Home>Home Maintenance>How To Put Freon In An Air Conditioner

Home Maintenance

How To Put Freon In An Air Conditioner

Modified: March 7, 2024

Learn how to put Freon in your air conditioner with this easy-to-follow home maintenance guide. Keep your AC running smoothly and efficiently.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on how to put freon in an air conditioner. If you’re a homeowner or a DIY enthusiast, understanding the process of adding freon to your air conditioner can help you effectively maintain its cooling efficiency. Freon, also known as refrigerant, plays a crucial role in the cooling process by absorbing heat and releasing it outside. Over time, your air conditioner may lose some freon due to leaks or normal wear and tear, which can result in reduced cooling performance. By learning how to add freon to your air conditioner, you can ensure that it operates at its optimum level, providing you with a comfortable indoor environment even on the hottest days.

Before we dive into the step-by-step process of adding freon to an air conditioner, it’s important to note that handling refrigerants requires caution and adherence to safety guidelines. If you don’t feel comfortable doing this yourself, it’s best to consult a professional HVAC technician who can safely diagnose any issues and recharge your air conditioner with freon, if necessary.

Now, let’s get started with the first step: understanding the importance of adding freon to an air conditioner.

Key Takeaways:

- Properly maintaining freon levels in your air conditioner is crucial for efficient cooling and energy savings. Follow safety guidelines and manufacturer instructions for a successful freon refill.

- Regular monitoring and maintenance of freon levels can prevent poor cooling performance and potential damage to your air conditioner. If in doubt, consult a professional HVAC technician for assistance.

Read more: How Often To Put Freon In Air Conditioner

Step 1: Understand the Importance of Adding Freon to an Air Conditioner

Before learning how to add freon to your air conditioner, it’s crucial to understand why this process is necessary. Freon is the refrigerant that circulates through the air conditioning system, absorbing heat from indoor air and releasing it outside. It plays a vital role in the cooling process, allowing your air conditioner to maintain a comfortable temperature.

Over time, air conditioners may experience refrigerant leaks or lose freon due to normal wear and tear. When the freon levels in your air conditioner drop, it can significantly affect its cooling performance. The system will have to work harder to reach the desired temperature, resulting in increased energy consumption and higher utility bills.

Adding freon to your air conditioner helps restore the correct refrigerant levels, ensuring its optimal performance and efficiency. It allows the system to effectively cool your home without putting excessive strain on its components.

Regularly monitoring and maintaining the freon levels in your air conditioner can help prevent issues like poor cooling, inefficient operation, and potential damage to the compressor. By understanding the importance of adding freon, you can take proactive steps to keep your air conditioner running smoothly and prolong its lifespan.

Now that you recognize the significance of maintaining adequate freon levels, let’s move on to the next step: gathering the necessary materials and equipment for the freon refill process.

