediately.

- Leaking Coolant: A water pump that is beginning to fail may develop leaks. You may notice coolant pooling under your vehicle or dripping from the front of the engine. Coolant leaks can lead to a loss of coolant, which in turn can cause the engine to overheat. If you observe any signs of coolant leakage, it is essential to have the water pump inspected.

- Noisy Operation: A failing water pump can produce unusual noises. You may hear a squeaking, squealing, or grinding sound coming from the front of the engine. These noises can indicate a worn-out bearing or a loose impeller, both of which require immediate attention.

- Engine Belt Tension Issues: The water pump is typically connected to the engine’s drive belt. If there is a problem with the water pump, it can cause the belt to slip or become loose. This can be observed by a squealing noise coming from the belt area, or even the belt coming off completely. If you notice any issues with the engine belt, have the water pump inspected as well.

- Coolant Contamination: A failing water pump can allow coolant to mix with other engine fluids. This can result in a frothy or milky appearance of the coolant, indicating a coolant contamination issue. If you notice unusual color or texture in your coolant, it is advisable to have the water pump examined to prevent further damage to the engine.

If you experience any of these signs, it is crucial to have your vehicle inspected by a qualified mechanic. Addressing water pump issues promptly can help prevent more significant damages to the engine and cooling system, ensuring the overall longevity of your vehicle.

Overheating Issues

One of the most significant problems associated with a failing water pump is overheating. The water pump plays a crucial role in maintaining the engine’s optimal operating temperature by circulating coolant throughout the cooling system. When the water pump fails to function correctly, it disrupts this circulation, leading to inadequate cooling and eventual overheating of the engine.

Overheating can have severe consequences for the engine. The high temperatures can cause the engine components to expand, leading to warping, cracking, or even complete engine failure in extreme cases. Additionally, overheating can damage gaskets, hoses, and other cooling system components, resulting in leaks and additional repair expenses.

It’s important to address overheating issues promptly to prevent further damage. If you notice the temperature gauge in your vehicle consistently rising, or if the engine temperature warning light illuminates, take immediate action. Here’s what you can do:

- Stop Safely: When you notice the signs of overheating, pull over to a safe location as soon as possible. Continuing to drive with an overheated engine can cause severe damage.

- Turn Off the Engine: Once safely stopped, turn off the engine to prevent any further overheating and potential damage.

- Allow the Engine to Cool: It’s essential to let the engine cool down before attempting to assess or address the issue. Opening the hood immediately after stopping can release a surge of steam and hot coolant.

- Check Coolant Level: Once the engine has cooled down, check the coolant level in the radiator or coolant reservoir. If the level is low, it may indicate a coolant leak or insufficient coolant circulation due to a failing water pump.

- Inspect for Leaks: Look for any signs of coolant leakage around the water pump or other areas of the cooling system. If you notice any leaks, it is advisable to have the water pump inspected and repaired.

- Seek Professional Help: If you are unable to identify the cause of the overheating or if the issue persists after adding coolant, it’s best to seek assistance from a qualified mechanic. They will be able to diagnose the exact cause of the overheating and recommend the necessary repairs.

Remember, ignoring overheating issues can lead to severe engine damage. Addressing the problem promptly can save you from costly repairs and ensure the continued reliable performance of your vehicle.

Leaking Coolant

Leaking coolant is a common sign of a failing water pump. The water pump is responsible for circulating coolant throughout the engine’s cooling system, and when it malfunctions, it can cause coolant leaks. Coolant leaks can be detrimental to the engine’s performance and can lead to overheating if not addressed promptly.

Here are some key points to understand about coolant leaks and their association with a failing water pump:

- Visible Coolant Pooling: If you notice a puddle of coolant forming under your vehicle after it has been parked for some time, it is a clear sign of a coolant leak. The location of the puddle can give you an indication of the general area where the water pump may be located.

- Dripping Coolant: In addition to pooling coolant, you may also observe coolant dripping from the front of the engine. This can be a result of a compromised water pump seal or a crack in the pump housing.

