Home>diy>Building & Construction>Why Is Steel Widely Used In Construction?

Building & Construction

Why Is Steel Widely Used In Construction?

Modified: January 6, 2024

Steel is a popular choice in building construction due to its exceptional strength, durability, and versatility. Find out why steel is widely used in construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to construction, steel has become a staple material that is widely used across the industry. Its popularity is not without reason; steel offers a myriad of advantages that make it the go-to choice for builders and architects alike.

Known for its strength, durability, and cost-effectiveness, steel has revolutionized the construction industry. Its versatility and flexibility allow for innovative designs and efficient construction processes. Additionally, steel is highly sustainable and can be recycled, making it an eco-friendly option.

In this article, we will delve into the various reasons why steel is so widely used in construction. We will explore its strength and durability, its cost-effectiveness, its versatility and flexibility, its speed of construction, its sustainability and recyclability, and its resistance to fire and other hazards.

By understanding the benefits that come with using steel, we can appreciate the pivotal role it plays in shaping the modern construction landscape and ensuring the safety and longevity of buildings.

Key Takeaways:

- Steel’s exceptional strength, durability, and cost-effectiveness make it the go-to choice for construction. Its versatility, speed of construction, and sustainability ensure safe, resilient, and visually striking structures.

- With steel’s resistance to fire and hazards, along with its recyclability and speed of construction, it’s the cornerstone of modern construction. Its myriad of advantages shapes our built environment for the better.

