Home>Technology>Smart Home Devices>How To Use Sublimation Printer For Shirts

Smart Home Devices

How To Use Sublimation Printer For Shirts

Modified: January 14, 2024

Learn how to use a sublimation printer to create custom shirts at home with our step-by-step guide. Discover the best techniques for printing on smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of sublimation printing for shirts! If you're eager to create custom, vibrant, and long-lasting designs on your shirts, then sublimation printing is the perfect technique for you. This innovative printing method allows you to transfer your unique designs onto specially coated materials, resulting in stunning, permanent images that won't fade, crack, or peel over time.

Sublimation printing is a popular choice for creating personalized shirts, as it offers a level of detail and color vibrancy that traditional printing methods simply can't match. Whether you're a small business owner looking to expand your product offerings, a creative individual with a passion for DIY projects, or someone interested in exploring the world of custom apparel, sublimation printing opens up a world of possibilities.

In this comprehensive guide, we'll delve into the intricacies of sublimation printing for shirts, covering everything from understanding the sublimation process to choosing the right printer, setting up your equipment, and bringing your designs to life. By the end of this journey, you'll be equipped with the knowledge and confidence to embark on your own sublimation printing adventures, creating personalized shirts that stand out with their exceptional quality and visual appeal.

So, let's embark on this exciting exploration of sublimation printing for shirts and unleash your creativity onto the fabric canvas!

Key Takeaways:

- Sublimation printing creates vibrant, long-lasting designs on polyester shirts by bonding ink with the fabric at a molecular level, resulting in exceptional detail and durability.

- To ensure successful sublimation printing, choose a dedicated sublimation printer, meticulously prepare the shirts, and follow proper finishing and care practices to preserve the quality of the printed designs.

Read more: How To Use A Sublimation Printer

Understanding Sublimation Printing

Sublimation printing is a unique and versatile method for transferring designs onto shirts and other polyester-coated items. Unlike traditional printing techniques that rely on ink sitting on the surface of the material, sublimation printing involves the use of special dyes that, when heated, transform into a gas and bond with the polyester fibers on a molecular level. This results in vibrant, durable, and fade-resistant designs that become an integral part of the fabric.

The sublimation process begins with creating a design on a computer and printing it onto special sublimation transfer paper using sublimation ink. The design is then transferred to the shirt through a heat press, where the combination of high temperature and pressure causes the sublimation ink to change from a solid to a gas without passing through the liquid state. This allows the ink to permeate the fibers of the polyester material, resulting in a seamless integration of the design.

It’s important to note that sublimation printing is specifically suited for polyester fabrics or materials coated with a polyester-based coating. This is because the sublimation process relies on the interaction between the sublimation ink and the polyester fibers, which enables the ink to bond permanently with the material. As a result, sublimation printing is not compatible with natural fabrics such as cotton or non-coated materials.

One of the key advantages of sublimation printing is its ability to produce high-resolution, full-color designs with exceptional detail and clarity. Unlike traditional printing methods, sublimation printing allows for the reproduction of intricate patterns, gradients, and photographic images without compromising on quality. The resulting prints are not only visually striking but also incredibly durable, making them ideal for creating custom shirts that withstand the test of time.

By understanding the science behind sublimation printing and its unique capabilities, you’ll be better equipped to harness the full potential of this innovative technique and unleash your creativity in the realm of custom shirt design.

Choosing the Right Sublimation Printer

When venturing into the world of sublimation printing for shirts, selecting the right sublimation printer is a crucial step that significantly impacts the quality and precision of your designs. With a myriad of options available in the market, it’s essential to consider several key factors to ensure that you choose a printer that aligns with your specific needs and budget.

