Home>Furniture & Design>Interior Design Trends>What Grit Sandpaper For Glass Edge

Interior Design Trends

What Grit Sandpaper For Glass Edge

Modified: April 22, 2024

Discover the latest interior design trends for glass edge finishing and learn which grit sandpaper is best for achieving a flawless result. Explore expert tips and techniques for a polished interior design look.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

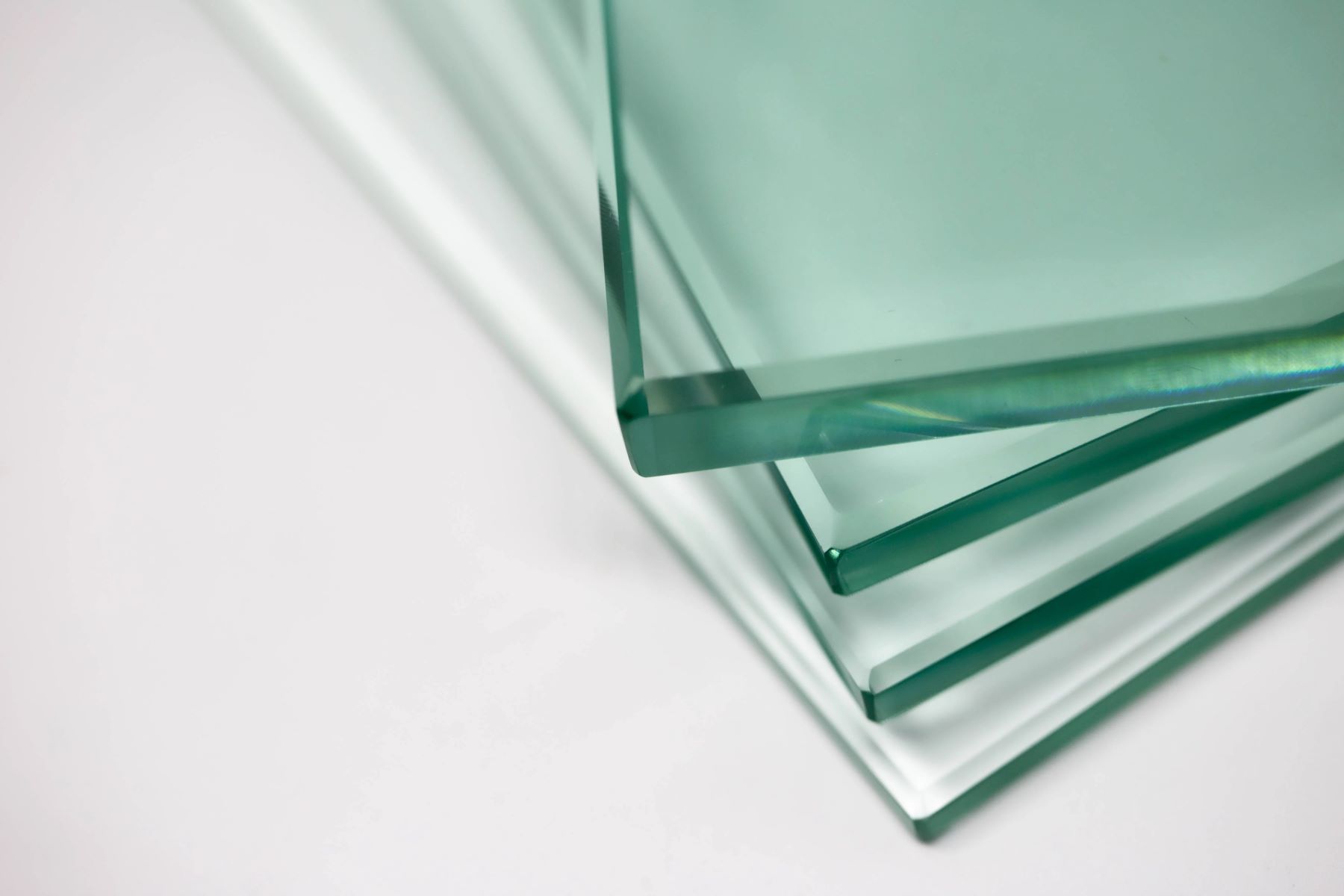

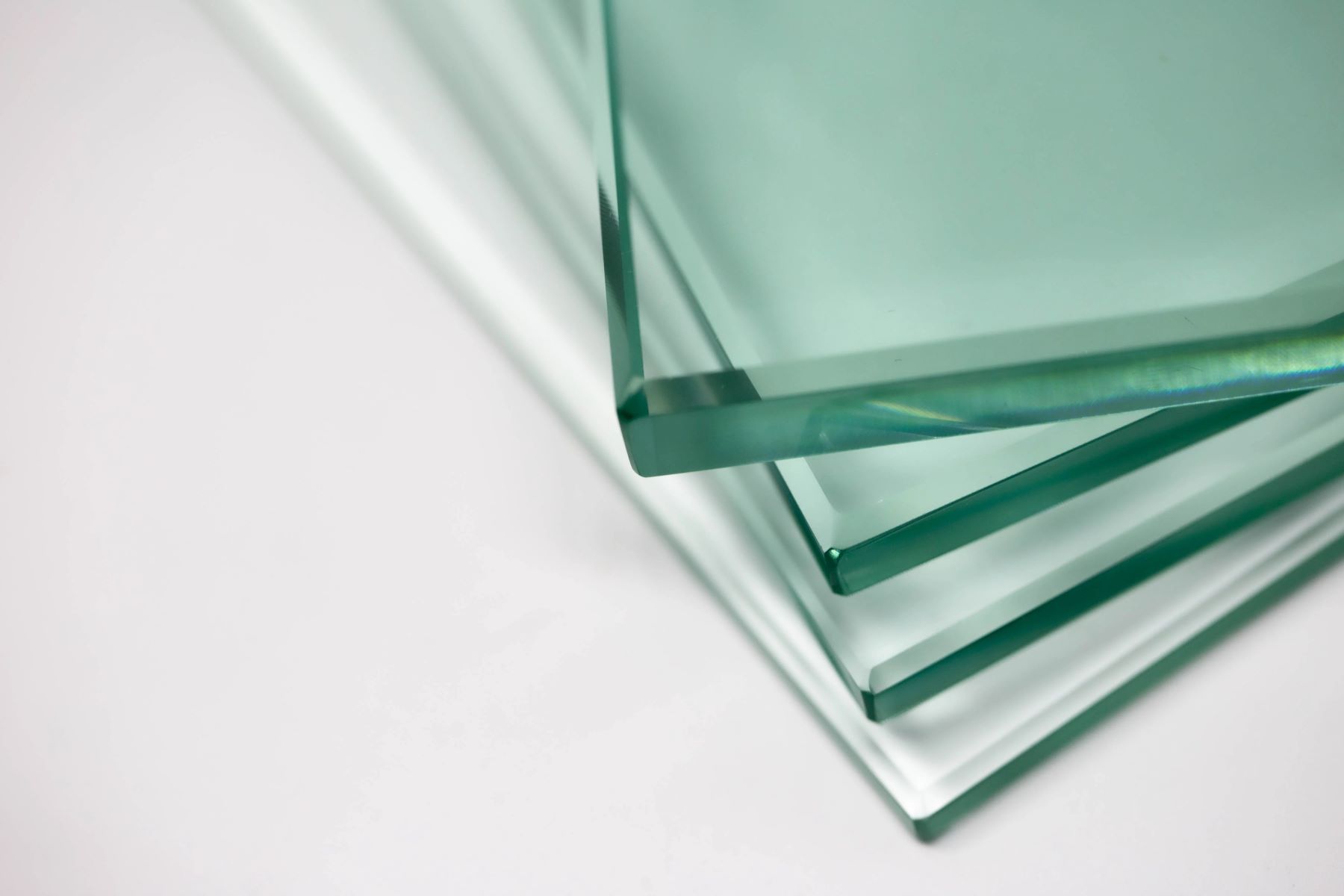

Sanding glass edges is a crucial step in creating smooth, polished surfaces for various glass projects. Whether you are crafting a custom mirror, designing stained glass art, or working on a DIY glass furniture piece, achieving a flawless edge is essential for both aesthetics and safety. To accomplish this, selecting the appropriate grit sandpaper is paramount.

Understanding the intricacies of grit sandpaper and its impact on glass surfaces is fundamental to this process. By delving into the nuances of grit sizes and their respective applications, you can make informed decisions that yield exceptional results. Additionally, learning valuable tips for sanding glass edges will empower you to navigate this task with confidence and precision.

In the following sections, we will explore the significance of grit sandpaper in glass edge sanding, discuss the factors to consider when choosing the right grit, and provide practical tips to enhance your glass sanding techniques. By the end of this article, you will have a comprehensive understanding of grit sandpaper for glass edges, equipping you with the knowledge to elevate your glasswork to new heights.

Key Takeaways:

- Choose the right grit sandpaper for glass edge sanding based on the project’s needs and glass type. Progress from coarse to fine grits for a flawless, polished finish.

