Home>Furniture & Design>Interior Design Trends>How To Sublimate On Glass

Interior Design Trends

How To Sublimate On Glass

Published: February 3, 2024

Learn how to sublimate on glass to create stunning interior design trends. Discover the latest techniques and ideas for sublimating on glass. Elevate your interior design with unique glass sublimation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Sublimation is a fascinating process that allows you to transfer high-quality images onto various surfaces, including glass. The art of sublimating on glass has gained popularity in the realm of personalized gifts, home decor, and promotional items. By harnessing the power of sublimation, you can transform ordinary glass objects into stunning, custom pieces that capture cherished memories or showcase captivating designs.

Sublimating on glass opens up a world of creative possibilities, enabling you to adorn glassware, photo frames, ornaments, and more with vibrant, permanent images. Whether you're a seasoned sublimation enthusiast or a newcomer eager to explore this innovative technique, mastering the art of sublimating on glass can elevate your crafting endeavors to new heights.

In this comprehensive guide, we will delve into the intricacies of sublimation on glass, providing you with valuable insights, essential materials, and step-by-step instructions to embark on your sublimation journey. By understanding the nuances of this process and following the outlined steps, you can unlock the potential to produce awe-inspiring, personalized glass creations that resonate with your unique style and vision.

Join us as we unravel the art of sublimating on glass, empowering you to infuse ordinary glass surfaces with extraordinary designs and memories. Let's embark on this creative adventure and discover the transformative magic of sublimation on glass.

Key Takeaways:

- Sublimation on glass allows you to transfer vibrant images onto glass surfaces, creating personalized and enduring glass products. With the right materials and meticulous steps, you can infuse ordinary glass with extraordinary designs and memories.

- By mastering the art of sublimating on glass, you can transform ordinary glass items into visually captivating and enduring personalized creations. Embrace the transformative magic of sublimation on glass to unleash your creativity and craft stunning, one-of-a-kind glass products.

Read more: How To Convert A Printer To Sublimation

Understanding Sublimation on Glass

Sublimation on glass involves the transfer of vibrant, high-resolution images onto glass surfaces using a combination of heat, pressure, and specialized sublimation dyes. This process enables the seamless integration of intricate designs, photographs, and graphics onto glassware, photo frames, ornaments, and various other glass-based items. The result is a permanent, visually striking image that is resistant to fading, peeling, or scratching, making it an ideal method for creating personalized and long-lasting glass products.

The key to successful sublimation on glass lies in the unique properties of sublimation dyes. When exposed to heat and pressure, these dyes undergo a phase transition, transforming from a solid state directly into a gaseous state without passing through the liquid phase. This allows the dyes to permeate the surface of the glass, bonding with the substrate at a molecular level. As the glass cools, the dyes solidify within the surface, resulting in a durable, seamless image that becomes an integral part of the glass itself.

Glass, with its smooth and non-porous surface, provides an excellent substrate for sublimation. The absence of surface texture allows for the faithful reproduction of intricate details and vibrant colors, ensuring that the transferred images retain their clarity and brilliance. Additionally, the versatility of glass as a medium for sublimation offers endless creative opportunities, from producing personalized gifts and keepsakes to crafting custom home decor and promotional items.

Understanding the intricacies of sublimation on glass empowers crafters and entrepreneurs to unleash their creativity and bring their designs to life in a visually captivating and enduring manner. By mastering the art of sublimating on glass, individuals can elevate their crafting endeavors, offering unique and personalized glass products that resonate with their customers' preferences and aspirations.

In the following sections, we will explore the essential materials required for sublimating on glass and provide detailed step-by-step instructions to guide you through the sublimation process, enabling you to create stunning, personalized glass creations with confidence and precision. Let's embark on this exciting journey and unlock the transformative potential of sublimation on glass.

