Home>Garden Essentials>What Is The Best Infill Pattern

Garden Essentials

What Is The Best Infill Pattern

Modified: March 7, 2024

Discover the best garden infill pattern for your project. Whether you're looking for durability, aesthetics, or both, our guide will help you make the right choice.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to 3D printing, achieving the desired strength and structural integrity of the printed object is crucial. This is where infill patterns come into play. Infill patterns refer to the internal structure of a 3D printed object, which can greatly affect its strength, durability, and overall quality.

Infill patterns are essentially a series of interconnected lines or shapes that fill the empty space within a 3D printed object. They are responsible for providing support and stability to the object while minimizing the amount of material used and reducing print time. By strategically choosing the right infill pattern, you can optimize the strength, weight, and cost-effectiveness of your 3D printed creations.

In this article, we will explore the importance of infill patterns in 3D printing and discuss various types of infill patterns available. We will also compare different infill patterns, highlighting their strengths and weaknesses. Finally, we will provide insights into the factors to consider when choosing the best infill pattern for your specific applications.

Key Takeaways:

- Choose infill patterns like honeycomb for lightweight and rigid parts, or triangular for high strength mechanical components. Consider print time, material usage, and object application for optimal 3D prints.

- Experiment with different infill patterns and percentages to find the best combination for your specific 3D printing needs. Consider factors like strength, print time, and surface finish for successful prints.

Read more: What Is The Fastest Infill Pattern

Definition of Infill Pattern

Infill patterns, as mentioned earlier, refer to the internal structure of a 3D printed object. They are used to fill the empty space within the object, providing support and stability. In other words, infill patterns determine the density and strength of the interior of the 3D printed object.

The infill pattern is created by dividing the empty space into a series of interconnected lines or shapes. These lines or shapes are typically arranged in a grid-like pattern, evenly spaced throughout the object. The infill density, which refers to the amount of space occupied by the infill pattern, can be adjusted to meet specific requirements.

