Home>Furniture & Design>Interior Design Trends>What Glue To Use For Glass

Interior Design Trends

What Glue To Use For Glass

Modified: October 18, 2024

Discover the latest interior design trends for glass and find out which glue to use for your next project. Explore expert tips and recommendations for a stunning finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to home decor and DIY projects, glass is a versatile material that adds elegance and sophistication to any space. Whether you're repairing a broken vase, creating a custom mosaic, or assembling a stunning stained glass window, choosing the right glue for glass is crucial for achieving a durable and visually appealing result.

Selecting the appropriate adhesive for glass surfaces can be a daunting task, given the wide array of options available in the market. From clear drying adhesives to UV-curing glues, each type offers unique properties and applications. Understanding the characteristics of different glass glues and their compatibility with specific projects is essential for achieving optimal results.

In this comprehensive guide, we will explore the various types of glue suitable for bonding glass, discuss the key factors to consider when selecting the right adhesive, and provide best practices for using glue on glass. Whether you're a seasoned crafter or a novice DIY enthusiast, this article will equip you with the knowledge and insights needed to tackle glass-related projects with confidence.

Let's delve into the world of glass adhesives and discover the best practices for achieving seamless and durable bonds on this exquisite material.

Key Takeaways:

- Choose the right glue for glass based on transparency, strength, and curing time to achieve seamless and durable bonds. Consider aesthetics and environmental resistance for optimal results.

- Prepare glass surfaces thoroughly, apply adhesive sparingly, and follow curing and inspection best practices for strong and visually appealing glass bonds.

Read more: What Kind Of Glue To Use On Glass

Types of Glue for Glass

When it comes to bonding glass, selecting the right type of glue is crucial for achieving strong and long-lasting adhesion. Various types of adhesives are specifically formulated to bond glass surfaces effectively. Understanding the characteristics and applications of these glass glues is essential for choosing the most suitable option for your project. Here are some common types of glue for glass:

-

Cyanoacrylate (Super Glue): This fast-acting adhesive is well-suited for bonding glass to glass or glass to non-porous materials such as metal or plastic. It dries clear and forms a strong bond, making it ideal for quick repairs and small-scale projects.

-

UV-curing Glue: Also known as UV resin, this type of adhesive cures rapidly when exposed to ultraviolet light. It is commonly used for glass-to-glass bonding and is favored for its transparency and ability to create seamless joints.

-

Epoxy Resin: Epoxy adhesives are known for their exceptional strength and versatility. They are suitable for bonding glass to various materials and offer excellent resistance to moisture and temperature fluctuations. Epoxy resin is often used for larger glass assemblies and structural bonding applications.

-

Silicone Adhesive: Silicone-based glues are flexible and weather-resistant, making them suitable for outdoor glass projects such as sealing glass aquariums or attaching glass panels in outdoor fixtures. They provide a durable and watertight bond, making them ideal for applications requiring flexibility and resilience.

-

Polyurethane Adhesive: This type of adhesive is valued for its strong bonding capabilities and resistance to impact and vibration. It is commonly used for bonding glass to metal or wood, making it a versatile choice for a wide range of glass-related projects.

-

Clear-drying Adhesive: These adhesives are formulated to dry transparent, making them ideal for applications where aesthetics are a priority. They are often used for bonding decorative glass elements or assembling intricate glass art pieces.

Each type of glass glue offers unique properties and is designed to address specific bonding requirements. When choosing the right adhesive for your glass project, consider factors such as transparency, curing time, flexibility, and the intended application to ensure optimal results.

Understanding the characteristics and applications of different glass glues is essential for selecting the most suitable adhesive for your specific project. By choosing the right type of glue for glass, you can ensure a strong and durable bond that meets the unique requirements of your project.

Factors to Consider When Choosing Glue

When selecting the most suitable glue for glass, several crucial factors should be taken into account to ensure the success of your project. Understanding these considerations will help you make an informed decision and achieve optimal bonding results.

Transparency and Aesthetics

The transparency of the adhesive is a critical factor, especially for projects where aesthetics are a priority. For applications such as glass art, stained glass assembly, or decorative glass elements, opt for a clear-drying adhesive that ensures a seamless and unobtrusive bond. This allows the natural beauty of the glass to shine through without any visible residue, enhancing the overall visual appeal of the finished piece.

Bond Strength and Durability

The strength and durability of the bond are essential considerations, particularly for structural or load-bearing applications. Epoxy resin and polyurethane adhesives are renowned for their exceptional bonding strength, making them ideal choices for projects that require long-term durability and resistance to environmental stressors. Assess the specific demands of your project to determine the level of bond strength required for optimal performance.

Read more: What Glue Works On Glass

Curing Time and Application Flexibility

The curing time of the adhesive plays a significant role in project timelines and workflow efficiency. Fast-acting adhesives such as cyanoacrylate (super glue) are suitable for quick repairs and small-scale projects, offering rapid bonding capabilities. On the other hand, UV-curing glues provide the advantage of controlled curing through exposure to ultraviolet light, allowing for precise adjustments before the final bonding process. Consider the application requirements and desired flexibility during the bonding process to select an adhesive with an appropriate curing time.