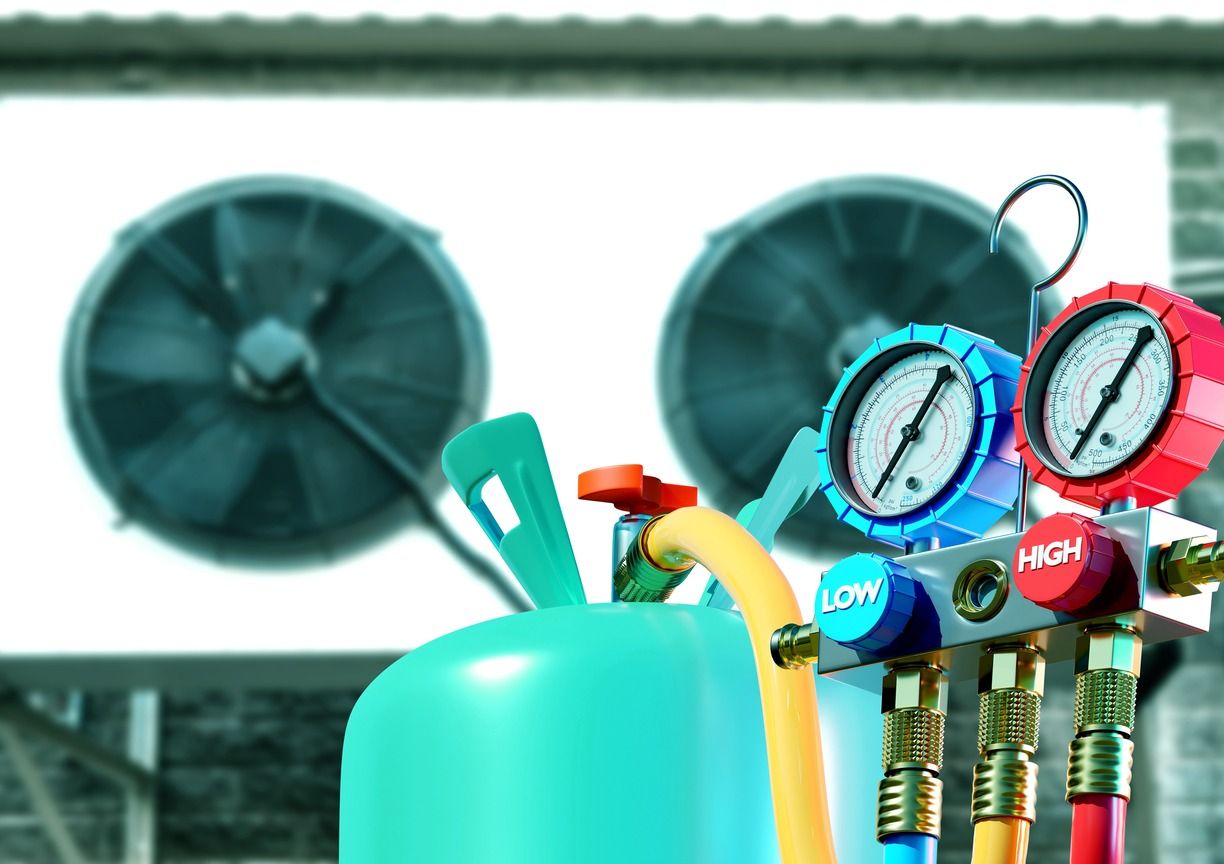

Step 2: Gather the Required Materials and Equipment

Before you start adding freon to your air conditioner, it’s important to gather the necessary materials and equipment. Having everything prepared before you begin will streamline the process and ensure a smooth freon refill. Here are the items you’ll need:

- Refrigerant: Determine the specific type of refrigerant your air conditioner requires. It’s essential to use the correct refrigerant specified by the manufacturer. Common types include R-410A and R-22. Consult your air conditioner’s manual or contact the manufacturer for the correct refrigerant information.

- Refrigerant Can: Purchase a can of refrigerant that matches the type required for your air conditioner. Make sure the can contains enough freon to properly replenish your system. Consider purchasing a can with a built-in pressure gauge for easier monitoring.

- Safety Gear: It’s crucial to protect yourself during the freon refill process. Wear safety goggles, gloves, and a face mask to prevent exposure to the refrigerant, which can be harmful if it comes into contact with your skin or eyes.

- Screwdriver or Wrenches: Depending on the design of your air conditioner, you may need a screwdriver or wrenches to access specific components or panels during the refill process. Check your air conditioner’s manual for information on the necessary tools.

- Pressure Gauge: If your refrigerant can doesn’t have a built-in pressure gauge, you’ll need a separate pressure gauge to monitor the freon levels while adding it to the air conditioner. A pressure gauge allows you to ensure that you’re adding the correct amount of freon without overfilling the system.

- Air Conditioner Manual: Keep your air conditioner’s manual handy throughout the process. It provides valuable information about the system’s components, location of the service valve, and specific instructions for adding freon.

Once you have gathered all the required materials and equipment, you’re ready to move on to the next step: preparing the air conditioner for freon refilling.