- Enhance glass edge sanding with tips like using lubrication, maintaining consistent pressure, and frequent grit progression. Safety precautions and thorough cleaning ensure refined, polished results.

Read more: What Grit Sandpaper For Glass

Understanding Grit Sandpaper

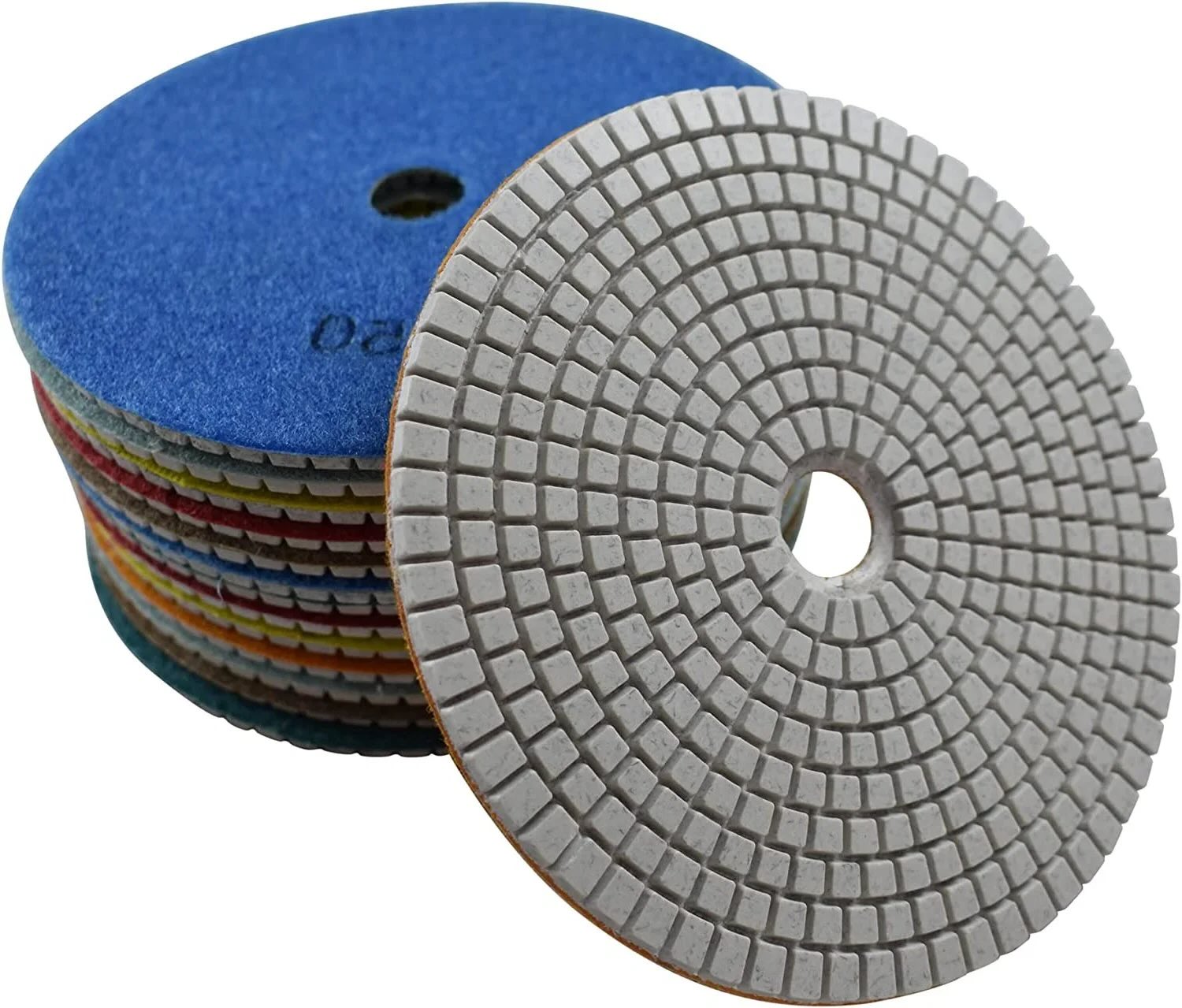

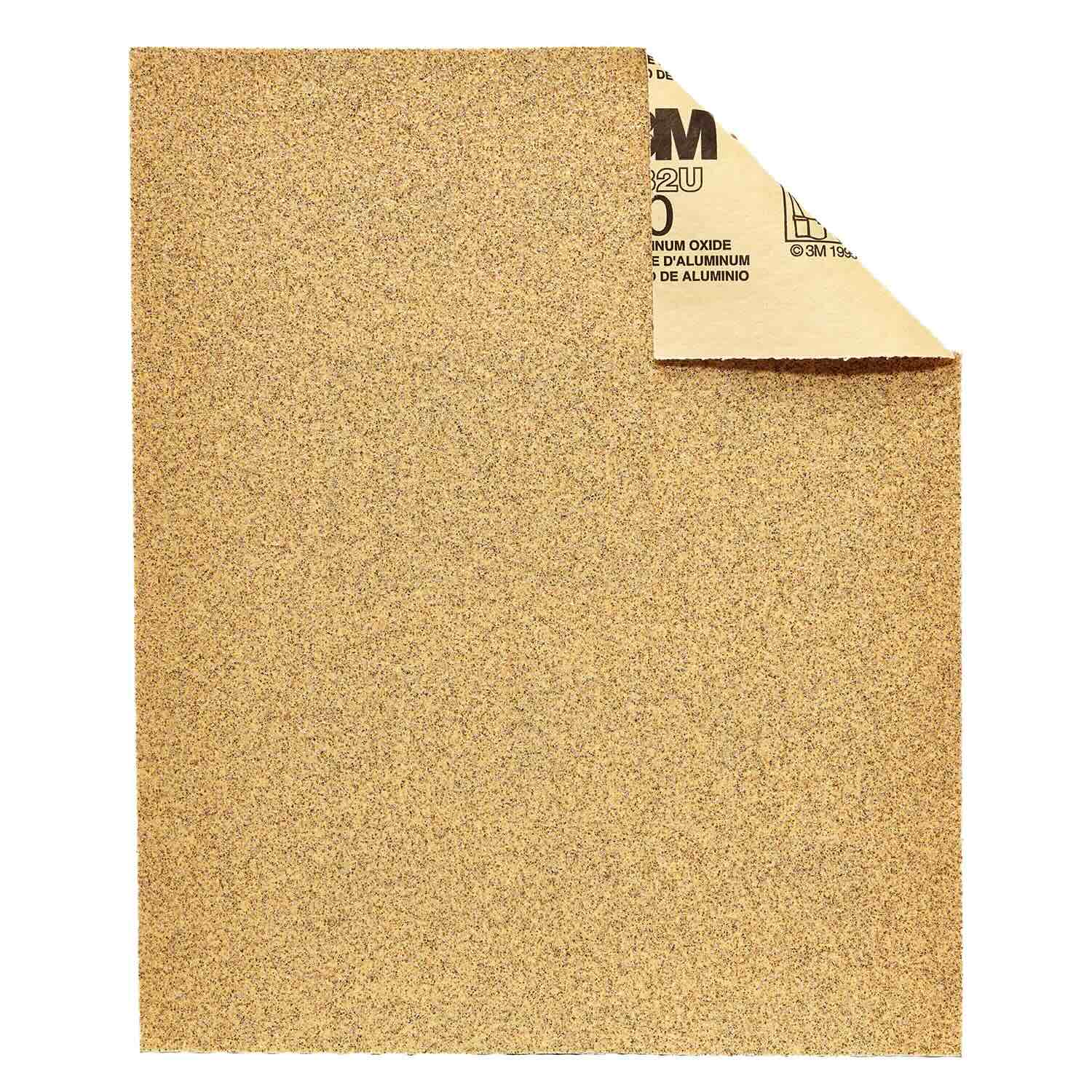

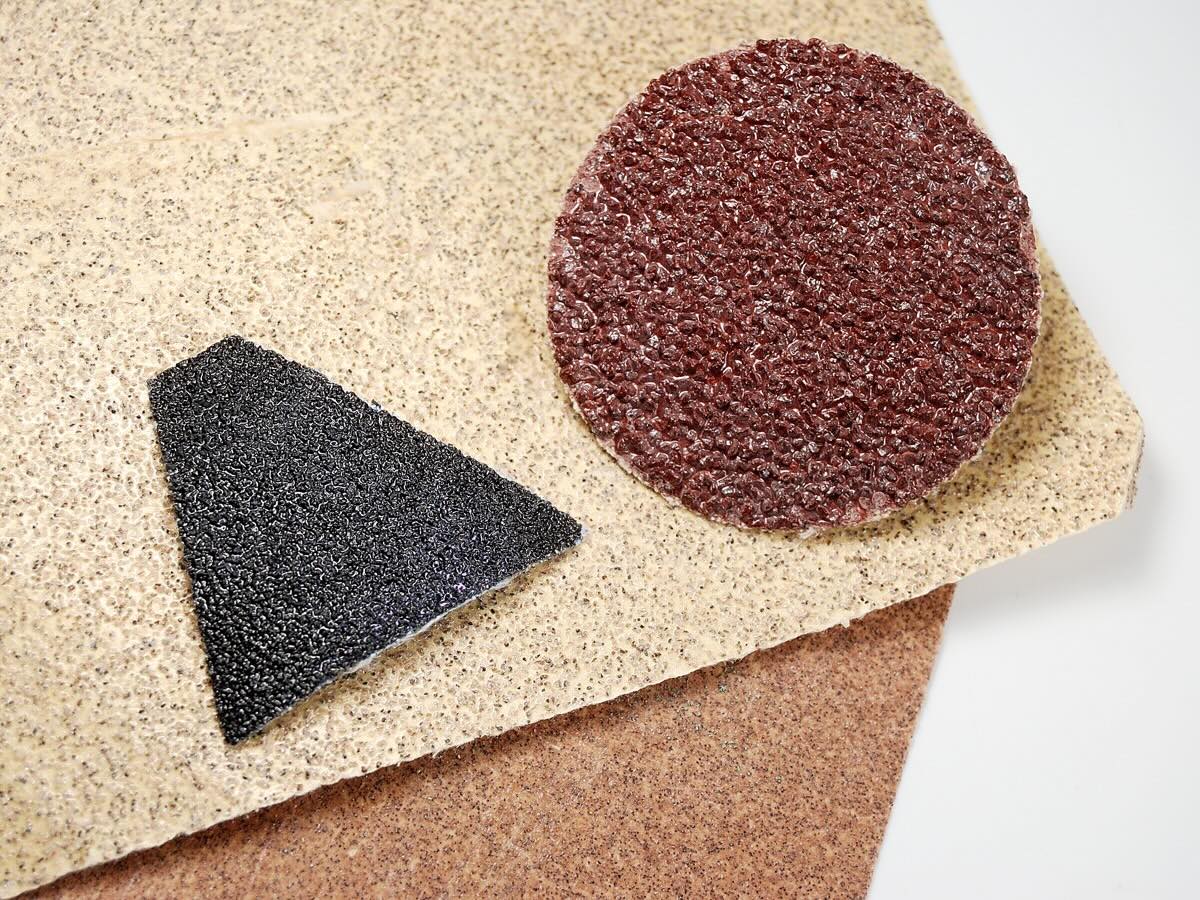

Grit sandpaper serves as a versatile tool for refining and smoothing various surfaces, including glass. The term "grit" refers to the coarseness or fineness of the abrasive particles embedded in the sandpaper. These particles, typically made of aluminum oxide or silicon carbide, are distributed across the paper in a specific pattern, creating a textured surface that abrades materials upon contact.

The grit size of sandpaper is denoted by a numerical value, which indicates the number of abrasive particles per square inch. Lower grit numbers signify coarser particles, while higher numbers represent finer