Home>Furniture & Design>Bathroom Accessories>How To Lubricate A Syringe Plunger

Bathroom Accessories

How To Lubricate A Syringe Plunger

Modified: March 2, 2024

Learn how to properly lubricate a syringe plunger for smooth operation. Find out the best lubricants and step-by-step instructions. Perfect for bathroom accessories maintenance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Lubricating a syringe plunger is a crucial aspect of maintaining the functionality and longevity of medical equipment. Whether you are a healthcare professional, a veterinarian, or an individual administering medication at home, understanding the process of lubricating a syringe plunger is essential for ensuring the accuracy and precision of medication delivery.

The syringe plunger, a fundamental component of syringes used for various medical purposes, facilitates the smooth and controlled movement of the medication or solution within the syringe barrel. Over time, the repeated use of syringes can lead to increased friction between the plunger and the barrel, potentially resulting in resistance and erratic movement. This can compromise the accuracy of medication dosage and administration, posing risks to patient care and treatment outcomes.

By comprehensively addressing the lubrication of the syringe plunger, this article aims to provide valuable insights into the significance of this maintenance practice, the selection of appropriate lubricants, and the step-by-step process for effectively lubricating the syringe plunger. Additionally, it will highlight essential precautions and safety measures to ensure the proper handling and usage of lubricants in medical settings.

Understanding the intricacies of lubricating a syringe plunger is not only beneficial for maintaining the functionality of medical equipment but also contributes to the overall safety and efficacy of medical procedures. With this in mind, let's delve into the essential aspects of this process, empowering individuals to optimize the performance and reliability of syringes in various healthcare settings.

Key Takeaways:

- Properly lubricating a syringe plunger with medical-grade silicone lubricant ensures smooth movement, accurate dosage measurement, and safe medication administration, enhancing patient care and treatment outcomes.

- Choosing the right lubricant, following meticulous steps for application, and observing essential safety measures are crucial for maintaining a secure and hygienic environment while optimizing the performance and reliability of syringes in healthcare settings.