Materials Needed

To embark on the captivating journey of sublimating on glass, you will need a carefully curated selection of materials and equipment to ensure a seamless and successful sublimation process. These essential items are instrumental in facilitating the transfer of vibrant, high-resolution images onto glass surfaces, enabling you to create personalized and enduring glass products that captivate the senses. Here's a comprehensive list of the materials needed to commence your sublimation adventure:

-

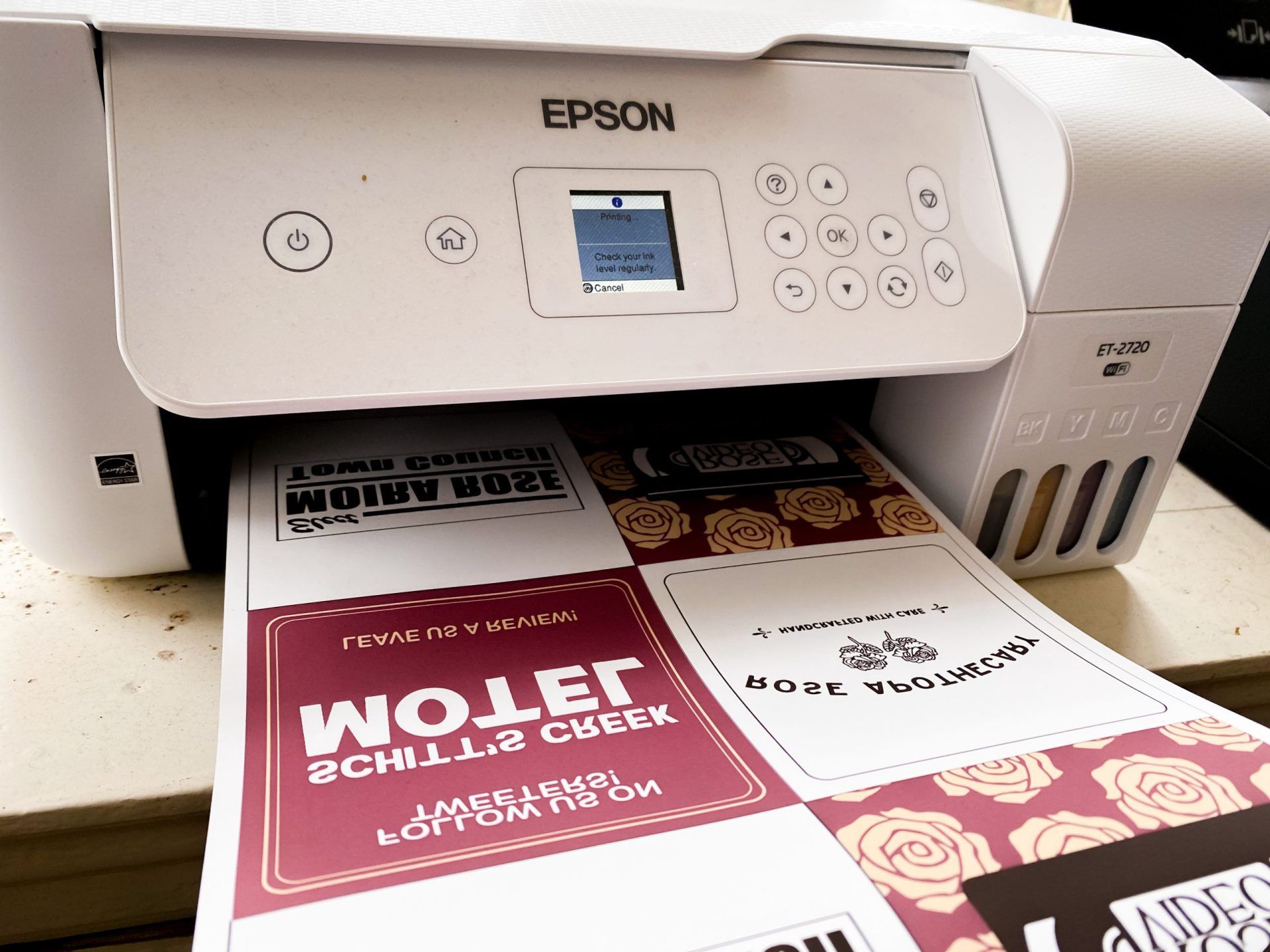

Sublimation Printer: A high-quality sublimation printer equipped with sublimation inks is the cornerstone of the sublimation process. Ensure that your printer is compatible with sublimation inks and capable of producing vivid, color-accurate prints for optimal sublimation results.

-

Sublimation Paper: Specialized sublimation paper is designed to hold sublimation inks and release them onto the glass surface during the heat transfer process. It is crucial to use sublimation paper specifically formulated for sublimating on glass to achieve exceptional image transfer quality.

-

Sublimation Inks: Sublimation inks, available in a range of vibrant colors, are essential for producing high-fidelity images that can be transferred onto glass surfaces. These inks undergo a phase transition from solid to gas under heat and pressure, ensuring a seamless and durable image transfer onto the glass.

