Home>diy>Building & Construction>What Is Lead Used For In Construction

Building & Construction

What Is Lead Used For In Construction

Modified: January 6, 2024

Discover the various uses of lead in building construction. From roof flashing to soundproofing, lead has a range of applications in the construction industry.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Lead is a versatile material that has been used in a variety of industries, including construction, for centuries. Its unique properties make it an excellent choice for various applications in the building industry.

In this article, we will explore the properties of lead and its uses in construction. From roofing to plumbing, lead proves to be a valuable material that offers durability, functionality, and aesthetic appeal.

So, let’s dive into the world of lead and discover how it has played a vital role in shaping the construction industry.

Key Takeaways:

- Lead has been a staple in construction for centuries, offering durability, weather resistance, and aesthetic appeal in applications such as roofing, flashings, radiation shielding, and historical ornamental details.

- Despite its declining use in some applications due to health concerns, lead continues to be valued for its unique properties, including density, corrosion resistance, and malleability, making it a preferred choice in specific construction needs.

Read more: What Do Lead Construction Engineers Do

Properties of Lead

Before delving into the uses of lead in construction, it is important to understand its unique properties. Lead is a heavy metal with a low melting point and a soft, malleable texture. It is highly resistant to corrosion, which contributes to its durability and long lifespan.

One of the most notable characteristics of lead is its exceptional density. This density provides excellent acoustic and thermal insulation properties, making it an ideal material for soundproofing and energy-efficient construction.

Lead is also highly resistant to radiation, making it an ideal choice for applications requiring radiation shielding. Its ability to absorb and block harmful radiation has made it an essential component in medical facilities, laboratories, and nuclear power plants.

Furthermore, lead has a high resistance to corrosion and weathering, making it suitable for outdoor applications. It can withstand extreme temperatures, moisture, and harsh weather conditions, ensuring its longevity in roofing and cladding installations.

Despite its many beneficial properties, it is important to handle lead with caution, as it can be toxic if ingested or inhaled. Proper safety measures and precautions must be taken during its installation, maintenance, and removal to mitigate any health risks.

Now that we have explored the unique properties of lead, let us discover its various applications in the construction industry.

Lead Uses in Construction

Lead has been utilized in construction for centuries due to its exceptional properties. Let’s explore some of its common applications in the building industry:

-

Roofing

Lead roofs have a long history and are known for their durability and ability to withstand the elements. The malleability of lead allows it to be easily formed and shaped, providing a seamless and watertight roofing solution. It is commonly used in historical buildings, churches, and other structures where aesthetics and longevity are crucial.

-

Flashings and Gutters

Lead is frequently used for flashings and gutters due to its resistance to corrosion. Flashings ensure a waterproof connection between different building components, such as where the roof meets the walls or around chimneys and skylights. Lead gutters offer excellent drainage and can be custom-made to fit any roof shape or size.

-

Read more: How To Get Construction Leads

Radiation Shielding

Lead’s ability to absorb and block radiation makes it an essential material for shielding in areas where radiation exposure must be kept at a minimum. It is commonly used in medical facilities, radiation therapy rooms, and nuclear power plants to protect people and sensitive equipment from harmful radiation.

-

Plumbing

Lead pipes have historically been used for plumbing installations. However, due to health concerns associated with lead exposure, modern plumbing systems now use alternative materials. Nonetheless, lead is still used in specialized plumbing applications, such as for the lining of water storage tanks or in laboratory settings.

-

Wall Cladding

Lead can be used as a decorative cladding material on exterior walls. It adds a unique aesthetic appeal and can be shaped and formed to create intricate designs. Additionally, lead cladding offers weather resistance and serves as a durable exterior finish for buildings.

-

Soundproofing

Lead’s density and acoustic insulation properties make it an excellent choice for soundproofing applications. It can be used as an underlay material in floors, walls, and ceilings to reduce noise transmission both within a building and from the outside environment.

-

Read more: How To Get Leads For Construction Business

Electrical Applications

Lead has good electrical conductivity, making it suitable for various electrical applications. It is commonly used in the production of cables, wires, and electrical connectors. Its malleability allows for easy installation and connection.