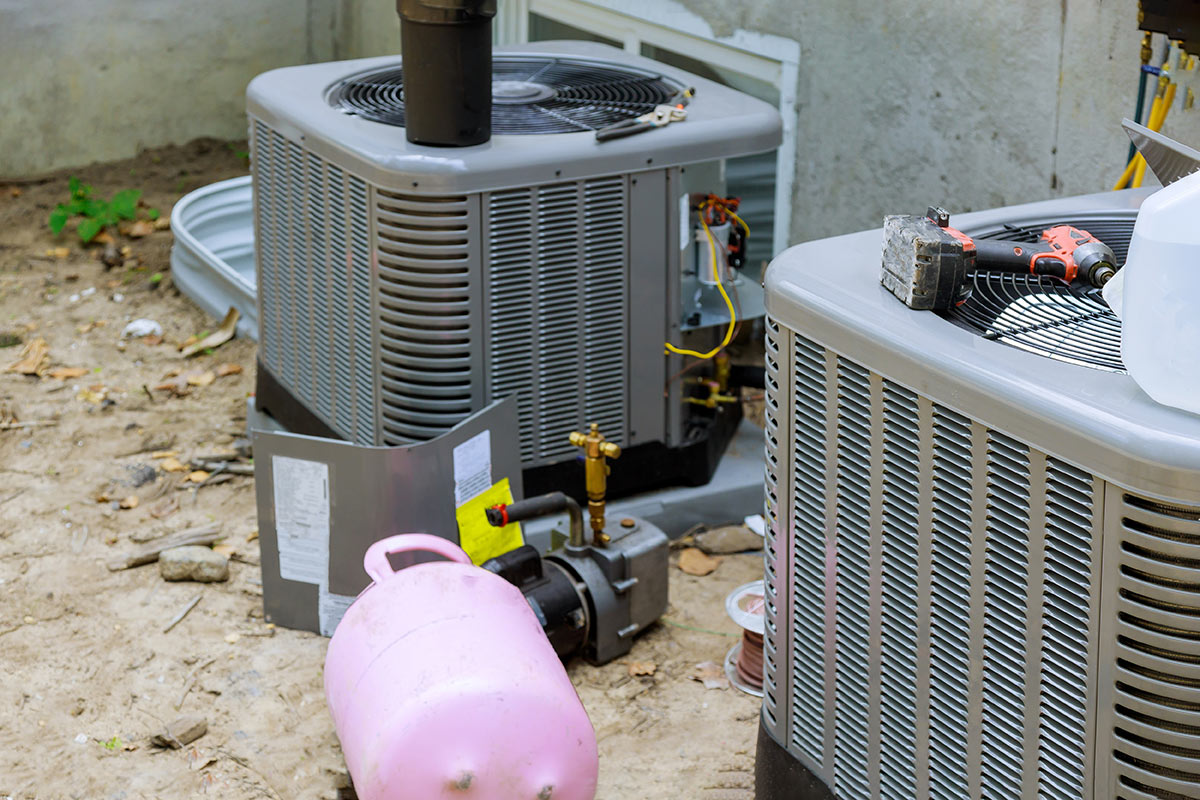

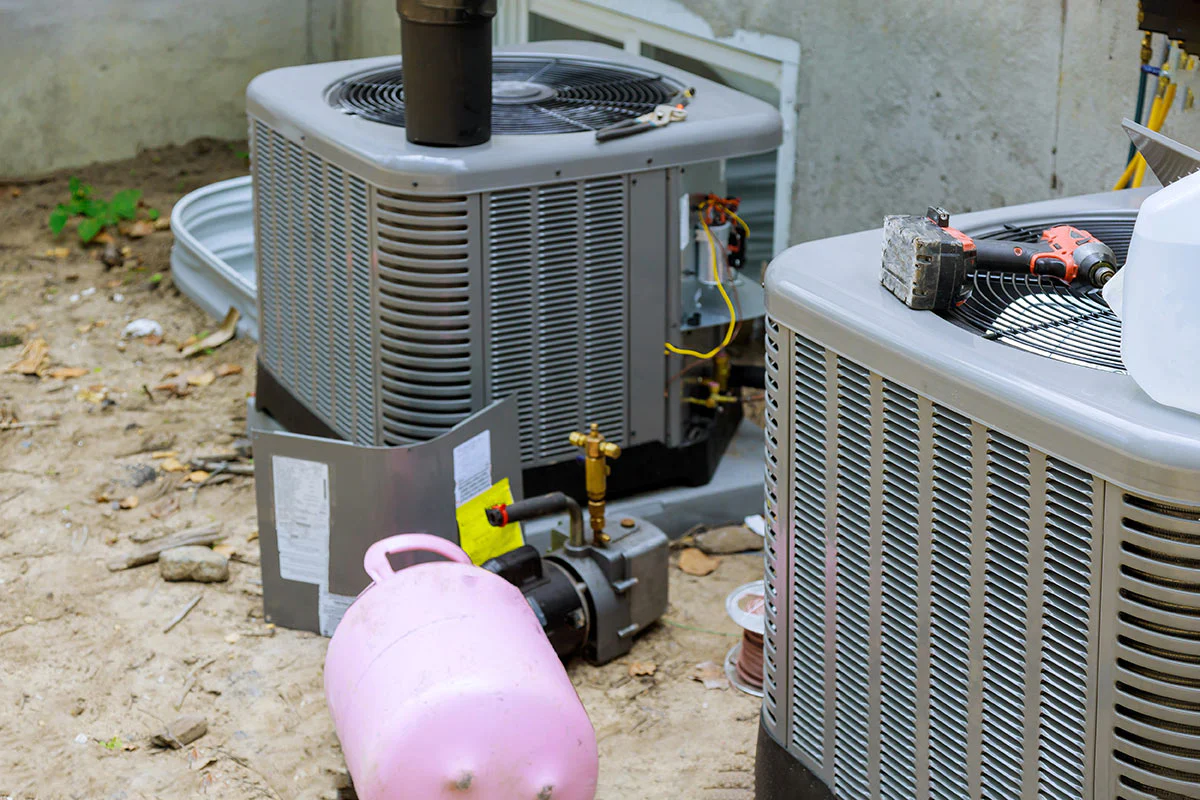

Step 3: Prepare the Air Conditioner for Freon Refilling

Before you can add freon to your air conditioner, it’s crucial to prepare the system for the refilling process. Proper preparation ensures that you can access the necessary components and perform the refill safely and efficiently. Follow these steps to prepare your air conditioner:

- Turn off the Power: Start by turning off the power to your air conditioner. Locate the circuit breaker that controls the unit and switch it off to prevent any electrical accidents during the refill process.

