Articles

What Noise Does A Cold Water Pump Make?

Modified: January 8, 2024

Discover the underlying causes of water pump noise when cold in this informative article. Find solutions and tips to address this common issue.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When you start your car on a cold morning and hear an unusual noise coming from under the hood, it can be concerning. One common issue that car owners may encounter is water pump noise when the engine is cold. The water pump is an essential component of the engine’s cooling system, responsible for circulating coolant to regulate the engine’s temperature.

Understanding the causes of water pump noise when cold and how to address them can help prevent potential damage to the engine and ensure smooth operation of your vehicle. In this article, we will explore the common reasons for water pump noise and provide tips on resolving the issue.

Key Takeaways:

- Address water pump noise by bleeding the cooling system, inspecting and adjusting the belt, checking and replacing the water pump bearing, addressing water pump cavitation, and verifying and replacing the thermostat.

- Regular maintenance and proactive inspections of the cooling system are essential for resolving water pump noise and ensuring optimal vehicle performance.

Read more: Does Water Pump Make Noise When Going Bad

Understanding Water Pump Noise

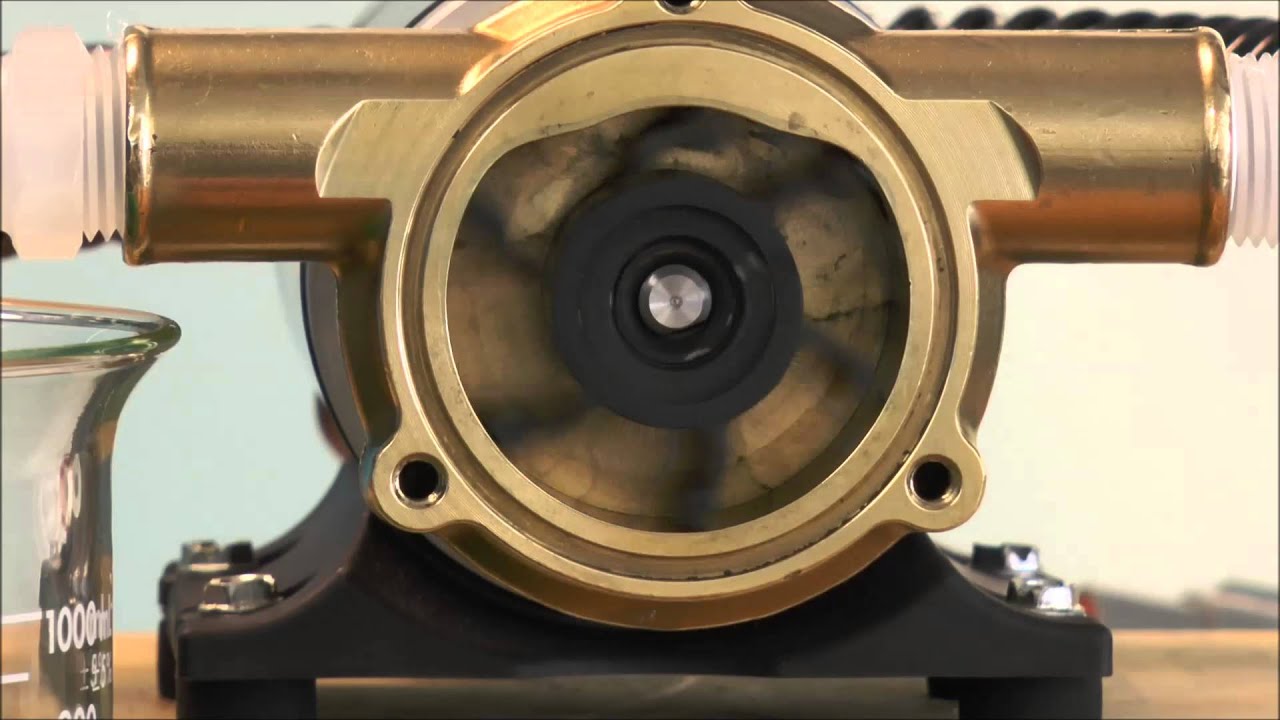

Before we delve into the causes and solutions for water pump noise when the engine is cold, it is important to have a basic understanding of how the water pump works. The water pump is typically driven by a belt connected to the engine’s crankshaft. Its main function is to circulate the coolant throughout the engine and radiator, cooling the engine and preventing overheating.

When the water pump is functioning properly, it operates silently. However, if you notice any abnormal noise coming from the water pump, it may indicate an underlying issue. The noise can vary from a grinding or squeaking sound to a loud whirring or knocking noise. It is important to diagnose and address the problem promptly to avoid potential engine damage.

Water pump noise can occur at any temperature, but it is more common to notice it when the engine is cold. This is because when the engine is cold, the components may be tighter, and any issues with the water pump can become more apparent. Now, let’s explore the common causes of water pump noise when cold and how to resolve them.

Common Causes of Water Pump Noise When Cold

There are several potential causes for water pump noise when the engine is cold. Identifying the underlying issue is crucial for properly resolving the problem. Here are some common causes to consider:

1. Air Pocket in the System

An air pocket in the cooling system can cause erratic flow of coolant, leading to noise in the water pump. This can happen if the system was not properly bled after a coolant flush or if there is a coolant leak. The air pocket disrupts the smooth circulation of coolant and can create noise.

2. Loose or Worn Belt

A loose or worn belt can cause the water pump to make noise. If the belt is loose, it may slip and cause the water pump to rotate irregularly, resulting in noise. Similarly, if the belt is worn and has lost its grip, it can create noise as it slips against the pulley.

Read more: Why Is My Water Pump Making Noise

3. Faulty Water Pump Bearing

The water pump bearing supports the rotating shaft of the water pump. Over time, the bearing may wear out or become damaged, causing it to make noise. A faulty bearing can create a grinding or squealing noise when the water pump is in operation.

4. Water Pump Cavitation

Cavitation occurs when the water pump impeller spins faster than the coolant flow can keep up with. This can create tiny air bubbles that implode when they come into contact with the impeller blades, causing noise. Cavitation can be caused by restricted coolant flow, low coolant levels, or a malfunctioning thermostat.

5. Thermostat Issues

If the engine thermostat is stuck open or closed, it can affect the proper functioning of the water pump. When the thermostat is stuck open, the engine may take longer to reach operating temperature, putting additional strain on the water pump. Conversely, if the thermostat is stuck closed, it may cause the engine to overheat, affecting the water pump’s performance and potentially causing noise.

These are some of the common causes of water pump noise when the engine is cold. Identifying the specific issue will help in determining the appropriate solution. In the next section, we will discuss how to resolve water pump noise when cold and restore the proper functioning of the cooling system.

Air Pocket in the System

An air pocket in the cooling system can disrupt the flow of coolant and contribute to water pump noise when the engine is cold. When the cooling system is not properly bled or if there is a coolant leak, air can become trapped in the system, hindering the smooth circulation of coolant.

To resolve an air pocket issue, follow these steps:

- Ensure that the engine is cool and the vehicle is on a level surface.

- Locate the coolant reservoir or radiator cap (if your vehicle has one).

- If using the coolant reservoir, check the level of coolant and add more if necessary. If using the radiator cap, carefully remove it and check the coolant level in the radiator.

- If the coolant level is low, top it up with the appropriate coolant mixture recommended by the vehicle manufacturer.

- Start the engine and let it idle for a few minutes to warm up.

- Observe the coolant level and look for any signs of air bubbles or sudden drops in the level.

- If air bubbles are present, gently squeeze the radiator hoses to help release trapped air pockets.

- If necessary, repeat the process of adding coolant and bleeding the system until no more air bubbles are observed and the coolant level remains steady.

- Once the bleeding process is complete, securely replace the coolant reservoir cap or radiator cap.

By properly bleeding the cooling system, you can eliminate air pockets and ensure that the coolant flows smoothly, reducing the likelihood of water pump noise when the engine is cold.

If the air pocket issue persists or if you are unsure about the process, it is recommended to consult a professional mechanic for assistance.

Read more: What Noise Does A Kettle Make

Loose or Worn Belt

A loose or worn belt can be a common cause of water pump noise when the engine is cold. The belt, often referred to as the serpentine belt, drives various engine components, including the water pump. Over time, the belt can become stretched or worn, leading to a loss of proper tension and grip.

To address a loose or worn belt, follow these steps:

- Start by visually inspecting the belt for any signs of wear, cracks, or damage. If you notice significant damage, the belt may need to be replaced.

- Check the tension of the belt by pressing down on it firmly with your finger. If there is excessive give or slack, it may indicate that the belt needs to be tightened or replaced.

- Refer to the vehicle’s owner manual or a repair guide for specific instructions on how to adjust the belt tension. This process may involve locating and adjusting the belt tensioner.

- If the belt tension is adjustable, use a wrench or ratchet to turn the belt tensioner and increase tension on the belt. Make sure not to overtighten the belt, as it may lead to other issues.

- Recheck the tension of the belt after making adjustments to ensure it is properly tightened.

- If the belt appears to be in good condition but still produces noise, it may be necessary to replace it altogether. Consult a professional mechanic for guidance on belt replacement.

By ensuring the belt is properly tensioned or replaced as needed, you can reduce the likelihood of water pump noise caused by a loose or worn belt. Regular maintenance and periodic inspection of the belt can help prevent future issues.

If you are unsure about the condition of the belt or require assistance with the adjustment or replacement process, it is recommended to seek the help of a qualified mechanic.

Faulty Water Pump Bearing

A faulty water pump bearing can be a common culprit behind water pump noise when the engine is cold. The water pump bearing supports the rotating shaft of the water pump and allows it to spin smoothly. Over time, the bearing can wear out or become damaged, resulting in noise.

To address a faulty water pump bearing, follow these steps:

- Start by visually inspecting the water pump for any signs of leaks or damage. A leaking water pump or excessive play in the pulley may indicate a problem with the bearing.

- If you suspect a faulty bearing, it is best to replace the entire water pump assembly, as the bearing is an integral part of it. Consult the vehicle’s service manual or a repair guide for specific instructions on how to remove and replace the water pump.

- Drain the coolant from the cooling system to prevent any spills or contamination during the replacement process. Follow proper disposal procedures for coolant.

- Remove the drive belts or any other components that may obstruct access to the water pump. This may involve loosening and removing the belt tensioner or accessory mounts.

- Disconnect the hoses and electrical connectors attached to the water pump.

- Remove the mounting bolts securing the water pump to the engine block or timing cover.

- Carefully remove the old water pump from its position and clean the mating surface of the engine block or timing cover.

- Install the new water pump following the manufacturer’s instructions. Use a new gasket or sealant as recommended.

- Reattach the hoses, electrical connectors, and any other components that were removed.

- Refill the cooling system with the appropriate coolant and purge any air pockets following the proper bleeding procedure mentioned earlier.

Replacing the water pump with a faulty bearing should eliminate the noise and restore proper functionality to the cooling system. Remember to use high-quality replacement parts that are compatible with your vehicle’s make and model.

If you are unsure about replacing the water pump yourself, it is advisable to seek the assistance of a professional mechanic to ensure the job is done correctly.

Water Pump Cavitation

Water pump cavitation is another possible cause of water pump noise when the engine is cold. Cavitation occurs when the water pump’s impeller spins at a speed that exceeds the flow rate of coolant. This imbalance creates small air bubbles that collapse violently when they come into contact with the impeller blades, causing noise.

To address water pump cavitation, follow these steps:

- Check the coolant level in the radiator or coolant reservoir. Low coolant levels can contribute to cavitation. If the coolant level is low, refill it to the recommended level using the appropriate coolant mixture.

- Inspect the cooling system for any restrictions or blockages that could impede the flow of coolant. This can include clogged hoses, a blocked radiator, or a malfunctioning thermostat.

- If the cooling system is clean and unobstructed, consider installing a coolant additive specifically designed to reduce cavitation. These additives create a protective layer on the water pump’s impeller, minimizing the formation of air bubbles.

- Ensure that the radiator cap or coolant reservoir cap is functioning correctly. A faulty cap can contribute to cavitation by allowing air to enter the cooling system.

- If the cavitation issue persists, it may be necessary to replace the water pump with a model that is better suited to handle the coolant flow rate. Consult a professional mechanic to determine the appropriate water pump replacement for your vehicle.

By addressing water pump cavitation, you can minimize the noise and maintain the proper functioning of the cooling system. Regular maintenance and ensuring the cooling system is clean and well-maintained can help prevent cavitation from occurring in the first place.

If you are uncertain about the cause or resolution of water pump cavitation, it is recommended to seek the assistance of a qualified mechanic who can diagnose and address the issue effectively.

Thermostat Issues

Faulty thermostat operation can contribute to water pump noise when the engine is cold. The thermostat is a crucial component of the engine cooling system, regulating the flow of coolant to maintain optimal engine temperature. If the thermostat is stuck open or closed, it can impact the water pump’s performance and potentially cause noise.

To address thermostat issues, follow these steps:

- First, visually inspect the thermostat housing and surrounding components for any signs of leaks, cracks, or damage. A faulty thermostat housing or gasket can affect the proper operation of the thermostat.

- Next, check the engine temperature gauge while the engine is running. If the engine takes an excessively long time to reach operating temperature or if it overheats, it may indicate a problem with the thermostat.

- If you suspect a faulty thermostat, it is recommended to replace it. Consult the vehicle’s service manual or a repair guide for specific instructions on how to remove and replace the thermostat.

- Drain the coolant from the cooling system to prevent any spills or contamination during the replacement process. Follow proper disposal procedures for coolant.

- Remove any components that obstruct access to the thermostat. This may involve disconnecting hoses or removing housing covers.

- Remove the old thermostat from its housing and clean the mating surfaces.

- Install the new thermostat, ensuring it is properly seated and aligned with the housing. Use a new gasket or sealant as recommended by the manufacturer.

- Reassemble the components, reattach hoses, and reconnect any electrical or sensor connections that were removed.

- Refill the cooling system with the appropriate coolant, following the recommended procedure for bleeding air out of the system.

Replacing a faulty thermostat should restore proper coolant flow and regulate the engine’s temperature, reducing the likelihood of water pump noise. Regular inspection and maintenance of the thermostat can help prevent future issues.

If you are unsure about replacing the thermostat yourself or if the issue persists after replacement, it is advisable to consult a professional mechanic for further diagnosis and assistance.

Read more: What Does The Water Pump Do In An Rv

Resolving Water Pump Noise When Cold

Resolving water pump noise when the engine is cold requires identifying the underlying cause and taking appropriate steps to address it. Here are some general tips to help you resolve water pump noise and restore the smooth operation of your vehicle’s cooling system:

1. Bleeding the Cooling System

If an air pocket is causing the water pump noise, it is crucial to properly bleed the cooling system. Follow the manufacturer’s instructions or the steps outlined earlier in this article to remove any trapped air and ensure the coolant flows smoothly.

2. Inspecting and Adjusting the Belt

If a loose or worn belt is the culprit, visually inspect it for damage and proper tension. Adjust the belt tension if necessary or replace the belt altogether for optimal performance and reduced noise.

3. Checking and Replacing the Water Pump Bearing

A faulty water pump bearing may require replacing the entire water pump assembly. Consult the manufacturer’s instructions or seek professional assistance to ensure a proper replacement.

Read more: What Does Gph Mean On A Water Pump

4. Addressing Water Pump Cavitation

To resolve water pump cavitation, ensure the coolant levels are sufficient, inspect and address any restrictions in the cooling system, consider using a coolant additive, and verify the functionality of the radiator cap or coolant reservoir cap.

5. Verifying and Replacing the Thermostat

If a faulty thermostat is suspected, visually inspect it for any damage or leaks. Replace the thermostat as needed to ensure proper coolant flow and engine temperature regulation.

It is important to note that these tips provide general guidance but may vary depending on the specific make and model of your vehicle. Always consult the vehicle’s owner manual or seek the advice of a professional mechanic for specific instructions related to your vehicle.

By taking the necessary steps to address the underlying issue causing water pump noise, you can ensure the proper functioning of the cooling system and mitigate potential damage to your vehicle’s engine.

Bleeding the Cooling System

If water pump noise when the engine is cold is caused by an air pocket in the cooling system, bleeding the system is essential to resolve the issue. Bleeding the cooling system helps remove trapped air and allows coolant to flow smoothly, reducing noise and promoting efficient cooling. Here’s how you can perform this procedure:

- Ensure that the engine is cool and the vehicle is parked on a level surface.

- Locate the coolant reservoir or radiator cap. Note that some vehicles have a bleeder valve specifically for releasing air from the system.

- If using the coolant reservoir, check the coolant level and top it up if necessary. If using the radiator cap, carefully remove it and check the coolant level in the radiator. Refer to the vehicle’s manual for the appropriate type and mixture of coolant.

- Start the engine and let it idle for a few minutes. This will help warm up the coolant and ensure proper circulation during the bleeding process.

- Observe the coolant level as the engine runs. Monitor for any signs of air bubbles or sudden drops in the level, as these indicate the presence of an air pocket.

- If air bubbles are detected, carefully squeeze the radiator hoses to help release trapped air. Start from the lower hose and work your way up to the upper hose. Be cautious as the coolant may be hot.

- Repeat this process until no more air bubbles are observed, and the coolant level remains stable.

- Once the bleeding process is complete, securely replace the radiator cap or coolant reservoir cap and ensure it is tightly sealed.

Bleeding the cooling system can effectively remove air pockets that contribute to water pump noise when the engine is cold. It is important to follow proper bleeding techniques to ensure thorough removal of air from the system. However, if you are unsure about the procedure or encounter any difficulties, it is advisable to consult a professional mechanic for assistance.

Inspecting and Adjusting the Belt

If a loose or worn belt is causing water pump noise when the engine is cold, inspecting and adjusting the belt can help resolve the issue. It is important to ensure that the belt is in good condition and properly tensioned for optimal performance. Here’s a step-by-step guide on how to inspect and adjust the belt:

- Start by visually inspecting the belt for signs of wear, cracks, fraying, or damage. Pay attention to the grooves and edges of the belt, as these areas are prone to wear.

- If you notice any significant damage to the belt, it is recommended to replace it. Consult the vehicle’s manual or seek the advice of a professional mechanic for the appropriate replacement belt.

- Next, check the tension of the belt. With the engine turned off and the vehicle in park or neutral, press down on the belt with your finger. It should have a certain amount of tension and spring back when released.

- If the belt feels loose or has excessive give, it may require adjustment. Refer to the vehicle’s manual or a repair guide for the specific procedure to adjust the belt tension.

- Most modern vehicles have an automatic tensioner that takes care of belt tension. In such cases, there is usually no adjustment necessary, and a loose belt may indicate a worn-out tensioner that needs replacement.

- If the belt tension is adjustable, locate the belt tensioner. It is typically a pulley that applies tension to the belt. Use a suitable tool, such as a wrench or ratchet, to rotate the tensioner and increase tension on the belt.

- Be cautious not to overtighten the belt, as excessive tension can put strain on other components and potentially cause damage. Refer to the vehicle’s manual for the recommended tension specifications.

- Once the belt is properly tensioned, reinspect the belt for any signs of damage. Ensure it is aligned correctly with the pulleys and runs smoothly along its path.

Regularly inspecting and adjusting the belt can help prevent water pump noise caused by a loose or worn belt. It is important to use the correct replacement belt and follow the manufacturer’s guidelines for tension adjustment. If you are unsure about the process or have difficulty adjusting the belt, it is best to consult a professional mechanic for assistance.

Read more: What Does Water Pump Do In A Car

Checking and Replacing the Water Pump Bearing

If a faulty water pump bearing is the cause of water pump noise when the engine is cold, it is necessary to check and replace the water pump bearing. The water pump bearing supports the rotating shaft of the water pump and ensures smooth operation. Here’s a step-by-step guide on how to inspect and replace the water pump bearing:

- First, visually inspect the water pump for any signs of leaks, excessive play, or damage. A leaking water pump or a loose pulley may indicate a problem with the bearing.

- If you suspect a faulty bearing, it is recommended to replace the entire water pump assembly, as the bearing is an integral part of it. Consult the vehicle’s service manual or a repair guide for specific instructions on how to remove and replace the water pump.

- Begin by ensuring the engine is cool and the vehicle is on a level surface. Drain the coolant from the cooling system to prevent any spills or contamination.

- Identify the water pump location. It is typically located at the front of the engine, driven by a belt connected to the crankshaft.

- Remove any components, such as the drive belt or other accessories, that obstruct access to the water pump.

- Disconnect the hoses and electrical connectors attached to the water pump.

- Remove the mounting bolts securing the water pump to the engine block or timing cover.

- Carefully remove the old water pump from its position, taking note of any gaskets or seals that may need replacement.

- Clean the mating surface of the engine block or timing cover to ensure a proper seal with the new water pump.

- Install the new water pump, following the manufacturer’s instructions and using the appropriate gaskets or seals.

- Tighten the mounting bolts to the specified torque provided in the manual or instructions.

- Reattach the hoses and electrical connectors to the new water pump.

- Reinstall any components that were removed, ensuring proper alignment and tension.

- Refill the cooling system with the recommended coolant mixture and purge any air pockets following the proper bleeding procedure.

Replacing the water pump, including the faulty bearing, should eliminate the noise and restore proper functionality to the cooling system. It is crucial to use high-quality replacement parts that are compatible with your vehicle’s make and model.

If you are unsure about replacing the water pump bearing yourself or encounter any difficulties during the process, it is advisable to seek the assistance of a professional mechanic to ensure the job is done correctly.

Addressing Water Pump Cavitation

Water pump cavitation can be a common cause of water pump noise when the engine is cold. Cavitation occurs when the water pump’s impeller spins at a speed that exceeds the flow rate of coolant, resulting in the formation of air bubbles that collapse and create noise. Here are the steps to address water pump cavitation:

- Check the coolant level in the radiator or coolant reservoir. Low coolant levels can contribute to cavitation. If the coolant level is low, refill it to the recommended level using the appropriate coolant mixture as specified by the manufacturer.

- Inspect the cooling system for any restrictions or blockages that may impede the flow of coolant. Check for clogged hoses, a blocked radiator, or a malfunctioning thermostat. Clear any obstructions if necessary.

- Consider using a coolant additive specifically designed to reduce cavitation. These additives create a protective layer on the water pump’s impeller, minimizing the formation of air bubbles. Follow the instructions provided by the additive manufacturer for proper usage and dosage.

- Verify the functionality of the radiator cap or coolant reservoir cap. A faulty cap can contribute to cavitation by allowing air to enter the cooling system. Replace the cap if needed.

- If the cavitation issue persists, it may be necessary to replace the water pump. Consult the vehicle’s service manual or a repair guide for specific instructions on how to remove and replace the water pump assembly.

- When replacing the water pump, ensure that the new pump matches the specifications and requirements of your vehicle. Use quality replacement parts to ensure reliable performance.

- During the installation of the new water pump, make sure to properly align and tighten all mounting bolts and reconnect any hoses and electrical connectors.

- Refill the cooling system with the appropriate coolant mixture and follow the recommended bleeding procedure to remove any trapped air pockets.

By addressing water pump cavitation, you can minimize noise and optimize the performance of the cooling system. Regular maintenance and inspection are crucial to prevent cavitation and ensure efficient cooling.

If you are unsure about the cause or resolution of water pump cavitation or encounter difficulties during the process, it is recommended to consult a professional mechanic for further diagnosis and assistance.

Check the coolant level and condition, as low levels or old coolant can cause the water pump to make noise when cold. Also, inspect the water pump for leaks or damage.

Verifying and Replacing the Thermostat

If a faulty thermostat is causing water pump noise when the engine is cold, verifying and replacing the thermostat can help resolve the issue. The thermostat plays a critical role in regulating engine temperature and coolant flow. Follow these steps to verify and replace the thermostat:

- Start by visually inspecting the thermostat housing and surrounding components for any signs of leaks, cracks, or damage. A faulty thermostat housing or gasket can affect the proper operation of the thermostat.

- Next, check the engine temperature gauge while the engine is running. If the engine takes an excessively long time to reach operating temperature or if it overheats, it may indicate a problem with the thermostat.

- If you suspect a faulty thermostat, it is recommended to replace it. Consult the vehicle’s service manual or a repair guide for specific instructions on how to remove and replace the thermostat.

- Before you begin the replacement process, ensure that the engine is cool and the vehicle is parked on a level surface. Drain the coolant from the cooling system to prevent any spills or contamination.

- Locate the thermostat housing, which is typically attached to the engine block and connected to the upper radiator hose. Carefully remove any components, such as air intake ducts or hose clamps, that may obstruct access to the thermostat housing.

- Disconnect the hoses and electrical connectors attached to the thermostat housing. Take note of their positions for reinstallation.

- Remove the mounting bolts securing the thermostat housing. Carefully lift off the housing and remove the old thermostat.

- Clean the mating surfaces of the thermostat housing and engine block to ensure a proper seal with the new thermostat.

- Install the new thermostat according to the manufacturer’s instructions, making sure it is properly seated and aligned with the housing. Use a new gasket or sealant as recommended.

- Reassemble the components, reattach the hoses and electrical connectors, and tighten the mounting bolts to the specified torque.

- Refill the cooling system with the appropriate coolant mixture and follow the recommended bleeding procedure to remove any air pockets.

Replacing a faulty thermostat should restore proper coolant flow and help eliminate water pump noise. It is important to use a high-quality replacement thermostat that is compatible with your vehicle’s make and model.

If you are unsure about replacing the thermostat yourself or encounter any difficulties during the process, it is advisable to seek the assistance of a professional mechanic to ensure the job is done correctly.

Conclusion

Water pump noise when the engine is cold can be a cause for concern, as it may indicate underlying issues with the cooling system. Understanding the common causes of water pump noise and knowing how to resolve them is essential for maintaining the health and performance of your vehicle.

In this article, we have explored the common causes of water pump noise, including air pockets in the system, loose or worn belts, faulty water pump bearings, water pump cavitation, and thermostat issues. We have provided step-by-step instructions on how to address each of these issues to resolve water pump noise effectively.

Bleeding the cooling system can help remove air pockets and ensure proper coolant flow. Inspecting and adjusting the belt can ensure that it is in good condition and properly tensioned. Checking and replacing the water pump bearing can eliminate noise caused by a faulty bearing. Addressing water pump cavitation involves checking coolant levels, inspecting the cooling system for restrictions, using additives, and checking the functionality of the radiator cap. Verifying and replacing a faulty thermostat can restore proper coolant flow and regulate the engine’s temperature.

By following these steps and properly maintaining your vehicle’s cooling system, you can resolve water pump noise when the engine is cold, prevent potential damage to the engine, and ensure efficient and reliable performance.

However, if you are unsure about any of the procedures or encounter difficulties during the process, it is always recommended to seek the assistance of a professional mechanic. They have the expertise and knowledge to accurately diagnose and resolve issues related to the water pump and cooling system.

Remember, regular maintenance and periodic inspections of the water pump and cooling system are crucial for identifying and addressing any potential issues before they escalate. By staying proactive, you can enjoy a smoothly running vehicle with minimal water pump noise and optimal cooling performance.

Frequently Asked Questions about What Noise Does A Cold Water Pump Make?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Noise Does A Cold Water Pump Make?”