particles. For instance, sandpaper with a grit size of 60 to 100 is considered coarse and is suitable for heavy material removal, while grit sizes ranging from 150 to 600 are finer and ideal for smoothing and polishing surfaces.

When it comes to sanding glass edges, understanding the relationship between grit sizes and their effects on the glass is crucial. Coarser grits are effective for initial shaping and removing rough edges, as they can swiftly grind down the glass to the desired contour. However, using coarse grit sandpaper alone may result in visible scratches and an uneven surface texture. This is where the progression to finer grits becomes essential.

Finer grit sandpaper, such as those with grit sizes above 200, is instrumental in refining the glass edge, eliminating scratches left by coarser grits, and achieving a smooth, polished finish. The gradual transition from coarse to fine grits ensures that the glass edge undergoes a comprehensive refinement process, ultimately yielding a flawless and professional-looking result.

In summary, the understanding of grit sandpaper lies in its ability to cater to specific sanding requirements. By recognizing the diverse grit sizes and their corresponding functions, artisans and DIY enthusiasts can effectively harness the power of sandpaper to transform raw glass edges into refined, visually appealing surfaces. This knowledge forms the foundation for selecting the right grit sandpaper for glass edge sanding, a topic we will delve into in the subsequent section.

Choosing the Right Grit Sandpaper for Glass Edge

When selecting the right grit sandpaper for sanding glass edges, it is essential to consider the specific requirements of the project and the desired outcome. The choice of grit size directly influences the efficiency and quality of the sanding process, ultimately determining the smoothness and appearance of the glass edge. To make an informed decision, it is crucial to understand the characteristics and applications of different grit sizes.

