Home>Articles>What Type Of Energy Does An Electric Motor Create?

Articles

What Type Of Energy Does An Electric Motor Create?

Modified: August 27, 2024

"Discover how an electric motor converts electrical energy into mechanical energy through this informative article. Learn the principles behind this fascinating process."

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors are essential components in various devices and appliances that we use in our daily lives. From powering household appliances to propelling electric vehicles, electric motors play a crucial role in converting electrical energy into mechanical energy. But have you ever wondered how an electric motor accomplishes this conversion? In this article, we will explore the fascinating world of electric motors and delve into the process of converting electric energy into mechanical energy.

Electric motors are a significant part of our modern technological landscape, enabling countless devices, machinery, and transportation systems to function efficiently. Whether it’s the spinning of a washing machine drum, the rotation of a fan, or the propelling force in an electric car, electric motors are at the heart of it all.

Understanding how electric motors work and the type of energy they convert is crucial for comprehending the underlying principles of numerous applications and technologies. This knowledge will shed light on the significance of electric motors in our lives and the advancements made in the field of electrical engineering.

So, let’s embark on a journey of discovery and uncover the secrets behind the conversion of electric energy into mechanical energy with the help of electric motors.

Key Takeaways:

- Electric motors are the powerhouse behind countless devices, converting electrical energy into mechanical energy through the interaction of magnetic fields. Their versatility and efficiency drive innovation and sustainability in our modern world.

- From electric vehicles to industrial machinery, electric motors power a diverse range of applications, offering precise control and reliability. As technology advances, ongoing innovations aim to enhance efficiency and minimize environmental impact, shaping a more sustainable future.

Read more: What Does An Electric Motor Do

Electric Motors: An Overview

Electric motors are devices that convert electrical energy into mechanical energy. They are widely used in various industries and applications, ranging from transportation to manufacturing, HVAC systems, robotics, and more. Electric motors are crucial in the functioning of appliances, machinery, and vehicles, making them indispensable in today’s modern world.