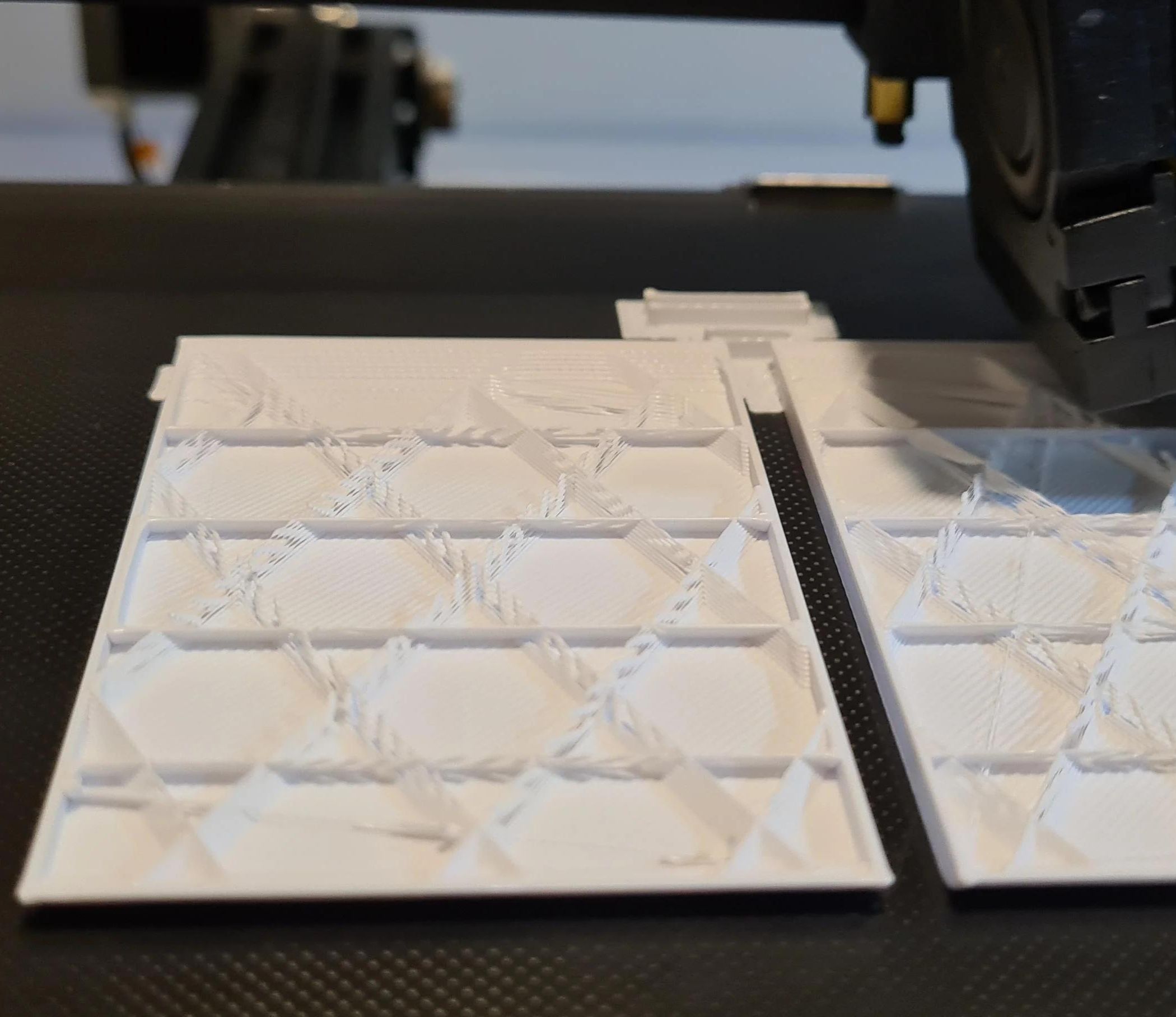

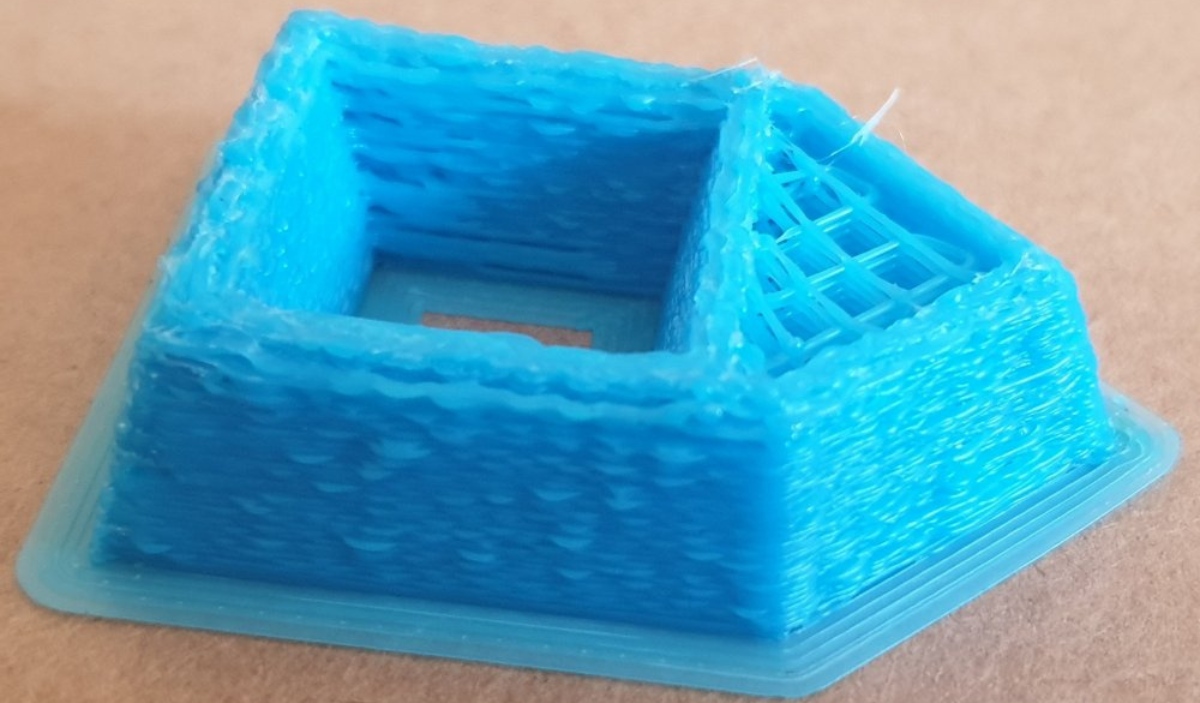

When 3D printing an object, the printer head moves along a predefined path, depositing the material layer by layer. Infill patterns are printed during the process by filling the empty space between the outer shell of the object. The pattern is repeated for each layer to create a solid and robust structure.

