Articles

How To Lubricate A Water Pump

Modified: January 8, 2024

Learn how to properly lubricate your water pump with this informative article. Discover the best techniques and products to keep your pump running smoothly.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Water pumps are vital components in various systems, including automotive engines, HVAC systems, and irrigation systems. These pumps play a crucial role in circulating and moving water, ensuring the efficient operation of the system they are a part of. Like any mechanical device, water pumps require regular maintenance to keep them running smoothly and to extend their lifespan. One important aspect of their maintenance is proper lubrication.

Lubricating a water pump helps to minimize friction, reduce wear and tear, and prevent overheating. This maintenance task ensures that the pump operates efficiently, maximizing its performance and reliability. In this article, we will delve into the importance of lubrication for water pumps and provide a step-by-step guide on how to properly lubricate them.

Key Takeaways:

- Proper lubrication is crucial for water pump maintenance, reducing friction, preventing wear and tear, and dissipating heat, ensuring optimal performance and longevity.

- Choosing the right lubricant and following safety precautions are essential for effective water pump lubrication, maximizing efficiency and minimizing potential maintenance issues.

Read more: How To Fix Water Pump

Understanding the Water Pump

A water pump is a mechanical device that is responsible for moving water from one location to another. It is commonly used in various applications, such as circulating coolant in engines, pumping water in irrigation systems, and maintaining optimal water flow in HVAC systems. Understanding the different components of a water pump is essential for effective maintenance.

A typical water pump consists of several key parts. The impeller is a rotating component that creates the necessary pressure and flow, pushing the water through the system. The pump housing or body encloses the impeller and directs the water flow. The shaft connects the impeller to the engine or motor, allowing it to spin and generate the pumping action. Bearings support the rotating shaft, reducing friction and ensuring smooth operation.

Water pumps can be classified into two main types: centrifugal pumps and positive displacement pumps. Centrifugal pumps work by converting rotational energy into kinetic energy, using the impeller to accelerate the water. Positive displacement pumps, on the other hand, use mechanical forces to displace a fixed amount of water with each pump stroke.

It is important to note that different water pump designs may require specific lubricants and maintenance procedures. Therefore, consulting the manufacturer’s guidelines and specifications is crucial to ensure optimal performance and avoid potential damage.

Importance of Lubrication

Lubrication is a critical aspect of water pump maintenance that should not be overlooked. Proper lubrication ensures smooth and efficient operation by minimizing friction and reducing wear and tear on the pump’s components.

One of the primary benefits of lubrication is the reduction of friction between moving parts. In a water pump, the impeller spins rapidly, creating pressure and forcing the water to move. Without proper lubrication, the metal components of the impeller and the pump housing can rub against each other, leading to increased friction and heat generation. Over time, this friction can cause damage to the pump, resulting in decreased performance and potentially costly repairs.

Lubrication also helps to prevent wear and tear on the pump’s components. As the impeller rotates, the shaft and bearings support the rotating motion. Without lubrication, the continuous friction can wear down the bearings, leading to premature failure. Lubricants act as protective barriers, reducing the contact between metal surfaces and preventing excessive wear.

Furthermore, lubrication plays a crucial role in dissipating heat. Water pumps can generate a significant amount of heat during operation, particularly in demanding applications. The lubricant acts as a coolant, absorbing and dispersing the heat away from critical components. This helps to maintain the pump’s optimal operating temperature and prevent overheating, which can cause severe damage to the pump’s internal parts.

Proper lubrication also contributes to the overall efficiency of the water pump. By minimizing friction and reducing wear, the pump can operate more smoothly and require less energy to perform its intended function. This translates to improved performance, lower energy consumption, and potentially reduced operating costs.

Overall, lubrication is essential for maintaining the longevity and reliability of water pumps. By avoiding excessive friction, reducing wear and tear, dissipating heat, and improving efficiency, proper lubrication ensures that the water pump operates at its best, providing optimal performance and prolonging its lifespan.