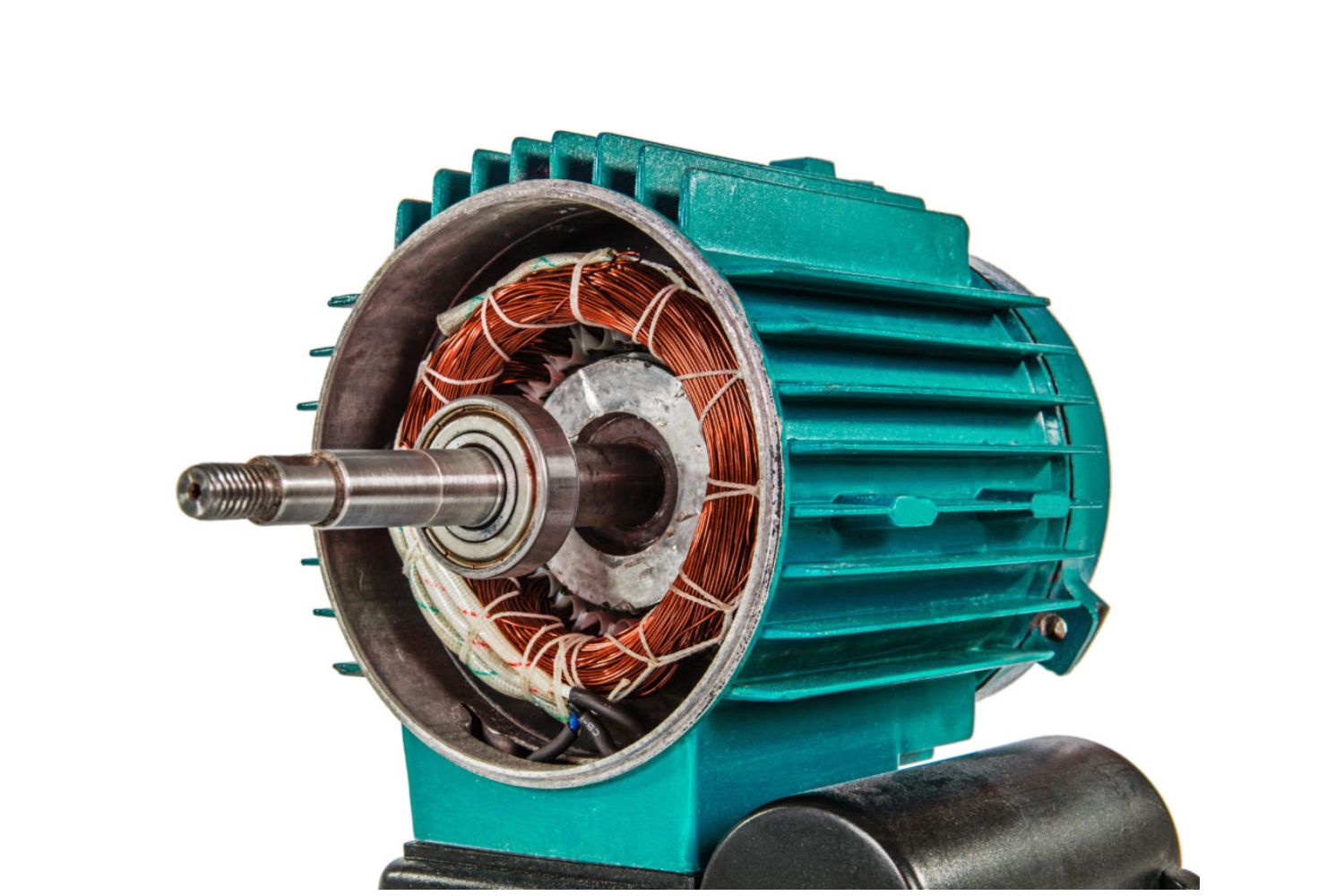

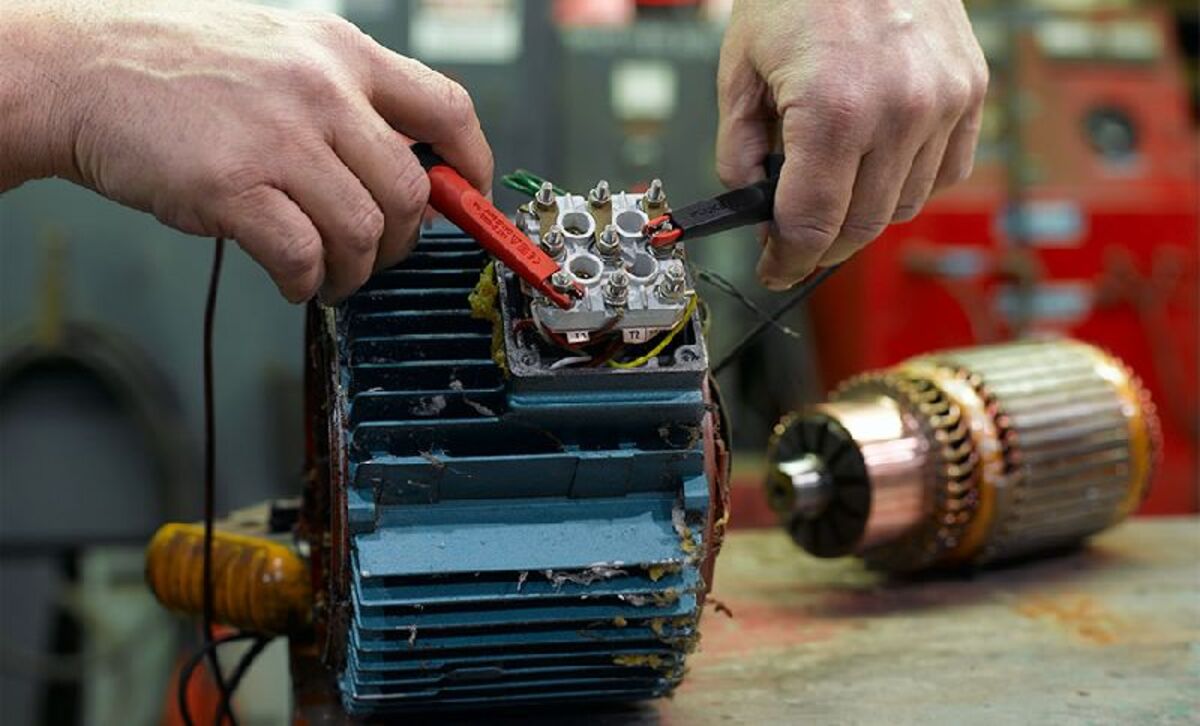

At their core, electric motors consist of a stator, rotor, and a power source. The stator is the stationary part of the motor that houses the windings, while the rotor is the rotating part connected to the load being driven. When an electric current is supplied to the motor, it creates a magnetic field that interacts with the magnetic field produced by the rotor.

