Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Epoxy Tumblers

Tools & Equipment

What Grit Sandpaper For Epoxy Tumblers

Modified: January 4, 2024

Discover the best grit sandpaper for epoxy tumblers with our comprehensive guide. Find the right tools and equipment for your next project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Creating epoxy tumblers can be a delightful and rewarding craft, but achieving a smooth, flawless finish requires careful attention to detail and the use of the right tools. Sanding plays a crucial role in the process of perfecting epoxy tumblers, and choosing the correct grit sandpaper is essential for achieving the desired results. In this article, we will delve into the world of grit sandpaper for epoxy tumblers, exploring the different grit levels and techniques necessary to achieve a professional and polished final product.

Sanding epoxy tumblers is a critical step in the crafting process, as it helps to eliminate imperfections, smooth out rough surfaces, and prepare the tumbler for a flawless coating. Understanding the intricacies of grit sandpaper and its application is vital for any individual looking to create stunning epoxy tumblers. Let's embark on a journey through the world of grit sandpaper, uncovering the nuances of its application and the impact it has on the quality of epoxy tumbler craftsmanship.

Key Takeaways:

- Choose the right sandpaper grit for each stage: coarse grit (40-60) for initial sanding, medium grit (80-120) for refinement, and fine grit (150-180) for final finishing of epoxy tumblers.

- Employ effective sanding techniques like consistent pressure, circular motion, and progressive grit levels to transform rough surfaces into polished epoxy tumblers.