- Loss of Coolant: A failing water pump can cause a gradual loss of coolant. If you find yourself frequently needing to add coolant to the reservoir or notice a significant decrease in the coolant level, it could be due to a leak caused by a malfunctioning water pump.

- Engine Overheating: Coolant leaks can lead to a reduction in coolant levels, which in turn impairs the cooling efficiency of the engine. This can result in the engine overheating, as the coolant is unable to effectively regulate the engine temperature.

- Visible Signs of Leakage: Look for any signs of coolant residue or staining around the water pump or other cooling system components. These visual indicators can help pinpoint the source of the leak and assist in diagnosing the problem.

If you suspect a coolant leak, it is essential to have the water pump inspected and repaired by a qualified mechanic. Ignoring coolant leaks can lead to more severe engine damage and increased repair costs.

Remember, coolant is a vital component in maintaining the engine’s optimal temperature, and any loss of coolant due to a failing water pump can have detrimental effects on your vehicle’s performance and longevity. Addressing coolant leaks promptly will help ensure the continued reliability of your vehicle’s cooling system.

Read more: What Causes A Water Pump To Keep Running

Noisy Operation

A failing water pump can produce various abnormal noises, which can serve as warning signs of its impending failure. If you hear unusual sounds coming from the engine compartment, it’s essential to investigate and address the issue promptly. Here are some common noises associated with a failing water pump:

- Squeaking or Squealing: A squeaking or squealing noise from the front of the engine can indicate a worn-out water pump bearing. Over time, the bearings inside the water pump can become worn or damaged, causing friction and resulting in these high-pitched noises. It’s important not to ignore these sounds, as continued operation with a deteriorated bearing can lead to complete water pump failure.

- Grinding or Whining: A grinding or whining noise can indicate a loose or damaged impeller within the water pump. The impeller is responsible for moving the coolant through the system, and any looseness or damage can result in an uneven or erratic movement, leading to these mechanical noises. A loose impeller can also disrupt the coolant flow, causing inefficient cooling and potential engine overheating.

- Rattling or Clattering: If you hear a rattling or clattering noise when the engine is running, it could be a sign of a loose water pump pulley. The pulley, which is driven by the engine’s belt, can become loose if the water pump is failing. A loose pulley can cause the belt to slip or make contact with other components, resulting in these noise symptoms.

- Metallic Tapping or Clicking: A metallic tapping or clicking sound can indicate a problem with the water pump’s internal components, such as a loose shaft or damaged impeller blades. These noises may increase with engine speed or become more pronounced when the water pump is under load. It’s crucial to address these noises promptly, as they can be indicative of severe water pump damage.

If you hear any of these noises, it’s advisable to have your vehicle inspected by a qualified mechanic. They will be able to diagnose the source of the noise and determine if the water pump is the culprit. Ignoring these noises can lead to further damage to the water pump or other engine components, resulting in more significant repair costs.

Remember that a properly functioning water pump should operate quietly and smoothly. Any unusual noises should not be ignored and should be addressed promptly to ensure the continued performance and reliability of the cooling system.

Causes of Water Pump FailureWater pumps are designed to be durable and reliable. However, there are several factors that can contribute to their failure over time. Understanding the common causes of water pump failure can help you take preventive measures and prolong the lifespan of this critical cooling system component. Here are some key causes to be aware of:

- Age and Wear: Like any mechanical component, water pumps are subject to wear and tear over time. The constant rotation of the impeller, exposure to coolant, and high operating temperatures can cause the internal parts to degrade. As the water pump ages, the components can become worn, leading to decreased performance and eventual failure.

- Excessive Heat: The engine’s cooling system functions under high temperatures, and the water pump is exposed to this heat. Over time, the repeated exposure to extreme temperatures can cause the seal on the water pump to deteriorate, leading to leaks. Additionally, the heat can cause the impeller blades to warp or become damaged, affecting the efficiency of the pump.

- Incorrect Installation: When a water pump is not installed correctly, it can lead to premature failure. Improper installation can result in air pockets within the cooling system, causing improper coolant circulation. Additionally, using incorrect or subpar parts during installation can affect the performance and longevity of the water pump.