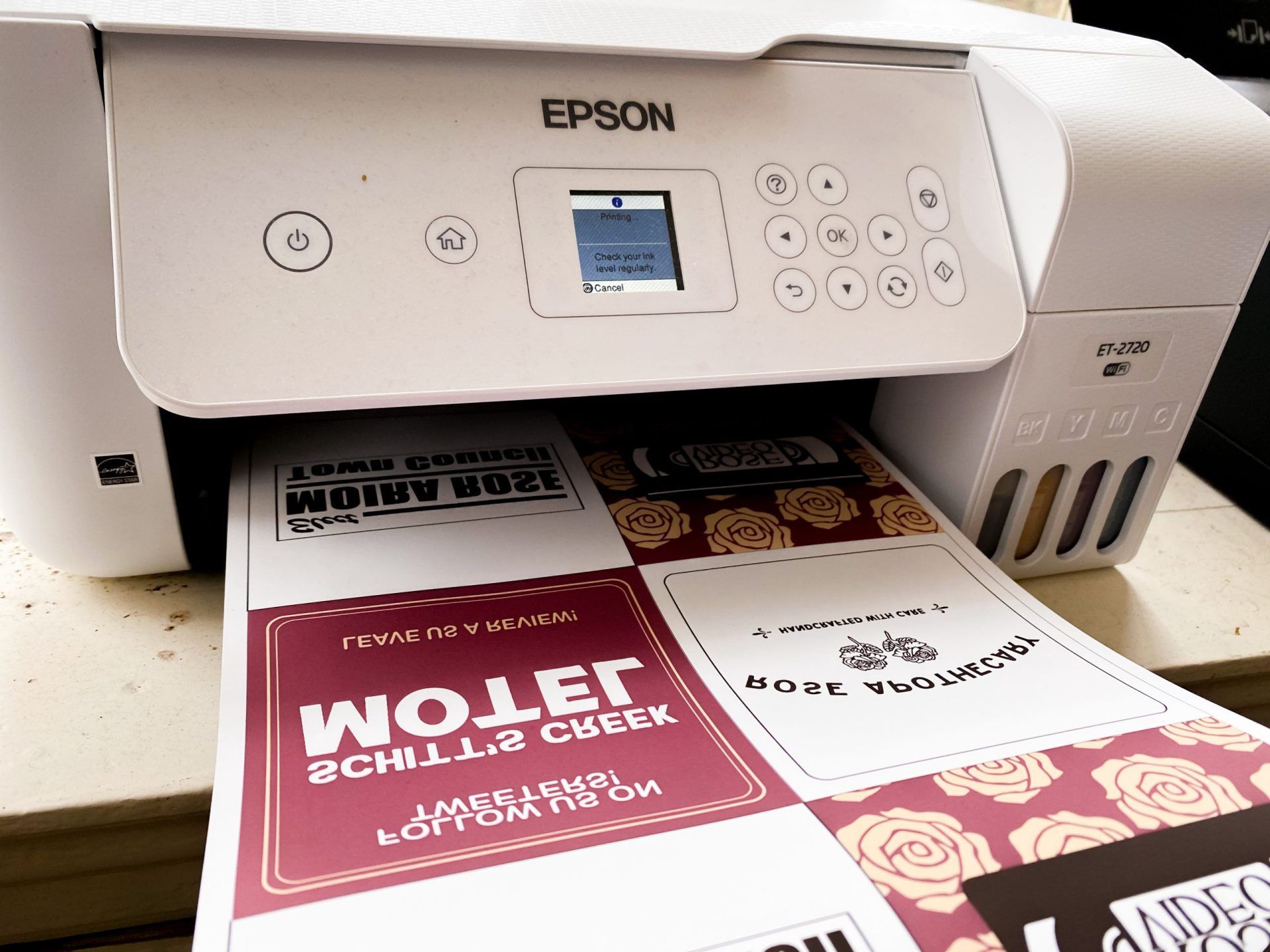

First and foremost, it’s important to opt for a dedicated sublimation printer that is specifically designed to accommodate sublimation ink and transfer paper. While some standard inkjet printers can be converted for sublimation use, dedicated sublimation printers are engineered to deliver optimal results, ensuring vibrant colors and precise ink transfer during the sublimation process.

Resolution and print size are also critical considerations when selecting a sublimation printer. Look for a printer with a high resolution, typically measured in dots per inch (DPI), to ensure that your designs are reproduced with exceptional clarity and detail. Additionally, assess the maximum print size offered by the printer to determine its suitability for your intended shirt designs.

Another crucial factor to evaluate is the ink delivery system of the sublimation printer. Some printers utilize refillable ink tanks or cartridges, while others integrate continuous ink supply systems (CISS) for uninterrupted printing. Assess the ink delivery mechanism to determine which option best aligns with your printing volume and convenience preferences.

Consider the overall cost of ownership, including the price of replacement ink and maintenance supplies, when evaluating different sublimation printers. Additionally, assess the compatibility of the printer with third-party sublimation inks and transfer papers, as this can impact the flexibility and cost-effectiveness of your printing setup.