The choice of infill pattern can greatly influence the performance of the 3D printed object. Different infill patterns have different characteristics in terms of strength, flexibility, weight, and print time. This allows for customization based on the specific requirements of the object and its intended application.

Importance of Infill Patterns in 3D Printing

Infill patterns play a vital role in the overall quality and performance of 3D printed objects. They provide structural support, enhance strength, and optimize material usage. Understanding the importance of infill patterns is crucial for achieving successful and reliable 3D prints.

One of the main advantages of using infill patterns is the ability to control the strength and weight of the printed object. By adjusting the infill density, you can achieve a balance between strength and weight. This is especially important for applications where lightweight and durable parts are required, such as aerospace components or robotics.

Infill patterns also contribute to the stability and rigidity of the 3D printed object. The internal structure provided by the infill helps to prevent deformation or warping during the printing process and in real-world use. This is particularly beneficial for larger or structurally complex objects that are prone to distortion.

Moreover, infill patterns allow for efficient material usage. By strategically placing the infill lines or shapes, you can reduce the amount of material required to fill the object while maintaining its overall strength. This not only lowers production costs but also reduces print time since less material needs to be deposited.

Another notable advantage of using infill patterns is improving the print quality and surface finish of the 3D printed object. The presence of infill provides a solid foundation for the outer shell of the object, reducing the likelihood of gaps or voids in the print. This results in a smoother and more aesthetically pleasing surface.

Overall, infill patterns are essential for achieving strong, lightweight, and cost-effective 3D prints. They provide structural support, enhance stability, optimize material usage, and improve the overall quality of the printed object. By carefully selecting the appropriate infill pattern, you can customize your prints to meet the specific requirements of your applications.