Read more: When Was Steel First Used In Construction

Strength and Durability of Steel

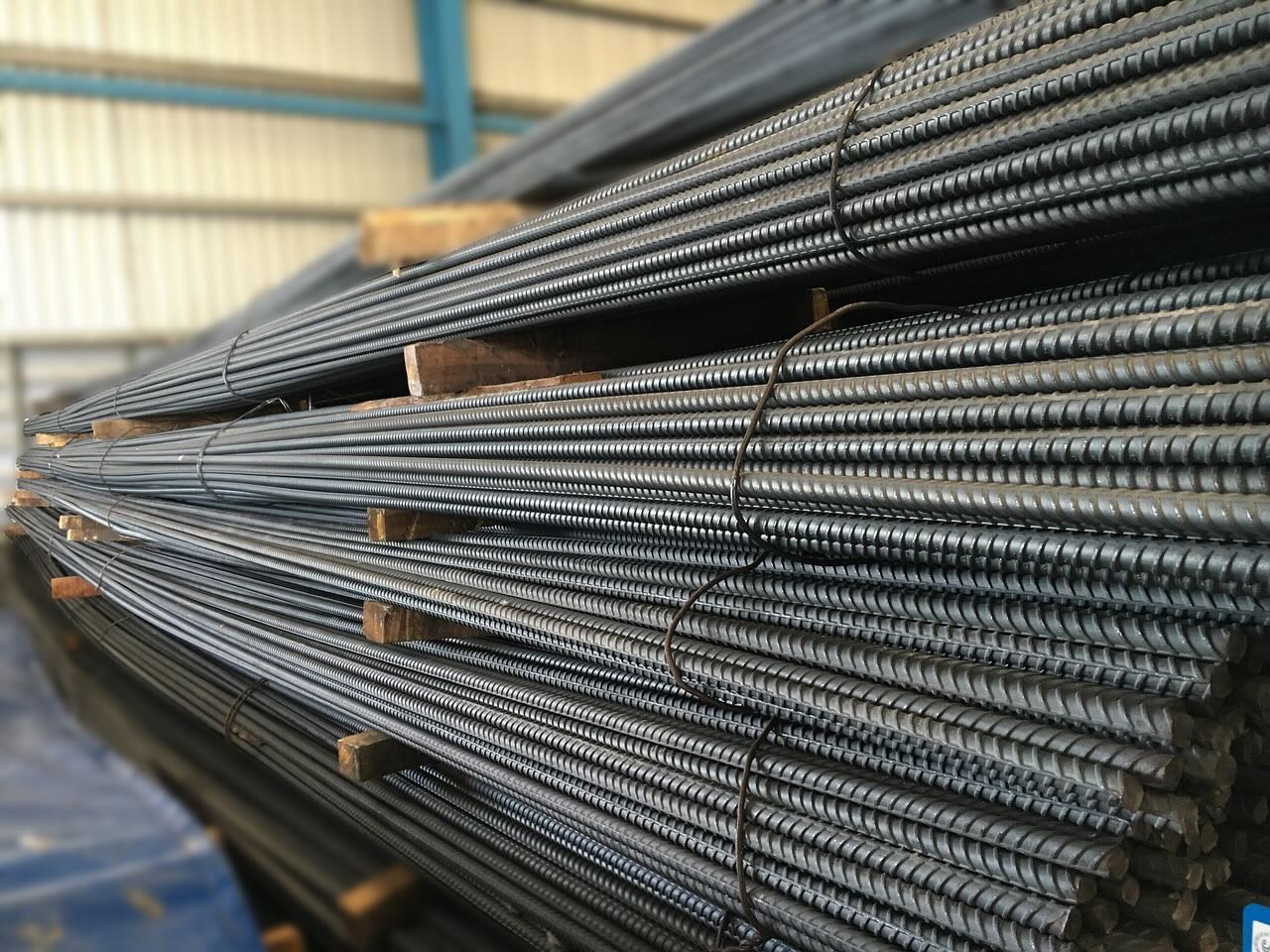

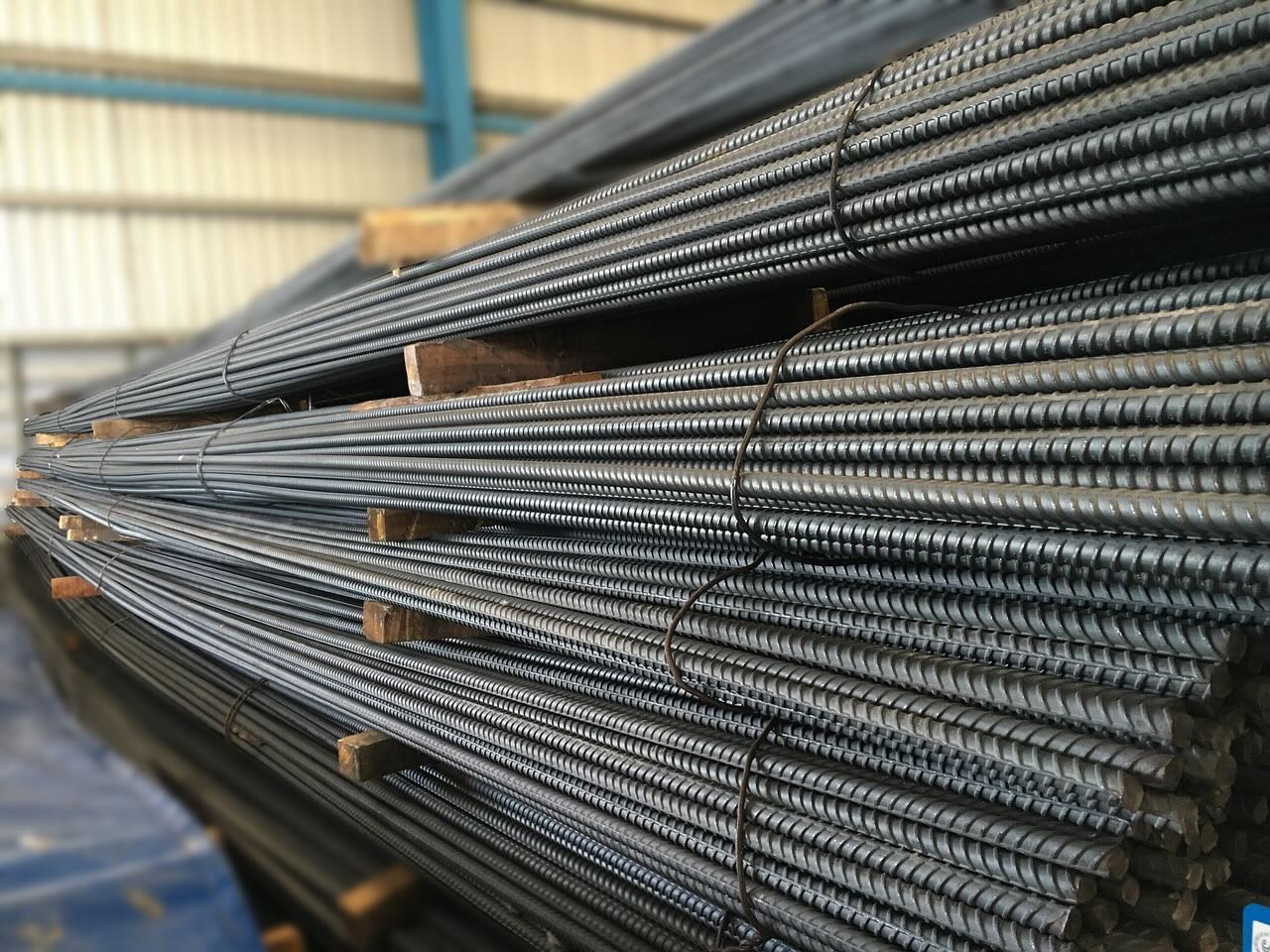

One of the primary reasons why steel is widely used in construction is its exceptional strength and durability. Steel is known for its high tensile strength, which means it can withstand tremendous force without bending, breaking, or deforming. This strength allows for the construction of tall and large buildings, bridges, and other structures that require the ability to support heavy loads.

