Home>Technology>Smart Home Devices>How To Turn A Printer Into A Sublimation Printer

Smart Home Devices

How To Turn A Printer Into A Sublimation Printer

Modified: March 14, 2024

Learn how to convert your regular printer into a sublimation printer for creating smart home devices. Follow our step-by-step guide for seamless printing.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Introduction

Welcome to the world of sublimation printing! If you're looking to expand your printing capabilities and delve into the vibrant realm of sublimation, you're in for an exciting journey. Sublimation printing offers a captivating way to infuse designs onto a variety of substrates, from mugs and apparel to phone cases and more. In this comprehensive guide, we'll explore how to transform your standard printer into a sublimation printer, select the right sublimation ink, and make the most of your newly upgraded printing setup.

Whether you're a small business owner aiming to offer personalized merchandise or an avid crafter seeking to add a unique touch to your creations, the potential of sublimation printing is boundless. By understanding the intricacies of sublimation and mastering the art of converting your printer, you can unlock a world of creative possibilities.

Throughout this guide, we'll delve into the essential steps for transforming your printer into a sublimation powerhouse, the nuances of selecting the ideal sublimation ink, and the ins and outs of printing with your newly upgraded setup. Additionally, we'll address common troubleshooting issues to ensure a smooth and seamless sublimation printing experience.

So, whether you're a newcomer to the world of sublimation or a seasoned printing enthusiast seeking to expand your repertoire, join us as we embark on this captivating journey into the realm of sublimation printing. Let's dive in and uncover the magic of turning a standard printer into a sublimation marvel!

Understanding Sublimation Printing

Key Takeaways:

- Transforming a standard printer into a sublimation printer unlocks endless creative possibilities, allowing vibrant, long-lasting designs on various substrates through the unique properties of sublimation ink and heat transfer.

- Selecting the right sublimation ink is crucial for achieving vivid, fade-resistant prints with exceptional color accuracy, ensuring that designs come to life in stunning detail and vibrancy on a diverse range of materials.

Read more: How To Convert A Printer To Sublimation

Understanding Sublimation Printing

Sublimation printing is a unique and versatile method of transferring designs onto various substrates using heat and pressure. Unlike traditional printing methods that rely on ink that dries on the surface of the substrate, sublimation ink undergoes a chemical transition from a solid to a gas state without passing through the liquid phase. This transformation occurs under the influence of heat and pressure, allowing the ink to permeate the surface of the substrate and bond with its polymers.

One of the key elements in sublimation printing is the use of specially formulated sublimation ink. This ink is designed to sublimate, or transition directly from a solid to a gas when exposed to heat. When the sublimation ink is heated and pressed onto a compatible substrate, such as polyester fabric or polymer-coated items, the ink particles penetrate the surface and bond with the polymers, resulting in a vibrant, permanent, and durable image.

Sublimation printing offers several advantages, including the ability to produce high-resolution, full-color designs with intricate details. The resulting prints are not only vivid and long-lasting but also resistant to fading, making them ideal for various applications, from personalized gifts and promotional items to custom apparel and vibrant home decor.

It’s important to note that sublimation printing is most effective on polyester-based or polymer-coated substrates, as the process relies on the ink bonding with the polymers within the material. Additionally, the color of the substrate can impact the final appearance of the printed design, as sublimation inks are transparent, allowing the base color of the substrate to influence the overall color rendition of the print.

By understanding the fundamental principles of sublimation printing and the unique properties of sublimation ink, you can harness the power of this innovative printing method to unleash your creativity and bring your designs to life in stunning, vibrant detail.

Converting Your Printer into a Sublimation Printer

Converting Your Printer into a Sublimation Printer

Transforming your standard inkjet printer into a sublimation printer involves a series of essential steps to ensure optimal performance and compatibility with sublimation ink. Here’s a comprehensive guide to help you navigate the process:

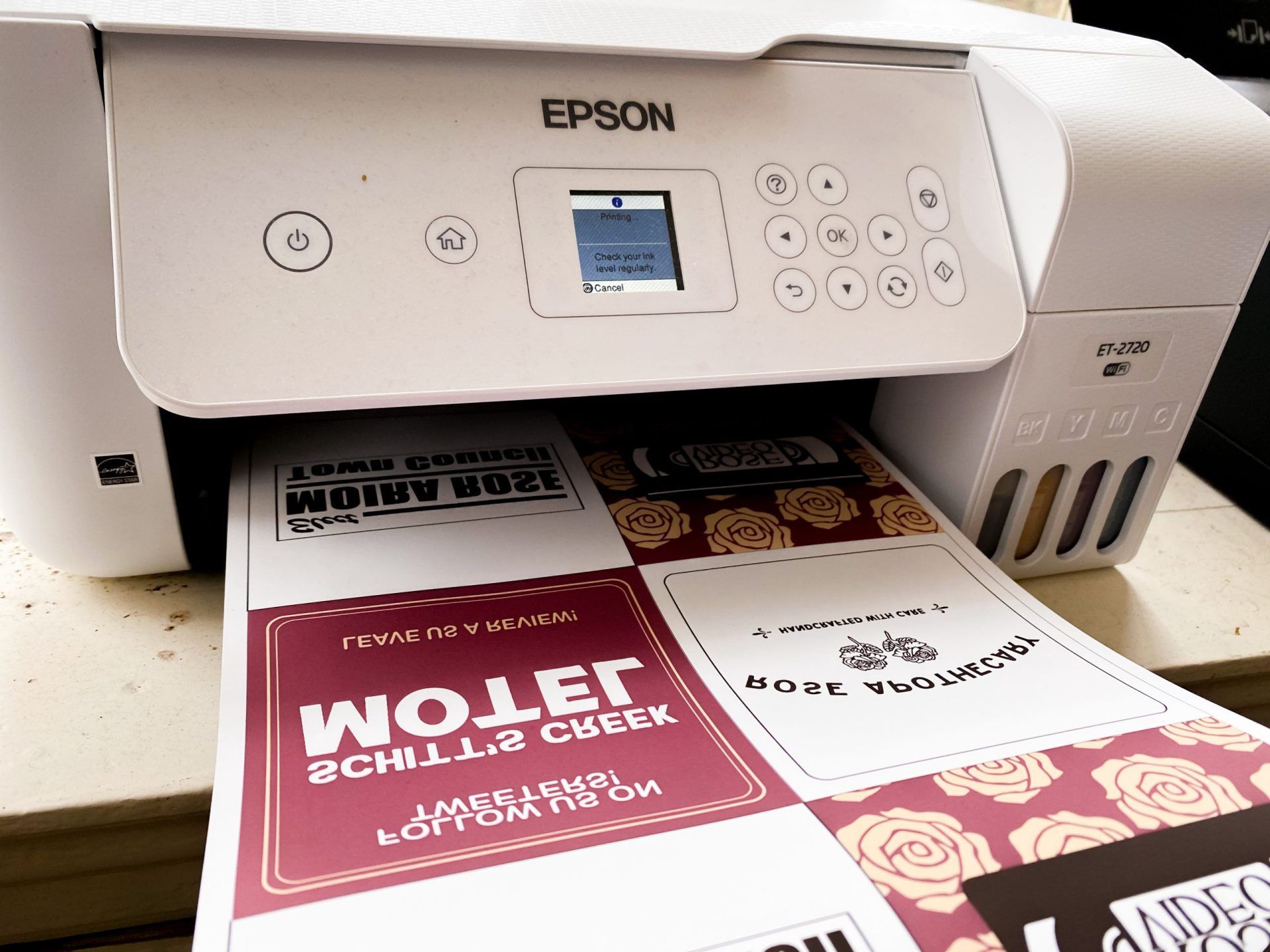

- Printer Selection: Not all inkjet printers are suitable for sublimation printing. It’s crucial to choose a printer model that is compatible with sublimation ink and features print heads capable of handling the unique properties of sublimation ink. Popular printer models for sublimation conversion include select Epson and Ricoh models, known for their compatibility with third-party sublimation ink systems.

- Cleaning and Preparation: Before converting your printer, it’s essential to thoroughly clean the printer’s internal components, including the print heads and ink delivery system, to remove any residual ink and ensure optimal performance with sublimation ink. This process may involve flushing the existing ink system and conducting print head cleanings to eliminate any traces of standard ink.

- Sublimation Ink System Installation: Once the printer is cleaned and prepared, the next step involves installing a sublimation ink system designed for your specific printer model. This typically includes replacing the existing ink cartridges with sublimation ink cartridges and installing compatible ink delivery systems, such as continuous ink supply systems (CISS) or refillable ink tanks.