- Contaminated Coolant: Contaminated coolant can wreak havoc on the water pump and other components of the cooling system. Rust, debris, and sediment in the coolant can cause blockages within the water pump, impairing its ability to circulate coolant effectively. It is crucial to regularly flush and replace the coolant to prevent contamination and maintain the health of the water pump.

It is important to note that these causes are not exclusive, and often, a combination of factors can contribute to water pump failure. In many cases, failures can be attributed to a combination of age, wear, and other detrimental factors.

To mitigate the risk of water pump failure, routine maintenance and inspection are essential. Regularly checking for coolant leaks, listening for unusual noises, and performing coolant flushes according to the manufacturer’s recommendations can help identify potential issues and address them early on.

By understanding the causes of water pump failure and taking proactive measures, you can ensure the longevity of this critical component and maintain the optimal performance of your vehicle’s cooling system.

Age and Wear

Age and wear are common factors that contribute to water pump failure. Over time, the constant operation and exposure to coolant and high temperatures can take a toll on the internal components of the water pump. Understanding how age and wear affect water pumps can help you anticipate potential issues and take preventive measures.

As a water pump ages, the components within it gradually degrade. The impeller, which is responsible for circulating the coolant, can experience wear on its blades or become loose on its shaft. The bearing that supports the impeller can also become worn, leading to increased friction and eventual failure. Seals, which prevent coolant leakage, can deteriorate over time due to heat and exposure to coolant chemicals.

As wear progresses, the performance of the water pump decreases. It may become less efficient in circulating coolant, resulting in inadequate cooling of the engine. This can lead to engine overheating and potential damage if not addressed promptly.

Regular inspection is crucial to assess the condition of the water pump. Signs of wear, such as loose or damaged impeller blades, leaks, or excessive play in the pulley, should be investigated and addressed. Additionally, paying attention to the vehicle’s maintenance schedule and replacing the water pump according to the manufacturer’s recommendations can help ensure that it is replaced before it reaches the point of failure due to age-related wear.

It’s important to note that the lifespan of a water pump can vary depending on several factors, including the quality of the pump, the driving conditions, and the maintenance performed. In general, water pumps may last anywhere from 60,000 to 100,000 miles or more.

Regular maintenance, such as coolant flushes and inspections, can help extend the life of the water pump. Flushing the coolant according to the manufacturer’s recommendations removes debris and sediment that can contribute to pump damage. Inspecting the water pump during routine maintenance allows for early detection of wear and potential issues before they lead to failure.

While age and wear are inevitable factors in water pump failure, proper maintenance and timely replacement can help prolong the life of this critical component. By staying proactive and addressing potential issues promptly, you can ensure the proper functioning of the water pump and avoid more extensive engine damage that can result from a failing pump.

Excessive Heat

Excessive heat is a significant factor that can contribute to water pump failure. The water pump is exposed to high temperatures in the engine’s cooling system, and prolonged exposure to extreme heat can cause various issues that affect its performance and longevity.

The heat generated by the engine during operation can have several detrimental effects on the water pump:

Seal Deterioration: The high temperatures can cause the seals in the water pump to deteriorate over time. The seals play a crucial role in preventing coolant leakage. When the seals degrade, they can develop leaks, leading to a loss of coolant and potential engine overheating.

Impeller Damage: The impeller, which is responsible for circulating coolant, can be affected by excessive heat. The heat can cause the impeller blades to warp or become damaged, resulting in decreased pump efficiency and inadequate coolant circulation.

Bearing Wear: The bearings within the water pump can also be adversely affected by excessive heat. The constant exposure to high temperatures can cause the bearings to wear out faster, leading to increased friction and potential failure of the water pump.

Moreover, inadequate cooling of the engine due to a failing water pump exacerbates the heat-related issues. If the water pump fails to circulate coolant efficiently, the engine’s temperature can rise to dangerous levels, leading to engine overheating and potential damage to engine components.

Prevention and maintenance are key to mitigating the effects of excessive heat on the water pump:

Cooling System Maintenance: Regular maintenance of the cooling system, such as flushing and replacing coolant, is crucial. Coolant breaks down over time and can lose its heat transfer properties, so regular replacement helps maintain optimal cooling efficiency.