Read more: What Is The Plunger Of A Syringe

Understanding the Syringe Plunger

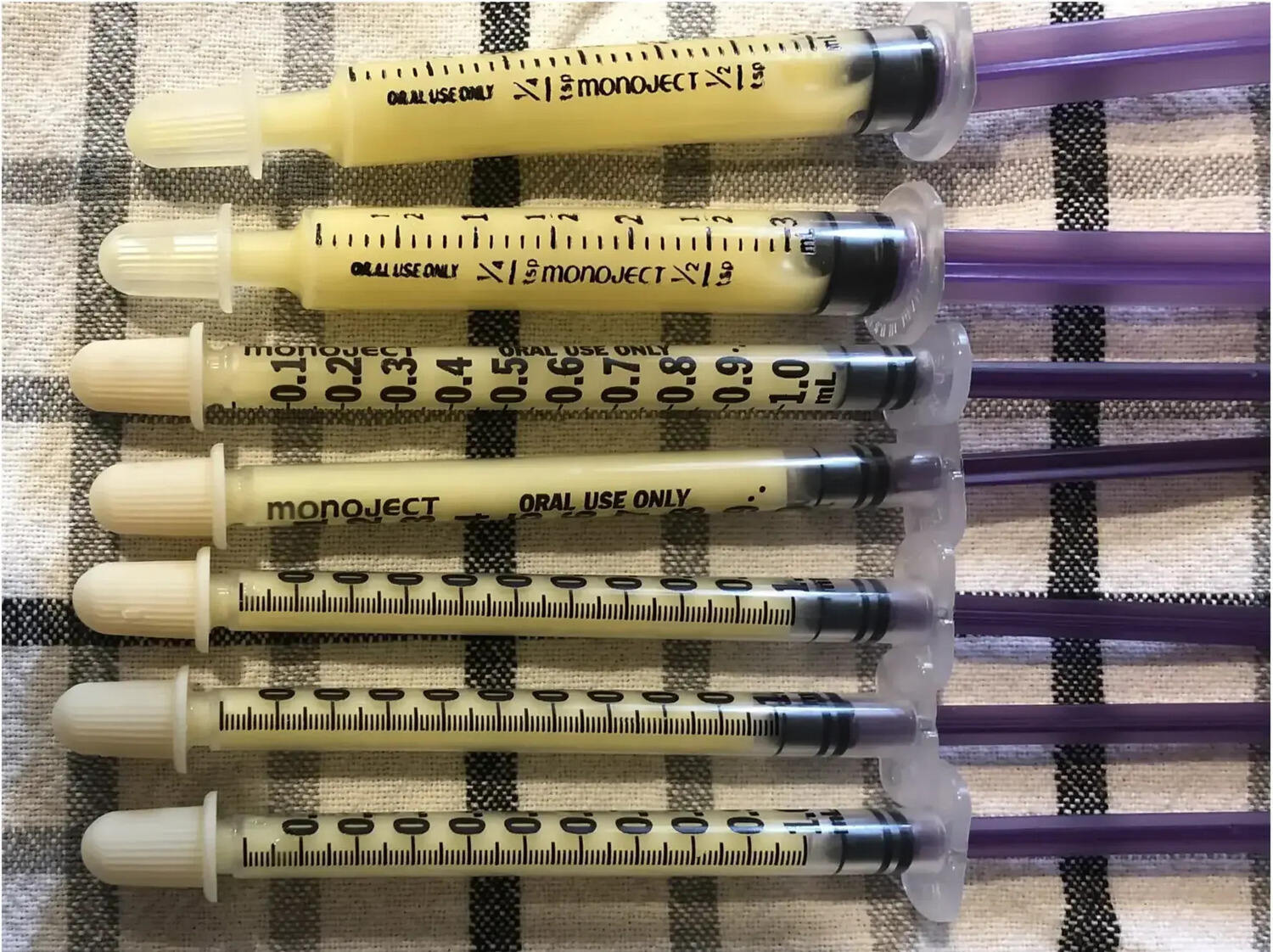

The syringe plunger, a fundamental component of syringes used for various medical purposes, plays a pivotal role in the accurate and controlled administration of medications and solutions. Comprising a cylindrical shaft with a rubber or silicone tip, the plunger fits snugly within the syringe barrel, creating a seal that enables the precise measurement and delivery of fluids.

The functionality of the syringe plunger is based on the principles of displacement and pressure. When the plunger is pulled back, the volume within the syringe barrel increases, creating a vacuum that draws the medication or solution into the syringe. Conversely, pushing the plunger forward expels the contents from the syringe. This mechanism allows for the accurate measurement and administration of specific dosages, making the syringe plunger a critical tool in medical procedures.

The plunger's rubber or silicone tip is designed to create an airtight seal within the syringe barrel, preventing leakage and ensuring the controlled movement of fluids. This seal is essential for maintaining the integrity of the medication or solution, safeguarding it from contamination and preserving its efficacy.

Furthermore, the smooth and unhindered movement of the syringe plunger is vital for precise dosage measurement and delivery. Any resistance or irregularity in the plunger's movement can compromise the accuracy of medication administration, potentially leading to underdosing or overdosing, which can have significant implications for patient care and treatment outcomes.

Understanding the syringe plunger's construction, functionality, and significance in medical procedures is essential for healthcare professionals and individuals involved in medication administration. By gaining insights into the role of the plunger in facilitating accurate dosage measurement and fluid movement, individuals can appreciate the importance of maintaining its optimal functionality through proper lubrication.

In the subsequent sections, we will delve into the importance of lubricating the syringe plunger, the selection of suitable lubricants, and the step-by-step process for effectively lubricating the plunger, empowering individuals to uphold the performance and reliability of syringes in diverse healthcare settings.

Importance of Lubricating the Syringe Plunger

Lubricating the syringe plunger holds immense significance in ensuring the optimal performance and longevity of medical equipment. The smooth and unhindered movement of the plunger within the syringe barrel is essential for accurate medication administration and dosage measurement. Over time and with repeated use, the plunger can experience increased friction against the barrel, leading to resistance and erratic movement. This friction can be attributed to factors such as the nature of the medication or solution being administered, the frequency of syringe use, and environmental conditions.

By lubricating the syringe plunger, the friction between the plunger and the barrel is significantly reduced, facilitating seamless movement and enhancing the precision of dosage measurement. This is particularly crucial in medical settings where precise medication dosing is imperative for patient care and treatment efficacy. Lubrication not only mitigates resistance but also ensures that the plunger moves in a controlled manner, allowing for accurate withdrawal and delivery of fluids.

Moreover, the proper lubrication of the syringe plunger helps maintain the integrity of the rubber or silicone tip, which forms an airtight seal within the syringe barrel. This seal is vital for preventing leakage and contamination of the medication or solution, safeguarding its potency and efficacy. Without adequate lubrication, the plunger's movement may become uneven, potentially compromising the integrity of the seal and leading to issues such as fluid leakage or inaccurate dosage delivery.

Furthermore, lubricating the syringe plunger contributes to the overall functionality and reliability of medical equipment. It minimizes wear and tear on the plunger and barrel, prolonging the operational lifespan of the syringe. This proactive maintenance approach not only ensures the consistent performance of the syringe but also reduces the likelihood of mechanical issues that could impact the accuracy of medication administration.