-

Heat-Resistant Tape: Heat-resistant tape is utilized to secure the sublimation paper onto the glass substrate during the heat transfer process. This ensures that the paper remains in place, preventing any movement that may compromise the image transfer.

-

Heat-Resistant Gloves: When working with heat presses or ovens during the sublimation process, heat-resistant gloves are indispensable for ensuring safety and protection from high temperatures. These gloves enable you to handle hot glass substrates and equipment with confidence and ease.

-

Heat Press or Convection Oven: A heat press or convection oven serves as the primary heat source for sublimating on glass. It applies the necessary heat and pressure to facilitate the sublimation process, ensuring the seamless transfer of images from the sublimation paper to the glass substrate.

-

Glass Substrates: Select glass substrates such as glassware, photo frames, ornaments, or any other glass-based items that serve as the canvas for your sublimated designs. Ensure that the glass surfaces are clean, smooth, and free from any contaminants to achieve optimal sublimation results.

-

Protective Paper: Utilize protective paper to cover the sublimation paper and glass substrate during the heat transfer process. This protective layer prevents any potential ink or residue from coming into direct contact with the heat press or oven, safeguarding the equipment and ensuring clean, consistent transfers.

By assembling these essential materials, you are poised to embark on a captivating sublimation journey, where you can infuse ordinary glass surfaces with extraordinary designs and memories. With these foundational materials at your disposal, you are well-equipped to explore the step-by-step process of sublimating on glass, transforming your creative visions into stunning, personalized glass creations.

Preheat the glass before sublimating to ensure the design adheres properly. Use a lint-free cloth to clean the glass and a heat-resistant tape to secure the design in place.

Steps to Sublimate on Glass

-

Image Selection and Preparation: Begin by selecting the desired image or design for sublimation onto the glass substrate. Ensure that the chosen image is of high resolution and compatible with the dimensions of the glass surface. Use graphic design software to adjust the image size and enhance its visual appeal if necessary.

-

Printing the Image: Load the sublimation printer with the specialized sublimation paper and print the selected image using sublimation inks. It is crucial to mirror the image during the printing process to ensure that it transfers onto the glass substrate in the correct orientation.

-

Preparing the Glass Substrate: Thoroughly clean the glass substrate to remove any dust, fingerprints, or debris that may interfere with the sublimation process. Ensure that the glass surface is smooth and free from imperfections to facilitate optimal image transfer.

-

Securing the Sublimation Paper: Place the printed sublimation paper onto the clean glass substrate, ensuring that the image is positioned accurately. Use heat-resistant tape to secure the sublimation paper in place, preventing any movement during the heat transfer process.

-

Protective Layer Placement: Place a sheet of protective paper over the secured sublimation paper and glass substrate. This protective layer serves to shield the heat press or convection oven from any potential ink or residue, ensuring clean and consistent image transfers.

-

Heat Transfer Process: Utilize a heat press or convection oven to apply the necessary heat and pressure for the sublimation process. Follow the manufacturer's guidelines for temperature and duration, allowing the sublimation inks to transform into a gaseous state and permeate the glass surface.

-

Cooling and Unveiling: Once the heat transfer process is complete, carefully remove the glass substrate from the heat press or oven. Allow it to cool before gently peeling off the sublimation paper and revealing the transferred image. The result is a vibrant, permanent image seamlessly integrated into the glass substrate.

-

Final Touches: After the image transfer, inspect the glass substrate for any imperfections or areas that may require touch-ups. If necessary, use a soft cloth and gentle cleaning solution to enhance the clarity and brilliance of the transferred image, ensuring a flawless and visually captivating final product.

By following these meticulous steps, you can master the art of sublimating on glass, transforming ordinary glass surfaces into personalized and enduring works of art. The seamless integration of vibrant, high-resolution images onto glass substrates opens up a world of creative possibilities, allowing you to craft custom glassware, photo frames, ornaments, and more with precision and flair. Embrace the transformative magic of sublimation on glass and unleash your creativity to produce stunning, personalized glass creations that captivate the senses and resonate with your unique style and vision.

Tips and Tricks

Mastering the art of sublimating on glass requires attention to detail and a nuanced understanding of the sublimation process. To enhance your sublimation endeavors and achieve impeccable results, consider the following tips and tricks that can elevate your craft and ensure a seamless and rewarding sublimation experience:

-

Optimal Image Resolution: Prioritize high-resolution images to ensure the clarity and vibrancy of the transferred designs. Images with higher pixel density result in sharper and more detailed transfers onto glass substrates, enhancing the visual impact of the final products.