Types of Lubricants for Water Pumps

When it comes to lubricating water pumps, it is important to choose the right type of lubricant for optimal performance and protection. Different lubricants offer various properties and are designed for specific applications. Here are some common types of lubricants used for water pumps:

- Grease: Grease is a semi-solid lubricant that is commonly used in water pumps. It offers excellent adhesion and provides a protective film on the pump’s components, minimizing friction and wear. Grease is particularly suitable for pumps with slower rotational speeds and high loads. It is important to select a grease that is designed for use in water pumps and can withstand the operating conditions, such as temperature and moisture levels.

- Oil: Oil lubricants are popular in high-speed water pumps and applications that require continuous lubrication. They have low viscosity, allowing for easy flow and lubrication of intricate components. Oil lubricants can provide effective cooling and dispersal of heat, making them suitable for pumps exposed to high temperatures. It is important to choose an oil that is compatible with the pump’s materials and the specific operating conditions.

- Silicone-based lubricants: Silicone-based lubricants are often used in water pumps that come into contact with rubber components. These lubricants are chemically inert and do not degrade rubber seals or gaskets. They provide excellent lubrication and prevent the drying and cracking of rubber parts, extending their lifespan. Silicone-based lubricants are commonly used in automotive water pumps and other applications where rubber components are present.

- Polytetrafluoroethylene (PTFE) lubricants: PTFE lubricants, commonly known as Teflon lubricants, offer excellent lubrication and resistance to heat and moisture. They reduce friction and provide long-lasting protection against wear. PTFE lubricants are often used in water pumps that operate in extreme conditions or with high-performance requirements, such as racing engines or industrial applications.

It is important to consult the manufacturer’s guidelines and specifications to determine the recommended lubricant type for your specific water pump. Consider factors such as the pump design, operating conditions, and materials used. Using the right lubricant will ensure optimal performance, minimize wear and tear, and prolong the pump’s lifespan.

Regularly lubricate the bearings of the water pump with a high-quality, waterproof grease to ensure smooth and efficient operation.

Step-by-Step Guide: How to Lubricate a Water Pump

Proper lubrication is essential for maintaining the performance and longevity of a water pump. Here is a step-by-step guide on how to effectively lubricate a water pump:

- Refer to the manufacturer’s guidelines: Consult the manufacturer’s manual or documentation for specific instructions on lubrication. Different water pump models may have varying lubrication requirements, so it is important to follow the recommended guidelines.

- Gather the necessary tools and lubricant: Ensure that you have the proper tools and lubricant for the job. Common tools may include a wrench or screwdriver to access the pump, along with the appropriate lubricant recommended for your specific water pump.

- Shut off the pump: Before lubricating the water pump, it is crucial to turn off the power supply or shut down the system to prevent any accidental start-ups or injuries.

