Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper To Resurface Heads

Tools & Equipment

What Grit Sandpaper To Resurface Heads

Modified: May 6, 2024

Find the right grit sandpaper for resurfacing heads with our comprehensive guide. Get the best tools and equipment for the job.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

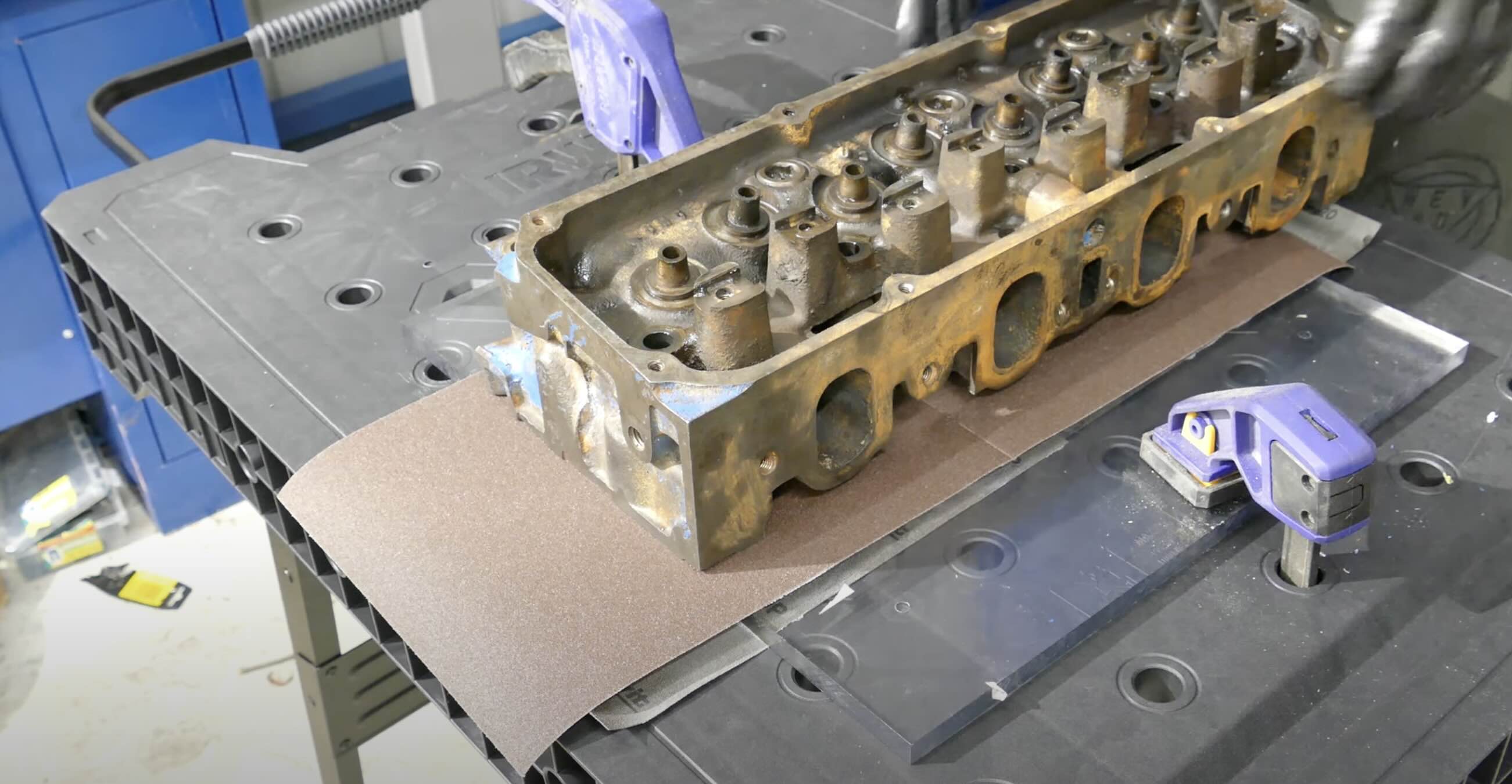

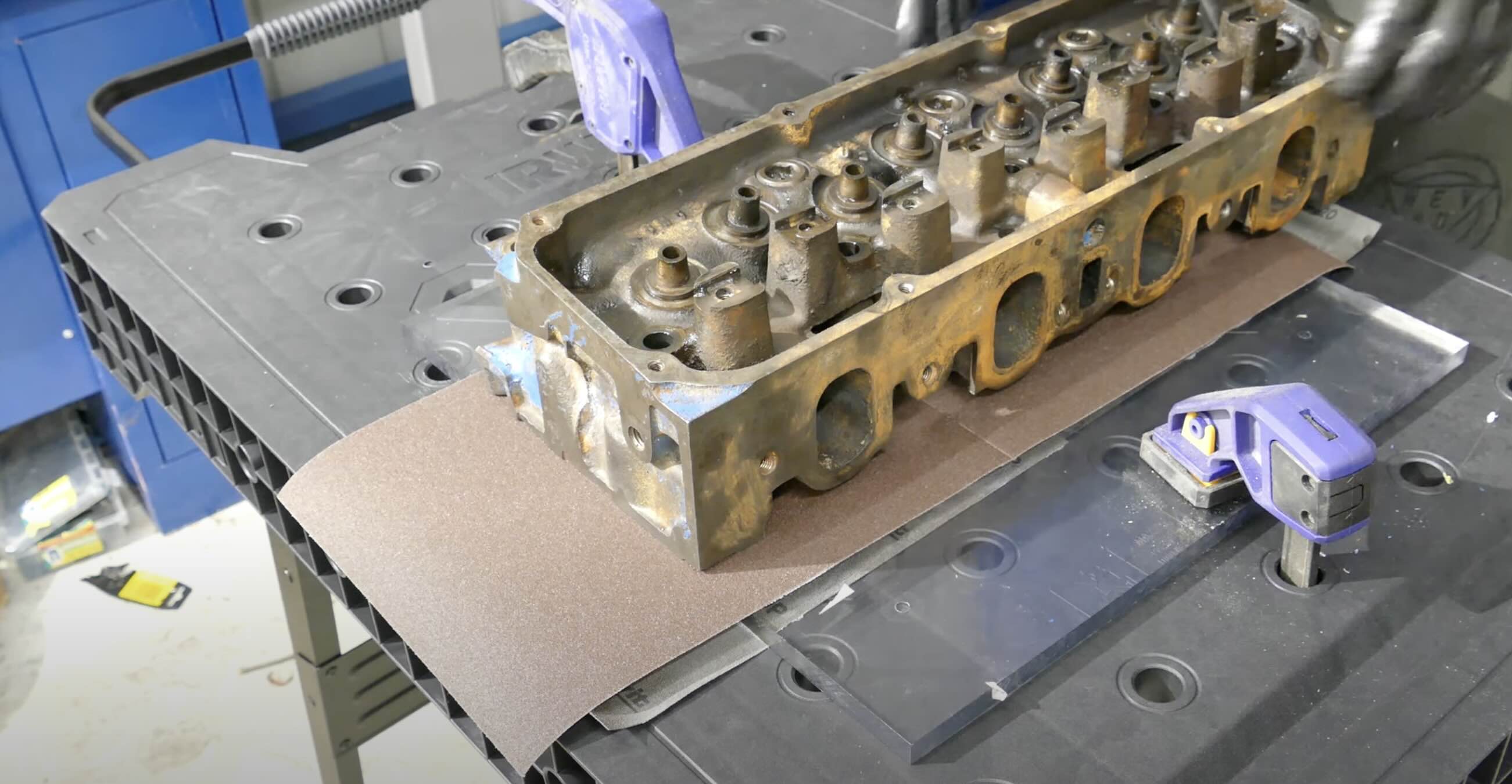

Resurfacing cylinder heads is a critical process in engine maintenance and performance enhancement. It involves smoothing the surface of the cylinder head to ensure a proper seal with the engine block. One of the essential tools for this task is sandpaper, which comes in various grit levels. Choosing the right grit sandpaper is crucial to achieving the desired surface finish and ensuring optimal engine functionality. In this article, we will delve into the intricacies of selecting the appropriate grit sandpaper for resurfacing cylinder heads, equipping you with the knowledge to make informed decisions and achieve exceptional results. Let's explore the world of grit sandpaper and its role in head resurfacing.

