Home>Technology>Smart Home Devices>How To Convert A Printer To Sublimation

Smart Home Devices

How To Convert A Printer To Sublimation

Modified: February 18, 2024

Learn how to convert your printer to sublimation for vibrant prints on smart home devices. Follow our step-by-step guide for stunning results.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Welcome to the world of sublimation printing, where ordinary items can be transformed into personalized, vibrant creations. Converting a standard printer into a sublimation printer opens up a realm of creative possibilities, allowing you to transfer intricate designs onto various surfaces with exceptional clarity and durability.

Sublimation printing is a versatile technique that has gained popularity for its ability to produce high-quality, long-lasting prints on a wide range of materials, including garments, mugs, phone cases, and more. By harnessing the power of sublimation, you can breathe new life into everyday objects, turning them into unique works of art or personalized gifts.

In this guide, we will delve into the intricacies of sublimation printing and explore the process of converting a regular printer into a sublimation powerhouse. From understanding the fundamentals of sublimation to selecting the right printer, acquiring the necessary ink and paper, and executing the conversion process, this comprehensive resource will equip you with the knowledge and confidence to embark on your sublimation printing journey.

So, whether you are a seasoned crafter looking to expand your creative repertoire or a budding entrepreneur seeking to add a personalized touch to your products, join us as we unravel the fascinating world of sublimation printing and learn how to convert a printer to sublimation.

**

Key Takeaways:

- Unleash your creativity by converting a standard printer into a sublimation powerhouse, bringing vibrant, long-lasting prints to life on a variety of surfaces with exceptional clarity and durability.

- Dive into the captivating world of sublimation printing, where ordinary items are transformed into personalized works of art, offering endless possibilities for customization and self-expression.

Read more: How To Convert To A Sublimation Printer

Understanding Sublimation Printing

Sublimation printing is a unique method that allows for the transfer of full-color images onto a variety of surfaces using heat and pressure. Unlike traditional inkjet or laser printing, which applies ink onto the surface of the material, sublimation printing involves the conversion of solid dye particles into a gas, which permeates the substrate and solidifies upon cooling. This results in vibrant, permanent, and high-resolution prints that are resistant to fading, peeling, or washing out.

The magic of sublimation lies in the chemical process of sublimation, where a solid substance bypasses the liquid phase and transforms directly into a gas under specific conditions. In the case of sublimation printing, specialized sublimation inks are used, containing solid dyes that have the remarkable ability to sublimate when exposed to heat. This process enables the dyes to infuse the surface of the substrate, creating a seamless bond that is both durable and visually striking.

One of the key advantages of sublimation printing is its versatility. It can be applied to a wide range of items, including polyester fabrics, ceramic mugs, metal plates, and polymer-coated substrates, offering endless possibilities for customization and personalization. Whether you are looking to adorn apparel with intricate designs, create custom home décor, or produce promotional items with a professional finish, sublimation printing empowers you to unleash your creativity and bring your vision to life.

Furthermore, sublimation prints are known for their exceptional washability and resistance to abrasion, making them ideal for items that will endure frequent use and laundering. The resulting prints boast a soft, smooth feel without compromising on color vibrancy, making them highly sought after in the world of personalized products and custom merchandise.

By understanding the principles of sublimation printing and the science behind its transformative capabilities, you can harness this innovative technique to elevate your crafting endeavors and unlock new opportunities for self-expression and creativity.

