Home>Garden Essentials>How Does Slicer Algorithm Handle Infill Patterns

Garden Essentials

How Does Slicer Algorithm Handle Infill Patterns

Modified: March 7, 2024

Discover how the Slicer Algorithm efficiently handles infill patterns in garden designs, optimizing your space for maximum growth and beauty.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of 3D printing! As an emerging technology, 3D printing has revolutionized various industries, including manufacturing, healthcare, and even hobbies. One of the key components in the 3D printing process is the slicer algorithm, which plays a crucial role in creating intricate and accurate prints.

The slicer algorithm is responsible for converting a 3D model into a set of instructions that the 3D printer can understand and execute. It breaks down the model into layers and generates a series of paths for the printer to follow. This ensures that the printer deposits the material in the right locations and creates a physical representation of the digital design.

One essential aspect of the slicing process is the infill pattern. Infill refers to the internal structure of the print, which adds strength and stability to the object while minimizing material usage. The slicer algorithm determines the infill pattern based on user-defined parameters, such as density and pattern type.

In this article, we will explore how the slicer algorithm handles infill patterns. We will delve into the different types of infill patterns commonly used, and discuss the benefits and limitations of the slicer algorithm’s infill handling. By the end, you will have a better understanding of this crucial element in the 3D printing process.

Key Takeaways:

- Infill patterns, handled by the slicer algorithm in 3D printing, enhance strength, reduce material usage, and enable lightweight designs, benefiting various industries and applications.

- While infill patterns improve 3D print quality, they may impact strength, surface texture, print time, and accuracy. Understanding and mitigating these limitations is crucial for optimal printing results.

Read more: What Is The Fastest Infill Pattern

Background on Slicer Algorithm

Before we dive into the details of how the slicer algorithm handles infill patterns, let’s first gain a basic understanding of what the slicer algorithm is and how it works.

The slicer algorithm is a software component that takes a 3D model file, typically in the form of an STL or OBJ format, and prepares it for 3D printing. It segments the model into thin horizontal layers, a process known as slicing. Each layer is then converted into a series of instructions for the 3D printer, specifying how the print head should move and how the material should be deposited. The result is a set of G-code instructions that the printer can follow to recreate the 3D model layer by layer.

The slicing process involves various parameters that can be adjusted to optimize the print quality and performance. These parameters include layer height, print speed, nozzle size, and infill density, among others. The infill density determines how much material is used to fill the internal structure of the print and plays a significant role in the overall strength and stability of the object.

There are several popular slicer software programs available, such as Ultimaker Cura, PrusaSlicer, and Slic3r, each with its own unique slicer algorithm. These algorithms employ different techniques and approaches to ensure precise and accurate printing results.

The slicer algorithm takes into account various factors when determining the toolpaths for the printer. These factors include the shape and complexity of the model, the desired print quality, and the capabilities of the printer itself. It analyzes the geometry of the model to identify areas where support structures are needed, as well as the orientation of the print to optimize for strength and minimize the need for support material.

Now that we have a basic understanding of the slicer algorithm and its role in the 3D printing process, let’s dive into the fascinating world of infill patterns and how the slicer algorithm handles them.