Furthermore, explore the available software and driver support for the sublimation printer, as well as its compatibility with popular design programs. Seamless integration with design software can streamline the printing process and enhance your ability to bring intricate and personalized designs to life on shirts.

By carefully considering these factors and conducting thorough research, you can make an informed decision when choosing a sublimation printer that meets your specific requirements, empowering you to embark on your sublimation printing journey with confidence and creativity.

Setting Up Your Sublimation Printer

Once you’ve selected the ideal sublimation printer for your shirt printing endeavors, it’s time to set up the printer and prepare it for the sublimation process. Proper installation and configuration of the printer are essential to ensure consistent and high-quality results when transferring your designs onto shirts.

The first step in setting up your sublimation printer is to carefully follow the manufacturer’s instructions for unpacking and assembling the printer. Ensure that all components, such as ink cartridges or tanks, printheads, and paper trays, are correctly installed according to the provided guidelines. Additionally, connect the printer to a reliable power source and compatible computer system as per the manufacturer’s specifications.

Next, it’s crucial to install the appropriate sublimation ink into the designated ink reservoirs of the printer. Follow the manufacturer’s instructions for filling the ink tanks or cartridges, ensuring that the ink is loaded accurately to prevent potential issues during the printing process. Take care to use genuine sublimation ink that is compatible with your specific printer model to maintain optimal performance and print quality.

After the ink installation, it’s essential to configure the printer settings to align with the sublimation transfer paper and the desired print quality. Adjust parameters such as print resolution, paper type, and color management settings to optimize the printing process for sublimation applications. Most sublimation printers offer preset profiles or settings tailored for sublimation printing, simplifying the setup process for optimal results.

Ensure that the printer drivers and software are correctly installed on your computer, allowing seamless communication between the design software and the sublimation printer. Verify that the printer is recognized by your operating system and that any necessary updates or patches are applied to ensure compatibility and performance.

Finally, conduct a test print using the sublimation transfer paper and a sample design to verify the printer’s functionality and the accuracy of the printed output. Adjust any settings or calibration as needed to achieve the desired color accuracy and image clarity before proceeding with actual shirt printing.

By meticulously setting up your sublimation printer in accordance with the manufacturer’s guidelines and best practices, you can establish a reliable and efficient printing system that lays the foundation for creating stunning and enduring designs on shirts through the sublimation process.

Before printing on shirts with a sublimation printer, make sure to use high-quality sublimation ink and transfer paper. Also, ensure that the shirt is made of a polyester fabric for the best results.

Preparing Your Shirt for Printing

Before diving into the sublimation printing process, it’s essential to properly prepare the shirts that will serve as the canvases for your custom designs. Adequate preparation ensures that the sublimation ink adheres seamlessly to the fabric, resulting in vibrant and long-lasting prints that retain their visual appeal over time.

The first step in preparing your shirt for sublimation printing involves selecting high-quality, polyester-coated shirts that are specifically designed to accommodate the sublimation process. It’s crucial to choose shirts made from 100% polyester or a polyester blend with a high polyester content, as the sublimation ink bonds most effectively with polyester fibers, resulting in vivid and durable prints.

Prior to printing, it’s imperative to thoroughly inspect the shirts for any imperfections, stains, or blemishes that may affect the print quality. Ensure that the shirts are clean, free from wrinkles, and devoid of any residual substances that could interfere with the sublimation transfer process. Pre-treating the shirts with a lint roller can help remove any loose fibers or debris that might compromise the print clarity.

To optimize the sublimation transfer process, it’s recommended to pre-press the shirts using a heat press or a dedicated shirt press machine. Pre-pressing serves multiple purposes, including removing excess moisture from the fabric, eliminating wrinkles, and ensuring a flat and even surface for the sublimation transfer. Set the pre-press temperature and duration according to the specific requirements of the shirt material to achieve optimal results.

Once the shirts are prepped and pre-pressed, it’s essential to position them securely on the heat press or sublimation transfer press to facilitate the transfer of the design. Ensure that the shirts are laid out flat and taut, with no folds or creases that could impact the even distribution of the sublimation ink during the transfer process.

By meticulously preparing your shirts for sublimation printing, you set the stage for flawless and vibrant designs that seamlessly integrate with the fabric, resulting in custom shirts that showcase the full spectrum of your creativity and vision.

