Home>Articles>How To Identify Different Types Of Electric Motors

Articles

How To Identify Different Types Of Electric Motors

Modified: January 4, 2024

Learn how to identify different types of electric motors in this informative article. Gain valuable knowledge on electric motor types and their applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors are essential components in countless machines and devices that we use in our everyday lives. From powering household appliances to driving industrial machinery, electric motors play a crucial role in various applications. Understanding the different types of electric motors is important not only for those working in the field of electrical engineering but also for anyone who wants to have a deeper understanding of how these motors operate.

In this article, we will explore the various types of electric motors and discuss their distinguishing features and applications. By the end, you will have a better understanding of how to identify different types of electric motors based on their characteristics.

Before we dive into the specific types of electric motors, it’s important to note that all electric motors operate based on the fundamental principle of electromagnetism. This principle involves the interaction between electrical currents and magnetic fields, which results in the conversion of electrical energy into mechanical motion.

Now, let’s get started with the first type of electric motor – induction motors.

Key Takeaways:

- Induction motors are reliable and cost-effective, ideal for industrial applications requiring constant speed. However, they lack precise speed control and are unsuitable for high starting torque needs.

- Brushless DC motors offer superior efficiency, durability, and precise control, making them increasingly popular in various industries. They operate quietly, generate less heat, and have a longer lifespan.

Induction Motors

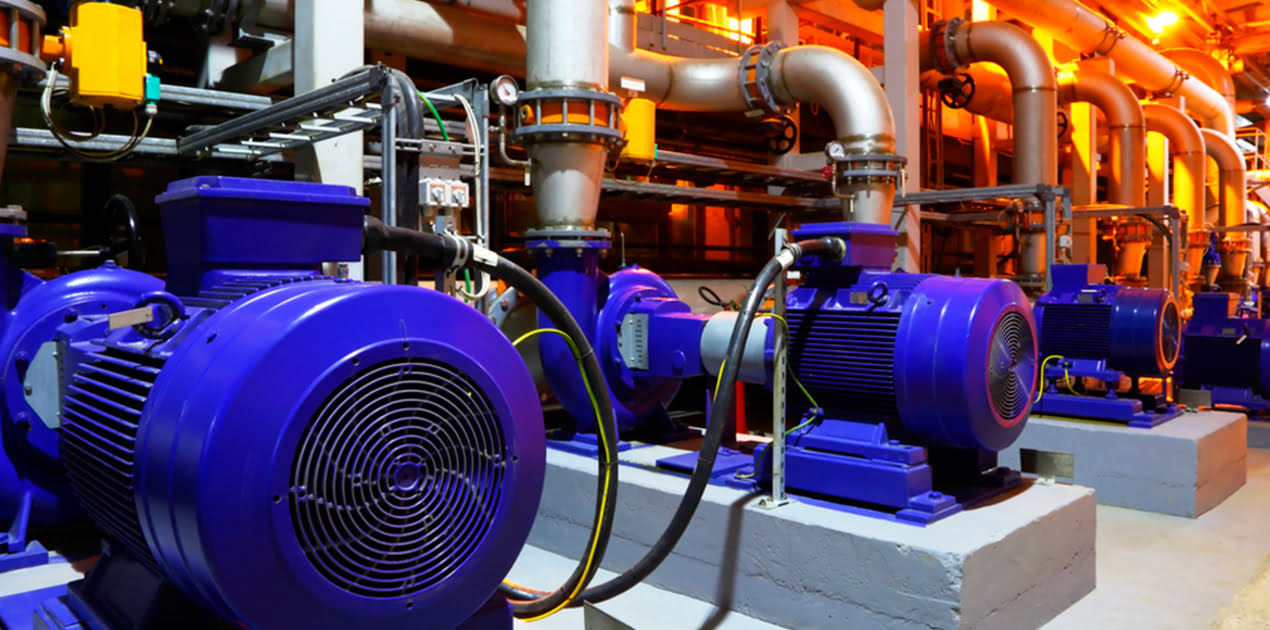

Induction motors are one of the most widely used types of electric motors due to their simplicity, reliability, and cost-effectiveness. These motors work on the principle of electromagnetic induction, where a rotating magnetic field is created by the interaction of multiple electromagnets.

Induction motors consist of two main components – a stationary stator and a rotating rotor. The stator is made up of a set of copper windings that are connected to an alternating current (AC) power supply. When the AC current flows through the windings, it creates a rotating magnetic field.