Environmental and Chemical Resistance

For glass projects exposed to varying environmental conditions or chemical exposure, it is crucial to choose an adhesive that offers resistance to moisture, temperature fluctuations, and chemical agents. Silicone adhesives are well-suited for outdoor applications, providing excellent weather resistance and flexibility. Epoxy resins also offer superior resistance to moisture and chemicals, making them suitable for demanding environments such as marine or industrial settings. Evaluate the environmental factors and potential chemical exposure in your project's surroundings to select an adhesive that ensures long-term stability and performance.

Surface Preparation and Compatibility

Proper surface preparation and compatibility are essential for achieving a strong and durable bond. Ensure that the adhesive is compatible with the specific type of glass you are working with, as well as any additional materials involved in the project. Some adhesives may require primers or surface treatments to enhance adhesion, especially when bonding to non-porous or smooth glass surfaces. Consider the surface preparation requirements and compatibility of the adhesive with the materials involved to facilitate a successful bonding process.

By carefully considering these factors when choosing a glue for glass, you can make an informed decision that aligns with the unique requirements of your project. Selecting the right adhesive based on transparency, bond strength, curing time, environmental resistance, and surface compatibility will contribute to the overall success and longevity of your glass-related endeavors.

Best Practices for Using Glue on Glass

When working with glass adhesives, employing best practices is essential to ensure successful bonding and the longevity of your projects. By following these guidelines, you can optimize the adhesive's performance and achieve seamless, durable bonds on glass surfaces.

Read more: What Glue Sticks To Glass

Surface Preparation

Before applying the adhesive, it is crucial to prepare the glass surfaces to promote optimal adhesion. Thoroughly clean the glass to remove any dust, grease, or residue that may hinder bonding. Use a gentle glass cleaner or isopropyl alcohol to ensure a clean and debris-free surface. Additionally, roughening smooth glass surfaces with fine-grit sandpaper can enhance the adhesive's grip, especially when working with non-porous glass materials.