- Printer Settings and Calibration: Configuring the printer settings and color profiles is crucial for achieving accurate color reproduction and optimal print quality with sublimation ink. This may involve adjusting the printer settings, color management options, and ICC profiles to ensure the printer accurately interprets and reproduces the colors in your designs.

- Test Printing and Fine-Tuning: After the conversion process is complete, it’s important to conduct test prints to assess the color accuracy, vibrancy, and overall print quality. Fine-tuning may be necessary to achieve the desired results, which can involve making adjustments to the printer settings, color profiles, and print head alignment.

By carefully following these steps and ensuring that your printer is properly configured and calibrated for sublimation printing, you can effectively transform your standard printer into a powerful tool for creating stunning, full-color sublimation prints on a diverse range of substrates.

Choosing the Right Sublimation Ink

Choosing the Right Sublimation Ink

When it comes to sublimation printing, selecting the right sublimation ink is a critical decision that directly impacts the quality, vibrancy, and longevity of your printed designs. Here’s a comprehensive guide to help you navigate the process of choosing the ideal sublimation ink for your printing needs:

- Ink Compatibility: Ensure that the sublimation ink you select is compatible with your specific printer model. Different printers may require ink formulations tailored to their printhead technology and ink delivery systems. It’s essential to choose sublimation ink that is explicitly designed for use with your printer to ensure optimal performance and compatibility.

- Color Accuracy and Vibrancy: Look for sublimation ink that offers exceptional color accuracy, vibrancy, and color gamut. High-quality sublimation inks are formulated to deliver vivid, true-to-life colors with excellent saturation, allowing you to reproduce intricate designs with stunning detail and precision.

- Fade Resistance: Opt for sublimation ink known for its fade resistance, ensuring that your printed designs maintain their brilliance and clarity over time. Fade-resistant sublimation inks are essential for producing long-lasting prints that withstand exposure to light, moisture, and environmental factors without compromising their visual appeal.

- Compatibility with Substrates: Consider the range of substrates you intend to print on and choose sublimation ink that is compatible with a diverse array of materials, including polyester fabrics, polymer-coated items, and other sublimation-ready substrates. Versatile sublimation inks enable you to expand your creative possibilities and produce vibrant, durable prints on various surfaces.

- Ink Configuration: Depending on your printing requirements, you can choose between different ink configurations, such as standard CMYK (Cyan, Magenta, Yellow, Black) inks or extended ink sets that include additional colors for enhanced color reproduction and subtlety. The choice of ink configuration can influence the color gamut and fidelity of your printed designs.

By carefully evaluating these factors and selecting sublimation ink that aligns with your specific printing goals, substrate requirements, and color expectations, you can ensure that your sublimation prints exude unparalleled vibrancy, longevity, and visual impact.

Printing with Your Sublimation Printer

To turn a regular printer into a sublimation printer, you will need to replace the regular ink with sublimation ink and use sublimation paper for printing. Additionally, you may need to adjust the printer settings for better results.

Printing with Your Sublimation Printer

Now that you’ve successfully converted your printer into a sublimation powerhouse and chosen the right sublimation ink, it’s time to embark on the exhilarating process of printing vibrant designs onto a diverse array of substrates. Here’s a comprehensive guide to help you make the most of your sublimation printer:

- Design Preparation: Before printing, ensure that your designs are tailored to the specific dimensions and layout requirements of the substrate you’ll be printing on. Whether you’re creating custom apparel, personalized mugs, or vibrant home decor, optimizing your designs for the intended substrates is crucial for achieving stunning results.

- Substrate Selection: Choose substrates that are compatible with sublimation printing, such as polyester fabrics, polymer-coated items, and other sublimation-ready materials. It’s essential to select high-quality substrates that are designed to bond effectively with sublimation ink, ensuring vibrant and durable prints with exceptional color retention.

- Heat Press Settings: When using a heat press for sublimation, it’s important to configure the appropriate time, temperature, and pressure settings based on the specific substrate and sublimation ink being used. Proper heat press settings are essential for activating the sublimation process and ensuring that the ink sublimates effectively, resulting in vivid, long-lasting prints.

- Printing Process: Load the prepared designs into your sublimation printing software and ensure that the printer settings are optimized for sublimation printing. This may involve selecting the appropriate color profiles, print quality settings, and ensuring that the printer is calibrated for accurate color reproduction.