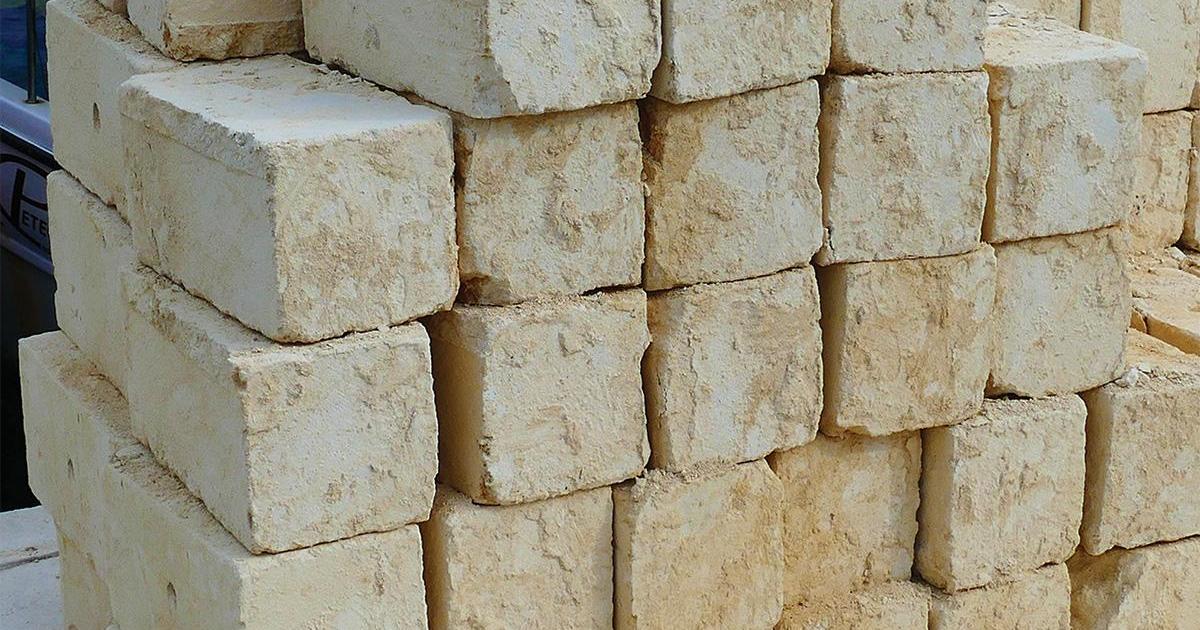

Compared to other construction materials, such as wood or concrete, steel offers superior durability. Unlike wood, steel is not susceptible to rot, termites, or decay. It is also resistant to moisture, which helps prevent corrosion and prolongs its lifespan. The durability of steel ensures that structures built with it can endure harsh weather conditions, natural disasters, and the test of time.