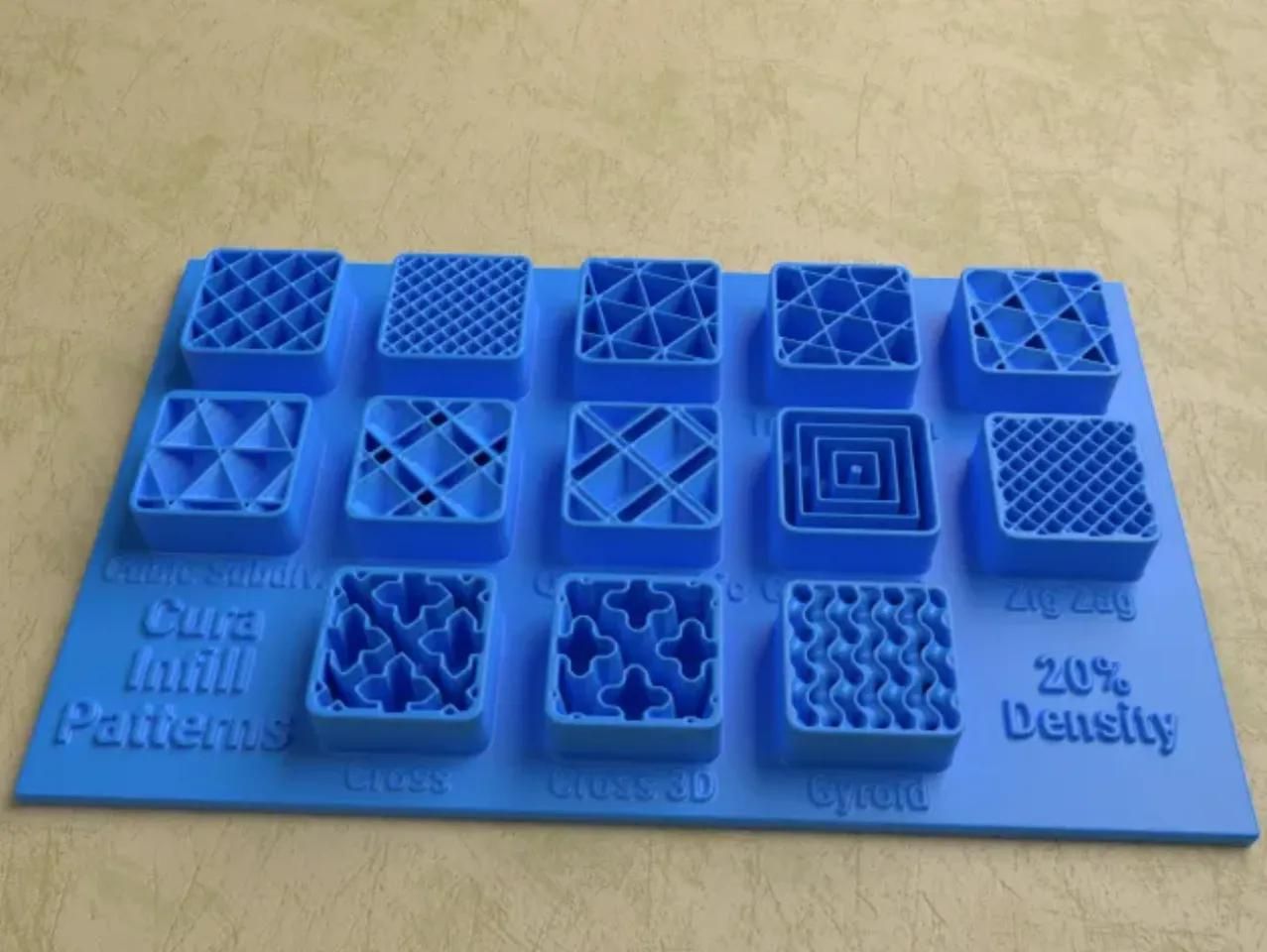

Types of Infill Patterns

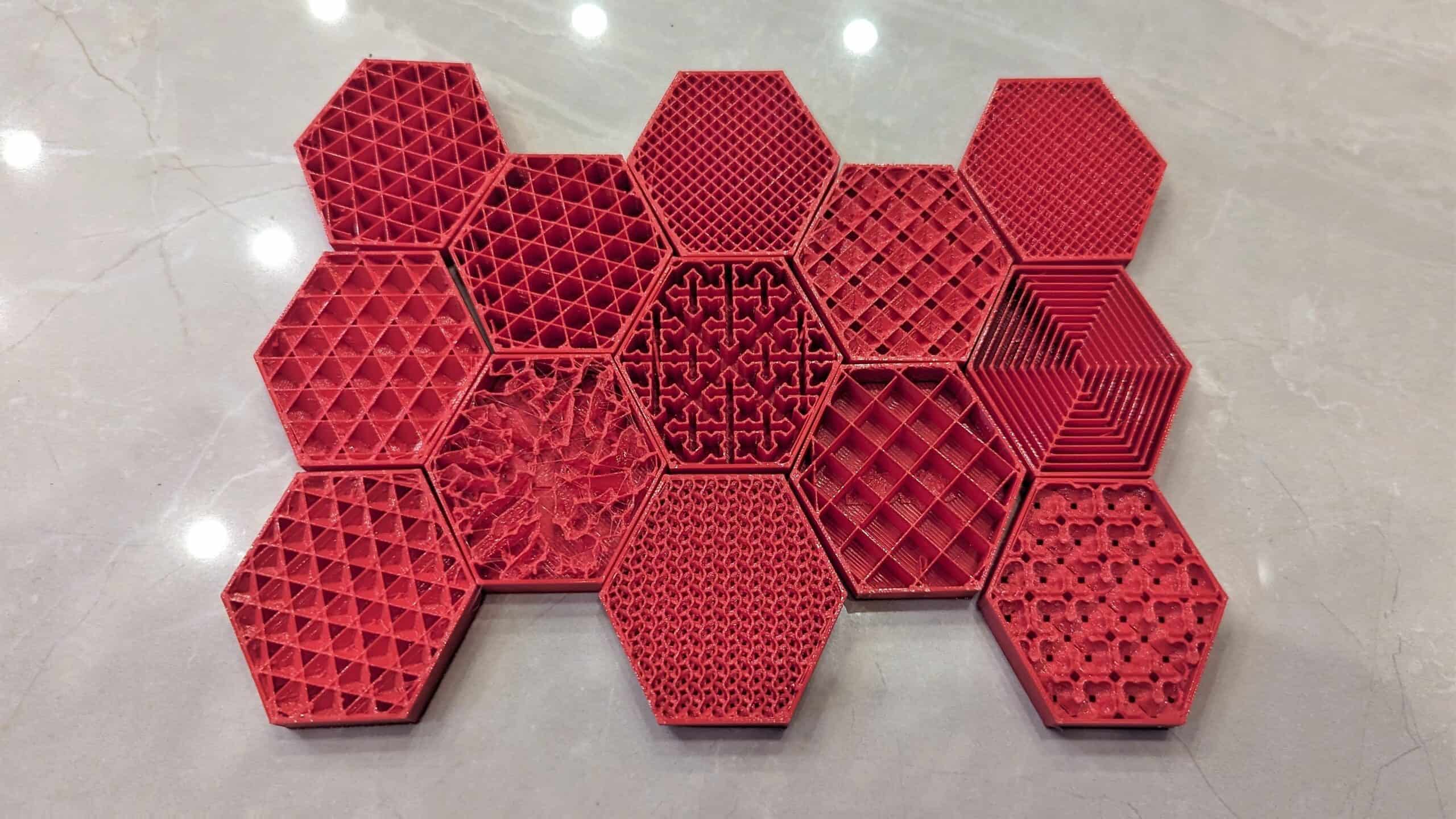

There are various types of infill patterns available in 3D printing, each with its own unique characteristics and suitability for different applications. Understanding the different types of infill patterns can help you choose the most appropriate one for your specific needs. Let’s explore some commonly used infill patterns:

- Rectilinear: The rectilinear infill pattern, also known as the grid pattern, consists of straight lines that are oriented along the x and y axes. This pattern provides good structural support and is easy to print. However, it may result in a slightly weaker part compared to other patterns due to the absence of diagonal connections.

- Triangular: The triangular infill pattern is formed by a series of interconnecting triangles. It offers excellent strength and stability, as the diagonal connections between the triangles reinforce the structure. The triangular pattern is ideal for parts that require higher strength and durability while minimizing material usage.