-

Historical Use in Construction

Lead has a strong historical significance in construction. It has been used in ornamental details, sculptures, and stained glass windows in grand cathedrals and historical buildings. The aesthetic appeal and versatility of lead made it a favored choice among craftsmen and architects throughout the centuries.

These are just a few examples of how lead is utilized in the construction industry. Despite its declining use in some applications due to health concerns, its unique properties continue to make it a valuable material for specific construction needs.

Roofing

Lead has long been a popular choice for roofing applications due to its exceptional durability and weather resistance. Its malleability allows it to be easily formed and shaped to fit any roof design, providing a seamless, watertight solution.

Lead roofs have a rich history, dating back centuries and commonly found in historical buildings, churches, and prestigious structures. One of the reasons for its continued use in these applications is its aesthetic appeal. The distinctive appearance of lead roofing adds a touch of elegance and charm to any building.

Moreover, lead roofs have proven to stand the test of time. They have a lifespan of up to 100 years or more, making them a cost-effective choice in the long run. This longevity is due to lead’s innate resistance to corrosion and weathering. It can withstand extreme temperatures, UV rays, rain, snow, and other environmental factors without deteriorating.

Another advantage of lead roofing is its flexibility. It can adapt to complex roof shapes and forms, including curved or domed roofs. This versatility allows for intricate designs and ensures proper coverage and water drainage.

During installation, lead roofing requires skilled craftsmanship. Experienced roofers meticulously cut and shape the lead sheets to fit the specific roof design, ensuring a tight bond between the sheets and the roof structure.

It is important to note that lead roofing should be periodically inspected and maintained to ensure its longevity. Regular inspections can identify any damage or corrosion that may occur over time, and the necessary repairs can be carried out promptly.

While lead roofing continues to be a popular choice, it is crucial to consider environmental and health factors. Some concerns have been raised about the potential impact of lead runoff on the surrounding soil and water. Therefore, proper measures should be taken to collect and manage rainwater from lead roofs.

Overall, lead roofing offers a combination of durability, aesthetics, and longevity that makes it an attractive option for both historical restoration projects and modern architectural designs.

Flashings and Gutters

In addition to roofing, lead is commonly used for flashings and gutters in construction. Flashings are essential components that provide a watertight seal between different building elements, preventing water penetration and potential leaks.

Lead flashings offer excellent durability and resistance to corrosion, making them an ideal choice for areas where water is likely to accumulate or where two different materials meet, such as the junction between a roof and a wall. The flexibility of lead allows it to be easily molded around corners, chimneys, skylights, and other architectural features, ensuring a seamless and effective water barrier.

Gutters play a crucial role in directing rainwater away from the roof and foundation of a building. Lead gutters offer several advantages over other materials. Firstly, lead is highly resistant to corrosion, ensuring long-lasting performance even in harsh environments. Additionally, lead gutters can be custom-made to fit any roof shape or size, ensuring proper water drainage and preventing water from pooling or overflowing.

The malleability of lead allows for precise installation, resulting in tight junctions between gutter sections and corner pieces. This minimizes the risk of leaks and ensures efficient water flow. Lead gutters also have a smooth surface, allowing for self-cleaning and preventing debris from obstructing the flow of water.

It is important to note that lead is a heavy material, and proper support is required for gutters to ensure stability and prevent sagging. Additionally, regular maintenance, such as clearing gutters of debris, is necessary to maintain their effectiveness and prevent clogs.

While lead flashings and gutters offer valuable benefits, environmental and health concerns regarding lead exposure exist. Care should be taken to minimize the risk of lead runoff into the environment. Proper collection and management of rainwater can help mitigate these concerns.

Overall, lead flashings and gutters provide a reliable and attractive solution for effective water management in buildings. Their durability, resistance to corrosion, and customizable nature make them a popular choice in construction projects.