**

Key Takeaways:

- Choosing the right grit sandpaper is crucial for smoothing cylinder heads. Start with coarse grits for leveling, then move to finer grits for a smooth finish. This ensures a proper seal with the engine block.

- Consider the cylinder head material, imperfections, engine requirements, and tool compatibility when selecting grit sandpaper. This ensures optimal resurfacing, contributing to engine performance and longevity.

Read more: What Grit Sandpaper For Marble

Understanding Grit Levels

**

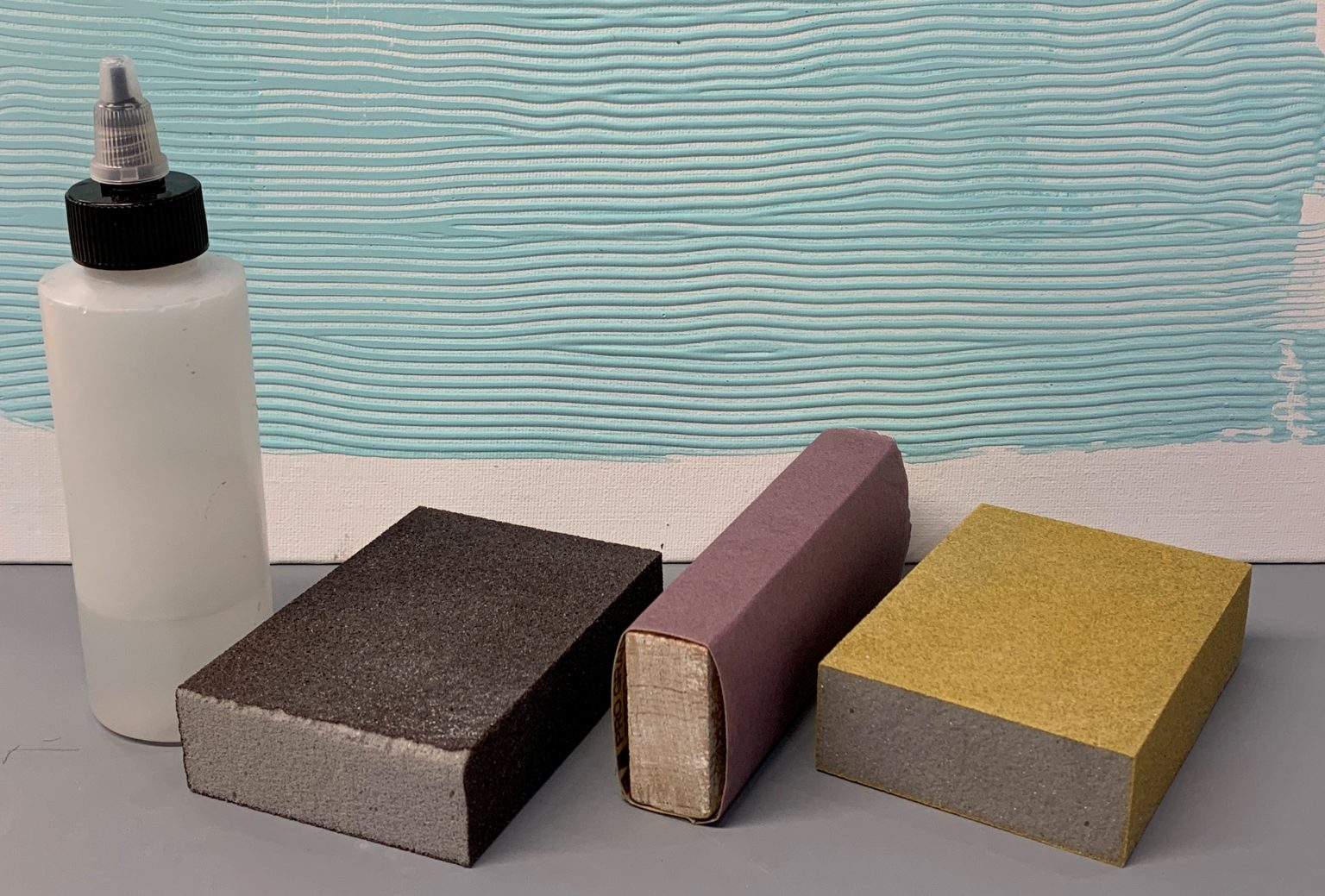

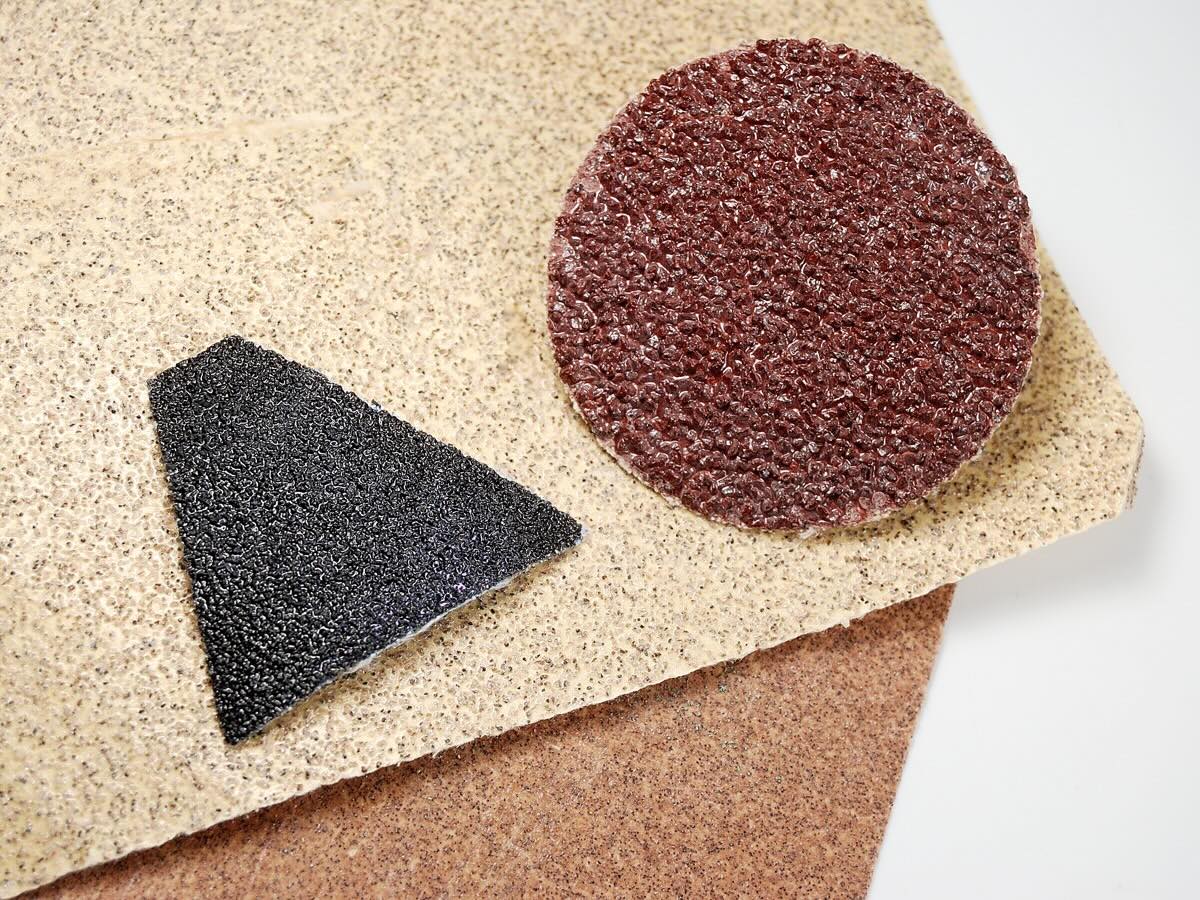

Before delving into the selection of grit sandpaper for head resurfacing, it’s crucial to understand the concept of grit levels. Grit refers to the coarseness or fineness of the abrasive particles on the sandpaper’s surface. It is denoted by a numerical value, typically ranging from 40 to 3000 or higher. The lower the grit number, the coarser the sandpaper, while higher grit numbers indicate finer abrasives.

Coarse grit sandpaper, such as 40 to 100 grit, is ideal for heavy material removal and shaping tasks. As the grit number increases, the sandpaper becomes finer, suitable for achieving smoother finishes and polishing surfaces. For cylinder head resurfacing, the selection of grit sandpaper plays a pivotal role in determining the surface texture and the effectiveness of the sealing interface between the cylinder head and engine block.