**

Choosing the Right Printer

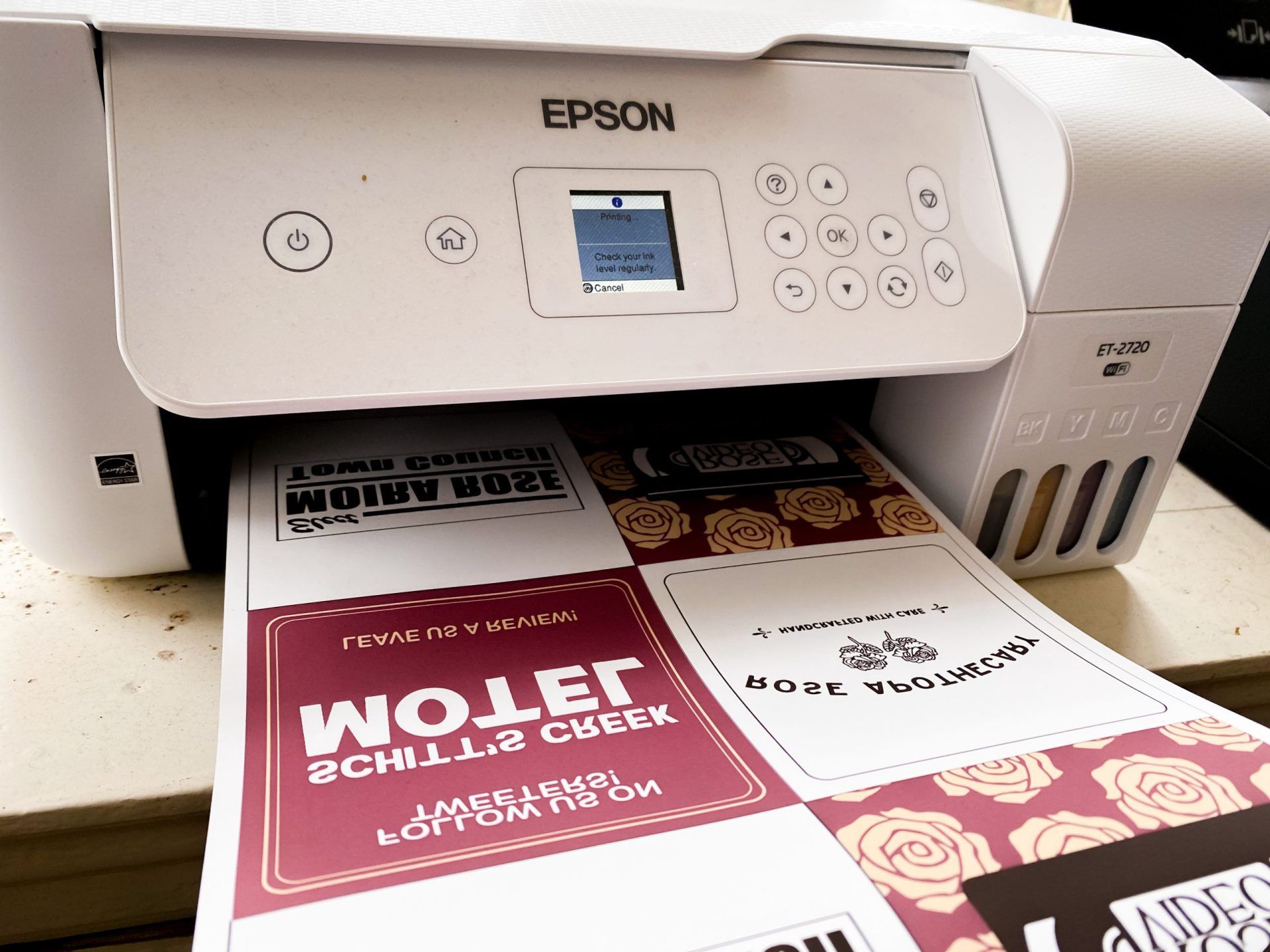

When venturing into the realm of sublimation printing, selecting the right printer is a crucial first step. Not all printers are compatible with sublimation inks, so it is essential to choose a model that is specifically designed or can be modified for sublimation printing.

One of the primary considerations when choosing a printer for sublimation is the printhead technology. Printers equipped with piezoelectric printheads are preferred for sublimation printing due to their ability to handle liquid sublimation inks effectively. These printheads are designed to produce precise droplet placement and consistent ink delivery, resulting in sharp, detailed prints with vibrant colors.

Additionally, it is important to opt for a printer that offers a wide color gamut and high resolution to ensure that your sublimation prints exhibit exceptional clarity and color accuracy. Look for models with dedicated black ink cartridges to achieve deep, rich blacks in your prints, as well as individual color cartridges for efficient ink usage and easy replacement.

Another crucial factor to consider is the size of the printer. Depending on your intended applications, you may require a printer with a larger format capability to accommodate various print sizes. Whether you plan to create large-scale artwork, produce custom apparel, or personalize oversized items, such as blankets or tapestries, a wide-format printer can provide the versatility and flexibility needed to bring your creative visions to fruition.

Furthermore, the compatibility of the printer with third-party sublimation inks and continuous ink supply systems (CISS) should be taken into account. Some printers may have restrictions or limitations when it comes to using non-OEM inks or CISS, so it is advisable to research and select a model that allows for seamless integration with sublimation-specific ink formulations and ink delivery systems.