Addressing Cooling System Issues: Any issues with the cooling system should be addressed promptly. This includes resolving leaks, replacing worn-out hoses, and ensuring the proper functioning of radiator fans and thermostats. A well-maintained cooling system helps regulate engine temperature and reduces the strain on the water pump.

Using High-Quality Coolant: Using a high-quality coolant that is specifically recommended for your vehicle can help withstand high temperatures and provide optimal protection against corrosion and cavitation.

Avoiding Overheating Situations: Avoid driving in extreme heat conditions and taking measures to prevent engine overheating, such as ensuring proper air flow through the radiator and avoiding prolonged idling.

By taking preventive measures and maintaining the cooling system, you can minimize the effects of excessive heat on the water pump and extend its lifespan. Regular inspections and timely replacement can help ensure that the water pump remains in optimal condition to perform its crucial role in the engine’s cooling system.

Regular maintenance and timely replacement of the water pump’s drive belt can help prevent premature failure. Additionally, using the recommended coolant and keeping the cooling system clean can also extend the life of the water pump.

Read more: How To Know If A Water Pump Is Bad

Incorrect Installation

Improper installation of a water pump can lead to premature failure and various issues within the cooling system. When a water pump is not installed correctly, it can result in inadequate coolant flow, air pockets, leaks, or other problems that compromise the performance and reliability of the pump.

Here are some key factors to consider when it comes to incorrect installation and its impact on water pump failure:

Air Pockets: Improper installation can lead to the presence of air pockets within the cooling system. Air pockets can impede the proper circulation of coolant and cause overheating. It’s crucial to ensure that the cooling system is properly bled after installing a new water pump to eliminate any trapped air.

Leakage: Incorrect installation techniques or the use of subpar gaskets and seals can result in leaks around the water pump. Leaks can lead to a loss of coolant, insufficient cooling, and potential engine damage. Properly aligning and tightening the water pump and ensuring that all connections are secure are essential aspects of the correct installation process.

Belt Tension: The proper tension of the drive belt that connects the water pump to the engine is crucial for the pump’s efficient operation. Incorrect belt tension can cause slippage or damage to the water pump pulley, leading to reduced performance and potential failure. It is important to follow the manufacturer’s recommended belt tension specifications during installation.

Use of Correct Parts: Using incorrect or subpar parts during water pump installation can contribute to malfunction and premature failure. It is always advisable to use original equipment manufacturer (OEM) or high-quality aftermarket parts designed specifically for your vehicle’s make and model. These parts meet the necessary specifications and ensure compatibility and reliability.

If you suspect that a water pump has been incorrectly installed, it is essential to address the issue promptly. Here are steps you can take:

Seek professional help: If you lack the experience or knowledge to perform proper water pump installation, it is best to consult a qualified mechanic. They can ensure that the water pump is correctly installed and aligned, and all connections are secure.

Have the installation inspected: If you suspect that a water pump has been improperly installed, it is advisable to have the installation inspected. A professional examination can identify any installation errors, leaks, or other issues that need to be rectified.

Follow manufacturer’s instructions: When installing a water pump yourself, always refer to the manufacturer’s instructions and guidelines specific to your vehicle. These instructions provide valuable information on proper installation techniques and specifications, ensuring a successful and correct installation.

By focusing on proper installation techniques, using the correct parts, and seeking professional help when needed, you can avoid the complications and failures associated with incorrect water pump installation. A properly installed water pump ensures the efficient functioning of the cooling system, preventing engine overheating and maintaining the longevity of the pump.

Contaminated Coolant

Contaminated coolant can be a significant factor in water pump failure. Coolant, also known as antifreeze, is responsible for regulating the engine’s temperature and protecting the cooling system from corrosion and debris. However, over time, coolant can become contaminated, leading to potential issues that can compromise the performance of the water pump and the overall health of the engine.

Here are some key points to consider regarding contaminated coolant and its impact on water pump failure:

Rust and Corrosion: Coolant contamination can occur due to the presence of rust and corrosion within the cooling system. Over time, metal components can corrode, releasing particles into the coolant. Corrosion and rust particles can clog the water pump’s passages, impede coolant flow, and even damage the pump’s impeller. This can result in reduced efficiency and eventual failure of the water pump.