Read more: What Is Lead Glass

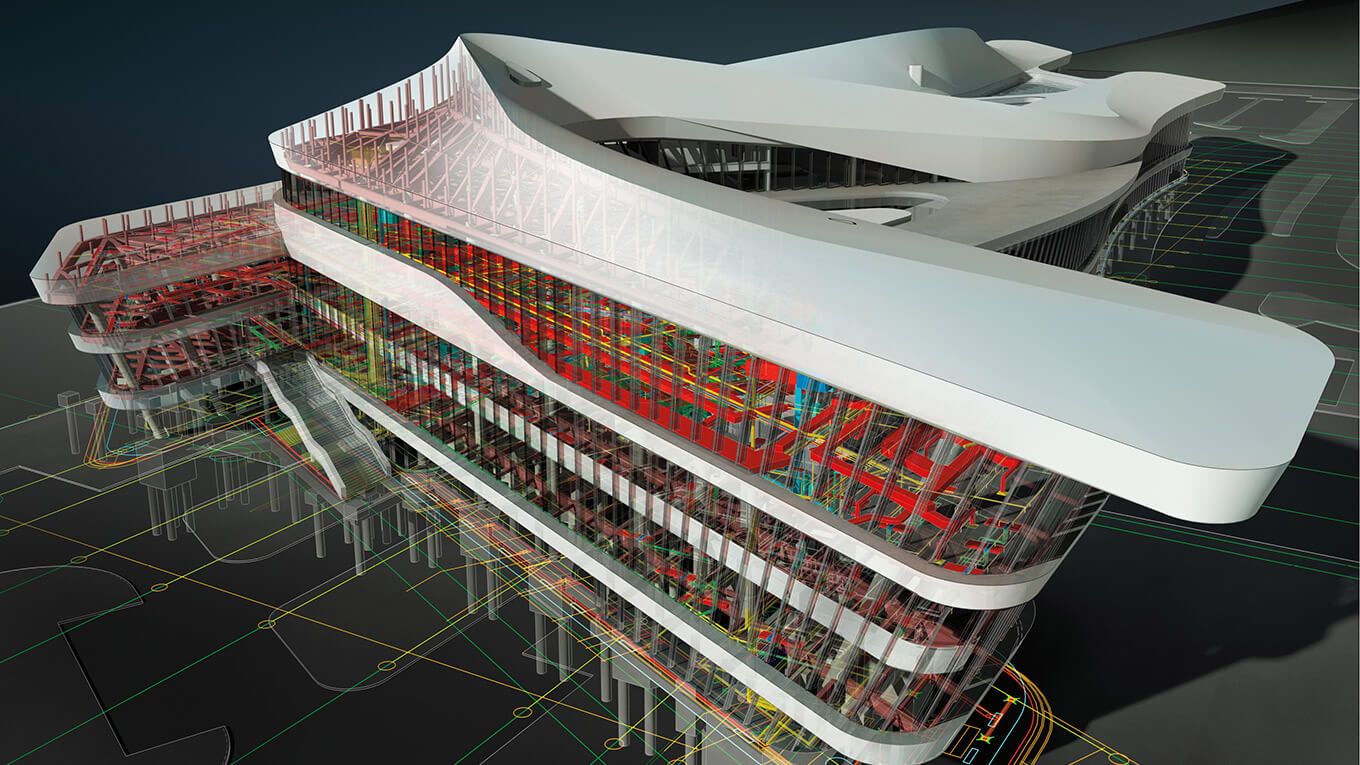

Radiation Shielding

Lead’s ability to absorb and block radiation makes it an invaluable material for radiation shielding in various construction applications. From medical facilities to laboratories and even nuclear power plants, lead is used to protect people and sensitive equipment from harmful radiation.

In medical facilities, lead is commonly used in areas where radiation is present, such as X-ray rooms, CT scan rooms, and radiation therapy rooms. Lead-lined walls, doors, and windows act as barriers, preventing the harmful radiation from escaping and minimizing the exposure of medical professionals, patients, and bystanders.

Laboratories that deal with radioactive substances also utilize lead shielding to ensure the safety of researchers and prevent radiation leaks. Lead-lined containers and cabinets provide secure storage and transportation options for radioactive materials.

Nuclear power plants extensively employ lead shielding to protect personnel working near radioactive materials and to prevent radiation leaks into the environment. Lead is used in the construction of containment vessels, shielding walls, and other critical components to reduce the risk of radiation exposure.

The density of lead makes it an excellent choice for radiation shielding because it can effectively absorb and attenuate ionizing radiation. The thickness and configuration of the lead shielding depend on factors such as the type of radiation and the required level of protection.