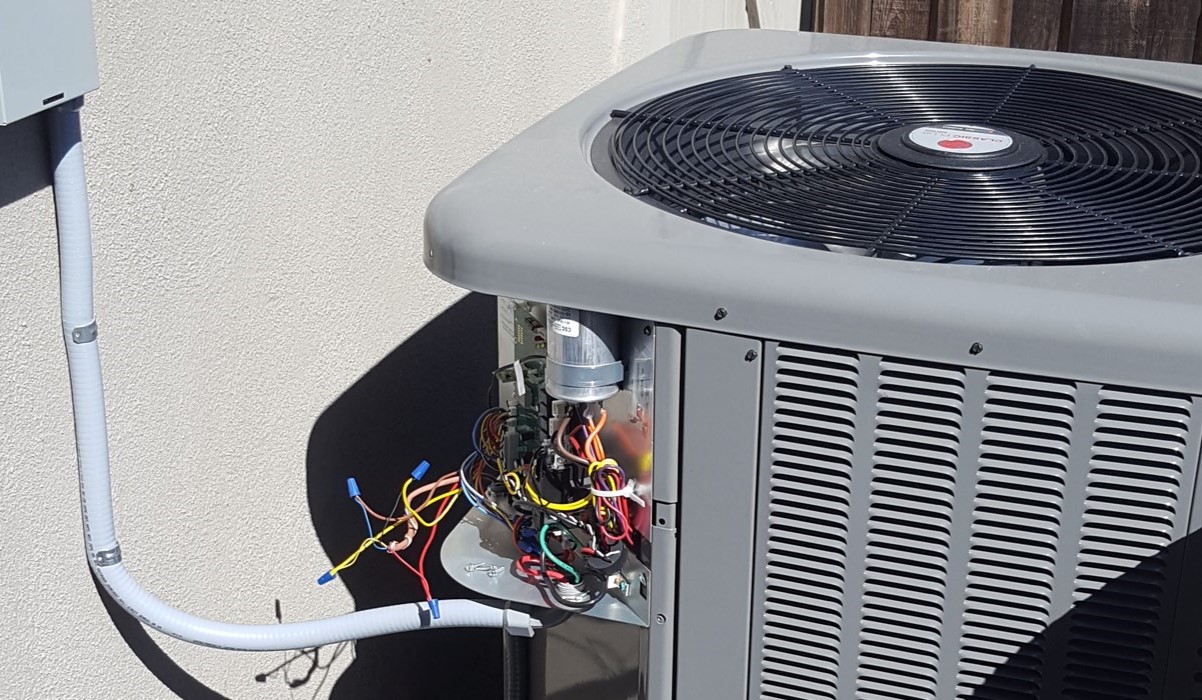

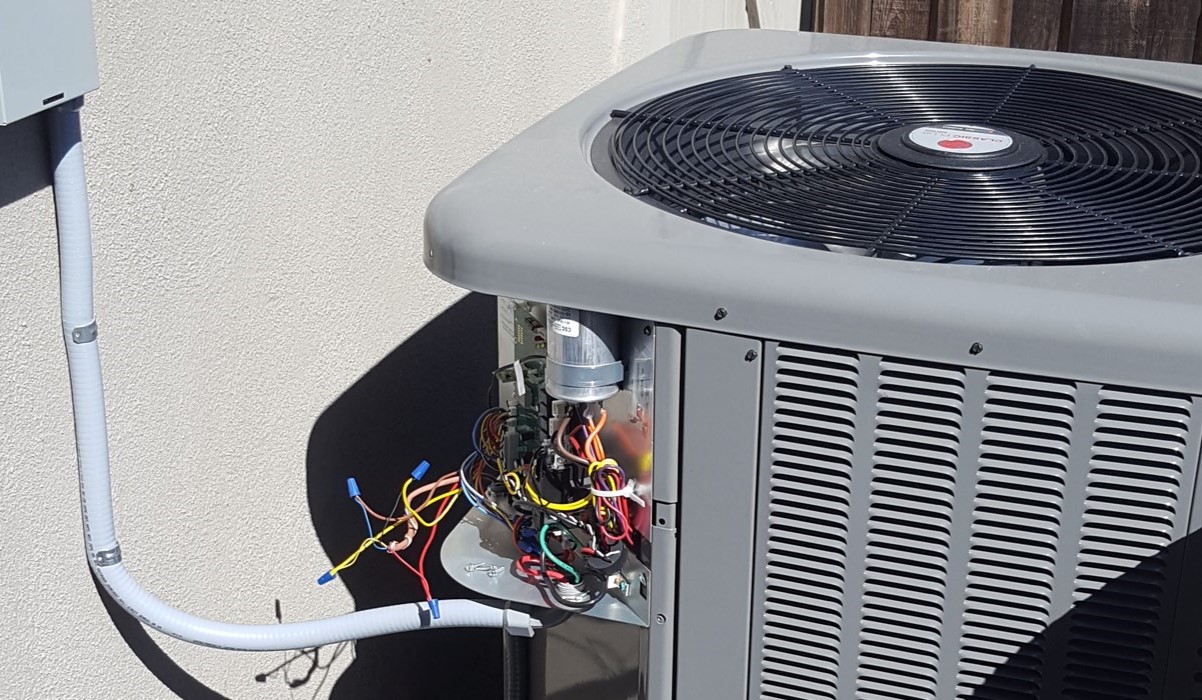

- Access the Service Panel: Depending on the design of your air conditioner, you may need to remove a service panel or access cover to reach the components where freon will be added. Consult your air conditioner’s manual to determine the location of the service panel and the specific steps required to remove it.

- Clean the Area: Once you have removed the service panel, take a moment to clean the area around the service valve. Remove any debris or obstructions that could impede the freon refill process. Ensure a clean and organized workspace before proceeding further.

- Inspect for Leaks: While preparing the air conditioner, it’s a good opportunity to inspect the system for any visible leaks. Look for signs of refrigerant oil stains or any loose connections. If you notice any leaks or damage, it’s recommended to consult a professional HVAC technician for repairs before proceeding with the freon refill.

By properly preparing your air conditioner, you create a safe and accessible environment for the freon refilling process. Once you’ve completed these steps, you’re ready to move on to the next step: locating the service valve.

Step 4: Locate the Service Valve

In order to add freon to your air conditioner, you need to locate the service valve. The service valve is the point where the refrigerant will be added to the system. The location of the service valve can vary depending on the make and model of your air conditioner. Here are some common places to find the service valve:

- Outdoor Unit: In many air conditioner units, the service valve is located on the outdoor condenser unit. Look for a valve with a cap or a fitting labeled with “Service” or “Refrigerant.” It is typically located on the larger copper refrigerant line leading from the condenser unit to the indoor evaporator coil.