The rotor, on the other hand, is made up of laminated iron cores and conductive bars. As the rotating magnetic field generated by the stator interacts with the rotor, it induces currents in the conductive bars, creating a magnetic field in the rotor. The interaction between the rotating magnetic field and the induced magnetic field in the rotor causes the rotor to rotate.

Induction motors are known for their high reliability and low maintenance requirements. They are widely used in HVAC systems, pumps, compressors, and various industrial applications where a constant speed is required. These motors are available in both single-phase and three-phase configurations, with three-phase motors being more common and efficient.

While induction motors offer many advantages, they have some limitations as well. One of the main drawbacks is their inability to provide precise speed control. Additionally, induction motors are not suitable for applications that require high starting torque or constant torque over a wide speed range.

Overall, induction motors are highly versatile and widely used in various applications where reliability, simplicity, and cost-effectiveness are paramount.

Synchronous Motors

Synchronous motors are another type of electric motor commonly used in industrial applications. Unlike induction motors that rely on the interaction between rotating magnetic fields, synchronous motors operate based on the synchronism between the stator and rotor magnetic fields.

Similar to induction motors, synchronous motors consist of a stator and a rotor. The stator windings are connected to an AC power supply, which creates a rotating magnetic field. However, the rotor in synchronous motors is designed with permanent magnets or electromagnets. These magnets create a fixed magnetic field in the rotor.

The key characteristic of synchronous motors is that the rotor rotates at the same speed as the rotating magnetic field created by the stator. This synchronization is achieved by controlling the frequency and phase of the AC power supply. As a result, synchronous motors offer precise speed control and are commonly used in applications that require highly accurate and constant speed, such as in electric clocks, electric generators, and certain industrial machinery.

One notable advantage of synchronous motors is their ability to provide a leading power factor. This means they can help improve the overall efficiency of the power system by compensating for the lagging power factor caused by inductive loads. Synchronous motors are also efficient in converting electrical energy into mechanical energy.

However, synchronous motors have some drawbacks as well. They require complex control systems to maintain synchronization between the stator and rotor, which can increase costs. Additionally, synchronous motors require an external power source to generate the magnetic field in the rotor, which can limit their applications in certain scenarios.

Overall, synchronous motors are highly suitable for applications that require precise speed control and improved power factor, making them a preferred choice in various industrial and power generation settings.

Brushed DC Motors

Brushed DC motors, also known as commutator motors, are a type of electric motor that operate based on the principles of direct current (DC) and electromagnetic fields. These motors are widely used in applications that require simple control and moderate speed ranges.

The basic construction of a brushed DC motor consists of a stationary stator and a rotating armature. The stator contains permanent magnets that create a magnetic field, while the armature is made up of multiple coils of wire that generate electromagnetic fields when current flows through them.

One of the distinguishing features of brushed DC motors is the presence of a commutator and brushes. The commutator is a segmented cylinder that is attached to the armature, and the brushes are spring-loaded conductive contacts that maintain contact with the commutator segments.

As the current flows through the armature coils, the commutator and brushes continuously switch the direction of the current in each coil, creating a rotating electromagnetic field that interacts with the fixed magnetic field of the stator. This interaction causes the armature to rotate and drives the motor’s shaft.

Brushed DC motors offer several advantages. They are relatively simple in design and are capable of delivering high torque at low speeds, making them suitable for applications such as robotics, electric vehicles, and household appliances. Furthermore, these motors can be easily controlled by adjusting the voltage applied to the armature.

However, brushed DC motors have some limitations as well. The brushes and commutator require regular maintenance and may cause electrical noise and brush wear over time. Additionally, the friction between the brushes and commutator can limit the motor’s speed and lifespan.

In recent years, the popularity of brushed DC motors has declined due to advancements in brushless DC motor technology, which offers better efficiency and durability. Nevertheless, brushed DC motors still find their applications in various fields where simplicity and cost-effectiveness are crucial.

When identifying an electric motor type, look for the motor’s nameplate which will typically provide information such as the motor’s type, horsepower, voltage, and speed. This information can help you determine the motor’s type.

Brushless DC Motors

Brushless DC motors, often referred to as BLDC motors or electronically commutated motors (ECMs), have gained significant popularity in recent years due to their superior performance, efficiency, and durability compared to brushed DC motors. These motors are widely used in various applications, ranging from consumer electronics to automotive and industrial equipment.

The construction and operating principle of brushless DC motors differ significantly from their brushed counterparts. Instead of using brushes and a commutator, brushless DC motors employ electronic commutation to control the flow of current in the motor’s coils.