- Heat Transfer: After printing, carefully transfer the designs onto the substrates using a heat press. The heat and pressure applied during the transfer process activate the sublimation ink, causing it to permeate the surface of the substrate and bond with its polymers, resulting in vibrant, durable prints with exceptional color retention.

By following these steps and paying attention to the nuances of design preparation, substrate selection, heat press settings, and the printing process, you can unleash the full potential of your sublimation printer and create captivating, full-color prints that elevate your creative endeavors to new heights.

Troubleshooting Common Issues

Read more: What Is A Sublimation Printer

Troubleshooting Common Issues

While sublimation printing offers a wealth of creative possibilities, it’s essential to be prepared to address common issues that may arise during the printing process. By understanding these potential challenges and implementing effective troubleshooting strategies, you can ensure a smooth and successful sublimation printing experience. Here are some common issues and their corresponding solutions:

- Inconsistent Color Reproduction: If you encounter inconsistencies in color reproduction, ensure that the printer settings, color profiles, and ICC profiles are correctly configured for sublimation printing. Additionally, verify that the sublimation ink cartridges are properly installed and that the ink delivery system is functioning optimally.

- Poor Image Transfer: If you notice issues with the transfer of the printed designs onto substrates, review the heat press settings to ensure that the time, temperature, and pressure are appropriate for the specific substrate and sublimation ink being used. Proper heat press settings are crucial for achieving optimal ink sublimation and bonding with the substrate.

- Bandings or Streaks in Prints: Bandings or streaks in prints can be attributed to clogged print heads or insufficient ink flow. Conduct print head cleanings and ensure that the sublimation ink is flowing smoothly through the ink delivery system. Regular maintenance and periodic print head cleanings can help prevent banding and ensure consistent print quality.

- Color Management Issues: If you encounter challenges with color management and accuracy, consider recalibrating the printer settings, color profiles, and ICC profiles to achieve accurate color reproduction. Additionally, verify that the design files are formatted in the appropriate color space and are optimized for sublimation printing.

- Substrate Compatibility Concerns: When experiencing issues with substrate compatibility, ensure that the substrates are specifically designed for sublimation printing and are capable of effectively bonding with sublimation ink. Choosing high-quality, sublimation-ready substrates is essential for achieving vibrant, durable prints.

By addressing these common issues with precision and implementing proactive maintenance and troubleshooting practices, you can overcome potential challenges and elevate the quality and consistency of your sublimation prints. Embracing a proactive approach to troubleshooting empowers you to unleash the full potential of your sublimation printing setup and achieve captivating, high-quality results with every print.

Conclusion

Conclusion

As we conclude this journey into the realm of sublimation printing, it’s evident that the transformation of a standard printer into a sublimation powerhouse opens up a world of creative possibilities. By understanding the principles of sublimation printing, selecting the right sublimation ink, and mastering the art of printing vibrant designs onto diverse substrates, you’ve embarked on a captivating and rewarding endeavor.

Sublimation printing empowers you to breathe life into your designs with vivid colors, exceptional detail, and remarkable durability. Whether you’re creating personalized apparel, custom home decor, or unique promotional items, the versatility and vibrancy of sublimation prints are bound to leave a lasting impression.

Throughout this guide, we’ve explored the essential steps for converting your printer into a sublimation printer, choosing the ideal sublimation ink, and navigating the intricacies of the printing process. Additionally, we’ve addressed common troubleshooting issues, ensuring that you’re equipped to overcome challenges and achieve exceptional results with confidence.

As you continue to explore the boundless potential of sublimation printing, remember the transformative impact of vibrant designs brought to life through the fusion of sublimation ink and compatible substrates. Embrace the creative freedom that sublimation printing offers, and let your imagination soar as you craft captivating designs that resonate with brilliance and longevity.

Whether you’re a small business owner, a passionate crafter, or an enthusiast seeking to expand your printing capabilities, the art of sublimation printing invites you to explore, create, and innovate with unparalleled vibrancy and enduring quality. Embrace the magic of sublimation printing, and let your designs speak volumes through the captivating language of color, detail, and durability.

As you embark on your sublimation printing endeavors, may your designs ignite joy, inspire creativity, and leave an indelible imprint on the world of personalized and custom-printed creations. Here’s to the vibrant journey that awaits as you unleash the full potential of your sublimation printer and bring your designs to life in stunning, enduring color.

Frequently Asked Questions about How To Turn A Printer Into A Sublimation Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Turn A Printer Into A Sublimation Printer”