- Indoor Unit: Some air conditioning systems may have the service valve located on the indoor air handler unit. Check for a valve or a fitting near the evaporator coil, which is typically in the form of a copper tube or a small manifold.

If you’re unsure about the exact location of the service valve, consult your air conditioner’s manual or reach out to the manufacturer for guidance. It’s important to locate the service valve before proceeding to the next step, as it will be the point of connection for adding freon to the air conditioner.

Once you have located the service valve, you’re ready to move on to the next step: connecting the refrigerant can to the service valve.

Read more: How To Put Freon In A Refrigerator

Step 5: Connect the Refrigerant Can to the Service Valve

Connecting the refrigerant can to the service valve is a critical step in the process of adding freon to your air conditioner. This connection allows the refrigerant to flow into the system to replenish the lost levels. Follow these steps to properly connect the refrigerant can to the service valve:

- Remove the Cap: Start by removing the cap from the service valve of your air conditioner. The cap is typically screwed on and may require a wrench or screwdriver to loosen and remove. Set the cap aside in a safe place, as you will need it later.

- Check the Refrigerant Can: Before connecting the refrigerant can to the service valve, inspect the can for any damage or leaks. Ensure that the can is upright and fully intact. Shake the can gently to mix the refrigerant properly, as some cans may require agitation.