Understanding the relationship between grit levels and surface finish is essential. Coarse grit sandpaper can efficiently remove imperfections and uneven surfaces from the cylinder head, preparing it for finer grits that will ultimately impart a mirror-like smoothness. The progression from coarse to fine grits is fundamental in achieving the desired resurfacing outcome, ensuring a proper mating surface for the cylinder head.

Now that we’ve established the significance of grit levels, let’s explore the factors that influence the selection of grit sandpaper for head resurfacing.

**

Selecting Grit Sandpaper for Head Resurfacing

**

When it comes to head resurfacing, the selection of grit sandpaper is a critical decision that significantly influences the final outcome. The process typically involves a progression from coarser to finer grits to achieve the desired surface finish. Here’s a guide to selecting the appropriate grit sandpaper for head resurfacing:

- Initial Preparation: Before diving into the grit selection, it’s essential to assess the condition of the cylinder head. If the surface exhibits significant irregularities, such as deep pitting or warping, starting with a coarse grit, such as 40 or 60, can effectively level the surface and remove imperfections. This initial stage sets the foundation for subsequent grits to refine the surface.

- Intermediate Grits: Once the initial leveling is accomplished, transitioning to intermediate grits, such as 120 or 180, allows for further smoothing and preparation for the final stages of resurfacing. These grits help eliminate the scratches left by coarser abrasives, gradually enhancing the surface texture.