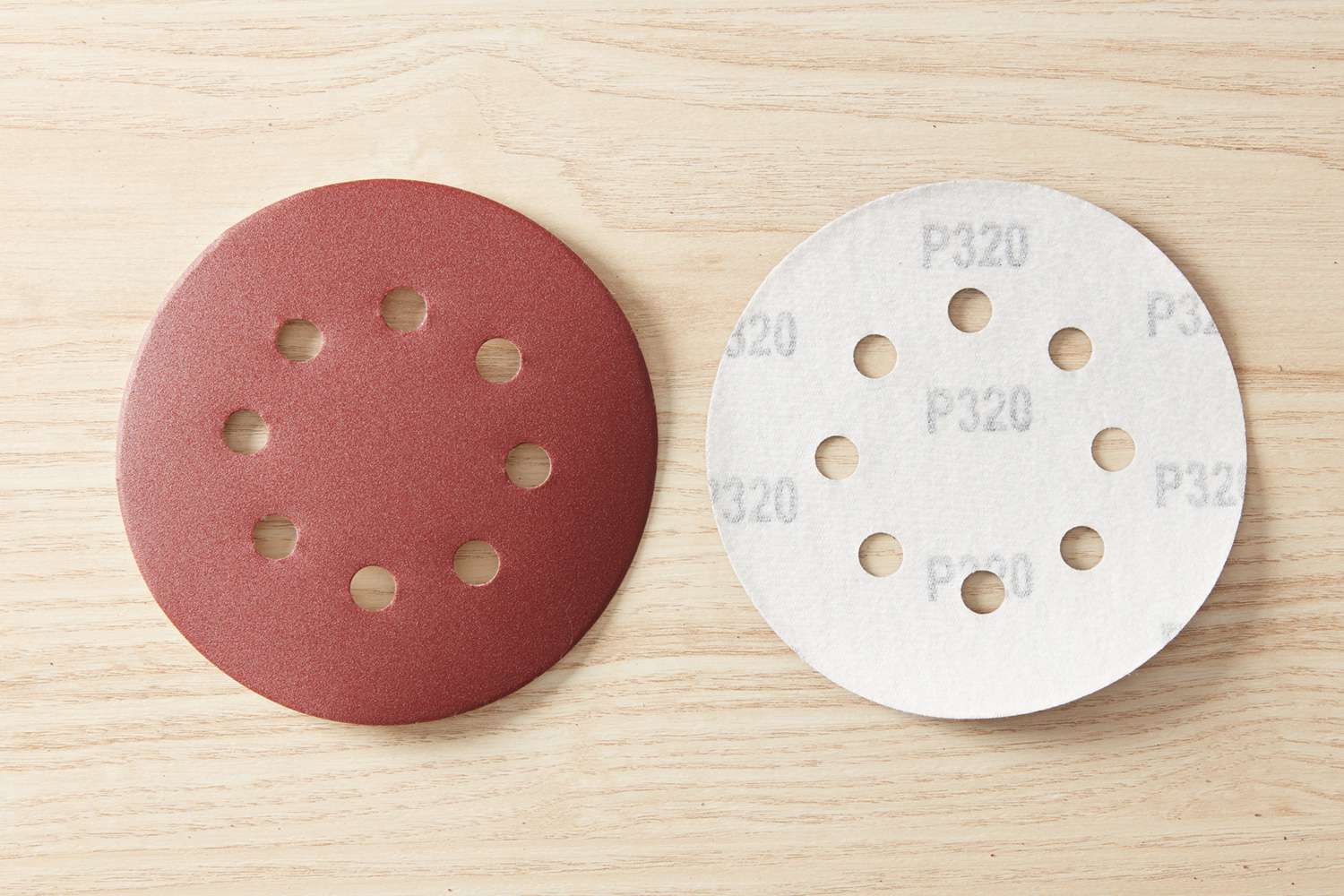

For initial shaping and the removal of rough edges, coarser grit sandpaper in the range of 60 to 100 is highly effective. This coarse grit swiftly grinds down the glass, allowing artisans to sculpt the desired edge profile. However, it is important to note that the use of coarse grit alone may result in visible scratches and an uneven surface texture. Therefore, transitioning to finer grits is imperative for achieving a polished finish.

As the sanding process progresses, transitioning to finer grits becomes paramount. Grit sizes ranging from 150 to 200 are ideal for refining the glass edge, smoothing out the scratches left by coarser grits, and preparing the surface for the final polishing stages. Subsequently, grit sizes above 200, such as 400 or 600, are instrumental in achieving a pristine, mirror-like finish. These fine grits effectively remove any remaining imperfections, resulting in a flawlessly smooth and polished glass edge.