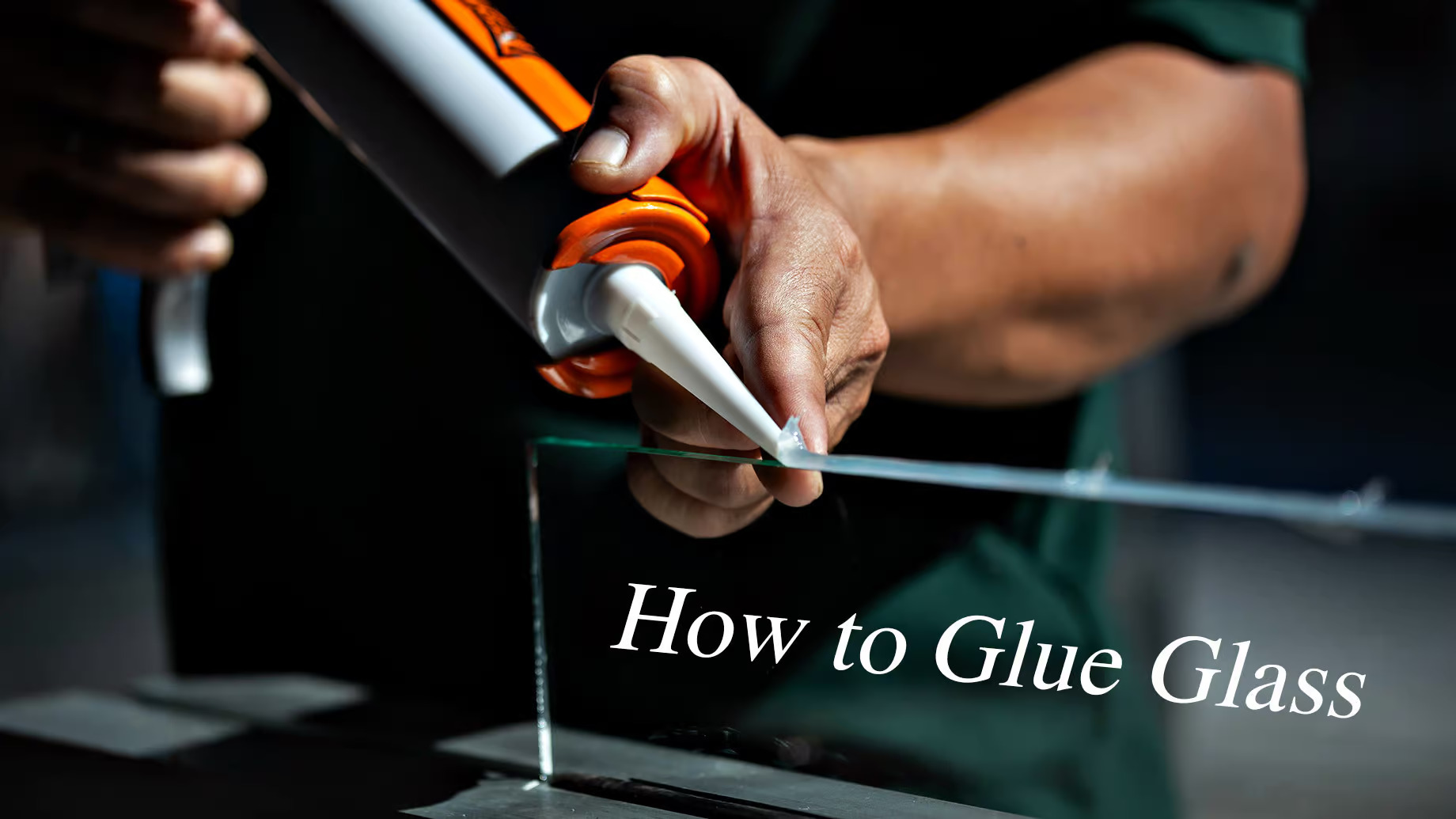

Adhesive Application

Apply the adhesive sparingly and precisely to the glass surfaces. For small-scale projects or delicate glass elements, use a fine-tip applicator or syringe to control the adhesive's application. Ensure that the adhesive is distributed evenly and covers the bonding area completely to facilitate a strong and uniform bond. Avoid excessive application, as it may lead to visible residue or uneven bonding.

Clamping and Support

In cases where the bonded glass surfaces require alignment or pressure during the curing process, utilize clamps or support structures to hold the pieces in place. This is particularly important for larger assemblies or structural bonding applications. Carefully follow the adhesive manufacturer's recommendations regarding clamping pressure and curing conditions to achieve optimal bonding results.

Curing and Drying

Allow the adhesive to cure or dry according to the specified timeframe provided by the manufacturer. Maintain the recommended environmental conditions, such as temperature and humidity, to facilitate proper curing. For UV-curing adhesives, ensure that the bonded areas are exposed to ultraviolet light for the prescribed duration to achieve complete curing and maximum bond strength.

Read more: What Glue Works On Car Glass?

Post-Bonding Inspection

After the adhesive has cured, inspect the bonded glass surfaces to ensure a seamless and durable bond. Check for any visible gaps, uneven bonding, or excess adhesive residue. If necessary, use a razor blade or fine-grit sandpaper to remove any excess adhesive and refine the bonded edges for a polished finish.

By adhering to these best practices for using glue on glass, you can enhance the quality and durability of your glass-related projects. Proper surface preparation, precise adhesive application, appropriate clamping, and meticulous post-bonding inspection are essential steps in achieving strong and visually appealing bonds on glass surfaces. Incorporating these best practices into your glass bonding process will contribute to the success and longevity of your DIY or professional glass projects.

Conclusion

In conclusion, the selection of the right adhesive for glass projects is a critical determinant of the overall success and durability of the finished piece. By understanding the diverse types of glues available for bonding glass, considering essential factors such as transparency, bond strength, curing time, environmental resistance, and surface compatibility, and implementing best practices for adhesive application, individuals can achieve seamless and long-lasting bonds on glass surfaces.

The versatility of glass as a material for artistic, decorative, and functional applications makes it a popular choice for DIY enthusiasts, artists, and professionals alike. Whether it's repairing a cherished glass heirloom, creating intricate stained glass art, or assembling structural glass elements, the appropriate adhesive plays a pivotal role in ensuring the integrity and longevity of the project.

By considering the transparency and aesthetics of the adhesive, individuals can preserve the natural beauty of glass while achieving discreet and unobtrusive bonds. Additionally, evaluating the bond strength, curing time, and environmental resistance of the adhesive enables the selection of a glue that meets the specific demands of the project, whether it's an indoor decorative piece or an outdoor architectural installation.

Furthermore, adhering to best practices such as thorough surface preparation, precise adhesive application, and meticulous post-bonding inspection contributes to the overall quality and durability of the bonded glass surfaces. These practices are essential for achieving professional-level results and ensuring that the adhesive performs optimally in various applications.

In essence, the world of glass adhesives offers a diverse range of options tailored to address specific bonding requirements. By leveraging the knowledge and insights shared in this guide, individuals can approach glass-related projects with confidence, knowing that they have the expertise to select the most suitable adhesive and employ best practices for achieving seamless and durable bonds on glass.

Whether it's a small-scale repair, a decorative art piece, or a structural glass installation, the right adhesive, coupled with informed decision-making and meticulous application, paves the way for stunning and enduring glass creations. With the right adhesive at hand, the possibilities for working with glass are as limitless as the creativity and vision of the individuals embarking on these captivating projects.

Frequently Asked Questions about What Glue To Use For Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Glue To Use For Glass”