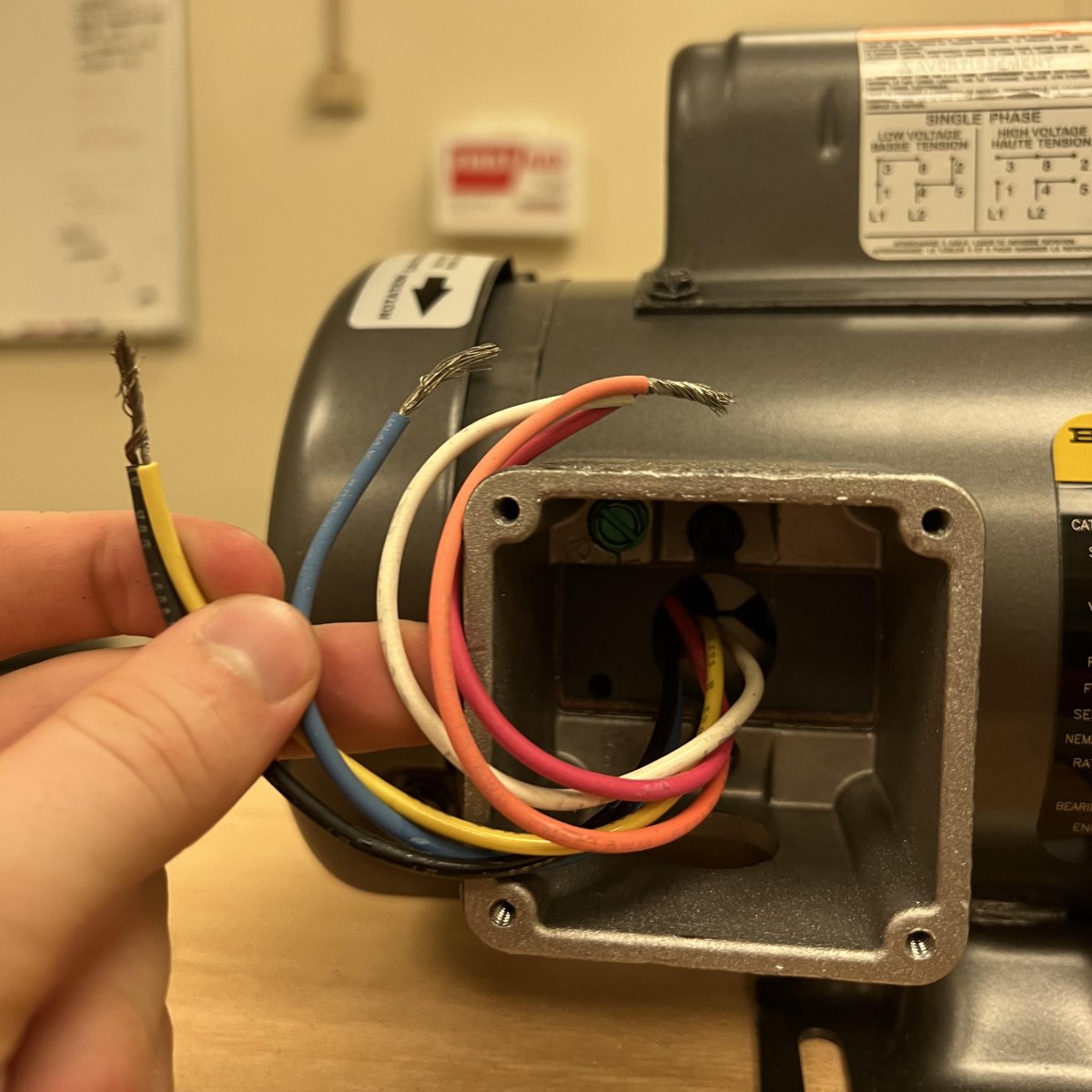

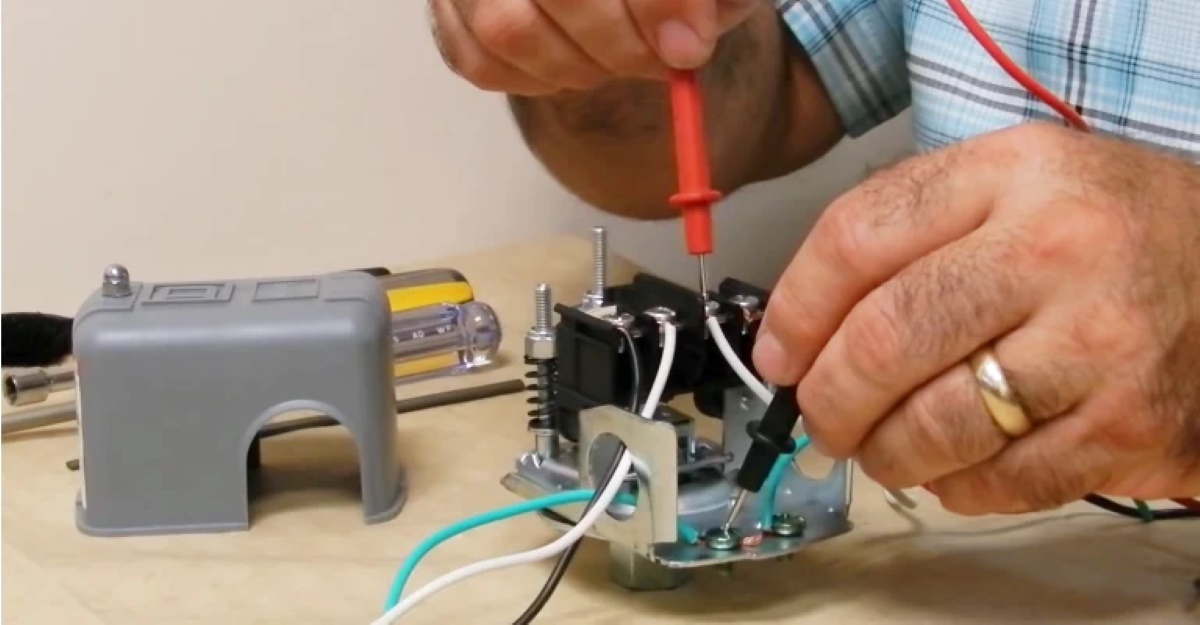

- Access the lubrication points: Locate the lubrication points on the water pump. These are typically marked with an “L” or indicated in the manufacturer’s documentation. Use the appropriate tool to access these points, which may involve removing a cover or loosening a screw or bolt.

- Clean the lubrication points: Before applying new lubricant, it is important to clean the lubrication points to remove any dirt, debris, or old grease. Use a clean cloth or a small brush to wipe away any contaminants.

- Apply the lubricant: Apply a small amount of the recommended lubricant to the lubrication points. Be sure to follow the manufacturer’s guidelines regarding the quantity of lubricant to use. Avoid over-lubrication, as excessive grease or oil can lead to performance issues or component damage.

- Distribute the lubricant: Once the lubricant is applied, rotate the pump’s impeller or shaft by hand to distribute the lubricant evenly. This helps to ensure that all moving parts are properly lubricated.

- Reassemble and test: Once the lubrication process is complete, reassemble any removed covers or components and ensure they are secured properly. Restart the pump or system and monitor its performance to ensure smooth operation.

Regular lubrication is essential for water pump maintenance. The frequency of lubrication will vary depending on factors such as pump usage, operating conditions, and the type of lubricant used. It is recommended to establish a maintenance schedule and adhere to it consistently to keep the water pump running smoothly and efficiently.

Read more: How To Use A Water Pump

Safety Precautions