Debris and Sediment: Coolant contamination can also happen due to the accumulation of debris and sediment within the cooling system. Contaminants such as dirt, debris, and particles from deteriorating hoses or gaskets can find their way into the coolant. These contaminants can clog the water pump and other components, impairing the flow of coolant and leading to inefficiencies and potential failure.

Coolant Breakdown: Over time, coolant can degrade and lose its effectiveness. Coolant breakdown can occur due to exposure to high temperatures, long-term use, or inadequate maintenance. As the coolant degrades, it can become less efficient in transferring heat and protecting the cooling system. Impaired coolant can contribute to overheating, increased wear on the water pump, and eventual failure.

To prevent water pump failure due to contaminated coolant, follow these preventive measures:

Regular Coolant Flush: Performing regular coolant flushes as recommended by the vehicle manufacturer is crucial. Coolant flushes help remove contaminants, debris, and sediment from the cooling system, ensuring the coolant remains clean and effective in protecting the water pump and other components.

Use Quality Coolant: Always use a high-quality coolant recommended by the vehicle manufacturer. Quality coolant is designed to provide optimal protection against rust, corrosion, and cavitation. It is formulated to resist breakdown and maintain its effectiveness for a longer period.

Inspect for Contamination: Regularly inspect the coolant for signs of contamination, such as discoloration or the presence of visible debris. If you notice any abnormalities, have the cooling system inspected and the coolant replaced as needed.

Maintain Cooling System Components: Replace worn-out hoses, gaskets, and other cooling system components as recommended. This prevents leaks and the introduction of debris into the coolant, reducing the risk of water pump damage.

By maintaining clean and effective coolant, regularly flushing the system, and ensuring the overall health of the cooling system, you can prevent water pump failure due to contaminated coolant. A properly functioning water pump allows for efficient coolant circulation, helping to regulate the engine’s temperature and protect its longevity.

Maintenance Tips to Prevent Water Pump Failure

Maintaining a healthy water pump is crucial for the overall performance and longevity of your vehicle’s cooling system. By following some key maintenance tips, you can significantly reduce the risk of water pump failure and avoid potentially costly repairs. Here are some essential maintenance tips to keep in mind:

Regular Coolant Flushes: Perform regular coolant flushes as recommended by the vehicle manufacturer. Coolant flushes help remove contaminants, debris, and sediment that can build up in the cooling system over time. Flushing the system ensures that the coolant remains clean and free of any elements that could clog the water pump or impede its performance.

Avoid Using Tap Water: When topping off or replacing coolant, it is important to use the correct coolant mixture recommended by the vehicle manufacturer. Avoid using tap water, as it may contain minerals and impurities that can lead to scale buildup and damage to the water pump and other cooling system components. Use distilled or demineralized water whenever possible.

Use OE or OEM Parts: When it comes to water pump replacement or any related repairs, always use original equipment (OE) or original equipment manufacturer (OEM) parts. These parts are specifically designed and tested for your vehicle’s make and model, ensuring proper fitment and compatibility. Using high-quality parts helps maintain the performance and longevity of the water pump.

Proper Installation and Maintenance: Ensure that the water pump is installed correctly, following the manufacturer’s instructions and guidelines. Proper installation includes properly aligning the pump, securing all connections, and ensuring the correct tension of the drive belt. Additionally, regular inspection of the water pump and the cooling system as a whole is essential for identifying any potential issues and addressing them promptly.

Monitor Coolant Levels and Quality: Regularly check the coolant level and monitor its quality. If you notice a significant decrease in coolant level or any abnormalities such as discoloration, debris, or a frothy appearance, it may indicate a problem with the water pump or the cooling system. Address these issues promptly by having the system inspected and the coolant replaced if necessary.

Address Leaks Immediately: Coolant leaks should never be ignored, as they can lead to a loss of coolant, engine overheating, and potential water pump failure. If you spot any signs of coolant leakage, have the water pump and the cooling system inspected by a qualified mechanic. Timely repair of leaks can prevent further damage and ensure the proper functioning of the water pump.