Infill Patterns in Slicer Algorithm

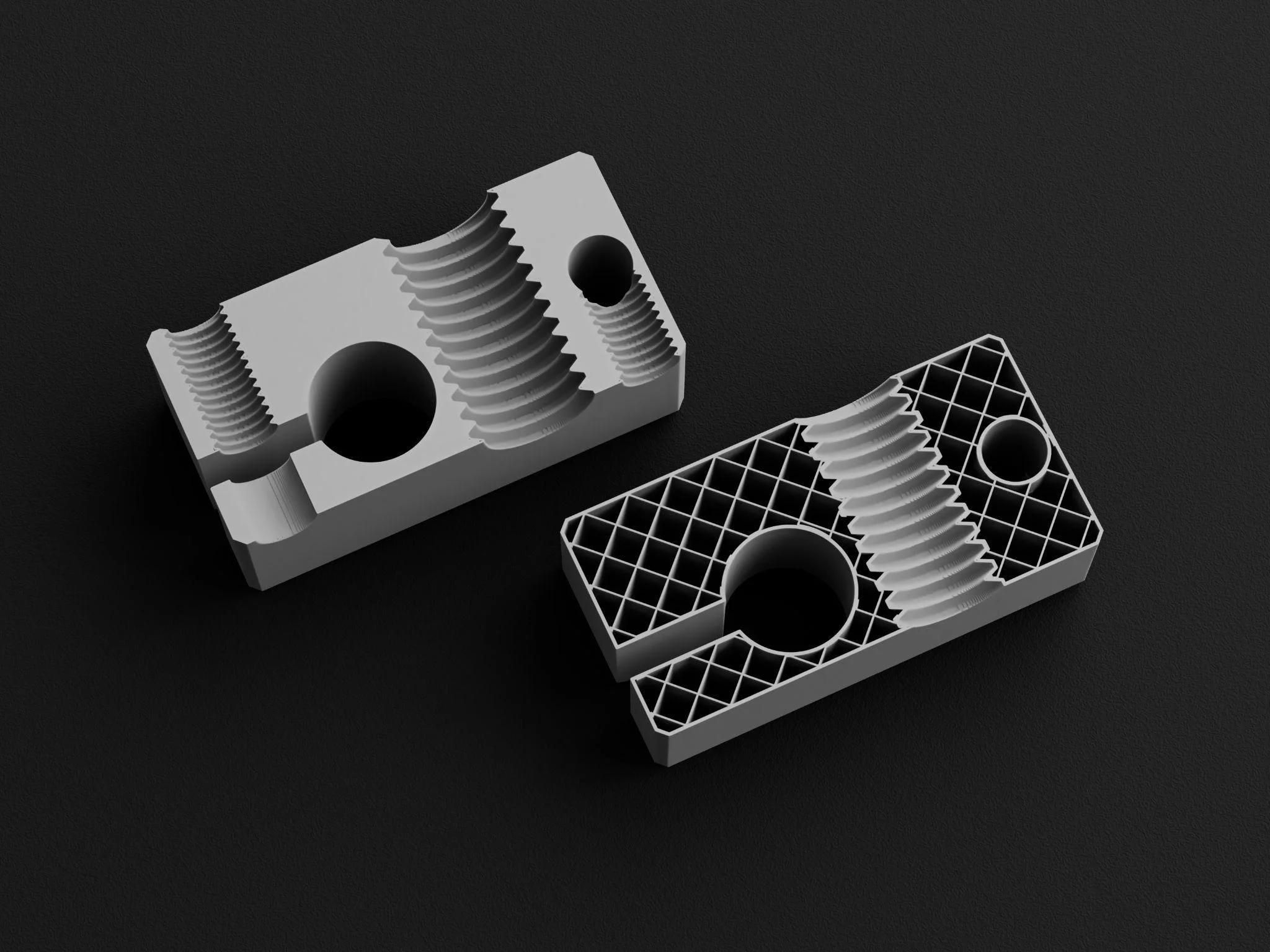

Infill patterns refer to the internal structure of a 3D print. Instead of solidifying the entire object, infill patterns fill the voids within the print, providing support and structural integrity while optimizing material usage and print time. Different infill patterns can be selected based on the desired strength, flexibility, and weight of the final print.