-

Mirror Image Printing: Always mirror the selected images during the printing process to ensure that they transfer onto the glass substrate in the correct orientation. This simple yet crucial step prevents the transferred designs from appearing reversed or distorted on the glass surface.

-

Even Pressure Distribution: When using a heat press for sublimation, ensure that the pressure is evenly distributed across the glass substrate. This promotes uniform ink transfer and prevents potential inconsistencies or distortions in the transferred images.

-

Temperature and Timing Precision: Adhere to the recommended temperature and duration guidelines provided by the sublimation equipment manufacturer. Maintaining precise control over the heat transfer process is essential for achieving optimal sublimation results and preserving the integrity of the transferred images.

-

Test Transfers and Calibration: Conduct test transfers on sample glass substrates to fine-tune the sublimation process and assess the color accuracy and image clarity. Calibration of the sublimation equipment and settings can help optimize the image transfer quality before proceeding with final production.

-

Surface Preparation: Thoroughly clean the glass substrates before sublimation to ensure a smooth and contaminant-free surface. Use lint-free cloths and specialized cleaning solutions to remove any residues or impurities that may compromise the image transfer quality.

-

Protective Measures: Employ protective paper and heat-resistant tape to safeguard the sublimation equipment and glass substrates during the heat transfer process. These protective measures help prevent any ink or residue from coming into direct contact with the equipment, ensuring consistent and clean transfers.

-

Post-Transfer Inspection: After the heat transfer process, carefully inspect the transferred images for any imperfections or areas that may require touch-ups. Address any minor flaws with gentle cleaning and touch-up techniques to enhance the overall quality of the transferred designs.

By incorporating these tips and tricks into your sublimation practices, you can elevate the precision and visual impact of your sublimated glass creations. These insights empower you to navigate the sublimation process with confidence and finesse, ensuring that your personalized glass products exude unparalleled quality and enduring beauty. Embrace these valuable tips and tricks as you embark on your sublimation journey, and revel in the transformative magic of sublimating on glass.

Read more: How To Sublimate A Blanket

Conclusion

In conclusion, the art of sublimating on glass presents a captivating avenue for infusing ordinary glass surfaces with extraordinary designs and memories. Through the seamless integration of vibrant, high-resolution images onto glass substrates, individuals can embark on a creative journey that yields personalized and enduring glass creations. The transformative magic of sublimation on glass empowers crafters, entrepreneurs, and enthusiasts to elevate their crafting endeavors, offering unique and visually captivating glass products that resonate with personal style and vision.

By understanding the nuances of sublimation on glass and following the meticulous steps outlined in this guide, individuals can unlock the potential to produce awe-inspiring glass creations with confidence and precision. The essential materials, including sublimation printers, specialized sublimation paper, inks, and heat-resistant equipment, form the foundation for a successful sublimation process. These materials, when combined with attention to detail and the incorporation of valuable tips and tricks, enable crafters to achieve impeccable results and elevate the visual impact of their sublimated glass products.

The journey of sublimating on glass encompasses the careful selection and preparation of images, the precise printing process, the meticulous preparation of glass substrates, and the application of heat and pressure to facilitate the seamless transfer of designs. Each step in the sublimation process contributes to the creation of personalized glassware, photo frames, ornaments, and various other glass-based items that capture cherished memories and showcase captivating designs.

As individuals delve into the realm of sublimation on glass, they are invited to explore the boundless creative opportunities that this innovative technique offers. From crafting custom home decor and personalized gifts to producing promotional items with enduring visual appeal, sublimating on glass empowers individuals to transform their creative visions into tangible, visually striking realities.

The journey of sublimating on glass is not merely a process; it is an immersive and rewarding experience that enables individuals to infuse their creativity and passion into every personalized glass creation. With each vibrant, permanent image seamlessly integrated into the glass substrate, the art of sublimation on glass becomes a testament to the enduring beauty and captivating allure of personalized craftsmanship.

In essence, the art of sublimating on glass transcends conventional crafting techniques, offering a transformative and visually captivating method for creating personalized glass products that resonate with individual style and sentiment. As individuals embark on their sublimation journey, they are invited to embrace the transformative magic of sublimation on glass and revel in the joy of crafting enduring, personalized glass creations that captivate the senses and enrich the lives of those who behold them.

Frequently Asked Questions about How To Sublimate On Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Sublimate On Glass”