Follow Manufacturer’s Maintenance Schedule: Adhere to the maintenance schedule outlined in your vehicle’s owner’s manual. The manufacturer’s recommended maintenance intervals include key services such as coolant and filter replacements, which directly contribute to the health and longevity of the water pump. Following the maintenance schedule helps ensure that the water pump and the cooling system receive the necessary care at the appropriate intervals.

By implementing these maintenance tips, you can significantly reduce the risk of water pump failure and keep your vehicle’s cooling system in optimal condition. Regular maintenance, proper installation, and attention to coolant quality and levels are key to preserving the performance and reliability of the water pump, allowing for effective engine cooling and smooth operation of your vehicle.

Regular Coolant Flushes

Regular coolant flushes are a crucial part of maintaining a healthy water pump and overall cooling system. Over time, coolant can break down and become contaminated with debris, rust, and other contaminants that can negatively impact the performance of the water pump. Performing regular coolant flushes helps remove these impurities and ensure the longevity and efficiency of the cooling system. Here’s why regular coolant flushes are essential:

Removal of Contaminants: Coolant circulates through the engine and the radiator, where it absorbs heat and helps regulate the engine’s temperature. During this process, the coolant can pick up debris, rust, and other contaminants from the engine and cooling system. Over time, these impurities can build up and clog the water pump, reducing its effectiveness and potentially leading to pump failure. A thorough coolant flush helps remove these contaminants, preventing them from causing damage to the water pump and other components.

Prevention of Corrosion: The cooling system is composed of various metal components that are exposed to coolant. Over time, coolant can break down and lose its ability to protect against corrosion. Corrosion can lead to the formation of rust and the weakening of the water pump and other cooling system parts. Regular coolant flushes help prevent the buildup of corrosive elements in the system, reducing the risk of damage to the water pump and promoting its longevity.

Optimal Cooling Efficiency: As impurities accumulate in the coolant, they can hinder its ability to effectively transfer heat. This can result in reduced cooling efficiency, leading to engine overheating and increased stress on the water pump. By performing regular coolant flushes, you ensure that the coolant remains clean and free from contaminants, allowing it to effectively regulate the engine’s temperature and support the water pump in its cooling duties.

Extended Lifespan of the Water Pump: The water pump plays a vital role in maintaining proper coolant circulation. By removing impurities and preventing corrosion within the cooling system, regular coolant flushes help prolong the life of the water pump. A well-maintained water pump can operate efficiently for a longer period, reducing the risk of premature failure and the need for costly repairs.

Preservation of Cooling System Components: The water pump is not the only component that benefits from regular coolant flushes. By keeping the coolant clean and free from contaminants, you help protect other parts of the cooling system, such as the radiator, hoses, and heater core. This preserves the overall health and performance of the cooling system, contributing to the reliability and longevity of your vehicle.

It is important to follow the manufacturer’s recommended maintenance schedule for coolant flushes. This schedule can vary depending on the vehicle make, model, and coolant type. Adhering to the recommended intervals ensures that the coolant is regularly refreshed, offering effective protection and promoting the optimal function of the water pump.

Regular coolant flushes are a proactive maintenance measure that can help prevent water pump failure and ensure the overall health of your vehicle’s cooling system. By performing this essential maintenance task, you can extend the lifespan of the water pump, maintain proper cooling performance, and avoid potential costly repairs.

Read more: How To Tell If Your House Water Pump Is Bad

Avoid Using Tap Water

When it comes to maintaining the health and performance of your vehicle’s cooling system, it is important to avoid using tap water as a coolant additive. While tap water may be readily available and seem like a convenient option, it can actually have detrimental effects on the cooling system and the water pump. Here’s why it’s crucial to avoid using tap water:

Minerals and Impurities: Tap water often contains minerals and impurities that can be harmful to the cooling system. These minerals, such as calcium and magnesium, can cause scale buildup on crucial components like the water pump and radiator. Over time, this scale can impair the efficiency of the water pump, reduce coolant flow, and even lead to clogs or overheating. Impurities in tap water can also contribute to corrosion and damage to the cooling system.