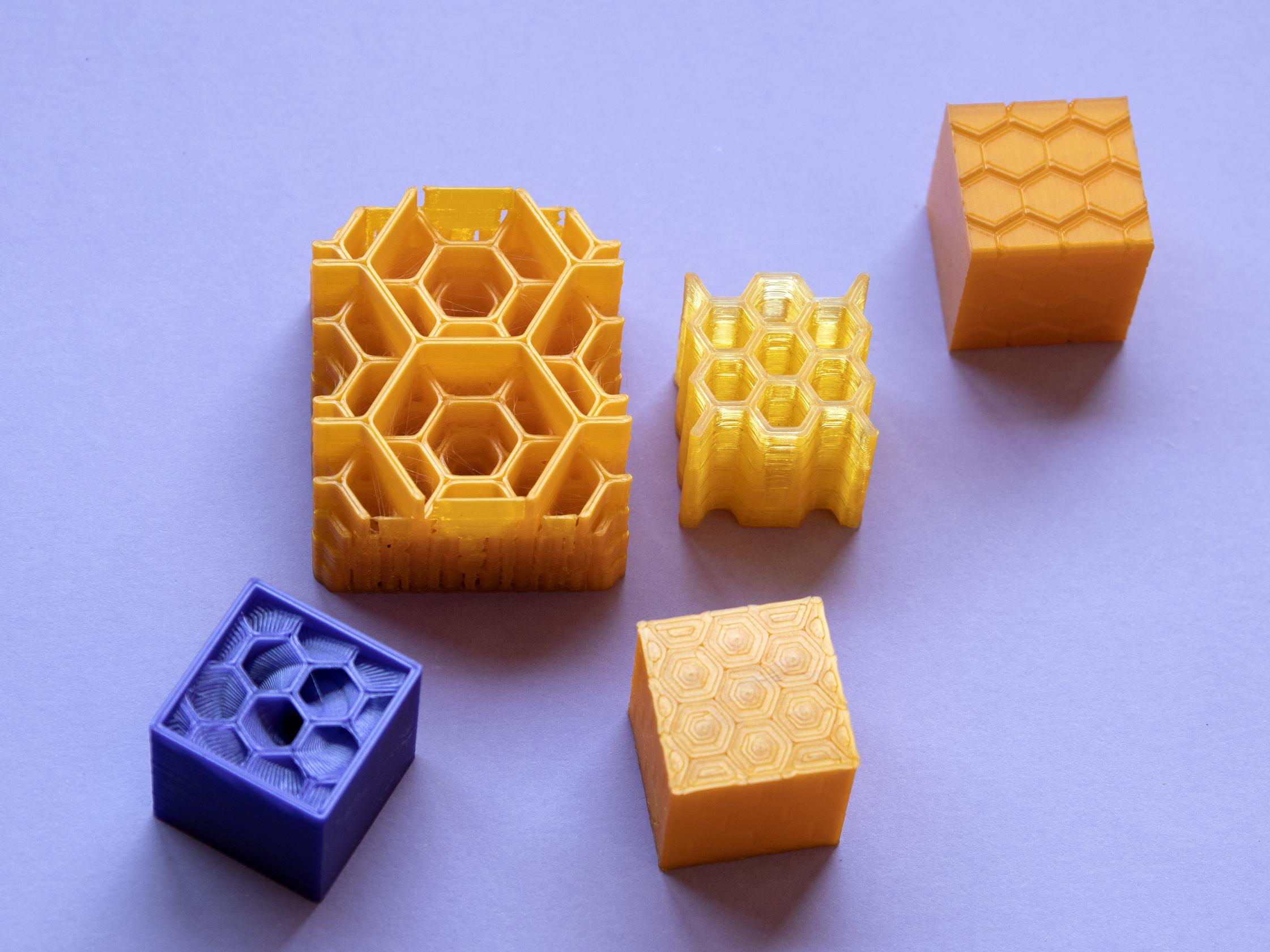

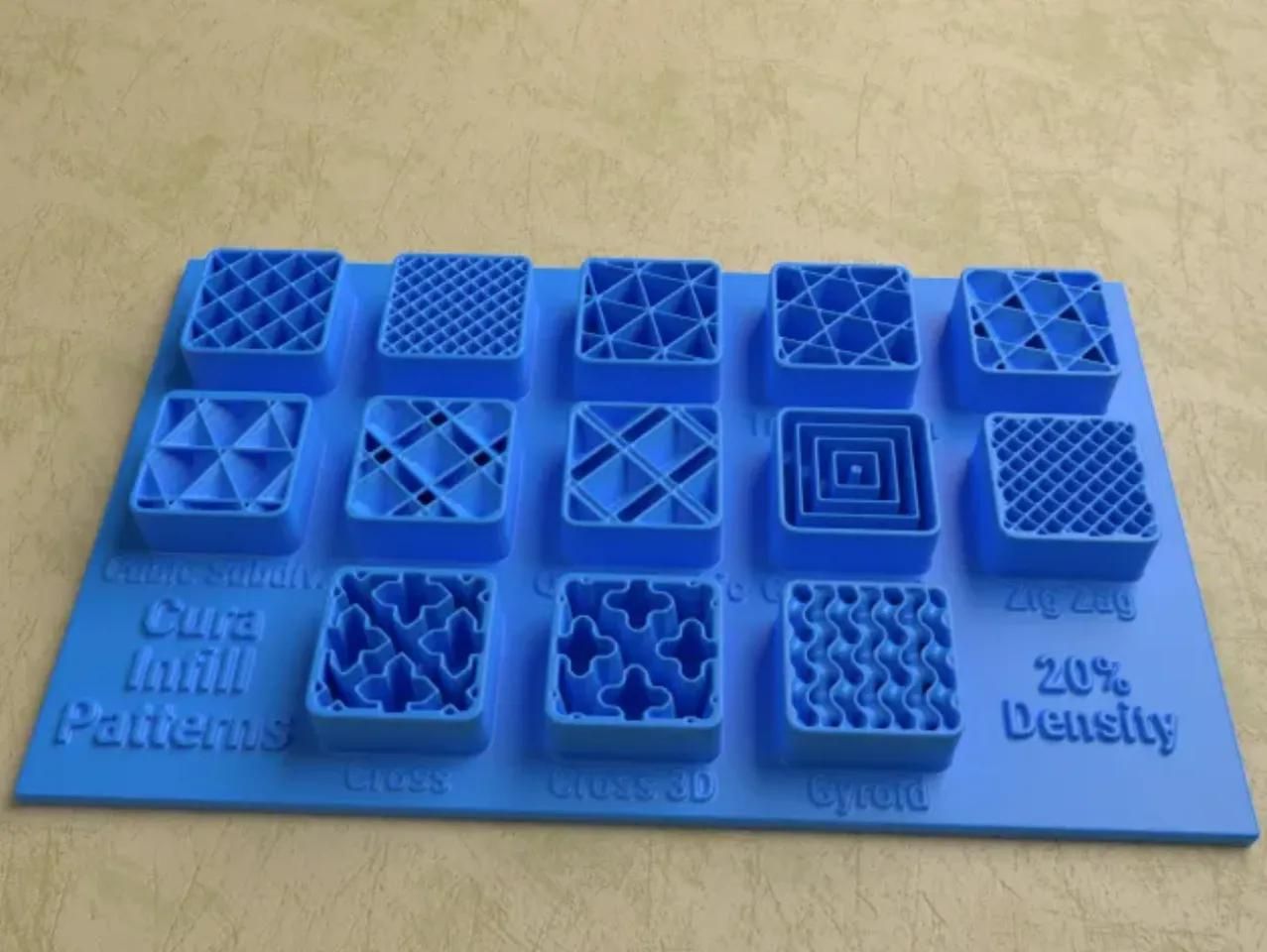

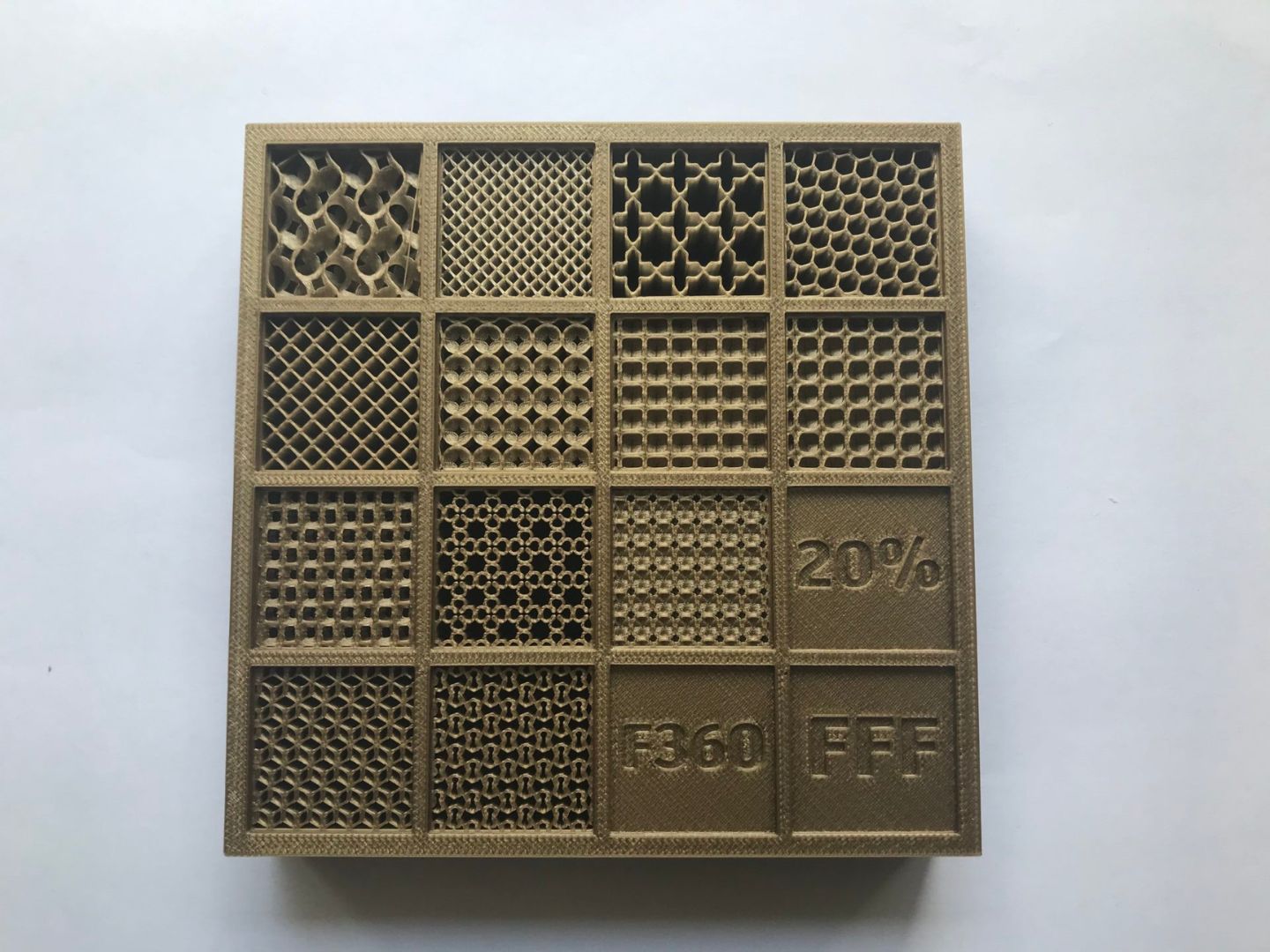

Within the slicer algorithm, there are several common infill patterns that can be chosen, including:

- Rectilinear: This pattern creates a grid-like structure with straight lines running parallel in both the x and y axes. It is the simplest and fastest infill pattern to print, but may not provide as much strength or flexibility compared to other patterns.