Before making a decision, it is beneficial to consult with knowledgeable suppliers or technicians who can provide guidance on choosing a printer that aligns with your specific sublimation printing requirements. By investing in a reliable and suitable printer, you can lay a solid foundation for achieving professional-quality sublimation prints and unlocking the full potential of this captivating printing technique.

**

Sublimation Ink and Paper

Central to the success of sublimation printing are the specialized inks and transfer paper used in the process. Unlike traditional printing inks, sublimation inks are formulated with dyes that have the unique ability to sublimate from a solid to a gas state under heat and pressure, enabling them to bond with the surface of the substrate at a molecular level.

Sublimation inks are typically available in individual color cartridges, mirroring the CMYK color model (cyan, magenta, yellow, and black), and are designed to deliver vibrant, true-to-life colors with exceptional fade resistance. The use of high-quality sublimation inks is paramount in achieving durable, long-lasting prints that retain their brilliance even after repeated washings or prolonged exposure to light.

When it comes to selecting sublimation transfer paper, it is essential to choose a type that is specifically engineered for sublimation printing. Sublimation transfer paper acts as the carrier for the sublimation inks during the transfer process, facilitating the release and absorption of the dyes onto the target substrate. The paper must be capable of withstanding the heat and pressure required for sublimation, while also promoting the precise transfer of the ink without smudging or blurring.

Sublimation transfer papers are available in different varieties, including standard, fast-drying, and tacky versions, each tailored to accommodate specific applications and substrates. Factors such as drying time, ink absorption, and adhesion properties should be taken into consideration when choosing the appropriate transfer paper for your sublimation projects.

It is important to note that sublimation inks and transfer papers are designed for use with sublimation-compatible printers and substrates, such as polyester fabrics, polymer-coated items, and certain rigid materials. The synergy between the ink, paper, and substrate is integral to the sublimation process, ensuring that the transferred images exhibit sharp detail, vivid colors, and superior durability.

By investing in high-quality sublimation inks and transfer papers that are tailored to your specific printing setup and intended applications, you can elevate the quality and longevity of your sublimation prints, bringing your designs to life with striking precision and enduring vibrancy.

**

Before converting a printer to sublimation, make sure it is compatible with sublimation ink. Research and follow a step-by-step guide to avoid damaging the printer.

Converting Your Printer

**

Converting a standard inkjet printer into a sublimation printer involves a series of steps to ensure that the printer is equipped to handle sublimation inks and produce high-quality, heat-activated prints. While the process may vary depending on the specific printer model, the following general guidelines can serve as a roadmap for the conversion process.

Assessing Printer Compatibility: Before embarking on the conversion, it is essential to verify that your printer is compatible with sublimation inks and can accommodate the heat and pressure requirements of the sublimation transfer process. Certain printer models may be better suited for conversion due to their printhead technology, ink delivery system, and overall design.

Cleaning and Preparation: Thoroughly clean the internal components of the printer, including the ink delivery system and printheads, to remove any residual ink or contaminants that could interfere with the performance of the sublimation inks. Proper cleaning and maintenance help ensure smooth ink flow and optimal print quality.

Installing Sublimation Ink System: Depending on the printer model, you may need to install a continuous ink supply system (CISS) or refillable cartridges designed for sublimation inks. This involves replacing the standard ink cartridges with sublimation-specific cartridges or reservoirs, allowing for the seamless delivery of sublimation inks to the printheads.

Adjusting Printer Settings: Configure the printer settings to align with the requirements of sublimation printing. This may involve adjusting print quality, color management, and ink density settings to optimize the output for sublimation transfers. Additionally, ensure that the printer driver is compatible with sublimation inks and transfer paper.

Performing Test Prints: After the conversion is complete, conduct test prints using sublimation inks and transfer paper to evaluate the print quality, color accuracy, and overall performance of the converted printer. Make any necessary adjustments to the settings or ink delivery system to achieve the desired results.

Calibrating Color Profiles: Calibrate the color profiles of the printer to ensure accurate color reproduction and consistency across different substrates. Proper color management is essential for achieving vibrant, true-to-life prints with precise color rendition.

Seeking Professional Assistance: If you are unsure about the conversion process or encounter technical challenges, consider seeking guidance from experienced professionals or technicians who specialize in sublimation printing. Their expertise can provide valuable insights and troubleshooting support.