The selection of the right grit sandpaper is also influenced by the type of glass being worked on. For softer glass varieties, such as fused or art glass, finer grits may be prioritized from the initial stages to prevent excessive material removal and minimize the risk of surface damage. Conversely, harder glass types, including tempered or borosilicate glass, may require the initial use of slightly coarser grits to effectively shape the edges before progressing to finer grits for refinement.

In summary, choosing the right grit sandpaper for glass edge sanding involves a thoughtful consideration of the project's specific needs, the type of glass being worked on, and the desired level of refinement. By understanding the distinct roles of various grit sizes and their impact on the glass surface, artisans and DIY enthusiasts can make informed decisions that lead to exceptional results. This knowledge forms the cornerstone of successful glass edge sanding, setting the stage for the application of effective sanding techniques, which will be explored in the subsequent section.

Use 80-120 grit sandpaper to smooth glass edges. Start with a coarser grit and gradually move to a finer grit for a polished finish. Always wear protective gear when working with glass.

Tips for Sanding Glass Edge

-

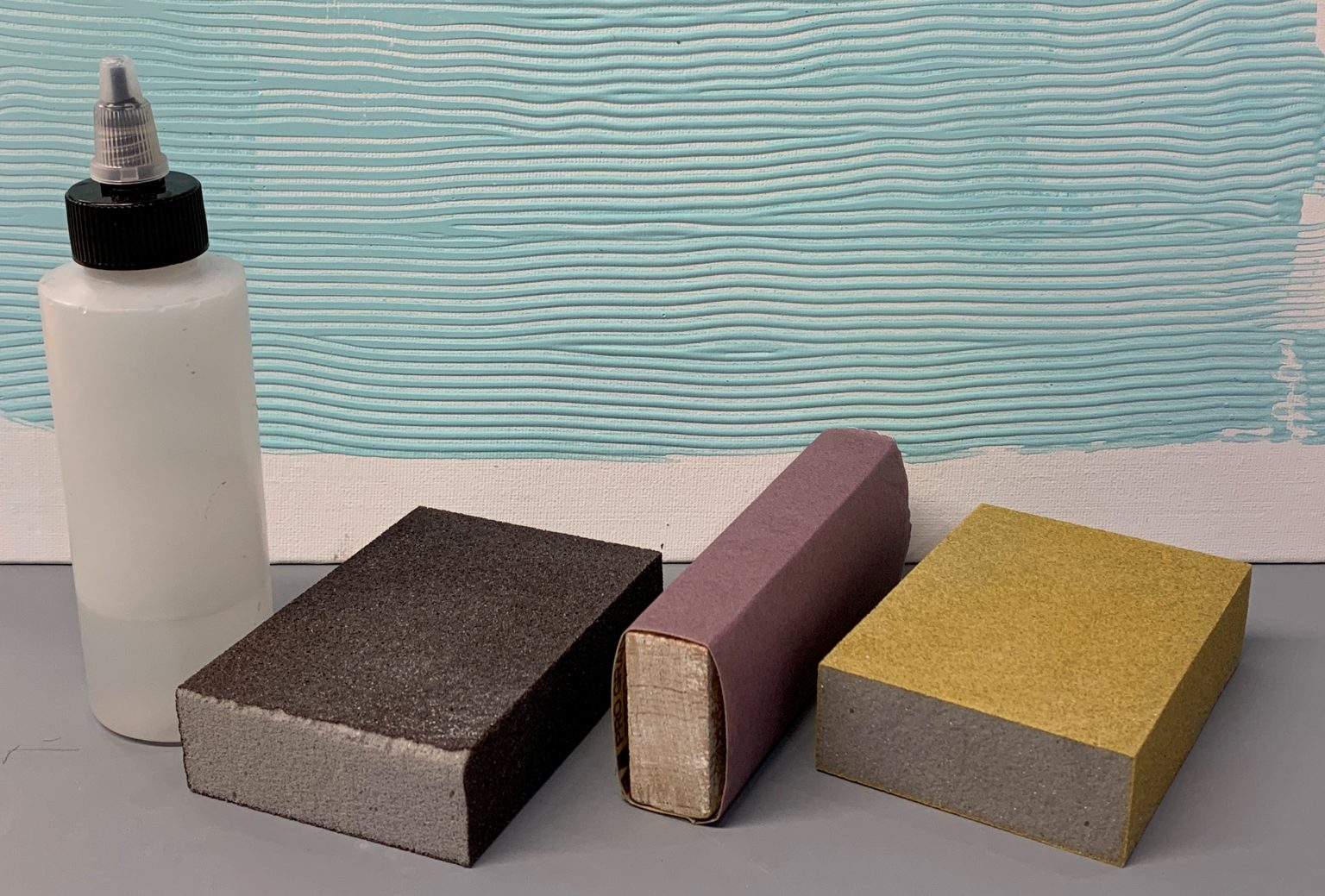

Use Lubrication: When sanding glass edges, employing a lubricant such as water or a specialized glass-cutting oil can significantly enhance the sanding process. The lubricant serves to reduce friction, prevent the sandpaper from clogging, and facilitate smoother, more controlled movements. Additionally, it helps dissipate heat generated during sanding, minimizing the risk of thermal stress that could potentially damage the glass.

-

Employ Consistent Pressure: Maintaining consistent pressure while sanding is crucial for achieving uniform results. Applying excessive force may lead to uneven surfaces or even glass breakage, while insufficient pressure might prolong the sanding process. By exerting steady, even pressure, artisans can effectively refine the glass edge without compromising its structural integrity.

-

Utilize Circular Motions: Incorporating circular motions during sanding can aid in achieving a more uniform finish. This technique helps distribute the abrasive action evenly across the glass edge, reducing the likelihood of creating uneven spots or over-sanding specific areas. By adopting a circular sanding motion, artisans can attain a balanced and polished surface.

-

Frequent Grit Progression: As the sanding process advances, it is essential to transition to finer grits at regular intervals. Gradually progressing from coarser to finer grits ensures that the glass edge undergoes comprehensive refinement, eliminating scratches and achieving a smooth, polished finish. This step-by-step approach is instrumental in attaining professional-quality results.

-

Inspect Regularly: Periodically inspecting the glass edge during the sanding process is crucial for monitoring progress and identifying any imperfections. This allows artisans to make real-time adjustments, ensuring that the desired edge profile and smoothness are consistently maintained throughout the sanding stages. Regular inspection facilitates precision and quality control.