- Triangular: Triangular infill consists of interconnected triangles, providing better strength compared to rectilinear. This pattern is often used when additional strength is required without sacrificing print speed.

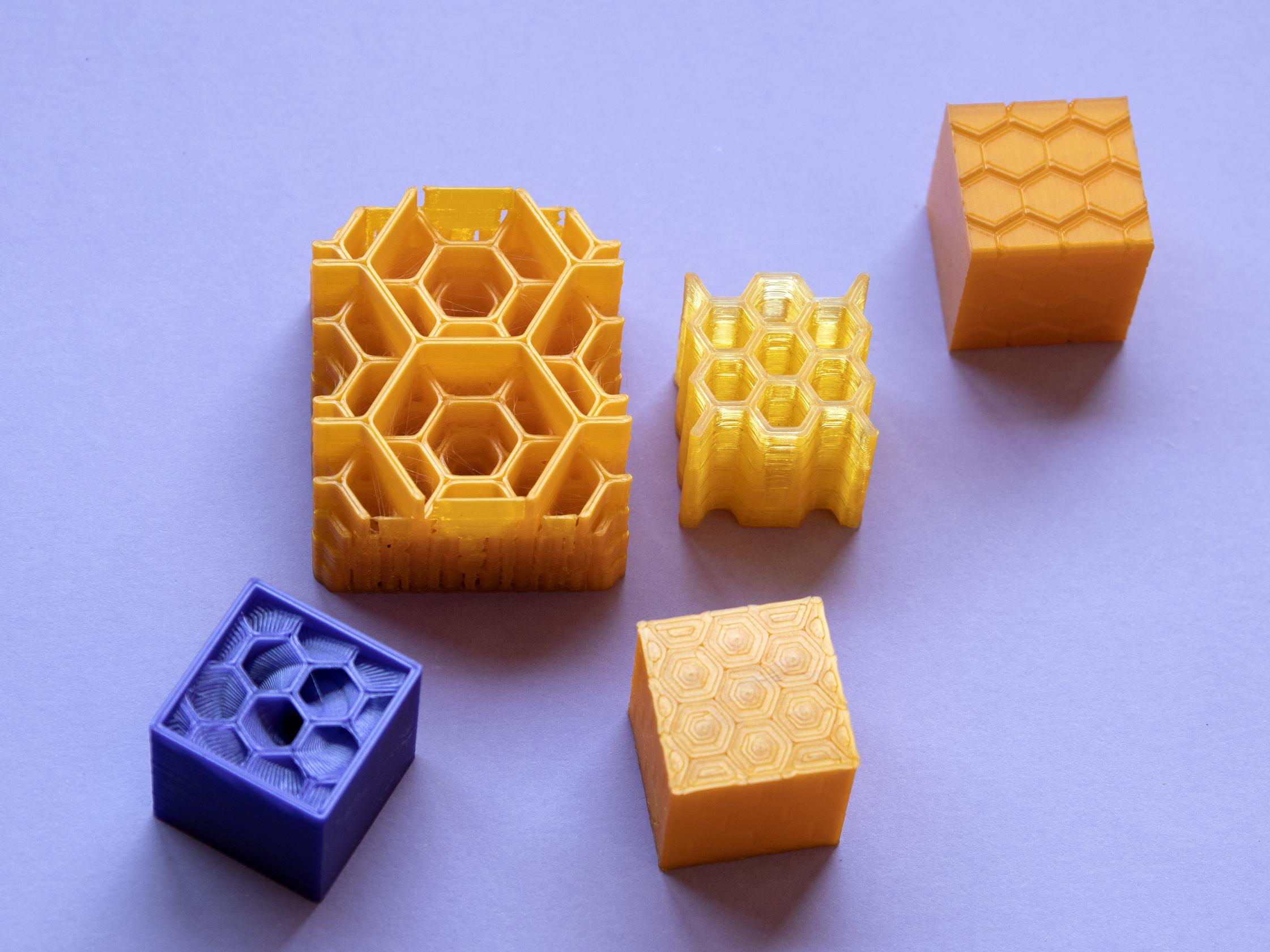