- Attach the Hose: With the refrigerant can in an upright position, attach the hose from the can to the service valve. Most refrigerant cans come with a hose and a fitting that screws onto the service valve. Make sure the connection is secure, but avoid overtightening.

- Tighten the Fitting: Once the hose is connected, use a wrench or your hands to tighten the fitting. It should be snug but not overly tight. This will prevent any leaks during the freon refill process.

It’s important to ensure a proper connection between the refrigerant can and the service valve to prevent any leaks or accidental disconnections. Take your time to check that everything is securely attached before continuing to the next step.

Now that you have connected the refrigerant can to the service valve, you’re ready to move on to Step 6: adding freon to the air conditioner.

Make sure to turn off the air conditioner before adding freon. Locate the service valve on the unit, connect the freon canister, and slowly release the freon into the system. Check the pressure to ensure it’s at the correct level.

Step 6: Add Freon to the Air Conditioner

Adding freon to your air conditioner involves injecting the refrigerant into the system to replenish the lost levels. It’s important to follow the proper procedure and guidelines to ensure a safe and efficient freon refill. Here’s how to add freon to your air conditioner:

- Open the Valve: Start by opening the valve on the refrigerant can. This will allow the freon to flow into the air conditioner. Refer to the instructions on the can for specific guidance on opening the valve. Some cans may require you to turn the valve counterclockwise to open it.

- Monitor the Pressure: As the freon flows into the air conditioner, it’s important to monitor the pressure gauge. Keep an eye on the pressure readings to ensure that you maintain the proper freon levels. Refer to your air conditioner’s manual or contact the manufacturer to determine the appropriate pressure range for your specific system.

- Add Freon Slowly: Slowly add the freon to the air conditioner. Avoid adding it too quickly, as this can cause issues such as overpressurization. Follow the manufacturer’s instructions on the refrigerant can to determine the appropriate rate at which to add the freon.

- Be Mindful of Temperature: Keep in mind that the temperature of the refrigerant can decrease as you add it to the air conditioner. If the can becomes extremely cold, consider using a towel or a glove to handle it to avoid any discomfort or damage to your hands.

- Monitor the Can: While adding freon, keep an eye on the refrigerant can. As the freon is released, the can will become lighter. This can help you estimate the amount of freon you have added, but it’s still crucial to rely on pressure gauge readings for accuracy.

Take your time to add the freon slowly and carefully. Keep a close eye on the pressure gauge throughout the process to ensure that you don’t overfill the system. Adding freon is a delicate process, and it’s crucial to follow the instructions and guidelines specific to your air conditioner model.

Once you have added the appropriate amount of freon to your air conditioner, it’s time to move on to the next step: monitoring the pressure gauge.