This interaction leads to a force that generates rotational motion, thereby converting electrical energy into mechanical energy. The size and design of the motor may vary based on its intended application, with different types of electric motors available to meet various needs.

Electric motors are highly efficient devices, offering advantages such as high power-to-weight ratio, low maintenance requirements, and precise control over rotational speed and torque. They are also environmentally friendly, producing zero exhaust emissions when powered by renewable energy sources.

Due to their versatility and efficiency, electric motors have become a key focus area for technological advancements. Innovations in motor design, materials, and control systems aim to further enhance their performance, reliability, and energy efficiency.

In the following sections, we will explore the inner workings of electric motors in detail, discussing how they convert electric energy into mechanical energy and understanding the different types of electric motors available in the market.

How Electric Motors Work

Electric motors work on the principle of electromagnetic induction, which means that they utilize the interaction between electrical currents and magnetic fields to produce mechanical motion. Understanding the basic working principle of electric motors is essential to grasp their functionality.

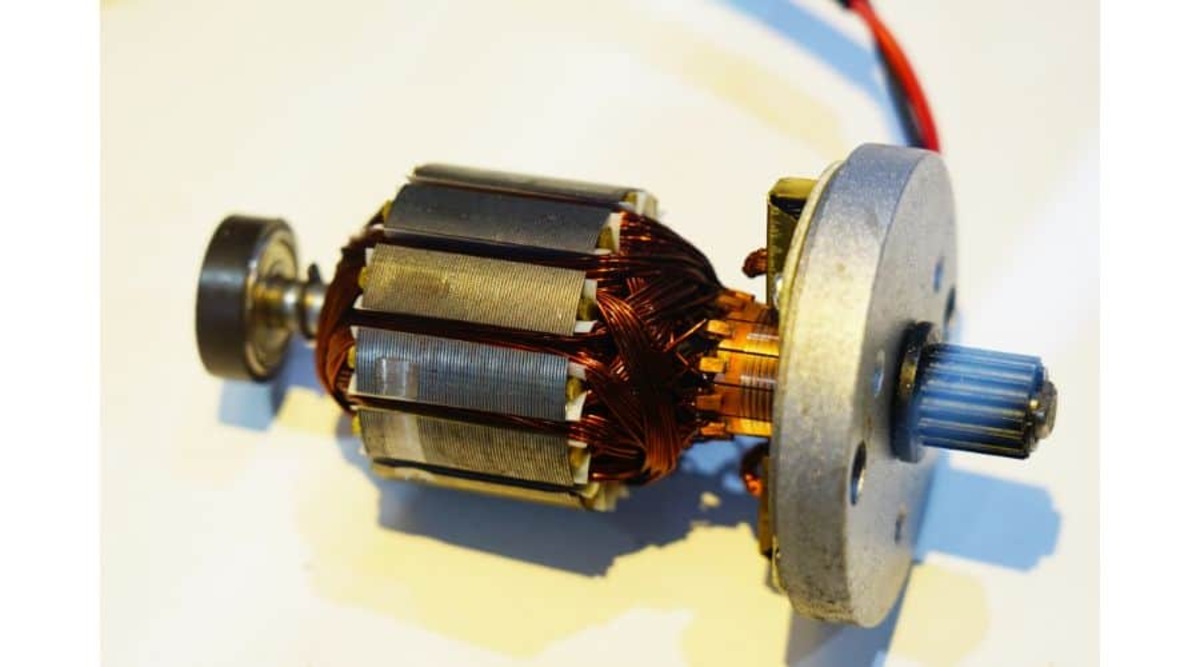

Electric motors typically consist of two main components: a rotor and a stator. The stator is a stationary part of the motor that houses the winding arrangement, while the rotor is the rotating part. The stator contains a set of coils made from conducting wire, which is wound in a specific pattern to create a magnetic field.