Moreover, steel’s durability translates into long-term cost savings for building owners. With minimal maintenance required, steel structures have a longer lifespan and lower repair and replacement costs compared to structures made from other materials.

Steel is also highly resistant to external factors that can degrade other construction materials. It can withstand high wind loads, seismic activity, and even impacts from accidents or collisions. This makes steel an ideal choice for areas prone to earthquakes, hurricanes, or other extreme weather events.

Additionally, the strength and durability of steel contribute to the structural integrity of buildings. Steel structures can support heavy loads, allowing for open floor plans without the need for numerous support columns. This feature not only provides design flexibility but also enhances the functionality and aesthetics of the space.

In summary, the superior strength and durability of steel make it the ideal choice for constructing resilient, long-lasting structures that can withstand various external forces and maintain their structural integrity over time.

Cost-effectiveness of Steel in Construction

The cost-effectiveness of steel is another key factor that contributes to its widespread use in construction. While the initial cost of using steel can vary depending on factors such as project size and location, its long-term benefits often outweigh the initial investment.

Firstly, steel construction is known for its speed and efficiency. Steel components are typically prefabricated off-site and then transported to the construction site, minimizing construction time and labor costs. This accelerated construction process reduces overall project duration and allows for earlier occupancy or use of the building, leading to potential cost savings or revenue generation.

Furthermore, steel’s lightweight nature compared to other construction materials, such as concrete, results in reduced foundation requirements and associated costs. The ability to have lighter foundations or smaller footings translates into savings in excavation and material costs.

Steel’s durability and low maintenance requirements also contribute to its cost-effectiveness. Steel structures have a long lifespan and require minimal repairs and replacements, reducing ongoing maintenance costs over time. Additionally, its resistance to elements such as moisture and pests eliminates the need for costly treatments or inspections.

Another aspect that adds to the cost-effectiveness of steel is its recyclability. Steel is one of the most recycled materials in the world, with an impressive recycling rate of around 90%. At the end of their lifespan, steel structures can be easily deconstructed and the materials recycled for reuse. This not only reduces waste going to landfills but also saves on raw material costs for new construction projects.

Additionally, the recyclability of steel contributes to its environmental sustainability. By choosing steel, builders can meet green building standards and regulations, which are becoming increasingly important in the construction industry. This can lead to potential financial incentives, tax credits, or reduced operating costs through energy-efficient design and construction practices.

In summary, the cost-effectiveness of steel in construction stems from its efficiency in terms of construction time, reduced foundation requirements, low maintenance costs, and its recyclability. These factors make steel a sound investment that can provide long-term savings and environmental benefits for building owners.

Versatility and Flexibility of Steel in Construction

One of the major advantages of steel in construction is its remarkable versatility and flexibility. Steel can be easily manipulated and fabricated into various shapes and sizes, allowing for endless design possibilities.

With steel, architects and designers have the freedom to create innovative and unique structures. It can be curved, twisted, or bent to form complex shapes and geometries that would be difficult or impossible to achieve with other building materials. This flexibility enables the creation of iconic buildings and structures that showcase architectural prowess.

In addition to its aesthetic versatility, steel offers practical advantages as well. It can be easily modified, expanded, or retrofitted to accommodate changing needs or future renovations. This adaptability is particularly advantageous in commercial buildings where functionality and layout requirements may evolve over time.

The lightweight nature of steel also allows for a greater span of open space. With its high strength-to-weight ratio, steel structures can support larger floor areas without the need for excessive columns or load-bearing walls. This creates more versatile and usable interior spaces, providing flexibility for different room configurations and layouts.

Furthermore, steel’s versatility extends to its compatibility with other building materials. Steel is often used in conjunction with other construction materials, such as concrete or wood, to create hybrid structures that leverage the strengths of each material. This allows for greater design flexibility while maintaining structural integrity and optimizing cost-effectiveness.