Read more: What Grit Sandpaper For Polyurethane

Understanding Grit Sandpaper

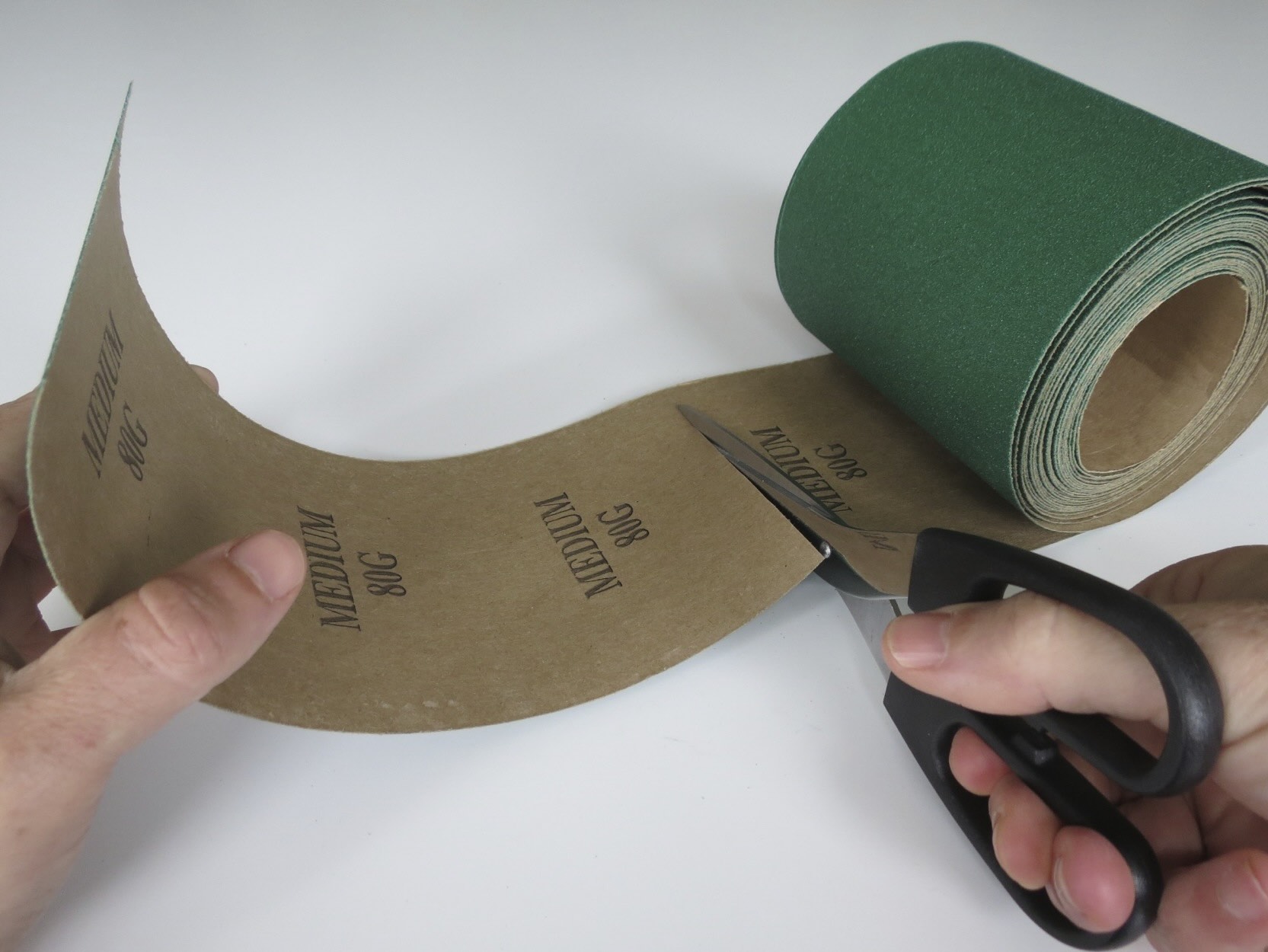

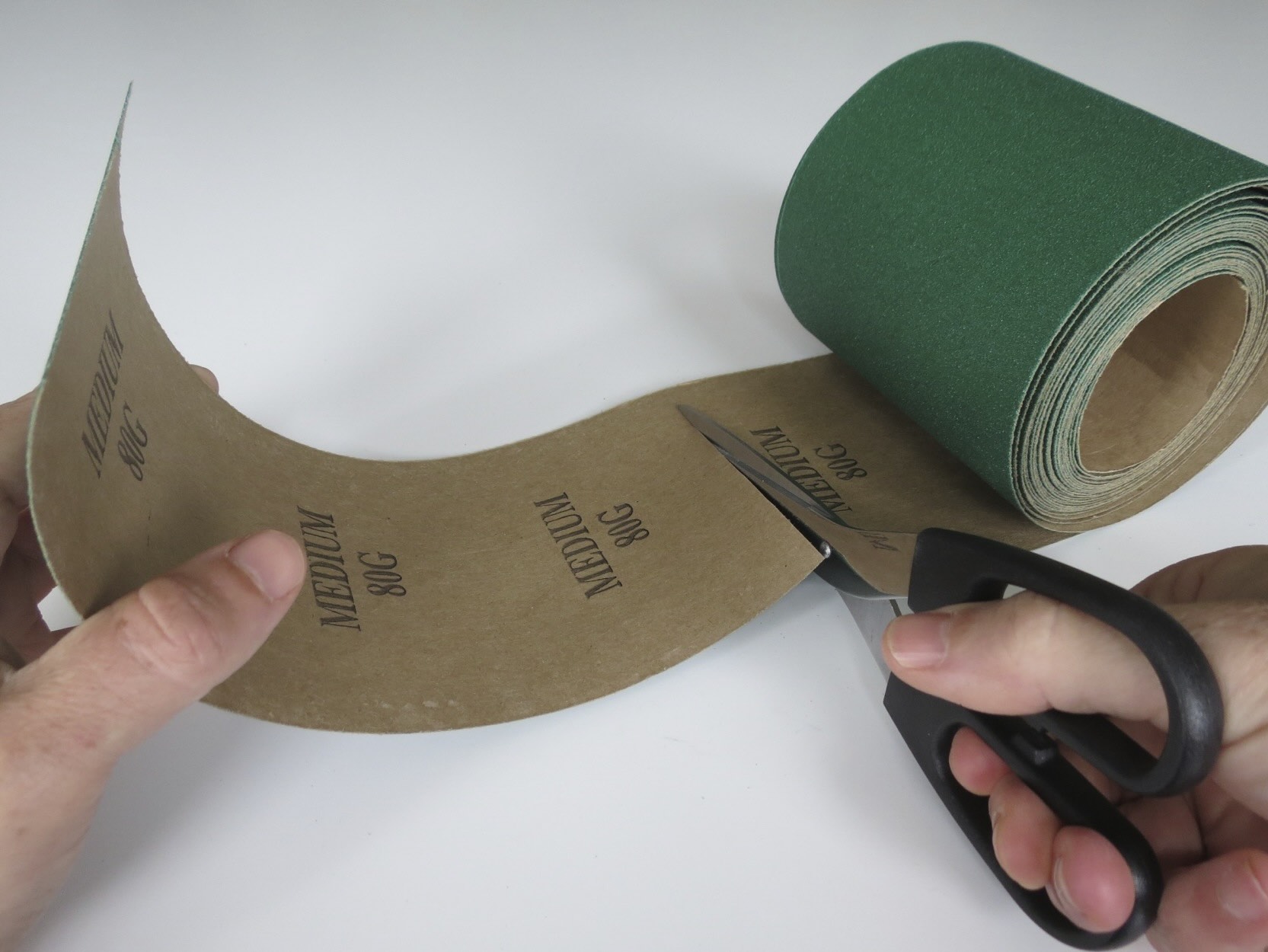

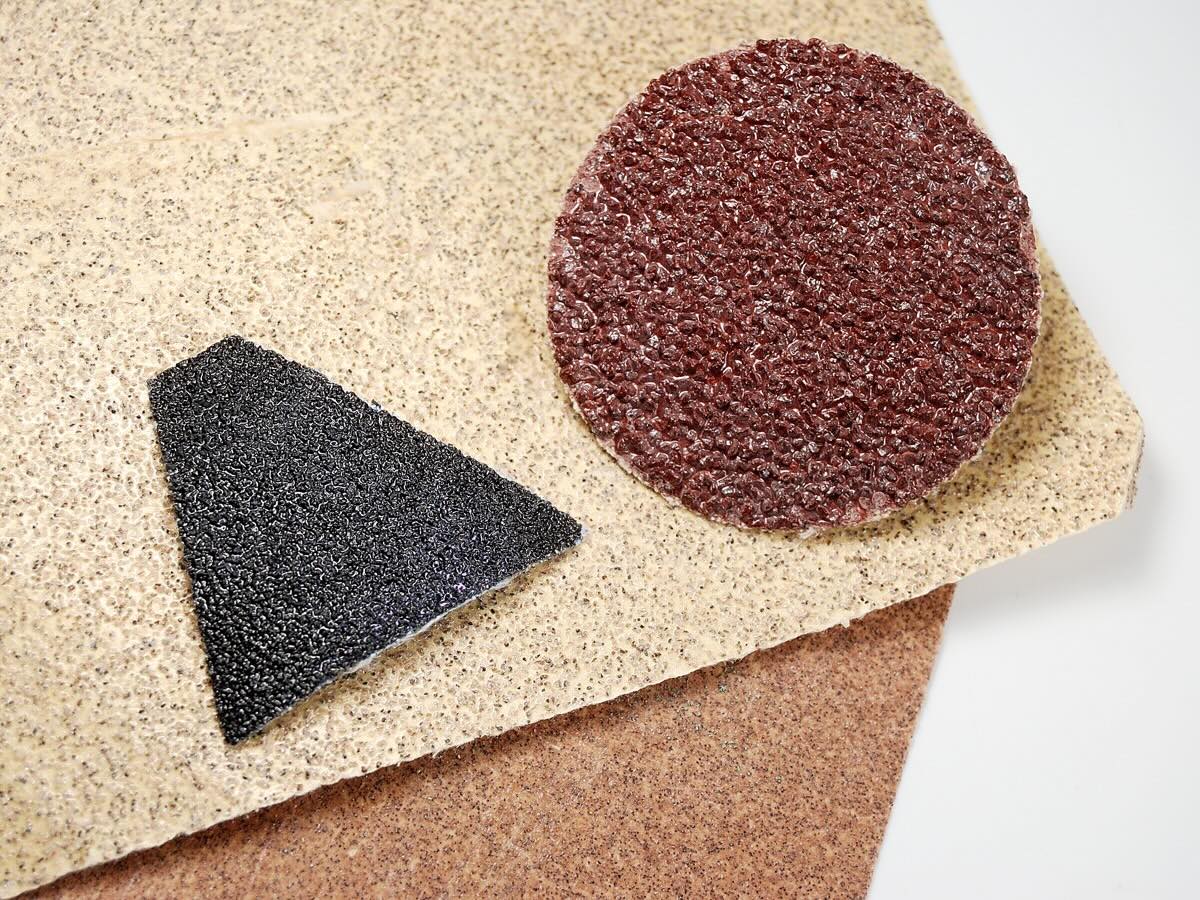

Grit sandpaper is a versatile and indispensable tool in the world of crafting and woodworking. It is categorized based on the size of the abrasive particles it contains, which determines its coarseness and the type of surface it is best suited for. The grit number, typically imprinted on the back of the sandpaper, indicates the coarseness of the abrasive particles. Lower grit numbers signify coarser sandpaper, while higher numbers denote finer grit.

Common grit ranges include:

- Coarse Grit (40-60): Ideal for heavy material removal, shaping, and smoothing rough surfaces.

- Medium Grit (80-120): Suitable for general sanding, refining surfaces, and preparing them for a finer finish.

- Fine Grit (150-180): Used for smoothing and preparing surfaces for finishing coats.

- Very Fine Grit (220-240): Perfect for finishing and polishing surfaces to a high sheen.

Understanding the characteristics of each grit level is crucial for selecting the appropriate sandpaper for specific tasks. Coarser grits are effective for initial sanding to remove imperfections and level surfaces, while finer grits are employed for achieving a smooth, blemish-free finish. When it comes to epoxy tumblers, the choice of grit sandpaper is determined by the desired level of smoothness and the stage of the finishing process.

Additionally, the backing of sandpaper also plays a significant role in its performance. Common backings include paper, cloth, and fiber, each offering unique advantages in terms of flexibility, durability, and resistance to tearing. Understanding the properties of different backings is essential for selecting sandpaper that can withstand the demands of sanding epoxy tumblers without compromising quality.

By comprehending the nuances of grit sandpaper and its various applications, crafters and artisans can make informed decisions when selecting the most suitable sandpaper for their specific projects. The next section will delve into the intricacies of choosing the right grit sandpaper for epoxy tumblers, shedding light on the optimal grit levels for achieving impeccable results.

Choosing the Right Grit Sandpaper for Epoxy Tumblers

When it comes to perfecting epoxy tumblers, selecting the right grit sandpaper is paramount for achieving a flawless finish. The choice of grit depends on the stage of the finishing process and the specific imperfections that need to be addressed. Let’s explore the optimal grit levels for sanding epoxy tumblers to ensure a professional and polished outcome.

Initial Sanding: For the initial sanding of epoxy tumblers to remove any rough spots, imperfections, or excess epoxy, coarse grit sandpaper in the range of 40-60 is recommended. This grit level is effective for shaping the tumbler and leveling any uneven surfaces, providing a smooth foundation for subsequent sanding.

Refinement and Smoothing: Once the initial imperfections have been addressed, transitioning to medium grit sandpaper within the range of 80-120 is ideal for refining the surface of the tumbler. This grit level helps to smooth out any remaining rough areas and prepares the tumbler for the next stage of the finishing process.

Final Finishing: To achieve a lustrous and polished surface on the epoxy tumbler, fine grit sandpaper ranging from 150-180 is employed for the final sanding. This finer grit level is essential for smoothing the surface to perfection, eliminating any visible scratches or blemishes, and preparing the tumbler for the application of a clear coat or polish.

It is important to note that the selection of grit sandpaper is not limited to these specific ranges, and crafters may find it beneficial to use additional grit levels to achieve the desired finish. Experimenting with different grits and observing their effects on the tumbler’s surface can provide valuable insights into the optimal sanding process for individual preferences and project requirements.

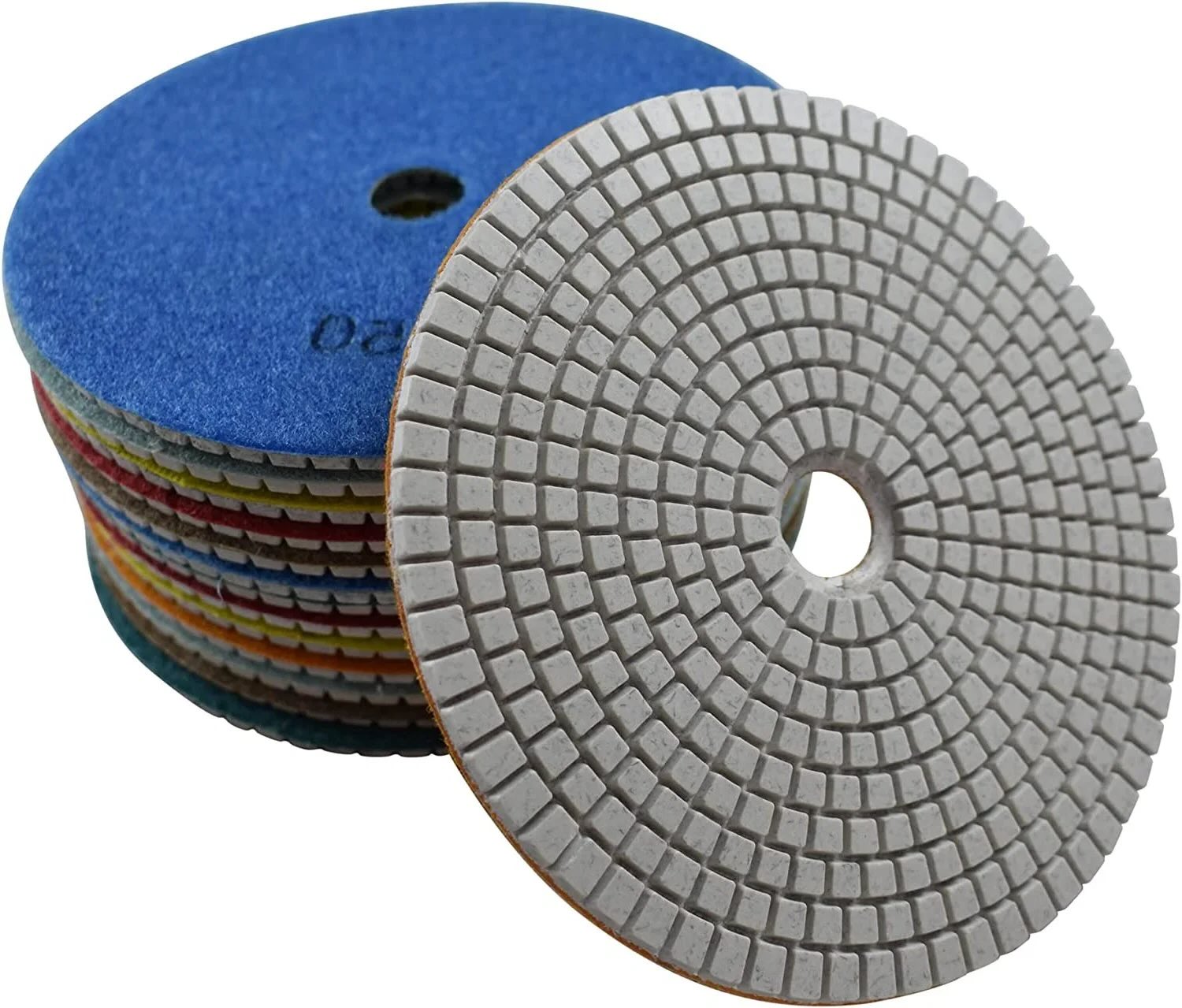

Furthermore, the use of very fine grit sandpaper in the range of 220-240 can be considered for achieving an exceptionally smooth and glossy finish on epoxy tumblers, especially for those intended for display or gifting purposes. This ultra-fine grit level is perfect for refining the surface to a high sheen, ensuring a professional and immaculate presentation.

By understanding the nuances of grit sandpaper and its impact on the finishing process, crafters can make informed decisions when selecting the appropriate sandpaper for sanding epoxy tumblers. The next section will explore effective sanding techniques tailored specifically for epoxy tumblers, providing valuable insights into achieving exceptional results through meticulous and skilled sanding practices.

For epoxy tumblers, start with 80-100 grit sandpaper to remove imperfections and rough edges. Then, move to 220-400 grit for a smooth finish before polishing.

Sanding Techniques for Epoxy Tumblers

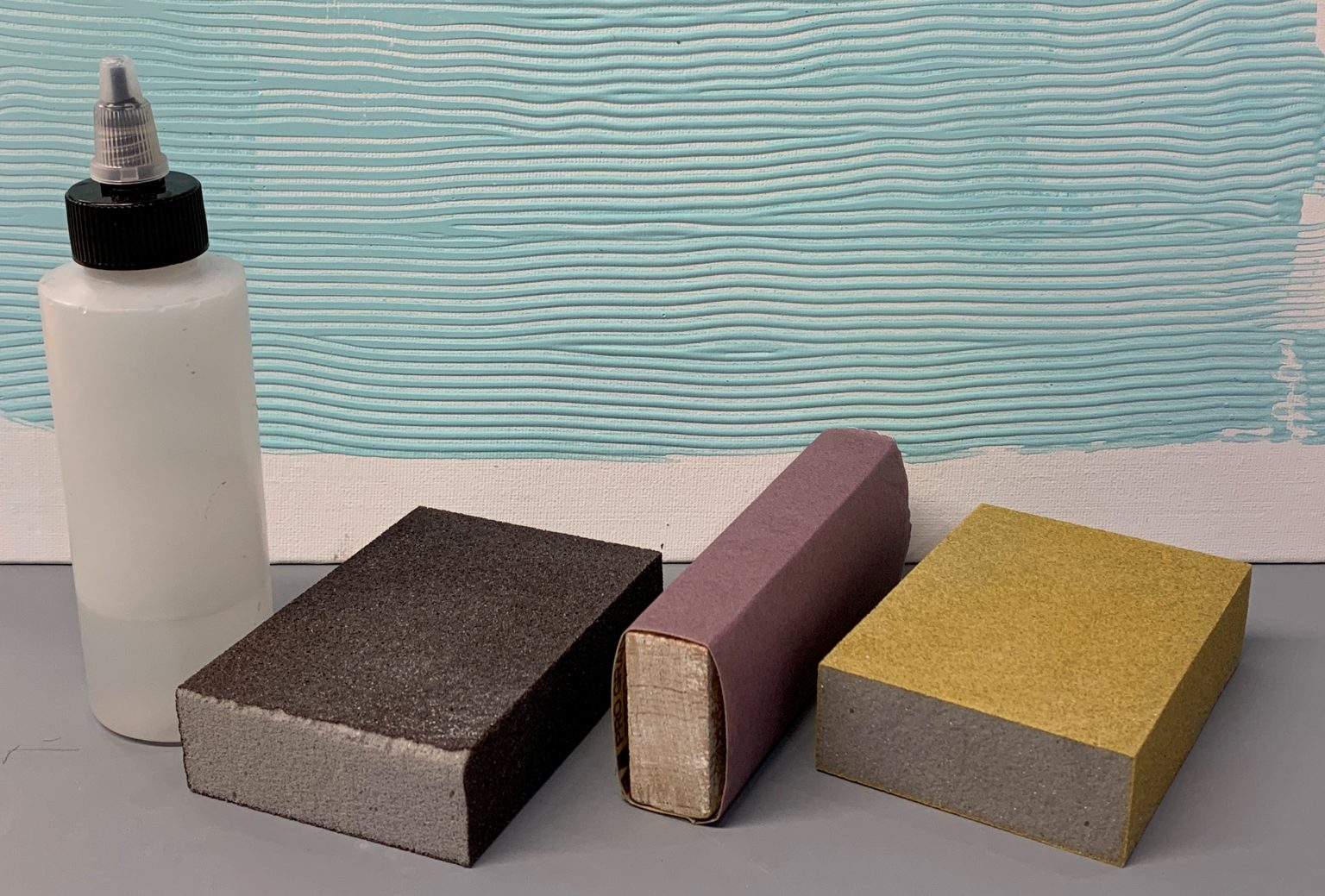

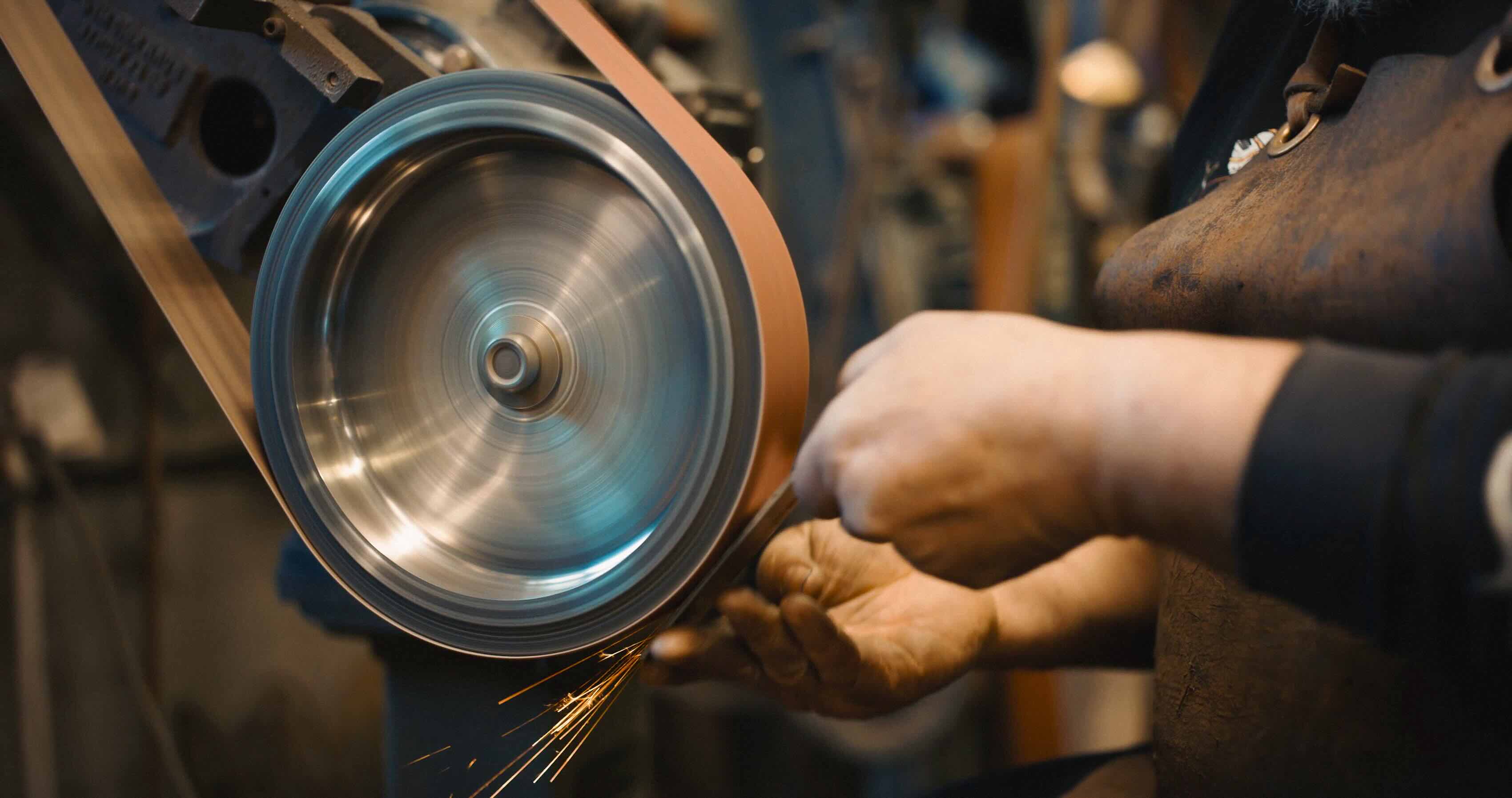

Effective sanding techniques are essential for achieving a flawless and professional finish on epoxy tumblers. By employing the right methods and tools, crafters can transform rough and uneven surfaces into smooth, lustrous masterpieces. Let’s explore the key sanding techniques tailored specifically for epoxy tumblers, ensuring meticulous attention to detail and exceptional results.

Consistent Pressure: When sanding epoxy tumblers, maintaining consistent pressure on the sandpaper is crucial for achieving an even and uniform finish. Applying excessive force may result in uneven sanding, while insufficient pressure could prolong the sanding process. By exerting consistent and controlled pressure, crafters can effectively smooth out imperfections and refine the tumbler’s surface.

Circular Motion: Employing circular motions while sanding helps to distribute the sanding pressure evenly across the surface of the tumbler, preventing the formation of uneven patches or visible sanding marks. This technique ensures a uniform and seamless finish, contributing to the overall aesthetic appeal of the epoxy tumbler.

Progressive Grit Levels: Gradually transitioning from coarser to finer grit sandpaper allows for the systematic refinement of the tumbler’s surface. Starting with a lower grit level and progressing to higher grits enables crafters to address initial imperfections before achieving a smooth and polished finish. This progressive approach ensures that each sanding stage contributes to the overall refinement of the tumbler.

Intermittent Inspections: Periodically inspecting the tumbler during the sanding process is essential for identifying areas that require additional attention. This practice allows crafters to address specific imperfections and ensures that the sanding process is thorough and comprehensive. Intermittent inspections contribute to the precision and quality of the final finish.

Water-Based Sanding: Utilizing water-based sanding techniques can enhance the effectiveness of sanding epoxy tumblers, especially when using finer grit sandpaper. The application of water helps to lubricate the sandpaper, reducing friction and preventing clogging, while also providing a clearer view of the sanded surface. This technique contributes to achieving a smooth and flawless finish.

By incorporating these specialized sanding techniques into the process of refining epoxy tumblers, crafters can elevate the quality of their craftsmanship and produce stunning, professional-grade results. The meticulous application of these techniques ensures that each tumbler is transformed into a work of art, characterized by its impeccable finish and visual allure.

As we conclude our exploration of sanding techniques for epoxy tumblers, it is evident that the careful and skilled application of these methods is instrumental in achieving exceptional results. The next section will summarize the key insights presented in this article, emphasizing the significance of grit sandpaper and expert sanding techniques in the creation of flawless epoxy tumblers.

Conclusion

In the realm of crafting epoxy tumblers, the meticulous application of grit sandpaper and expert sanding techniques is paramount for achieving flawless and professional results. The journey through the world of grit sandpaper has unveiled the significance of selecting the right grit levels for each stage of the finishing process, ensuring that imperfections are addressed and surfaces are refined to perfection.

Understanding the nuances of grit sandpaper, ranging from coarse to very fine grits, empowers crafters to make informed decisions when refining epoxy tumblers. The careful selection of grit levels tailored to specific imperfections and finishing stages is instrumental in achieving a smooth, blemish-free surface that serves as the canvas for a stunning final finish.

Moreover, the exploration of specialized sanding techniques tailored for epoxy tumblers has shed light on the importance of consistent pressure, circular motions, progressive grit levels, intermittent inspections, and water-based sanding. These techniques, when applied with precision and skill, contribute to the transformation of rough and uneven surfaces into polished and visually captivating masterpieces.

As crafters embark on their journey to create exquisite epoxy tumblers, they are equipped with the knowledge and expertise to navigate the intricacies of grit sandpaper and harness the power of effective sanding techniques. The fusion of artistry and precision in the sanding process culminates in the production of flawless epoxy tumblers that exude professionalism and allure.

In essence, the art of sanding epoxy tumblers is a harmonious blend of technical proficiency and creative vision, where each stroke of sandpaper contributes to the realization of a captivating and immaculate finish. Through the application of specialized sanding techniques and the strategic utilization of grit sandpaper, crafters can elevate their craftsmanship to new heights, producing epoxy tumblers that stand as testaments to their dedication and skill.

As we conclude our exploration of grit sandpaper and sanding techniques for epoxy tumblers, it is evident that the fusion of knowledge, expertise, and artistry is the cornerstone of achieving exceptional results in the crafting world. With a deep understanding of grit sandpaper and a mastery of sanding techniques, crafters can embark on a journey of creativity and precision, transforming rough surfaces into polished works of art.

Frequently Asked Questions about What Grit Sandpaper For Epoxy Tumblers

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Epoxy Tumblers”