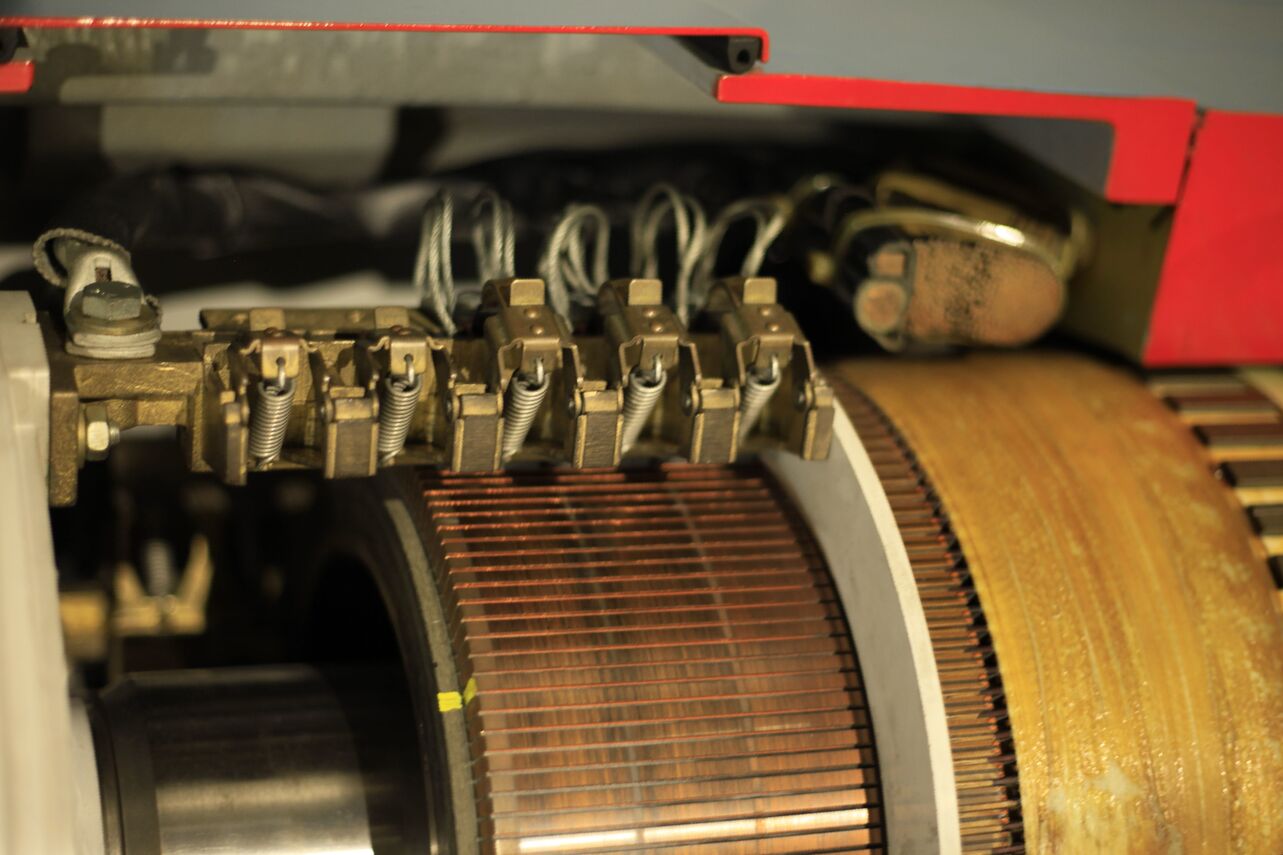

When an electric current flows through these coils, it generates a magnetic field around them. This magnetic field interacts with the magnetic field produced by the rotor, which causes the rotor to start rotating. The rotating motion is then transferred to the connected load, such as a fan or a conveyor belt, which performs the desired mechanical work.

There are various types of electric motors, each employing slightly different mechanisms to convert electrical energy into mechanical energy. However, the fundamental concept remains the same – the interaction between magnetic fields generated by the stator and the rotor.

The direction of the current flowing through the coils of the stator determines the direction of the magnetic field. By controlling the flow of current, it is possible to control the speed and direction of the motor’s rotation. This precise control allows for the smooth operation and efficient performance of electric motors in a wide range of applications.

Moreover, electric motors operate based on the principle of conservation of energy. The electrical energy supplied to the motor is converted into mechanical energy, following the law of energy conversion. By optimizing the design, materials, and control systems of electric motors, engineers strive to maximize their efficiency and minimize energy losses.

In summary, electric motors convert electrical energy into mechanical energy by utilizing the interaction between magnetic fields generated by the stator and the rotor. This mechanism forms the foundation of various types of electric motors and enables their widespread use across different industries and applications.

Conversion of Electric Energy

The conversion of electric energy into mechanical energy is a fundamental process that takes place within electric motors. This conversion is made possible through the key principles of electromagnetism and electromagnetic induction.

When an electric current flows through the coils of the stator, a magnetic field is created around them. This magnetic field interacts with the magnetic field produced by the rotor, resulting in a force that causes the rotor to rotate. As the rotor rotates, it transfers mechanical energy to the connected load, such as a fan or a pump, enabling it to perform its intended function.

This conversion process occurs due to the inherent relationship between electricity and magnetism. When an electric current flows through a wire, it generates a magnetic field. Similarly, when a magnetic field is in motion near a wire, it induces an electric current in the wire. This phenomenon, known as electromagnetic induction, is vital in the functioning of electric motors.

In an electric motor, a continuous flow of electrical energy is used to maintain a magnetic field in the stator. This magnetic field interacts with the magnetic fields in the rotor, creating a rotating force that drives the rotor’s motion. As a result, the electrical energy is converted into mechanical energy, allowing the motor to perform its intended task.

It’s important to note that the efficiency of this conversion process varies between different types of electric motors. Factors that affect the efficiency include the motor’s design, the quality of its components, and the control systems in place. Engineers continuously strive to improve motor efficiency to minimize energy losses and maximize the amount of converted energy.

Moreover, the conversion of electric energy is not limited to just mechanical energy. Electric motors can also be designed to convert electric energy into other forms such as hydraulic energy or rotational energy. These specialized motors have distinct applications and are used in various industries.

Overall, the conversion of electric energy into mechanical energy is at the heart of electric motors. By harnessing the principles of electromagnetism and electromagnetic induction, these devices play a vital role in powering numerous devices and systems, making our lives more efficient and convenient.

An electric motor converts electric energy into mechanical energy, which is used to produce motion or perform work.

Types of Electric Motors

There are several different types of electric motors, each designed to meet specific requirements and applications. These motors vary in their construction, operation, and functionality, allowing for versatility in various industries. Here are some common types of electric motors:

- DC Motors: DC motors, or direct current motors, are widely used in applications where precise speed control is required. They operate on the principle of a magnetic field’s interaction with a current-carrying conductor, creating rotational motion. DC motors are commonly found in robotics, electric vehicles, and small appliances.

- AC Motors: AC motors, or alternating current motors, are the most commonly used motors in the industry. They operate on the principle of magnetic fields generated by alternating currents, resulting in rotational motion. AC motors are known for their reliability and simplicity, making them suitable for a wide range of applications, including HVAC systems, industrial machinery, and household appliances.

- Induction Motors: Induction motors are a type of AC motor that utilizes electromagnetic induction to generate rotational motion. They are highly efficient, durable, and require minimal maintenance. Induction motors are widely used in industrial applications, such as pumps, compressors, and fans.

- Synchronous Motors: Synchronous motors operate at a fixed speed and maintain constant rotational synchronization with the frequency of the AC power supply. They are commonly used in applications requiring high torque at low speeds, such as conveyors and large machinery.

- Brushless DC Motors: Brushless DC motors are similar to traditional DC motors, but they eliminate the need for mechanical brushes and commutators. These motors offer improved efficiency, reliability, and lifespan, making them ideal for applications like electric vehicles, drones, and industrial automation.

- Stepper Motors: Stepper motors are specialized motors designed for precise position control. They divide a full rotation into a series of steps and can hold their position without using external feedback. Stepper motors are commonly used in CNC machines, printers, and robotics.