Steel’s versatility is not limited to building structures alone. It also finds applications in various architectural features, such as cladding, roofing, and façade systems. Its ability to be easily customized and fabricated into different shapes and finishes provides architects with endless design choices to enhance the aesthetic appeal of buildings.

In summary, the versatility and flexibility of steel in construction enable architects and designers to push boundaries and create remarkable structures. Its ability to be molded into various shapes, its adaptability for future modifications, and its compatibility with other materials make steel an essential ingredient in achieving architectural excellence and functional design.

Steel is widely used in construction due to its strength, durability, and versatility. It can be easily fabricated into different shapes and sizes, making it suitable for a wide range of building applications.

Speed of Construction with Steel

When it comes to construction projects, time is often of the essence. That’s where steel shines, as it offers significant advantages in terms of speed of construction.

One of the main reasons why steel is preferred in fast-track construction projects is its off-site fabrication capabilities. Steel components can be manufactured in a controlled factory setting while site preparation is underway, greatly reducing construction time. This simultaneous process of fabrication and site preparation allows for efficient project scheduling, resulting in faster overall construction timelines.

Since steel components are prefabricated off-site, they arrive at the construction site ready for installation. This eliminates the need for time-consuming on-site construction activities, such as formwork, curing, and drying time, which are required when using materials like concrete. As a result, steel structures can be erected quickly, accelerating the construction process.

The lightweight nature of steel also contributes to its speedy installation. Steel components can be easily handled and maneuvered, reducing the need for heavy machinery and labor-intensive tasks. This enables faster assembly and erection of the structure, leading to shorter project durations.

Moreover, the predictability and precision of steel components further streamline construction. Since steel is manufactured to precise specifications in a controlled environment, the chances of errors and rework on the construction site are minimized. This precision translates into faster construction as the components fit together seamlessly, reducing the time spent on adjustments and modifications.

The speed of construction with steel has additional benefits beyond time savings. Faster construction means earlier occupancy or use of the building, which can result in earlier revenue generation for commercial projects or quicker availability of housing. This can be particularly advantageous in situations where the project timeline is critical, such as in disaster recovery efforts or urgent infrastructure needs.

In summary, the speed of construction with steel stems from its off-site fabrication capabilities, ease of handling, and precision manufacturing, allowing for faster project completion. Embracing steel in construction can significantly reduce construction timelines, leading to time and cost savings, as well as quicker availability of structures for use.

Read more: Why Is Bamboo Used In Construction

Sustainability and Recyclability of Steel

As the construction industry continues to prioritize sustainable practices, steel emerges as a highly sustainable and recyclable building material.

One of the key sustainability advantages of steel is its long lifespan. Steel structures have a considerable service life, often lasting for several decades or more. This longevity reduces the need for frequent demolitions and reconstructions, resulting in decreased waste generation and resource consumption over time.

Additionally, steel is one of the most recycled materials in the world, with an impressive recycling rate of around 90%. At the end of a steel structure’s life cycle, it can be easily deconstructed and the materials reclaimed for reuse. This significantly reduces the environmental impact associated with mining and manufacturing new steel materials.

The recycling process of steel is highly energy-efficient. Recycled steel requires up to 75% less energy to produce compared to virgin steel. This energy savings translates to reduced greenhouse gas emissions, helping to combat climate change and minimize the carbon footprint of construction projects.

Furthermore, steel’s recyclability is a closed-loop cycle. Recycled steel can be used to manufacture new steel products repeatedly without compromising its quality or performance. This cradle-to-cradle approach ensures that steel remains a valuable and sustainable resource for generations to come.

Steel’s sustainability extends beyond its material recycling capabilities. Steel structures can also incorporate additional sustainable features, such as energy-efficient insulation systems, renewable energy technologies, and water-saving mechanisms. These features further enhance the environmental performance of steel buildings, contributing to sustainable development goals.

Choosing steel as a construction material aligns with green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method). By meeting these standards, builders can promote sustainability, improve building performance, and potentially benefit from financial incentives or tax credits.