-

Use Safety Precautions: Sanding glass edges requires adherence to safety protocols to prevent potential injuries. Wearing protective gear, including safety goggles and gloves, is imperative to shield against airborne glass particles and potential hand injuries. Additionally, working in a well-ventilated area minimizes exposure to glass dust and ensures a safe working environment.

-

Clean Thoroughly: After each grit progression, thoroughly clean the glass edge to remove any residual abrasive particles and glass debris. This meticulous cleaning process prevents cross-contamination of grits, maintains the effectiveness of the sandpaper, and ensures that subsequent grits can refine the glass surface without interference.

By incorporating these tips into the glass edge sanding process, artisans and DIY enthusiasts can elevate their techniques, resulting in refined, polished glass edges that enhance the visual appeal and quality of their projects.

Conclusion

In conclusion, the process of sanding glass edges is a meticulous art that demands precision, expertise, and the right tools. Understanding the significance of grit sandpaper and its impact on glass surfaces is fundamental to achieving exceptional results. By recognizing the diverse grit sizes and their corresponding functions, artisans and DIY enthusiasts can effectively harness the power of sandpaper to transform raw glass edges into refined, visually appealing surfaces.

Choosing the right grit sandpaper for glass edge sanding involves a thoughtful consideration of the project's specific needs, the type of glass being worked on, and the desired level of refinement. From initial shaping to final polishing, the strategic progression through various grit sizes is crucial for achieving a flawless, professional finish. The selection of the appropriate grit sandpaper is a pivotal step that sets the stage for successful glass edge sanding, laying the groundwork for the application of effective sanding techniques.

Moreover, incorporating essential tips such as using lubrication, maintaining consistent pressure, employing circular motions, and adhering to safety precautions can significantly enhance the sanding process, resulting in refined, polished glass edges that elevate the visual appeal and quality of glass projects. By integrating these tips into their sanding techniques, artisans and DIY enthusiasts can navigate the intricacies of glass edge refinement with confidence and precision.

In essence, the journey of sanding glass edges is a harmonious blend of technical expertise and artistic finesse. By embracing the knowledge of grit sandpaper, understanding its role in glass edge sanding, and implementing effective sanding techniques, individuals can elevate their glasswork to new heights, creating stunning, polished edges that exemplify craftsmanship and attention to detail. With the right grit sandpaper, informed decision-making, and refined sanding techniques, the transformation of raw glass edges into exquisite, polished surfaces becomes an attainable and rewarding endeavor.

Frequently Asked Questions about What Grit Sandpaper For Glass Edge

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Glass Edge”