When performing any maintenance task, including lubricating a water pump, it is important to prioritize safety. Here are some essential safety precautions to keep in mind:

- Read and follow the manufacturer’s instructions: Always refer to the manufacturer’s documentation for specific safety instructions and guidelines. Understand the recommended safety precautions and adhere to them throughout the lubrication process.

- Turn off the power supply: Before starting any work on the water pump, ensure that the power supply is turned off or that the system is shut down. This will prevent accidental start-ups and reduce the risk of injuries or electrical hazards.

- Use appropriate personal protective equipment (PPE): Wear the necessary PPE, such as safety goggles, gloves, and appropriate clothing, to protect yourself from any potential hazards. Different lubricants may have specific handling requirements, so read the product labels and follow the recommended safety precautions.

- Allow the pump to cool down: If the water pump has been running, give it sufficient time to cool down before starting any maintenance tasks. This will minimize the risk of burns or injuries from hot surfaces.

- Secure the pump: Ensure that the water pump is securely mounted or fixed in place before beginning any maintenance. This will prevent any accidental movements or falls during the lubrication process.

- Be cautious of moving parts: When accessing lubrication points, be mindful of any moving parts, such as the impeller or rotating shaft. Avoid placing your hands or fingers near these areas to prevent any injuries.

- Properly dispose of used lubricants: When disposing of used lubricants, follow proper disposal procedures. Some lubricants may be considered hazardous waste and should be disposed of according to local regulations.