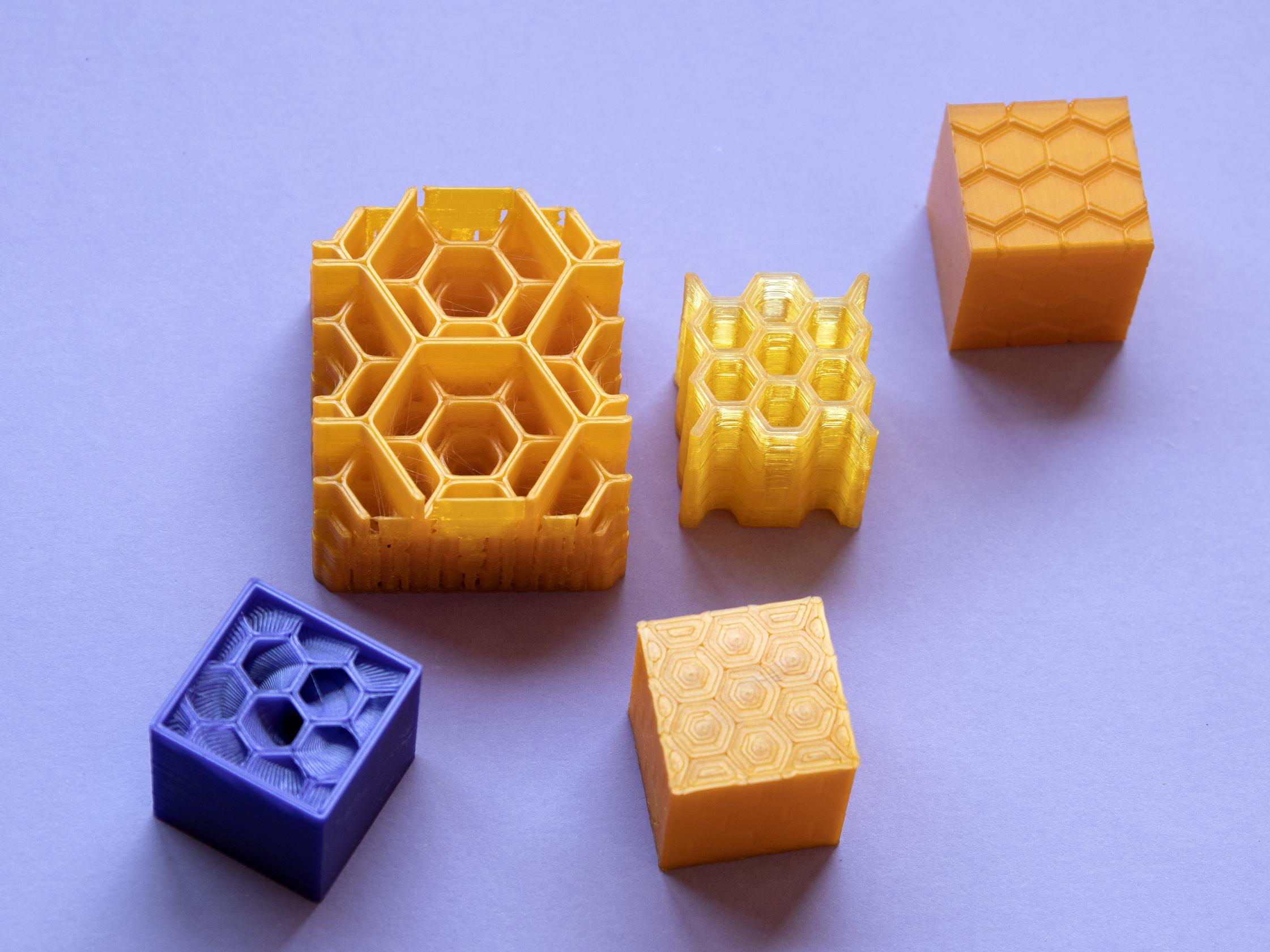

- Honeycomb: The honeycomb infill pattern resembles a hexagonal grid, with each individual cell forming a honeycomb-like shape. This pattern provides good strength and stability while reducing material usage. It offers a good balance between structural integrity and print time. The honeycomb pattern is commonly used for lightweight and rigid applications.

- Concentric: The concentric infill pattern consists of a series of concentric circles that gradually fill the interior space of the object. This pattern provides good structural support and reduces the likelihood of gaps between the infill and outer shell. The concentric pattern is suitable for objects that require added rigidity and surface smoothness.

- Gyroid: The gyroid infill pattern features intricate interlocking curved lines. This pattern offers excellent strength and stability, as the interlocking structure provides reinforcement. The gyroid pattern is particularly useful for applications that require lightweight yet robust parts, such as aerospace and automotive components.

These are just a few examples of infill patterns available in 3D printing. There are many other patterns, and some 3D printing software and slicers even allow for custom infill patterns. The choice of infill pattern depends on factors such as desired strength, weight, print time, and the specific requirements of the printed object’s application.

Consider using a honeycomb infill pattern for 3D printing. It provides a good balance of strength and material usage, making it suitable for a wide range of applications.

Comparison of Different Infill Patterns

When deciding on the best infill pattern for your 3D printed object, it’s essential to consider the characteristics and advantages of each pattern. Let’s compare and contrast some of the commonly used infill patterns to help you make an informed decision:

- Rectilinear: The rectilinear infill pattern is straightforward and easy to print. It provides a good balance between strength and material usage. However, it may result in a slightly weaker part due to the absence of diagonal connections.

- Triangular: The triangular infill pattern offers excellent strength and stability due to the diagonal connections between the triangles. It provides optimal material usage and is suitable for applications that require high strength. However, it may increase print time compared to other patterns.

- Honeycomb: The honeycomb infill pattern provides good strength and stability while optimizing material usage. It offers a good balance between structural integrity and print time. The honeycomb pattern is commonly used for lightweight and rigid applications.

- Concentric: The concentric infill pattern provides good structural support and reduces the likelihood of gaps between the infill and outer shell. It offers additional rigidity and surface smoothness. However, it may increase print time due to the intricate concentric circles.

- Gyroid: The gyroid infill pattern offers excellent strength and stability due to the interlocking curved lines. It provides a lightweight yet robust structure and is suitable for applications that require high strength with minimal material usage. However, it may increase the complexity of the print and extend the print time.

Each infill pattern has its strengths and weaknesses, and the choice depends on your specific requirements. If strength and material optimization are crucial, the triangular or gyroid patterns may be the best options. For a balance between strength and print time, the honeycomb or rectilinear patterns are viable choices. The concentric pattern is suitable when additional rigidity and smooth surface finish are desired.

It’s important to consider factors such as the intended application, object size and shape, desired strength, weight, and print time when selecting the most appropriate infill pattern. Additionally, experimenting with different infill percentages can further customize the performance of the printed object.