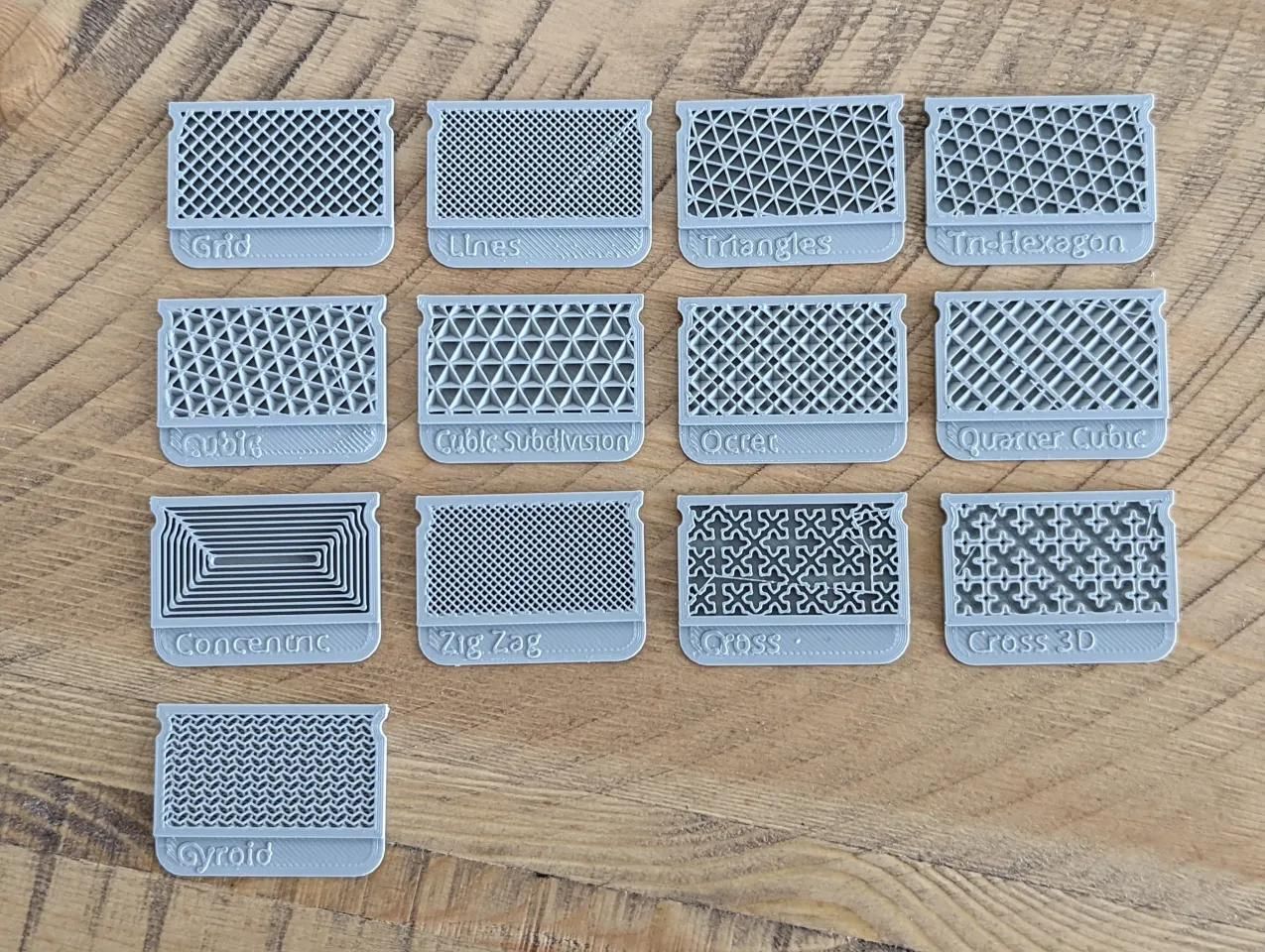

- Honeycomb: This pattern resembles a honeycomb structure, with a series of hexagonal cells interlocked together. Honeycomb infill offers excellent structural integrity and is commonly used for lightweight prints.

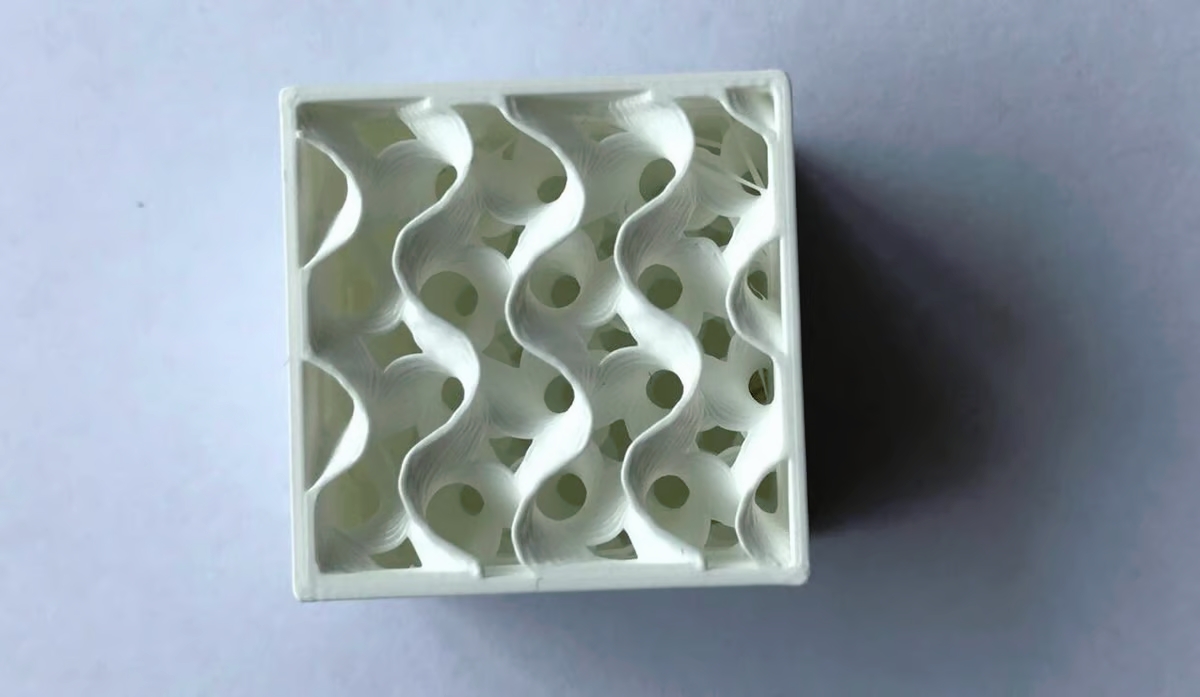

- Gyroid: The gyroid infill pattern features intricate and organic-looking structures that provide good strength and flexibility. It is a popular choice for complex prints that require both strength and aesthetic appeal.

- Concentric: Concentric infill consists of concentric circles or loops that gradually fill the inner regions of the print. It offers good strength and can be useful for prints that require balanced support and weight distribution.

The choice of infill pattern depends on various factors such as the intended use of the print, the desired strength-to-weight ratio, and the specific requirements of the model. Some slicer algorithms allow users to customize the infill pattern, density, and orientation, providing flexibility to achieve desired printing results.

Now that we have explored the different infill patterns available, let’s take a closer look at how the slicer algorithm handles these patterns to ensure a successful and efficient 3D printing process.

How Slicer Algorithm Handles Infill Patterns

The slicer algorithm plays a crucial role in determining how infill patterns are implemented in a 3D print. It takes into account various parameters and considerations to generate a toolpath that efficiently fills the internal structure of the print with the selected infill pattern.

When handling infill patterns, the slicer algorithm considers the following factors:

- Infill Density: The user-defined infill density determines the amount of infill material that will be used to fill the internal structure of the print. Higher densities result in a stronger print, but require more material and longer print times.

- Infill Placement: The slicer algorithm decides where to place the infill within the print. It is crucial to distribute the infill strategically to provide optimal support and structural stability while minimizing material usage. Typically, infill is placed in a grid-like pattern or in a zigzag path, depending on the selected infill pattern.

- Infill Pattern Connectivity: The slicer algorithm ensures that the lines or polygons of the infill pattern are properly connected to each other and to the exterior walls of the print. This connectivity is crucial in maintaining the structural integrity of the print and preventing any loose or weak infill sections.

- Infill Pattern Orientation: Depending on the shape and orientation of the model, the slicer algorithm adjusts the orientation of the infill pattern to optimize strength and print quality. For example, the orientation of the pattern may be aligned with the primary stress directions of the print or rotated to enhance structural robustness.

The slicer algorithm also provides the option to modify the infill pattern’s angle or rotation within the print. This allows users to experiment with different orientations to achieve specific mechanical properties or aesthetic effects.

Furthermore, some advanced slicer algorithms offer additional features to enhance infill handling, such as adaptive infill. With adaptive infill, the algorithm analyzes the geometry of the model and adjusts the infill density and pattern dynamically. This technique optimizes the use of material by concentrating the infill in areas that require more strength or support, while reducing density in less critical regions.

By intelligently handling the infill patterns, the slicer algorithm ensures that the internal structure of the print is accurately and efficiently filled. This, in turn, results in prints that exhibit the desired strength, stability, and material efficiency.

When using a slicer algorithm, consider adjusting the infill pattern to balance strength and material usage. A honeycomb pattern is often a good choice for a strong and efficient infill.

Benefits of Slicer Algorithm’s Infill Handling

The slicer algorithm’s handling of infill patterns offers several benefits that contribute to the overall quality and efficiency of 3D prints. Let’s explore some of these key benefits:

- Strength and Stability: By strategically filling the internal structure of the print with infill patterns, the slicer algorithm enhances the overall strength and stability of the printed object. The selected infill pattern provides additional support and rigidity, preventing the print from being too fragile or prone to deformation.

- Material Optimization: Infill patterns allow for significant material savings compared to printing objects with solid structures. The slicer algorithm intelligently calculates the infill pattern and density to optimize material usage while still maintaining the required strength and functionality of the print. This reduces material costs and waste, making 3D printing a more economical and sustainable process.

- Print Time Reduction: The slicer algorithm’s infill handling helps reduce the overall print time. By incorporating infill patterns, the algorithm decreases the amount of material that needs to be extruded, resulting in shorter print durations. This benefit is particularly noticeable when using infill patterns with lower densities or geometrically efficient structures, which can significantly accelerate the printing process.

- Weight Reduction: Infill patterns allow for lightweight prints, which can be advantageous in applications where weight is a critical factor. The slicer algorithm’s infill handling enables the creation of objects with internal structures that maintain strength while reducing mass. This benefit is especially valuable in industries such as aerospace or automotive, where lightweight components can contribute to fuel efficiency and overall performance.

- Design Flexibility: Infill patterns offer design flexibility as they enable the creation of objects with specific mechanical properties. The slicer algorithm provides a variety of infill patterns to choose from, allowing designers and engineers to tailor the internal structure of the print to meet specific requirements. This flexibility empowers users to achieve a balance between strength, flexibility, and weight for different applications.

Overall, the slicer algorithm’s infill handling provides a range of benefits that enhance the quality, efficiency, and versatility of 3D prints. By carefully selecting and implementing infill patterns, the algorithm optimizes material usage, reduces print time, improves strength and stability, and enables lightweight designs. These advantages contribute to the continued growth and advancement of 3D printing technology in various industries.

Read more: What Infill Pattern Is The Strongest

Limitations of Slicer Algorithm’s Infill Handling

Despite the many benefits of the slicer algorithm’s infill handling, there are some inherent limitations that are important to consider. These limitations can impact the overall performance and quality of 3D prints. Let’s explore some of these limitations:

- Print Strength: While infill patterns enhance the strength of 3D prints, the overall strength may still be lower compared to solid parts. The internal voids created by infill patterns can introduce weak points or areas of reduced structural integrity. It is crucial to consider the intended use and load-bearing requirements of the print to determine if additional reinforcement or solid infill is necessary.

- Print Surface Quality: Infill patterns can sometimes result in a textured or uneven print surface. The appearance and finish of the outermost layers of the print can be impacted by the underlying infill structure. This can be particularly noticeable in prints with low infill densities or when using infill patterns with noticeable gaps between lines.

- Print Time: While the infill patterns help reduce print time compared to solid prints, prints with higher infill densities or complex infill structures can still take longer than desired. The slicer algorithm’s infill handling requires additional material deposition and movement, which can extend the overall printing duration. It’s important to find the right balance between print time and desired print strength or weight.

- Support Structures: Infill patterns are not suitable for all parts of a print, especially in complex geometries or intricate overhangs. In such cases, additional support structures may be required to maintain stability and prevent sagging or warping. This adds complexity to the printing process and necessitates the removal of support structures post-printing, which can be time-consuming and require extra effort.

- Print Accuracy: The slicer algorithm’s infill handling can potentially introduce discrepancies in the final printed dimensions, especially for thin-walled prints with high infill densities. The expansion or contraction of the infill material can affect the overall dimensions of the print. It’s important to calibrate the printer and consider the potential dimensional variations during the design phase to ensure accurate results.

It is crucial to understand these limitations and account for them when utilizing the slicer algorithm’s infill handling. By considering these factors and making informed decisions, designers and print enthusiasts can overcome these limitations and optimize their prints for the desired applications.

Conclusion

The slicer algorithm’s handling of infill patterns is a crucial component in the 3D printing process. By strategically filling the internal structure of prints, infill patterns enhance strength, optimize material usage, reduce print time, and enable lightweight designs. These benefits have made infill patterns an integral part of 3D printing across various industries and applications.

Through the slicer algorithm’s infill handling, users can select from a variety of infill patterns such as rectilinear, triangular, honeycomb, gyroid, and concentric. Each pattern offers unique characteristics and advantages depending on the specific requirements of the print. Additionally, the ability to customize infill density and orientation further enhances the flexibility and adaptability of the printing process.

While there are limitations to consider, such as reduced print strength compared to solid prints, potential surface texture variations, increased print time for complex infill structures, the need for additional support structures, and possible dimensional variations, it’s important to understand and mitigate these limitations for optimal printing results.

The continued development of slicer algorithms and advancements in 3D printing technology allow for even more refined and precise infill handling. Adaptive infill algorithms, for example, dynamically adjust infill density based on the geometry of the model, maximizing strength and material efficiency.

In conclusion, the slicer algorithm’s infill handling is a vital aspect of the 3D printing process, offering numerous benefits and possibilities. It empowers designers and engineers to create objects with optimized strength, weight, and material usage, opening up new opportunities across industries and applications. By leveraging the capabilities of the slicer algorithm and understanding its limitations, 3D printing enthusiasts can unlock the full potential of this innovative technology.

Frequently Asked Questions about How Does Slicer Algorithm Handle Infill Patterns

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does Slicer Algorithm Handle Infill Patterns”