Read more: What Type Of Printer Is Used For Sublimation

Printing Your Design

With your sublimation printer set up and your shirts meticulously prepared, it’s time to bring your custom designs to life through the exhilarating process of printing. Whether you’re creating personalized shirts for your business, events, or personal use, the printing stage is where your creativity takes center stage, transforming digital concepts into tangible and vibrant designs on fabric.

The first step in printing your design involves selecting the desired image or artwork and transferring it to the sublimation transfer paper using the appropriate design software. Ensure that the design is sized and positioned to align with the dimensions of the shirt, allowing for a seamless and visually striking placement of the artwork on the fabric.

Load the sublimation transfer paper into the printer, ensuring that it is positioned correctly and securely to facilitate precise ink transfer during the printing process. Adjust the printer settings, including print resolution and color management, to match the specifications of the sublimation paper and optimize the output for vibrant and high-definition prints.

Before initiating the printing process, it’s essential to verify that the sublimation ink cartridges or tanks are adequately filled and that the printer is calibrated to deliver consistent and accurate ink distribution. Conduct a test print on regular paper to confirm the color accuracy and clarity of the design before proceeding to print on the sublimation transfer paper.

Once the printer is primed and the design is ready, initiate the printing process to transfer the vibrant and intricate design from the sublimation transfer paper to the polyester-coated shirts. The heat press or sublimation transfer press plays a pivotal role in this stage, as it facilitates the sublimation process by applying the precise combination of heat and pressure to activate the ink transfer onto the fabric.

Position the prepped shirts on the heat press, ensuring that they are aligned with the printed sublimation transfer paper to achieve accurate and seamless design transfer. Apply the appropriate heat and pressure settings based on the shirt material and the specific requirements of the sublimation ink to ensure optimal color penetration and bonding with the fabric.

Upon completion of the heat press cycle, carefully remove the shirts from the press and allow them to cool before inspecting the printed designs. Peel away the sublimation transfer paper to reveal the vibrant and permanent designs that have become an integral part of the fabric, showcasing your creativity and attention to detail.

By mastering the art of printing your designs through the sublimation process, you unleash a world of possibilities for creating custom shirts that captivate attention and embody the essence of your unique vision.

Finishing and Caring for Your Sublimation Shirt

Once the sublimation printing process is complete, it’s essential to apply the finishing touches to your custom shirts and implement proper care practices to preserve the vibrancy and longevity of the printed designs. By following these crucial steps, you can ensure that your sublimation shirts maintain their visual appeal and durability, delighting wearers with their striking and enduring custom designs.

After the sublimation transfer process, allow the shirts to cool completely before handling them to prevent any smudging or distortion of the printed designs. Once cooled, gently inspect the shirts to ensure that the designs have transferred seamlessly and vibrantly, with no imperfections or inconsistencies.

For added durability and color vibrancy, consider covering the printed designs with a protective silicone or Teflon sheet and subjecting the shirts to a brief heat press cycle. This step helps to further bond the sublimation ink with the fabric, enhancing the longevity and resilience of the printed designs, especially in high-wear areas such as the chest or sleeves.

When it comes to caring for sublimation shirts, it’s important to adopt practices that preserve the integrity of the designs and the fabric. Wash the shirts inside out using a mild detergent and cold water to protect the vibrancy of the prints and minimize the risk of fading. Avoid using bleach or fabric softeners, as these can compromise the colors and the bond between the sublimation ink and the fabric.

When drying sublimation shirts, opt for air drying or using a low-heat setting in the dryer to prevent excessive exposure to heat, which can affect the longevity of the prints. Avoid wringing or twisting the shirts vigorously, as this can distort the designs and the fabric. Instead, gently reshape the shirts and lay them flat or hang them to dry in a well-ventilated area.

Store sublimation shirts in a cool, dry place away from direct sunlight and sources of heat to prevent potential color fading or degradation of the printed designs. Folding the shirts neatly and storing them in a drawer or closet helps to maintain their visual appeal and prevents unnecessary wear and tear.

By implementing these finishing and care practices, you can ensure that your sublimation shirts continue to showcase their vibrant and enduring designs, captivating attention and preserving the essence of your creative expression with every wear.

Frequently Asked Questions about How To Use Sublimation Printer For Shirts

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use Sublimation Printer For Shirts”