In essence, the importance of lubricating the syringe plunger cannot be overstated. It directly influences the precision of medication dosage measurement, the integrity of the fluid seal, and the overall functionality of the syringe. By prioritizing the lubrication of syringe plungers, healthcare professionals and individuals involved in medication administration can uphold the highest standards of accuracy, safety, and efficacy in diverse healthcare settings.

Choosing the Right Lubricant

Selecting the appropriate lubricant for syringe plungers is a critical aspect of ensuring the optimal performance and longevity of medical equipment. The ideal lubricant should exhibit specific characteristics that align with the requirements of syringe plunger maintenance and usage in medical settings.

When choosing a lubricant for syringe plungers, it is essential to prioritize compatibility with medical-grade materials. Silicone-based lubricants are widely recommended for syringe plungers due to their inert nature and compatibility with rubber and silicone components. These lubricants are non-reactive and do not degrade the materials of the syringe plunger, ensuring that the integrity of the rubber or silicone tip is preserved. Additionally, silicone-based lubricants offer excellent lubricity, reducing friction and enabling smooth movement of the plunger within the syringe barrel.

Furthermore, the selected lubricant should adhere to stringent safety and regulatory standards applicable to medical devices and equipment. It is imperative to choose a lubricant that complies with relevant industry regulations and guidelines, ensuring that it is safe for use in medical environments and does not pose risks of contamination or adverse reactions. Lubricants specifically formulated for medical applications undergo rigorous testing to validate their biocompatibility and safety, making them suitable choices for lubricating syringe plungers.

In addition to compatibility and safety considerations, the lubricant should exhibit long-lasting effectiveness and stability. Opting for a lubricant with a durable formulation ensures that the syringe plunger remains adequately lubricated over extended periods, reducing the frequency of maintenance and reapplication. This characteristic is particularly advantageous in healthcare settings where efficiency and reliability are paramount, allowing healthcare professionals to focus on patient care without frequent interruptions for syringe maintenance.

Moreover, the lubricant should be free from potentially harmful additives or contaminants that could compromise the purity of medications or solutions administered using the syringe. Choosing a high-purity lubricant minimizes the risk of introducing foreign substances into the medical process, upholding the integrity and safety of medication administration.

By carefully considering these factors and selecting a lubricant that aligns with the specific requirements of syringe plunger maintenance in medical settings, healthcare professionals and individuals involved in medication administration can ensure the consistent performance, safety, and reliability of syringes. Prioritizing the use of suitable lubricants underscores a commitment to upholding the highest standards of quality and precision in healthcare practices.

Steps to Lubricate the Syringe Plunger

-

Gather the Necessary Supplies: Begin by assembling the essential supplies for the lubrication process. You will need a medical-grade silicone lubricant specifically formulated for syringe plungers, as well as clean, lint-free cloths or wipes. Ensuring that the lubricant and cloths are free from contaminants is crucial to maintaining the sterility and integrity of the syringe and its components.

-

Prepare the Work Area: Create a clean and well-lit work area where you can comfortably perform the lubrication process. It is essential to work in a controlled environment to minimize the risk of contamination and ensure the accuracy of the lubrication procedure.

-

Clean the Syringe Plunger: Before applying the lubricant, thoroughly clean the syringe plunger to remove any residual medication or debris. Use a mild detergent or alcohol swab to gently cleanse the plunger, ensuring that it is free from any substances that could compromise the lubrication process.

-

Apply the Lubricant: Dispense a small amount of the medical-grade silicone lubricant onto a clean, lint-free cloth or directly onto the syringe plunger. Ensure that the lubricant is evenly distributed and covers the entire surface of the plunger, including the rubber or silicone tip. Avoid over-application, as excess lubricant may lead to potential contamination or interfere with the syringe's functionality.

-

Spread the Lubricant: With the lubricant applied, gently spread it across the surface of the plunger, ensuring that it coats the rubber or silicone tip and the shaft evenly. This step is crucial for reducing friction and facilitating smooth movement within the syringe barrel.

-

Remove Excess Lubricant: After spreading the lubricant, use a clean, lint-free cloth to remove any excess lubricant from the plunger. Thoroughly wipe the plunger to ensure that only a thin, uniform layer of lubricant remains, preventing any potential buildup that could affect the syringe's performance.

-

Test the Plunger Movement: Once the lubrication process is complete, perform a test to ensure that the plunger moves smoothly and consistently within the syringe barrel. Verify that the lubricated plunger facilitates precise withdrawal and delivery of fluids, indicating that the lubrication has been effectively applied.

By following these meticulous steps, healthcare professionals and individuals can ensure that the syringe plunger is adequately lubricated, promoting optimal functionality and accuracy in medication administration. This systematic approach to lubrication underscores the commitment to maintaining the highest standards of performance and safety in medical practices.