- Keep a clean and organized work area: Maintain a clean and organized work area to prevent any accidents or injuries. Store tools and lubricants in a safe and easily accessible manner.

Following these safety precautions will help ensure a safe and successful water pump lubrication process. Remember, if you are unsure or uncomfortable with any aspect of the task, it is always wise to seek professional assistance or guidance.

Common Maintenance Issues and Troubleshooting

While regular maintenance and proper lubrication can go a long way in preventing issues with water pumps, occasional problems may still arise. Here are some common maintenance issues that can occur and some troubleshooting tips to address them:

- Insufficient lubrication: If the water pump is not adequately lubricated, it can result in increased friction and wear. Ensure that you are using the correct lubricant and applying it according to the manufacturer’s recommendations. Regularly check the lubrication points and reapply lubricant as needed.

- Loud or unusual noises: Unusual noises, such as squealing, grinding, or knocking sounds, can indicate problems with the water pump. This could be due to issues with bearings, misalignment, or a worn impeller. Inspect the pump for any signs of damage or loose components. In such cases, it is recommended to consult a professional for further diagnosis and repairs.

- Leakage: Water pump leaks can be caused by damaged seals, gaskets, or worn-out O-rings. Inspect the pump for any visible signs of leakage, such as water stains or puddles. Replace any faulty seals or gaskets and ensure they are properly installed and tightened.

- Overheating: If the water pump is overheating, it can lead to reduced performance and potential damage. Check for any obstructions in the pump’s intake or discharge pipes that may restrict water flow. Ensure that the cooling system is functioning correctly and that the pump is properly lubricated to dissipate heat effectively.

- Inconsistent water flow: Fluctuating water flow or a decrease in water pressure can be indicative of a water pump issue. Check for any clogs or blockages in the pump or the system it is connected to. Inspect hoses and pipes for leaks or damage. Clean or replace any clogged filters or strainers that may be affecting water flow.

- Excessive vibrations: Excessive vibrations can indicate misalignment or an unbalanced impeller. Check the pump’s mounting and ensure that it is securely installed. Inspect the impeller for any signs of damage, such as bends or cracks. Balancing the impeller may be necessary to eliminate vibrations and ensure smooth operation.

If you encounter persistent issues or are unable to diagnose and resolve the problem on your own, it is recommended to seek assistance from a professional water pump technician or contact the manufacturer for further guidance.

Conclusion

Maintaining and properly lubricating a water pump is crucial for ensuring its optimal performance, longevity, and reliability. By minimizing friction, reducing wear and tear, dissipating heat, and improving efficiency, lubrication plays a key role in the smooth operation of water pumps in various applications.

In this article, we have explored the importance of lubrication for water pumps and provided a step-by-step guide on how to effectively lubricate them. By following the manufacturer’s guidelines, gathering the necessary tools and lubricant, and taking proper safety precautions, you can ensure a successful lubrication process.

Additionally, we have discussed the different types of lubricants commonly used for water pumps, such as grease, oil, silicone-based lubricants, and PTFE lubricants. Choosing the right type of lubricant based on the pump’s design, operating conditions, and manufacturer’s recommendations is vital for achieving optimal results.

We have also highlighted some common maintenance issues that may arise with water pumps, such as insufficient lubrication, unusual noises, leakage, overheating, inconsistent water flow, and excessive vibrations. Troubleshooting these issues and taking appropriate measures, such as inspecting for damage, cleaning or replacing components, and seeking professional assistance as needed, can help resolve the problems effectively.

In conclusion, proper lubrication and maintenance are essential for keeping water pumps running smoothly and efficiently. By incorporating regular lubrication into your maintenance routine, you can extend the lifespan of your water pump, maximize its performance, and minimize the risk of potential issues. So, remember to follow the recommended lubrication procedures, adhere to safety precautions, and address any maintenance issues promptly to ensure the optimum functioning of your water pump.

Frequently Asked Questions about How To Lubricate A Water Pump

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Lubricate A Water Pump”