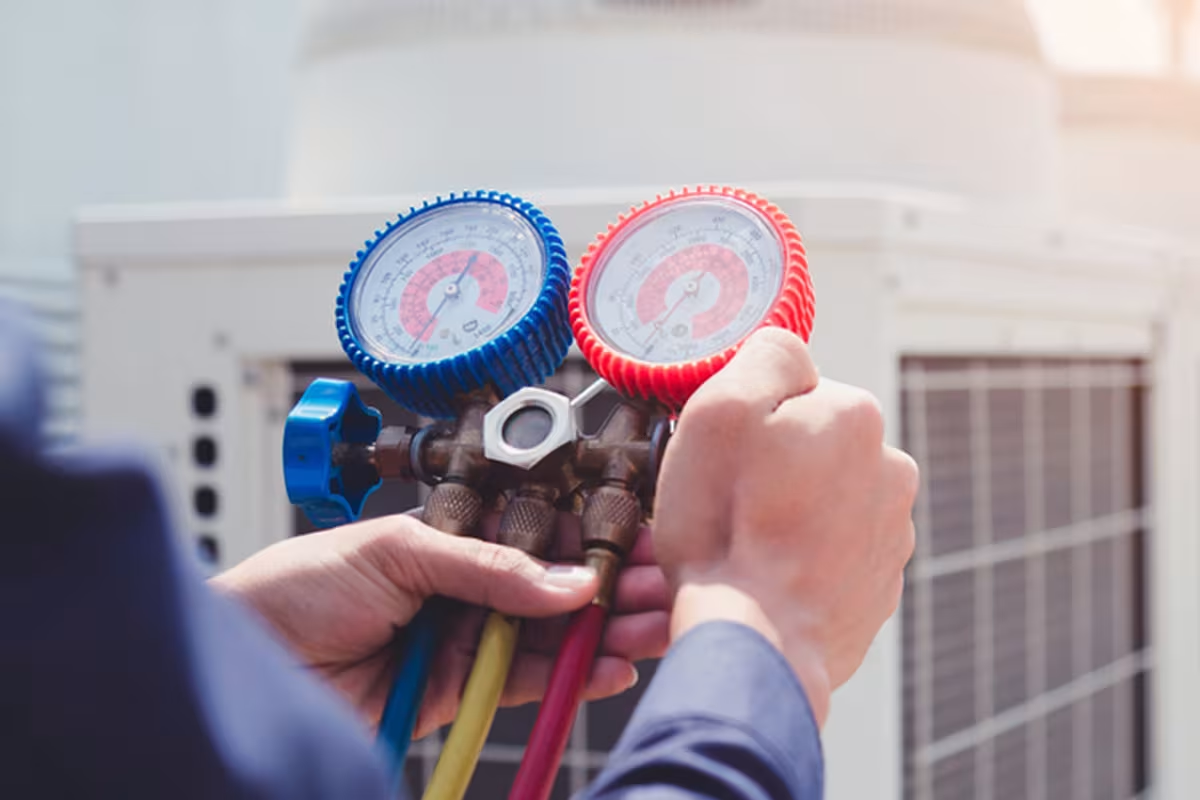

Step 7: Monitor the Pressure Gauge

Monitoring the pressure gauge is a crucial step when adding freon to your air conditioner. The pressure gauge provides valuable information about the freon levels in the system, allowing you to ensure that you’re adding the correct amount of refrigerant. Here’s how to monitor the pressure gauge:

- Observe the Initial Reading: Take note of the initial pressure reading on the gauge before adding freon. This will serve as a reference point for monitoring the changes throughout the process.

- Watch for Fluctuations: As you add the freon to the air conditioner, keep a close eye on the pressure gauge. It should start to rise as the refrigerant enters the system. Monitor for any fluctuations in the pressure reading and ensure that it stays within the recommended range specified in your air conditioner’s manual.

- Adjust the Amount of Freon Added: If the pressure reading is too low, you may need to add more freon to reach the desired level. Conversely, if the pressure reading is too high, you may need to slow down or stop adding freon to prevent overpressurization. Always refer to the manufacturer’s guidelines to determine the appropriate pressure range for your specific air conditioner model.

- Patience is Key: It’s important to be patient while monitoring the pressure gauge. Adding freon too quickly or in excessive amounts can cause damage to the air conditioner and lead to complications. Take your time and ensure that the pressure remains stable and within the recommended range throughout the process.

By closely monitoring the pressure gauge, you can ensure that you’re adding the correct amount of freon to your air conditioner. Remember to make adjustments as necessary and refer to the manufacturer’s guidelines to maintain proper pressure levels.

Now that you’ve monitored the pressure gauge, it’s time for Step 8: disconnecting the refrigerant can from the service valve.

Step 8: Disconnect the Refrigerant Can

After successfully adding freon to your air conditioner and monitoring the pressure gauge, it’s time to disconnect the refrigerant can from the service valve. This step ensures the safe removal of the freon canister from the system. Follow these steps to disconnect the refrigerant can:

- Close the Valve: Start by closing the valve on the refrigerant can. Refer to the instructions provided by the manufacturer to properly close the valve. Typically, you will need to turn the valve clockwise until it is fully closed.

- Release Pressure: In order to disconnect the refrigerant can safely, it’s important to release the pressure trapped in the system. You can do this by pressing down on the valve’s release button or by gently turning the can upside down and slowly loosening the connection to the service valve.

- Remove the Hose: Once the pressure is safely released, use a wrench or your hands to loosen and remove the hose from the service valve. Be cautious of any remaining pressure or refrigerant that may be expelled.

- Secure the Service Valve: After removing the hose, securely close the service valve on your air conditioner. This helps prevent any accidental leaks or damage to the system.

- Dispose of the Can Properly: Dispose of the empty refrigerant can responsibly according to your local regulations. Empty refrigerant cans should not be thrown into regular household waste. Some local authorities provide specific guidelines for their proper disposal.

Properly disconnecting the refrigerant can ensures the safe removal of the freon and prevents any potential accidents or leaks. Once you have completed this step, you can move on to the next step: verifying the proper freon levels in your air conditioner.

Read more: How To Put Freon In AC Unit

Step 9: Verify the Proper Freon Levels

After adding freon to your air conditioner and disconnecting the refrigerant can, it’s important to verify the proper freon levels in the system. This step ensures that you have added the correct amount of refrigerant, allowing your air conditioner to function efficiently. Follow these guidelines to verify the proper freon levels:

- Refer to the Manual: Consult your air conditioner’s manual or contact the manufacturer to determine the ideal freon levels for your specific model. Different systems have varying requirements, so it’s important to adhere to the manufacturer’s recommendations.

- Use a Refrigerant Scale: A refrigerant scale is a useful tool for accurately measuring the weight of the freon in the air conditioner. Place the refrigerant scale beneath the outdoor unit or at a location specified by the manufacturer. Record the weight displayed on the scale.

- Compare with Recommended Levels: Compare the weight recorded on the scale with the recommended freon levels provided in your air conditioner’s manual. Ensure the weight falls within the specified range to confirm that the proper amount of freon has been added.

- Adjust if Needed: If the freon levels are below the recommended range, you may need to add more freon. Refer to the manufacturer’s instructions and repeat the freon refill process. If the freon levels are too high, it’s crucial to consult a professional HVAC technician to resolve the issue.

- Take Note of Pressure: While verifying the freon levels, also monitor the pressure gauge. The pressure reading should be within the appropriate range specified by the manufacturer. Incorrect pressure levels may indicate an issue with the freon levels or another problem within the air conditioner.

By verifying the proper freon levels, you ensure that your air conditioner is operating at its optimal capacity. If you find that the freon levels are not within the recommended range, it’s best to consult a professional HVAC technician for further assistance and evaluation.

Now that you have confirmed the proper freon levels, it’s time to move on to the final step: reassembling and testing the air conditioner.

Step 10: Reassemble and Test the Air Conditioner

Once you have verified the proper freon levels in your air conditioner, it’s time to reassemble the unit and test its functionality. Follow these steps to reassemble and test your air conditioner:

- Replace the Service Panel: If you removed any service panels or access covers during the freon refill process, ensure they are securely reattached to the air conditioner. Use a screwdriver or wrench, if needed, to tighten the screws or bolts.

- Turn on the Power: Reconnect the power supply to your air conditioner by switching on the circuit breaker that controls the unit. This will restore the electrical power needed for the air conditioner to function.

- Set the Thermostat: Adjust the thermostat setting to your preferred temperature and turn on the air conditioner. Allow the unit to run for a few minutes to ensure that it is cooling properly.

- Observe the Cooling: Monitor the airflow and temperature to ensure that the air conditioner is effectively cooling the room. Feel the air coming from the vents and verify that it is cool and refreshing. If there are any issues or concerns, it is advisable to contact a professional HVAC technician for further inspection and troubleshooting.

- Check for Leaks: After the air conditioner has been running for a while, inspect the areas around the service valve and other connections for any signs of refrigerant leaks. Look for oil stains or bubbling refrigerant, which may indicate a leak. If you notice any leaks, contact a professional immediately to address the issue.

By reassembling and testing your air conditioner, you ensure that it is functioning properly and that the freon refill process was successful. If you have any concerns or notice any irregularities during the testing phase, it’s best to consult a professional HVAC technician for further assistance and resolution.

Congratulations! You have successfully completed the process of putting freon in your air conditioner. Regular maintenance and monitoring of the freon levels will help keep your air conditioner operating efficiently and effectively.

If you require further assistance or have more questions, don’t hesitate to reach out to a professional for guidance and support.

Thank you for following our guide, and we hope you enjoy the cool comfort provided by your properly functioning air conditioner!

Conclusion

Congratulations on successfully learning how to put freon in an air conditioner! By understanding the importance of adding freon, gathering the required materials, preparing the air conditioner, locating the service valve, connecting the refrigerant can, adding freon, monitoring the pressure gauge, disconnecting the refrigerant can, verifying the proper freon levels, and reassembling and testing the air conditioner, you have become equipped to maintain and optimize the cooling performance of your air conditioner.

Remember, handling refrigerants requires caution and adherence to safety guidelines. If you ever feel uncertain or uncomfortable with the freon refill process, it’s always best to consult a professional HVAC technician who can safely diagnose any issues and recharge your air conditioner with freon.

Regularly monitoring and maintaining the freon levels in your air conditioner is essential for its efficiency, cooling performance, and longevity. By following the steps in this guide, you can ensure that your air conditioner operates at its optimum level, providing you with a comfortable indoor environment even during the hottest days.

We hope that this comprehensive guide has empowered you with the knowledge and confidence to take care of your air conditioner’s freon needs. Stay cool and enjoy the refreshing comfort of your properly maintained air conditioner!

Frequently Asked Questions about How To Put Freon In An Air Conditioner

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.