Chemical Imbalance: Tap water may not have the proper chemical balance required for effective cooling system performance. Coolant is formulated with specific additives to protect against corrosion, cavitation, and other issues. Mixing tap water with coolant can disrupt this delicate chemical balance, rendering the coolant less effective in protecting the water pump and other components. This imbalance can lead to accelerated wear and potential failure of the water pump.

Quality Control: Tap water does not undergo the same level of quality control as coolant or distilled water. Coolant is specifically manufactured to meet certain standards and requirements, ensuring its effectiveness and compatibility with the cooling system. On the other hand, tap water can vary widely in terms of quality and purity, making it an unreliable choice for maintaining the health of the water pump and cooling system.

Corrosion and Rust: Using tap water can increase the risk of corrosion and rust within the cooling system. Tap water often contains higher levels of dissolved minerals, which can contribute to accelerated corrosion of metal components. The water pump, being a crucial part of the cooling system, can be directly affected by these corrosive elements. This corrosion weakens the water pump and can lead to reduced performance and potential failure.

Best Alternatives: Instead of tap water, it is recommended to use distilled or demineralized water for coolant mixtures. Distilled water has been purified to remove impurities and minerals, making it a clean and reliable choice. This ensures that the coolant maintains its optimal chemical balance, protecting the cooling system and water pump.

By avoiding tap water and using the proper coolant mixture with distilled water, you help maintain the effectiveness of the coolant, preserve the health of the water pump, and extend the lifespan of your vehicle’s cooling system. It is important to follow the manufacturer’s recommendations when it comes to the type and ratio of coolant to water, ensuring the best performance and protection for your vehicle.

Remember, a small investment in using the appropriate water for your coolant can save you from potential cooling system issues and the resulting repairs or replacements of components like the water pump. Taking this proactive step will contribute to the longevity and reliability of your vehicle.

Use OE or OEM Parts

When it comes to maintaining and repairing your vehicle, using original equipment (OE) or original equipment manufacturer (OEM) parts for components like the water pump is crucial. OE and OEM parts are designed specifically for your vehicle’s make and model, ensuring the best fit, performance, and reliability. Here’s why it’s important to use OE or OEM parts, including water pumps:

Quality and Reliability: OE and OEM parts are manufactured to the highest standards and meet the specifications set by the vehicle manufacturer. These parts undergo rigorous testing to ensure they perform optimally in the intended vehicle application. By using OE or OEM water pumps, you can trust in their quality and reliability, knowing they are designed to work seamlessly with your vehicle’s cooling system.

Compatibility: OE and OEM water pumps are specifically engineered to fit your vehicle precisely. They are designed to align perfectly with existing components and systems, ensuring proper functioning and minimizing the risk of leaks or performance issues. Using OE or OEM parts eliminates the need for modifications or adaptations, making the installation process smoother and more efficient.

Longevity and Durability: OE and OEM water pumps are built to last. They are constructed using high-quality materials and undergo stringent quality control measures. The superior craftsmanship of these parts ensures durability and longevity, allowing them to withstand the demands of the cooling system and the engine environment. By using these parts, you can expect a longer lifespan for your water pump and fewer issues down the road.

Warranty Coverage: Using OE or OEM parts often comes with the added benefit of warranty coverage. Most reputable manufacturers provide warranties for their parts, giving you peace of mind that any defects or issues will be addressed. Choosing OE or OEM water pumps ensures that you can take advantage of warranty protection, protecting your investment and providing valuable support in case of any unforeseen problems.

Consistent Performance: OE and OEM water pumps are designed to deliver consistent performance, meeting the original specifications set by the vehicle manufacturer. This consistency ensures that the cooling system functions optimally, effectively regulating engine temperature and preventing overheating. By using these parts, you can trust in their performance and avoid potential issues that could result from using aftermarket or generic alternatives.

To ensure the best fit and performance for your vehicle’s cooling system, it is recommended to use OE or OEM water pumps. These parts offer superior quality, compatibility, and durability, ultimately contributing to the overall reliability and longevity of your vehicle. When it comes to critical components like the water pump, investing in OE or OEM parts is a wise choice that pays off in terms of performance, peace of mind, and long-term savings.