Each type of electric motor has its advantages and is suitable for specific applications based on factors such as speed control requirements, torque output, energy efficiency, and operational stability. Engineers carefully select the appropriate motor type to optimize performance and ensure it meets the specific needs of the desired application.

As technology advances, new types of electric motors continue to emerge, offering enhanced efficiency, compact size, and improved performance. The evolution of electric motor technology is driven by the need for more sustainable and energy-efficient solutions in today’s rapidly changing world.

Applications of Electric Motors

Electric motors play a vital role in numerous industries and applications, powering a wide range of devices and machinery. Their versatility, efficiency, and precise control make electric motors a cornerstone of modern technology. Here are some common applications of electric motors:

- Transportation: Electric motors are widely used in the transportation sector, particularly in electric vehicles (EVs) and hybrid vehicles. Electric motors provide the necessary propulsion, allowing EVs to operate without relying on fossil fuels. Additionally, electric motors are utilized in trains, trams, ships, and aircraft systems for various functions, such as propulsion, steering, and power generation.

- Manufacturing and Robotics: Electric motors find extensive usage in manufacturing industries for driving conveyor systems, assembly lines, robotic arms, and machinery. Their precise control over speed and torque enables smooth and efficient production processes, ensuring consistent quality and productivity.

- Appliances: Electric motors are an integral part of everyday home appliances, such as refrigerators, washing machines, vacuum cleaners, and air conditioners. These motors provide the necessary mechanical motion for functions like cooling, rotating, and pumping. The efficiency and reliability of electric motors contribute to the overall performance of these appliances.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems rely on electric motors to power fans, blowers, and compressors. Electric motors provide the necessary airflow, allowing for effective temperature regulation and air circulation in residential, commercial, and industrial buildings.

- Industrial Machinery: Various types of electric motors are used in industrial machinery, such as pumps, compressors, generators, and mixers. These motors drive the mechanical components of the machinery, allowing for efficient operation and precise control over the manufacturing processes.

- Aerospace and Defense: Electric motors are employed in aerospace and defense applications for tasks such as actuating control surfaces, operating landing gear systems, powering missile systems, and driving aircraft generators. The lightweight and efficient nature of electric motors make them suitable for these critical missions.

- Renewable Energy Systems: Electric motors are used in renewable energy systems, such as wind turbines and hydroelectric generators. These motors convert the mechanical energy harvested from wind or water into electrical energy, contributing to the production of clean and sustainable power.

The applications of electric motors extend far beyond the examples mentioned above. Electric motors are integral in medical equipment, consumer electronics, agriculture, entertainment systems, and many other sectors. Their reliability, efficiency, and environmental friendliness make electric motors indispensable in the modern world, driving innovation and enabling a more sustainable future.

Conclusion

Electric motors are remarkable devices that convert electrical energy into mechanical energy, powering a vast array of applications and technologies in our daily lives. From the appliances in our homes to the machinery in factories, and even the vehicles on our roads, electric motors play a pivotal role in delivering functionality and efficiency.

By harnessing the principles of electromagnetism and electromagnetic induction, electric motors enable the conversion of electrical energy into mechanical energy, driving rotational motion and performing various tasks. The stator and rotor components, combined with precise control systems, allow for the seamless and efficient operation of these motors.

There are several types of electric motors to suit different requirements and applications. DC motors, AC motors, induction motors, synchronous motors, brushless DC motors, and stepper motors all offer unique advantages depending on factors such as speed control, torque output, and energy efficiency.

The applications of electric motors are vast and diverse. They power electric vehicles, aid in manufacturing processes, drive appliances, regulate HVAC systems, operate industrial machinery, contribute to aerospace and defense systems, and enable renewable energy generation.

As technology advances and the need for sustainability grows, electric motors continue to evolve. Ongoing innovations in motor design, materials, and control systems aim to improve efficiency, reduce energy consumption, and minimize environmental impact.

In conclusion, electric motors are a fundamental and essential part of our modern world. Their ability to convert electrical energy into mechanical energy and their wide range of applications make them indispensable. Advancements in electric motor technology hold the key to creating a more efficient, sustainable, and technologically advanced future.

Frequently Asked Questions about What Type Of Energy Does An Electric Motor Create?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Type Of Energy Does An Electric Motor Create?”