Read more: How To Fix A Syringe Plunger

Precautions and Safety Measures

Ensuring the safe and effective lubrication of syringe plungers necessitates adherence to essential precautions and safety measures to mitigate potential risks and uphold the integrity of medical equipment and procedures. By prioritizing safety considerations, healthcare professionals and individuals involved in medication administration can maintain a secure and hygienic environment while optimizing the performance of syringes.

Maintain Sterility:

Before initiating the lubrication process, it is imperative to uphold strict sterility standards to prevent contamination of the syringe and its components. Utilize sterile gloves and ensure that the work area is meticulously clean and free from potential contaminants. Any compromise in sterility could compromise the safety and efficacy of medication administration.

Use Appropriate Lubricants:

Selecting the correct lubricant is paramount to ensure compatibility with medical-grade materials and adherence to safety standards. Avoid using non-medical or unapproved lubricants, as they may introduce contaminants or compromise the integrity of the syringe plunger. Prioritize the use of medical-grade silicone lubricants specifically formulated for syringe maintenance.

Minimal Lubricant Application:

Exercise caution to apply the lubricant sparingly, ensuring that only a thin, uniform layer is distributed across the plunger's surface. Over-application of lubricant can lead to potential contamination and interfere with the syringe's functionality. Carefully follow the manufacturer's recommendations regarding the appropriate amount of lubricant to be used.

Read more: How To Read A Syringe Plunger

Prevent Cross-Contamination:

To prevent cross-contamination, designate specific lubrication tools and supplies exclusively for syringe maintenance. Avoid using the same lubrication materials for other medical equipment or devices to minimize the risk of introducing foreign substances or contaminants into the lubrication process.

Verify Compatibility:

Prior to applying the lubricant, verify its compatibility with the specific type and model of syringe being serviced. Different syringe designs and materials may require distinct lubrication considerations. Consult the syringe manufacturer's guidelines or seek professional advice to ensure the selected lubricant aligns with the syringe's requirements.

Dispose of Contaminated Materials:

After completing the lubrication process, promptly dispose of any used or contaminated materials in accordance with medical waste disposal protocols. This includes disposing of used cloths or wipes in designated biohazard waste containers to prevent potential exposure to hazardous substances.

By meticulously observing these precautions and safety measures, healthcare professionals and individuals can uphold the highest standards of safety, sterility, and equipment integrity during the lubrication of syringe plungers. Prioritizing safety considerations is integral to maintaining a secure and hygienic environment while optimizing the performance and reliability of medical equipment in diverse healthcare settings.

Conclusion

In conclusion, the proper lubrication of syringe plungers is a fundamental aspect of maintaining the functionality, accuracy, and safety of medical equipment in various healthcare settings. By understanding the significance of lubricating syringe plungers and following meticulous steps to apply the appropriate lubricant, healthcare professionals and individuals involved in medication administration can ensure the optimal performance and longevity of syringes.

The syringe plunger, with its rubber or silicone tip, plays a pivotal role in facilitating the precise measurement and delivery of medications and solutions. However, repeated use can lead to increased friction and resistance, potentially compromising the accuracy of dosage measurement and fluid movement. Through the application of medical-grade silicone lubricants, the friction between the plunger and the barrel is significantly reduced, enabling smooth and controlled movement within the syringe.

Choosing the right lubricant is paramount, as it ensures compatibility with medical-grade materials, adherence to safety standards, and long-lasting effectiveness. Silicone-based lubricants, specifically formulated for syringe maintenance, offer excellent lubricity while preserving the integrity of the plunger's components. By carefully selecting suitable lubricants, healthcare professionals uphold the highest standards of quality and precision in medication administration.

The step-by-step process of lubricating syringe plungers involves gathering necessary supplies, preparing the work area, cleaning the plunger, applying the lubricant, spreading it evenly, removing excess lubricant, and testing the plunger movement. This systematic approach ensures that the plunger is adequately lubricated, promoting optimal functionality and accuracy in medication administration.

Furthermore, adherence to essential precautions and safety measures, such as maintaining sterility, using appropriate lubricants, preventing cross-contamination, and verifying compatibility, is crucial for mitigating potential risks and upholding the integrity of medical equipment and procedures.

By prioritizing the lubrication of syringe plungers and observing safety considerations, healthcare professionals and individuals demonstrate a commitment to maintaining a secure and hygienic environment while optimizing the performance and reliability of syringes. This proactive approach contributes to the overall safety, accuracy, and efficacy of medication administration, ultimately enhancing patient care and treatment outcomes in diverse healthcare settings.

Frequently Asked Questions about How To Lubricate A Syringe Plunger

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Lubricate A Syringe Plunger”