Proper Installation and Maintenance

Proper installation and maintenance are essential for the optimal performance and longevity of your vehicle’s water pump. The water pump plays a crucial role in the cooling system, so it’s vital to ensure it is installed correctly and maintained regularly. Here’s why proper installation and maintenance are important:

Optimal Performance: Proper installation of the water pump helps guarantee its optimal performance. The water pump should be aligned correctly, ensuring that it operates smoothly and efficiently. When the water pump is installed properly, it can effectively circulate coolant throughout the engine, regulating its temperature and preventing overheating. This helps to preserve the overall performance of the vehicle.

Prevent Leaks: Correct installation of the water pump includes securing all connections and ensuring the seals are properly seated. Properly installed seals prevent coolant leaks, which are not only wasteful but can also lead to engine overheating and potential damage. By ensuring a tight and secure installation, you can minimize the risk of leaks and avoid costly repairs.

Reduced Risk of Premature Failure: Proper installation and maintenance help extend the lifespan of the water pump. If the water pump is installed incorrectly or if it is not properly maintained, it can lead to increased stress on the component, causing accelerated wear and potential premature failure. By following the manufacturer’s installation guidelines and performing regular maintenance, such as coolant flushes and inspections, you can keep the water pump in optimal condition and avoid unnecessary breakdowns.

Improved Efficiency: A properly installed and maintained water pump operates efficiently, resulting in improved cooling system performance. When the pump is functioning as intended, it can maintain the proper coolant flow and temperature regulation, preventing excessive heat build-up and ensuring the engine operates at its best. This improved efficiency can lead to better fuel economy, reduced emissions, and overall smoother operation of the vehicle.

Manufacturer Recommendations: Following the manufacturer’s recommendations for installation and maintenance is crucial. The manufacturer has extensive knowledge of their product and provides specific guidelines for the proper installation and maintenance of the water pump. Adhering to these recommendations ensures that you are taking the necessary steps to preserve the water pump’s performance and protect your investment in your vehicle.

Professional Assistance: If you are unsure about the installation process or if you require maintenance on the water pump, it is recommended to seek professional assistance. Qualified mechanics have the expertise and experience to install and maintain the water pump correctly, ensuring proper functionality and minimizing the risk of complications.

In summary, proper installation and maintenance of the water pump are crucial for its optimal performance and longevity. Taking the time to follow the manufacturer’s guidelines and schedule regular maintenance tasks, such as coolant flushes and inspections, will help ensure that your vehicle’s water pump functions properly, reducing the risk of leaks, premature failure, and costly repairs. By prioritizing proper installation and maintenance, you are investing in the overall health and reliability of your vehicle’s cooling system.

Conclusion

Your vehicle’s water pump plays a critical role in maintaining the proper function and health of the cooling system. Recognizing the signs of a failing water pump and understanding the factors that contribute to its failure are important for ensuring the longevity and reliability of this essential component.

By being aware of common symptoms such as overheating, coolant leaks, noisy operation, and understanding the causes of water pump failure, such as age, excessive heat, incorrect installation, and contaminated coolant, you can take proactive measures to address issues early and prevent further damage.

Maintaining your water pump and overall cooling system is key to avoiding costly repairs and maintaining the performance of your vehicle. Regular coolant flushes, using distilled water instead of tap water, using OE or OEM parts, proper installation, and following manufacturer’s maintenance recommendations all contribute to the health and longevity of your water pump.

Remember, maintaining a healthy water pump not only ensures optimal engine cooling but also prevents engine overheating, reduces the risk of other cooling system component failures, and extends the life of your vehicle.

By implementing these best practices and staying proactive with water pump maintenance, you can enjoy a reliable and efficient cooling system, helping to protect your engine and ensure a smooth and trouble-free driving experience.

So, take the time to prioritize water pump care and maintenance. Your vehicle will thank you with reliable performance and a properly regulated engine temperature for miles to come.

Frequently Asked Questions about What Causes A Water Pump To Go Bad

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Causes A Water Pump To Go Bad”