It is important to ensure proper installation and maintenance of lead shielding to guarantee its effectiveness. Regular inspections and checks for any signs of damage or deterioration are necessary to maintain the integrity of the shielding.

While lead is highly effective in radiation shielding, it is crucial to handle it with care due to its potential toxicity. Strict safety protocols should be followed during installation, maintenance, and removal to minimize any health risks associated with lead exposure.

Overall, lead’s exceptional ability to block radiation makes it an essential material in construction applications where radiation protection is paramount. Its effectiveness in shielding against harmful radiation ensures the safety of individuals and the integrity of critical equipment and infrastructure.

Plumbing

Although lead pipes were widely used in plumbing systems in the past, concerns regarding lead exposure and its potential health risks have led to a shift toward alternative materials. However, lead still finds niche applications in plumbing, particularly in specialized areas.

One of the main reasons lead was historically used for plumbing is its malleability. Lead pipes can be easily shaped and bent to fit the desired layout, allowing for efficient installation. Additionally, lead is highly resistant to corrosion, ensuring the longevity of the plumbing system.

In modern plumbing, lead is primarily used as a lining material for water storage tanks. The lead lining helps to prevent corrosion and maintains water quality. This application is mostly found in commercial and industrial settings.

Laboratory settings may also utilize lead in plumbing systems. The chemical resistance and reliability of lead pipes make them suitable for carrying specific types of fluids and ensuring the integrity of the laboratory experiments and processes.

It is important to note that lead plumbing systems can pose health risks, mainly due to the potential for lead leaching into the water supply. This is particularly relevant in older buildings where lead pipes may still be in use or where water comes into contact with lead solder joints. National and local regulations outline specific guidelines on lead content in plumbing materials to safeguard public health.

In recent years, there has been a significant effort to replace lead plumbing systems with safer alternatives. Materials such as copper, PEX (cross-linked polyethylene), and PVC (polyvinyl chloride) pipes have gained popularity due to their durability, flexibility, and reduced risk of lead contamination.

When considering plumbing options, it is essential to prioritize health and safety by choosing materials that comply with regulations and minimize the risk of lead exposure. Consulting with licensed professionals and adhering to local building codes ensures the installation of a reliable and safe plumbing system.

While lead’s use in plumbing has diminished, its historical significance and specific applications in water storage and laboratory settings demonstrate its unique properties and versatility in the construction industry.

Wall Cladding

Lead is increasingly being used as a unique and distinctive material for wall cladding in construction projects. The use of lead cladding provides not only an aesthetically pleasing appearance but also several functional benefits.

Lead cladding offers a distinct and elegant look that can enhance the overall design and visual appeal of a building. Its natural grey tone weathers over time, creating a beautiful and unique patina that adds character to the façade. Architects and designers often choose lead cladding to create a striking and timeless exterior.

One of the key advantages of lead cladding is its exceptional durability and resistance to corrosion. Lead is highly resistant to weathering, UV rays, and other environmental factors, making it suitable for long-term exterior use. It can withstand extreme temperatures, ensuring its stability and performance in various climates.

The malleability of lead allows for intricate detailing and customization, enabling architects to create unique designs and patterns on the cladding. It can be formed and shaped to fit curved or irregular surfaces, providing flexibility in design possibilities.

Lead cladding also offers excellent waterproofing qualities. When properly installed, it provides an effective barrier against moisture penetration, protecting the underlying structure from water damage and ensuring a dry and comfortable interior environment.

In addition to its aesthetic and functional benefits, lead cladding also has acoustic insulation properties. The density of lead helps to reduce outside noise, providing a quieter and more peaceful indoor environment.

When considering lead cladding, it is crucial to engage the services of experienced professionals who have expertise in working with lead. Proper installation techniques and considerations must be taken into account to ensure the cladding is securely attached to the building structure and properly sealed.

It is important to note that lead can be a heavy material, requiring appropriate structural support. The weight of the lead cladding should be factored into the design and engineering of the building to ensure safety and stability.

While lead cladding has its advantages, it is essential to consider environmental and health factors. Best practices should be followed to minimize any potential risk associated with lead runoff and address safety measures during installation, maintenance, and eventual removal.

Overall, lead wall cladding offers a combination of aesthetics, durability, and waterproofing capabilities. Its distinctive appearance and ability to withstand the elements make it a popular choice for enhancing the visual appeal and functionality of buildings.

Soundproofing

Lead’s density and acoustic insulation properties make it an excellent material for soundproofing applications in the construction industry. Whether it’s in residential, commercial, or industrial settings, incorporating lead into soundproofing projects can significantly reduce noise transmission and create a more peaceful environment.

Lead’s density allows it to effectively absorb and block sound waves, preventing them from traveling through walls, floors, and ceilings. This property makes it an ideal material for soundproofing partitions, doors, windows, and even entire rooms.

When used as an underlay material, lead can dampen vibrations and reduce airborne and impact noise. It is often installed between layers of drywall or flooring, creating a sound barrier that improves acoustic insulation and minimizes noise transfer between different areas of a building.

Lead’s ability to eliminate sound is particularly useful in environments where privacy and noise control are essential, such as recording studios, theaters, conference rooms, and bedrooms. By incorporating lead soundproofing solutions, unwanted noise can be significantly reduced, allowing for optimal sound quality or a peaceful and restful environment.

Furthermore, lead soundproofing materials can improve energy efficiency by reducing sound leakage through walls and windows. By sealing off air gaps and sound leaks, lead can contribute to thermal insulation, reducing heat or cold transfer and lowering energy consumption.

It is important to note that while lead is a highly effective soundproofing material, precautions should be taken due to its potential toxicity. When installing or working with lead-based soundproofing products, it is essential to follow proper safety measures, including using protective equipment and ensuring appropriate ventilation.

As the construction industry continues to prioritize noise control and acoustic comfort, the demand for lead-based soundproofing solutions has evolved. Alternative materials with similar soundproofing properties, such as recycled rubber, mass-loaded vinyl, and gypsum-based boards, have become popular choices for those seeking more environmentally friendly and safer options.

When considering soundproofing options, it is crucial to assess project requirements, budget, and environmental considerations. Consulting with acoustic experts and following local building regulations ensures the selection and installation of the most suitable soundproofing solution for the specific application.

In summary, lead’s density and acoustic insulation properties make it an effective material for soundproofing applications. Its ability to reduce noise transmission and create more peaceful environments contributes to improved comfort and enhances the overall acoustic performance of a building.

Read more: What Dinnerware Is Lead And Cadmium Free?

Electrical Applications

Lead’s excellent electrical conductivity makes it a valuable material for various electrical applications in the construction industry. Its ability to efficiently conduct electricity has led to its use in the production of cables, wires, and electrical connectors.

Electrical cables and wires made with lead or lead alloys offer several advantages. Lead’s conductivity allows for the efficient flow of electrical current, ensuring reliable performance and minimizing energy loss. Additionally, lead cables have high tensile strength, allowing them to withstand mechanical stress and maintain their integrity during installation and use.

In addition to its electrical conductivity, lead has corrosion resistance properties, which increases the lifespan and durability of electrical components. This makes lead a suitable choice for electrical connectors and terminals, allowing for secure connections and preventing degradation due to moisture or environmental factors.

Lead is often used in electrical grounding systems. Grounding plays a crucial role in electrical safety, redirecting excess electrical current to the ground and preventing electrical shocks or damage to equipment. Lead’s conductivity and corrosion resistance make it an effective material for grounding electrodes, rods, or plates.

While lead has been widely used in electrical applications in the past, there have been growing concerns about its toxicity. As a result, efforts have been made to reduce the use of lead in certain electrical components. This includes the development and adoption of alternative materials, such as copper, aluminum, and various alloys.

It is important to note that the presence of lead in electrical applications may still be regulated by national and local regulations. Compliance with these regulations ensures the safe use and disposal of lead-based electrical components, minimizing any potential health and environmental risks.

When considering electrical applications, it is important to balance the benefits of lead’s conductivity and durability with the potential health and environmental concerns. Consulting with electrical experts and adhering to relevant guidelines and regulations will help ensure the selection and safe use of suitable materials.

In summary, lead’s excellent electrical conductivity and corrosion resistance make it a valuable material for electrical applications in construction. While there have been efforts to reduce its use due to toxicity concerns, lead continues to play a role in some specialized electrical components, where its unique properties are advantageous.