In summary, the sustainability and recyclability of steel make it a preferred choice in construction. Its long lifespan, high recycling rate, energy efficiency, and closed-loop cycle ensure that steel structures contribute to a more sustainable built environment and help mitigate environmental challenges we face today.

Resistance to Fire and Other Hazards

When it comes to the safety of buildings, steel’s exceptional resistance to fire and other hazards sets it apart from other construction materials.

One of the key advantages of using steel in construction is its high fire resistance. Steel has a high melting point, making it resistant to the effects of fire and helping to prevent structural collapse during a fire incident. Unlike materials such as wood, which can fuel a fire, steel does not contribute to the spread of flames.

Moreover, steel structures can be designed to meet stringent fire safety regulations and building codes. Fire-resistant coatings and treatments can be applied to steel members to further enhance their fire performance. These coatings provide an additional layer of protection, delaying the onset of structural failure and allowing more time for occupants to evacuate safely.

Steel’s high strength also contributes to its resistance to other hazards, such as earthquakes, hurricanes, and impacts. The remarkable strength and ductility of steel allow it to absorb and dissipate energy during seismic events, reducing the risk of structural collapse. In regions prone to high winds or hurricanes, steel structures can be engineered and reinforced to withstand powerful gusts and protect against wind-induced damage.

In addition, steel structures are less susceptible to damage from environmental factors like moisture, pests, and rot that can compromise the integrity of other building materials. This resistance translates into lower maintenance and repair costs over the lifespan of the structure.

Furthermore, steel’s non-combustible nature makes it an ideal material for structures that require high levels of fire resistance, such as industrial facilities, commercial buildings, and public spaces. The use of steel in these applications enhances the overall safety of the built environment, providing peace of mind for occupants and stakeholders.

It is worth noting that while steel offers excellent resistance to fire and other hazards, proper design, construction, and maintenance practices are vital to ensure optimal performance. Collaboration with experienced professionals, adherence to relevant codes and standards, and regular inspections are crucial to maximizing the safety benefits of steel in construction.

In summary, steel’s resistance to fire and other hazards makes it a preferred choice in construction projects where safety is paramount. Its high fire resistance, strength, and durability help to protect structures and occupants from a range of potential risks, ensuring the long-term safety and integrity of the built environment.

Conclusion

Steel has undoubtedly earned its place as one of the most widely used materials in the construction industry. Its numerous advantages, including strength and durability, cost-effectiveness, versatility and flexibility, speed of construction, sustainability, and resistance to fire and other hazards, make it an indispensable resource for architects, engineers, and builders.

The strength and durability of steel enable the construction of resilient structures that can withstand heavy loads, harsh weather conditions, and the test of time. Its cost-effectiveness stems from its efficiency in terms of construction time, reduced foundation requirements, low maintenance costs, and its recyclability.

The versatility and flexibility of steel allow architects and designers to push boundaries and create iconic structures that are both aesthetically pleasing and functional. Its lightweight nature facilitates open floor plans and adaptable spaces.

The speed of construction with steel is unmatched, thanks to its off-site fabrication capabilities, ease of handling, and precision manufacturing. This accelerated construction process saves time and allows for earlier occupancy or use of the building.

Steel’s sustainability and recyclability contribute to a more environmentally-friendly approach to construction. With its high recycling rate, steel minimizes waste generation and reduces the need for mining and manufacturing of virgin materials. Steel structures can incorporate sustainable features, align with green building standards, and contribute to a more sustainable built environment.

Finally, steel’s resistance to fire and other hazards ensures the safety and integrity of structures. Its fire resistance, high strength, and durability protect against structural collapse, making it a reliable choice in areas prone to earthquakes, high winds, and other hazardous conditions.

In conclusion, steel’s myriad of advantages make it the material of choice for construction projects of all scales. Its versatility, cost-effectiveness, sustainability, and resistance to hazards position it as the cornerstone of modern construction, enabling the creation of safe, durable, and visually striking structures that shape our built environment.

Frequently Asked Questions about Why Is Steel Widely Used In Construction?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Is Steel Widely Used In Construction?”