- Final Finishing: As the surface approaches the desired smoothness, employing finer grits, such as 240 or 320, facilitates the removal of any remaining imperfections and refines the surface to a high degree of smoothness. This stage is crucial for achieving the precise mating surface required for optimal cylinder head functionality.

Understanding the progression of grit levels and their respective roles in the resurfacing process is essential for achieving exceptional results. It’s important to note that the selection of grit sandpaper should align with the specific requirements of the cylinder head, considering factors such as material composition, extent of surface imperfections, and the desired level of surface finish.

With the right grit sandpaper selected, the resurfacing process can effectively restore the cylinder head to its optimal condition, ensuring a proper seal and contributing to the overall performance and longevity of the engine.

**

Use 80-120 grit sandpaper to remove old gasket material and surface imperfections on cylinder heads. Then, switch to 320-400 grit for a smooth finish before installing new gaskets.

Factors to Consider

**

Several factors come into play when determining the appropriate grit sandpaper for head resurfacing. Consider the following aspects to make informed decisions and achieve superior resurfacing outcomes:

- Material Composition: The material of the cylinder head influences the choice of grit sandpaper. Aluminum cylinder heads, for instance, require careful consideration due to their relatively softer nature compared to cast iron. When working with aluminum, using finer grits, such as 240 to 320, is crucial to prevent excessive material removal and ensure a smooth finish without causing damage.

- