Articles

What Size Tubing For Kegerator

Modified: October 19, 2024

Find out the ideal size of tubing for your kegerator with our informative articles that cover all the essential aspects of choosing the right tubing.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When setting up a kegerator, there are many factors to consider to ensure that you have the perfect pour. One crucial element that often goes overlooked is the tubing size. The right tubing size not only affects the flow of beer but also plays a significant role in maintaining the quality and taste of your brew.

In this article, we will explore the different factors to consider when choosing tubing for a kegerator, the common tubing sizes available, and the benefits of each size. We will also provide you with tips on how to determine the correct tubing size for your specific kegerator setup and guide you through the installation process.

By the end of this article, you will have a clear understanding of the importance of tubing size and be equipped with the knowledge to make an informed decision for your kegerator setup.

Key Takeaways:

- Choose the right tubing size for your kegerator based on factors like material, inner diameter, and length to ensure optimal beer quality and a smooth pouring experience.

- Consider the benefits of different tubing sizes, such as 3/16 inch for home kegerators and 5/16 inch for gas lines, to meet specific beer serving needs and kegerator setups.

Read more: What Size Chest Freezer For Kegerator

Factors to Consider When Choosing Tubing for a Kegerator

Choosing the right tubing for your kegerator is crucial for maintaining the quality and taste of your beer. Here are some key factors to consider when making your decision:

- Material: The material of the tubing is an important consideration as it can affect the taste and cleanliness of your beer. Food-grade vinyl and polyurethane tubes are popular choices due to their durability, flexibility, and resistance to low temperatures. Avoid using regular PVC tubing as it can impart a plastic taste to your beer.

- Inner Diameter: The inner diameter of the tubing determines the flow rate of the beer. A larger diameter allows for faster flow, while a smaller diameter may result in a slower pour. It is important to strike the right balance based on your personal preferences and the type of beer you will be serving.

- Length: The length of the tubing is another crucial factor to consider. Longer tubing can lead to more resistance and slower flow, while shorter tubing may result in excessive foaming. Take into account the distance between your keg and faucet when determining the appropriate tubing length.

- Temperature Resistance: Beer needs to be kept at the proper temperature to maintain its flavor and carbonation. Make sure the tubing you choose is capable of withstanding the temperature requirements of your kegerator setup. Look for tubing with a high temperature rating to ensure it can handle the cold temperatures.

- UV Resistance: If your kegerator will be exposed to sunlight or other sources of UV light, it is important to choose tubing that is UV resistant. UV exposure can degrade the tubing over time, leading to potential leaks or off-flavors in your beer.

Considering these factors will help you select the right tubing for your kegerator, ensuring optimal beer quality and a smooth pouring experience.

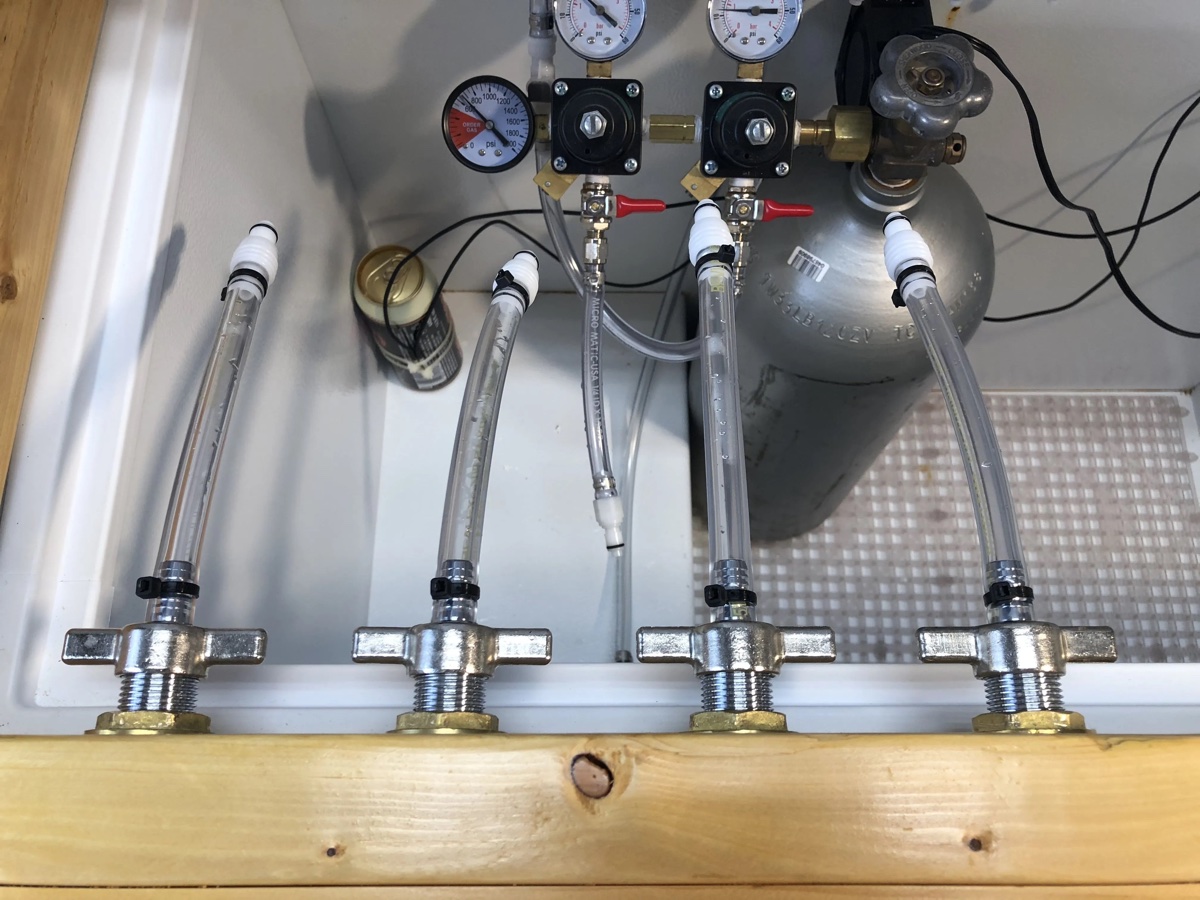

Common Tubing Sizes for Kegerators

When it comes to tubing sizes for kegerators, there are a few standard options that are commonly used. These sizes vary based on the inner diameter of the tubing. Here are the most common tubing sizes for kegerators:

- 3/16 inch: This is the most widely used tubing size for kegerators. It has an inner diameter of 3/16 inch (4.8mm) and is well-suited for most beer dispensing systems. It provides a good balance between flow rate and resistance, resulting in a smooth pour with minimal foam.

- 1/4 inch: 1/4 inch (6.4mm) tubing is less commonly used in kegerators but can be suitable for certain setups. It allows for a faster flow rate, which is ideal for commercial kegerators or setups that require a longer beer line length.

- 5/16 inch: 5/16 inch (7.9mm) tubing is often used for gas lines in kegerators. It provides a larger diameter for better pressure flow, making it ideal for delivering CO2 from the regulator to the keg.

- 3/8 inch: 3/8 inch (9.5mm) tubing is less common in kegerators but is sometimes used for beer dispensing in commercial setups. It provides a faster flow rate, which can be beneficial for establishments that require high-volume beer service.

These common tubing sizes provide flexibility to meet different kegerator setups and requirements. It’s essential to choose a tubing size that is compatible with your specific kegerator system and beer serving needs.

Benefits of Different Tubing Sizes

Each tubing size for kegerators offers its own set of benefits. Understanding these benefits will help you determine which size is most suitable for your specific needs. Let’s explore the advantages of different tubing sizes:

- 3/16 inch: The 3/16 inch tubing size is popular for a reason. Its smaller inner diameter creates enough resistance to balance the flow rate, resulting in a smooth and controlled pour. This size is ideal for home kegerators and most beer types, ensuring a well-balanced pour with minimal foam. It offers versatility and is compatible with various faucet types and couplers.

- 1/4 inch: If you have a commercial kegerator or require longer beer line lengths, the 1/4 inch tubing size can be advantageous. It allows for a faster flow rate, ensuring quicker beer delivery. This is particularly useful in high-volume settings where efficiency is key. However, be mindful that with faster flow, there is an increased risk of excessive foaming if not properly balanced.

- 5/16 inch: With its larger diameter, the 5/16 inch tubing size is commonly used for gas lines in kegerators. It offers better pressure flow for delivering CO2 from the regulator to the keg. This size ensures the proper carbonation of your beer and helps maintain a consistent flow. If you have a kegerator with multiple kegs or need to dispense beer over longer distances, 5/16 inch tubing can be beneficial.

- 3/8 inch: Although less common in kegerators, the 3/8 inch tubing size is advantageous for high-volume beer dispensing in commercial environments. It allows for a fast flow rate, enabling quick service to meet customer demands. This size is suitable for establishments such as bars, restaurants, or venues that require an efficient beer delivery system.

Considering the benefits of different tubing sizes will help you make an informed decision based on your specific requirements and the type of kegerator setup you have.

When choosing tubing for your kegerator, use 3/16 inch ID (inner diameter) tubing. This size provides the right balance of flow resistance and flexibility for dispensing beer.

How to Determine the Correct Tubing Size for Your Kegerator

Determining the correct tubing size for your kegerator is crucial to ensure optimal beer flow and minimize issues such as excessive foam. Here are some steps to help you determine the right tubing size:

- Consider your setup: Take into account the specific details of your kegerator setup, such as the distance between the keg and the faucet, the type of beer you will be serving, and the desired flow rate. These factors will play a significant role in determining the appropriate tubing size.

- Research recommended tubing sizes: Research the recommended tubing sizes for the type of kegerator you have. Different kegerators may come with specific tubing size recommendations based on their design and intended use. Check the manufacturer’s guidelines or consult with experts in the field to get accurate information.

- Consider the type of beer you will be serving: Different beer styles have varying carbonation levels and viscosity. High carbonation beers like lagers may require smaller tubing sizes to maintain the proper flow rate and prevent excessive foaming. Beers with lower carbonation levels, like stouts or ales, may work well with larger tubing sizes.

- Experiment and adjust: If you are unsure of the ideal tubing size, you may need to experiment and make adjustments based on your specific setup. Start with a standard size, such as 3/16 inch tubing, and monitor the flow rate and foam levels. If you experience excessive foaming or slow dispense, consider trying a slightly larger or smaller tubing size to find the optimal balance.

- Consider professional advice: If you are still unsure or struggling to determine the correct tubing size, it may be beneficial to seek advice from professionals or experienced homebrewers. They can provide valuable insights and recommendations based on their expertise and experience.

By considering these steps and factors, you can determine the correct tubing size for your kegerator setup, ensuring a smooth and enjoyable beer pouring experience.

Read more: What Size Of Keg Fits For Kegerator

Installation Tips for Tubing in a Kegerator

Installing tubing in a kegerator is a crucial step to ensure proper beer flow and maintain the quality of your brew. Here are some helpful installation tips to guide you:

- Clean and sanitize: Before installing the tubing, make sure to clean and sanitize all components of your kegerator, including the faucet, beer lines, and connectors. This helps prevent any contamination that could impact the taste and quality of your beer.

- Measure and cut: Measure the necessary length of tubing based on the distance between the keg and the faucet. It’s recommended to use a sharp knife or tubing cutter to achieve a clean and precise cut.

- Secure connections: Ensure that all connections between the tubing and the keg, couplers, and faucet are secure and leak-free. Use appropriate clamps or fittings to hold the tubing securely in place, but avoid overtightening, as this can cause damage to the tubing or connections.

- Route tubing properly: Pay attention to the routing of the tubing to minimize any kinks or bends that can restrict the flow of beer. Avoid sharp bends or twists that can cause excessive resistance and affect the pouring experience.

- Test for leaks: After installation, carefully inspect all connections for any signs of leakage. A simple test is to pressurize the system and check for any visible leaks or drips. Correct any leaks immediately to prevent beer or gas loss and maintain optimal performance.

- Regular maintenance: Regularly inspect and clean your tubing to ensure it remains in good condition and free from any buildup or contamination. Replace the tubing as needed to maintain the quality of your beer and prevent any potential issues.

- Keep tubing protected: It’s important to protect the tubing from UV light, extreme temperatures, and physical damage. Consider using insulation or tubing wraps to safeguard the tubing and maintain its performance.

By following these installation tips, you can ensure proper tubing placement in your kegerator, allowing for optimal beer flow and maintaining the integrity of your brew.

Conclusion

Choosing the right tubing for your kegerator is crucial for ensuring a smooth and enjoyable beer pouring experience. By considering factors such as material, inner diameter, length, temperature resistance, and UV resistance, you can select the tubing that best suits your specific needs and preferences.

Common tubing sizes, including 3/16 inch, 1/4 inch, 5/16 inch, and 3/8 inch, offer different benefits and are suitable for various kegerator setups. Whether you’re a homebrewer or running a commercial establishment, there is a tubing size that will meet your requirements.

Determining the correct tubing size for your kegerator involves considering your setup, researching recommendations, considering the type of beer you’ll be serving, experimenting, and seeking professional advice if needed. These steps will help you achieve the optimal balance between flow rate and foam control.

During installation, ensure you clean and sanitize all kegerator components, accurately measure and cut the tubing, secure connections properly, and test for leaks. Regular maintenance and protection of the tubing will also contribute to the longevity and quality of your kegerator system.

In conclusion, proper tubing selection and installation are essential for maintaining the taste and quality of your beer. By paying attention to these details, you can enjoy a perfect pour every time. Cheers to a well-crafted kegerator setup!

Frequently Asked Questions about What Size Tubing For Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Size Tubing For Kegerator”