Factors to Consider When Choosing the Best Infill Pattern

Selecting the most suitable infill pattern for your 3D printed object involves considering several factors. These factors will help determine the optimal balance between strength, weight, print time, and overall performance. Here are some key factors to consider when choosing the best infill pattern:

- Object Application: The intended use of the 3D printed object plays a crucial role in determining the appropriate infill pattern. For applications that require high strength and durability, triangular or gyroid patterns may be the best choices. If weight reduction is a priority, honeycomb or rectilinear patterns could be more suitable.

- Strength Requirements: Consider the level of strength required for your object. If maximum strength is needed, infill patterns with diagonal connections like the triangular or gyroid pattern are preferable. For less demanding applications, patterns like the rectilinear or concentric infill may suffice.

- Print Time: Depending on your timeline, the print time of your 3D object may be a factor to consider. Patterns that have more intricate designs, like the concentric or gyroid patterns, may require longer print times. Simpler patterns like the rectilinear or honeycomb offer faster print times while still maintaining good strength.

- Material Usage: If material optimization is important, infill patterns that utilize less material, such as the honeycomb or gyroid patterns, are advantageous. These patterns offer a good balance between strength and material usage, making them suitable for cost-effective printing.

- Print Quality: Consider the desired surface finish and overall print quality for your object. Patterns like the concentric infill may provide a smoother surface finish due to the concentric circles. If surface smoothness is a priority, this pattern may be the best choice.

- Geometry and Object Size: The geometry and size of your object should also be considered. Some patterns may work better for certain geometries or shapes. For instance, intricate or intricate objects with complex curves may benefit from patterns like the gyroid, while simple shapes can be printed efficiently with a rectilinear or honeycomb pattern.

By carefully considering these factors, you can make an informed decision when selecting the best infill pattern for your 3D printed object. It’s worth experimenting with different infill percentages and patterns to find the optimal combination that meets your specific requirements.

Recommended Infill Patterns for Different Applications

The choice of infill pattern depends on the specific application and the desired characteristics of the 3D printed object. Here are some recommended infill patterns for different types of applications:

- General-purpose objects: For everyday objects that require a balance of strength, print time, and material usage, the rectilinear or honeycomb infill patterns are recommended. These patterns provide good structural support and stability while optimizing material consumption.

- Mechanical components: Applications that involve mechanical stress and require high strength should consider infill patterns like the triangular or gyroid patterns. These patterns offer excellent strength due to their diagonal connections and interlocking geometry.

- Lightweight and rigid parts: When weight reduction is crucial but structural integrity is still necessary, the honeycomb infill pattern is a popular choice. Its hexagonal grid-like structure provides good strength while minimizing the use of material.

- Smooth surface finish: If achieving a smoother surface finish is a priority, the concentric infill pattern is recommended. The concentric circles help fill the empty space while reducing the likelihood of gaps and voids, resulting in a smoother surface.

- Complex geometries: For objects with intricate or complex geometries, the gyroid infill pattern is often recommended. Its interlocking curved lines provide excellent strength and stability in complex shapes while minimizing material consumption.

Keep in mind that these recommendations are general guidelines, and the optimal infill pattern may vary based on specific requirements and preferences. It’s always a good idea to experiment with different patterns and infill percentages to find the best combination that meets your needs.

Furthermore, it’s worth noting that some 3D printing software and slicers allow for customized infill patterns, so consider exploring those options if none of the recommended patterns suit your particular requirements.

Conclusion

Infill patterns play a crucial role in achieving strong, durable, and cost-effective 3D prints. By strategically selecting the right infill pattern, you can optimize the strength, weight, print time, and material usage of your 3D printed objects.

We have explored various types of infill patterns, such as the rectilinear, triangular, honeycomb, concentric, and gyroid patterns. Each pattern has its own strengths and weaknesses, making them suitable for different applications and desired outcomes.

Consideration of factors such as the object’s application, strength requirements, print time, material usage, print quality, geometry, and size can guide you in choosing the best infill pattern. Depending on your needs, you may opt for patterns that prioritize high strength, lightweight structure, smooth surface finish, or efficient material usage.

It’s important to remember that infill patterns are not one-size-fits-all solutions. Experimentation with different patterns and infill percentages may be necessary to find the optimal combination for your specific requirements.

By understanding the importance of infill patterns and their impact on the overall quality and performance of 3D printed objects, you can harness the power of this technique to create functional and aesthetically pleasing prints.

So, the next time you embark on a 3D printing project, carefully consider the infill pattern that best suits your needs and unleash the full potential of your creations.

Frequently Asked Questions about What Is The Best Infill Pattern

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Best Infill Pattern”