By following these steps and ensuring meticulous attention to detail, you can successfully convert your standard printer into a reliable and efficient sublimation printing workhorse, unlocking the potential to create stunning, personalized prints on a diverse array of substrates.

**

Testing Your Sublimation Printer

Once you have converted your standard printer into a sublimation powerhouse, it is essential to conduct thorough testing to gauge the performance, print quality, and color accuracy of the newly transformed device. Testing your sublimation printer allows you to fine-tune settings, verify ink compatibility, and ensure that the prints meet your expectations before embarking on full-scale production.

Print Quality Assessment: Begin by printing a series of test images that encompass a range of colors, gradients, and fine details. Evaluate the sharpness, clarity, and overall vibrancy of the prints to ascertain the capabilities of the sublimation printer in reproducing intricate designs and vivid hues.

Color Accuracy Verification: Test the color accuracy of the prints by comparing them to the original digital designs. Pay close attention to skin tones, subtle color transitions, and vibrant hues to confirm that the sublimation inks accurately replicate the intended colors without any shifts or discrepancies.

Wash and Wear Testing: To assess the durability of the sublimation prints, subject the test images to simulated washing and wearing conditions. Launder the printed fabrics according to the recommended guidelines for sublimation prints and examine the colorfastness, adhesion, and overall resilience of the prints after exposure to repeated wash cycles.

Substrate Compatibility Check: Experiment with different substrates, such as polyester fabrics, ceramic mugs, and metal panels, to determine the compatibility and versatility of the sublimation printer. Verify that the prints adhere effectively to various surfaces and exhibit consistent quality across different substrates.

Heat and Pressure Optimization: Fine-tune the heat press settings and pressure parameters when transferring sublimation prints onto different substrates. By experimenting with varying heat and pressure levels, you can optimize the transfer process to achieve optimal color saturation and ink penetration for each type of substrate.

Color Management Refinement: Utilize color management tools and software to refine the color profiles and achieve precise color rendition across different substrates. Calibrate the printer settings to ensure color consistency and accuracy, especially when producing prints for diverse applications and materials.

Feedback and Iterative Improvement: Solicit feedback from peers, clients, or trusted individuals to gather insights on the quality and appeal of the sublimation prints. Use constructive feedback to iteratively refine the printing process and address any areas that require enhancement or adjustment.

By conducting comprehensive testing and refinement of your sublimation printer, you can ascertain its capabilities, identify opportunities for improvement, and establish a solid foundation for delivering exceptional sublimation prints that captivate and endure.

**

Conclusion

Embarking on the journey to convert a standard printer into a sublimation printer opens up a world of creative possibilities, empowering you to produce vibrant, personalized prints on an array of surfaces with exceptional durability and color retention. Through the understanding of sublimation printing principles, careful selection of the right printer, and the utilization of specialized sublimation inks and transfer papers, you can embark on a transformative crafting experience that transcends traditional printing methods.

The process of converting your printer into a sublimation powerhouse involves meticulous attention to detail, from cleaning and preparing the printer to installing sublimation ink systems and fine-tuning printer settings. By embracing this conversion process and conducting thorough testing, you can ensure that your sublimation printer is primed to deliver professional-quality prints that meet your exacting standards.

Sublimation printing offers unparalleled versatility, allowing you to adorn a diverse range of items, including apparel, accessories, and home décor, with intricate designs and vibrant imagery. The durability and washability of sublimation prints make them ideal for creating personalized products, custom merchandise, and unique gifts that leave a lasting impression.

As you venture into the realm of sublimation printing, remember that continuous refinement and experimentation are key to unlocking the full potential of your sublimation printer. By honing your color management skills, optimizing heat and pressure settings, and exploring diverse substrates, you can expand your creative horizons and cultivate a signature style that resonates with your audience.

Whether you are a seasoned crafter seeking to elevate your creations or an entrepreneur aiming to offer bespoke, personalized products, the conversion of a printer to sublimation presents an exciting opportunity to infuse your designs with unparalleled vibrancy and longevity. Embrace the artistry of sublimation printing, and let your imagination soar as you transform ordinary items into extraordinary works of art.

With the knowledge and insights gained from this guide, you are poised to embark on a captivating sublimation printing journey, armed with the tools and expertise to convert a printer into a sublimation powerhouse and unlock a world of creative expression.

Frequently Asked Questions about How To Convert A Printer To Sublimation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Convert A Printer To Sublimation”