Lead is commonly used in construction for its malleability and resistance to corrosion. It is often used for flashing, roofing, and as a component in some building materials. When working with lead in construction, it is important to follow safety guidelines to prevent exposure to lead dust or fumes. Always wear appropriate protective gear and work in well-ventilated areas.

Historical Use in Construction

Lead has a long and rich history of use in construction, particularly in architectural and decorative elements of historical buildings. Its unique properties and versatility have made it a favored material among craftsmen and architects throughout the centuries.

One notable historical use of lead in construction is its application in ornamental details and sculptures. Lead’s malleability allows it to be easily shaped into intricate designs, enabling the creation of stunning architectural embellishments, such as friezes, cornices, and decorative motifs. These ornamental features often adorned grand cathedrals, palaces, and important buildings, adding a touch of elegance and sophistication.

Stained glass windows in historical buildings are also a notable example of lead’s historical use. The lead came used in the assembly of stained glass panels provides the structural framework that holds the individual glass pieces together. This technique, known as leaded glass or leadlight, has been employed for centuries in the creation of intricate and colorful windows that tell stories and depict religious or historical scenes.

Lead’s durability and weather resistance have contributed to its historical use in roofing applications. Its use as a roofing material can be traced back centuries, especially in European countries. Lead roofs were commonly found in grand houses, churches, and other significant buildings, where their longevity and aesthetic appeal were highly valued. Many of these lead roofs have stood the test of time and continue to protect buildings today.

In addition to roofs, lead was utilized in historical plumbing systems. Lead pipes were commonly used for water supply and drainage in ancient civilizations and throughout the medieval period. This historical use of lead in plumbing demonstrates its long-standing reputation for durability and water-resistant properties.

As the construction industry and architectural practices evolved, the use of lead in certain applications diminished due to health and environmental concerns associated with lead exposure. Nonetheless, the historical presence of lead in iconic buildings serves as a testament to its enduring qualities and the craftsmanship of generations past.

While the use of lead in construction has changed over time, its historical significance remains embedded in the architectural fabric of many cities around the world. Preservation efforts and specialized restoration work continue to utilize lead to maintain the authenticity and integrity of these historical structures.

In summary, lead’s historical use in construction encompasses a wide range of applications, from ornamental details and stained glass windows to roofing and plumbing. Its durability, malleability, and aesthetic appeal have made it a cherished material in historical buildings, leaving a lasting impression on architectural heritage.

Conclusion

Lead has played a significant role in the construction industry for centuries, thanks to its unique properties and versatile applications. From roofing and flashings to wall cladding and soundproofing, lead provides durability, functionality, and aesthetic appeal in various construction projects.

The properties of lead, including its density, corrosion resistance, and malleability, make it a preferred choice in specific construction applications. Lead roofs offer exceptional weather resistance and longevity, while lead flashings and gutters ensure effective water management and protection against leaks.

Lead’s ability to absorb and block radiation makes it an essential material for shielding against harmful radiation in medical facilities, laboratories, and nuclear power plants. Its excellent electrical conductivity has made it valuable in electrical applications, although alternatives are now being embraced due to health and environmental concerns.

Lead’s historical use in construction speaks to its legacy as an ornamental material in decorative details and stained glass windows. It continues to be appreciated for its unique patina and aesthetic appeal in historical and architectural preservation projects.

While lead offers many benefits, it is important to balance its advantages with environmental and health considerations. Proper safety measures and regulations must be followed during installation, maintenance, and eventual removal of lead-based materials to minimize any potential risks.

As the construction industry continues to evolve and prioritize sustainability and safety, alternative materials are being developed to replace lead in certain applications. It is crucial to consider environmental factors, health concerns, and local regulations when selecting materials for construction projects.

In conclusion, lead’s historical significance and its range of applications in construction demonstrate its enduring value. Its unique properties have contributed to the durability, functionality, and aesthetic appeal of buildings throughout history. Balancing the benefits of lead with safety and environmental considerations can help create sustainable and resilient construction practices for the future.

Frequently Asked Questions about What Is Lead Used For In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Lead Used For In Construction”