The basic components of a brushless DC motor include a stator and a rotor. The stator consists of stationary coils that are arranged in a circular pattern. The rotor, usually equipped with permanent magnets, is located in the center of the motor. Additionally, Hall effect sensors or magnetic encoders are incorporated into the motor to provide feedback about the position of the rotor.

Unlike brushed DC motors, the magnetic fields in a brushless DC motor are controlled by an electronic controller or driver. The controller monitors the Hall effect sensors or magnetic encoders to determine the position of the rotor and applies the appropriate currents to the stator coils. This precise control results in smoother rotation and eliminates the need for brushes, reducing friction and increasing efficiency.

Brushless DC motors offer numerous advantages over brushed DC motors. They operate quietly, generate less heat, and have a longer lifespan due to the absence of brushes, which eliminates brush wear and reduces maintenance requirements. Furthermore, brushless DC motors provide higher power density, faster response times, and improved efficiency, making them suitable for applications that require precise control and high performance.

Although brushless DC motors are generally more expensive than brushed DC motors, their benefits outweigh the initial cost for many applications. These motors are commonly used in drones, electric vehicles, computer cooling fans, HVAC systems, and many other devices that require reliable and efficient motor operation.

Read more: What Type Of Electric Motor Is Used In Cars

Universal Motors

Universal motors are a versatile type of electric motor that can operate on both alternating current (AC) and direct current (DC) power sources. They derive their name from their ability to work with a wide range of power supplies, making them suitable for various applications.

The construction of a universal motor is similar to that of a brushed DC motor, with a few modifications to enable operation on both AC and DC. It consists of a stator and an armature, both of which have coils and a commutator. However, the armature in a universal motor is designed with laminated iron cores and windings that can handle both AC and DC currents.

Universal motors can be powered by either an AC or DC power source due to the way the current flows through the motor. When connected to an AC power source, the motor operates as an induction motor, relying on the interaction between the stator’s magnetic field and the induced current in the rotor. On the other hand, when connected to a DC power source, the motor operates as a traditional brushed DC motor, with the commutator and brushes controlling the direction of the current in the coils.

One of the key advantages of universal motors is their high power-to-weight ratio, making them ideal for applications that require a compact and lightweight motor. They are commonly used in household appliances such as vacuum cleaners, blenders, and power tools, where portability and high speed are essential.

However, universal motors also have some drawbacks. They are known for their high noise levels and tend to generate significant amounts of heat during operation. Additionally, their brushes and commutator require regular maintenance and may need to be replaced periodically.

Despite these limitations, universal motors remain a popular choice in applications where versatility, high speed, and compact size are priorities. They offer the flexibility to operate on both AC and DC power sources, making them suitable for a wide range of appliances and devices.

Conclusion

Electric motors are integral to countless machines and devices, powering our modern world in various applications. Understanding the different types of electric motors is essential for anyone interested in the field of electrical engineering or simply wanting to gain a deeper understanding of how these motors operate.

In this article, we explored the main types of electric motors, including induction motors, synchronous motors, brushed DC motors, brushless DC motors, and universal motors. We discussed their operating principles, applications, advantages, and limitations.

Induction motors, with their simplicity and cost-effectiveness, are widely used in industrial applications that require reliability and a constant speed. Synchronous motors excel in applications demanding precise speed control and improved power factor. Brushed DC motors, known for their simplicity and high torque at low speeds, are commonly utilized in robotics, electric vehicles, and appliances. Brushless DC motors offer superior efficiency, durability, and precise control, making them increasingly popular in various industries. Universal motors stand out for their versatility, as they can operate on both AC and DC power, making them ideal for lightweight and portable applications.

Each type of motor has its own unique characteristics and advantages, allowing for a diverse range of applications. As technology advances, new motor types and variations continue to emerge, providing even more options to meet specific requirements.

Ultimately, understanding the different types of electric motors empowers us to make informed choices when selecting motors for various applications. It allows engineers, technicians, and enthusiasts to optimize performance, efficiency, and cost-effectiveness based on specific needs.

Whether it’s powering household appliances, driving industrial machinery, or propelling electric vehicles, electric motors play an indispensable role in our daily lives. By delving into the intricacies of these motors, we unlock the potential for innovation and advancement in various industries, contributing to a more efficient, sustainable, and electrified world.

Frequently Asked Questions about How To Identify Different Types Of Electric Motors

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Identify Different Types Of Electric Motors”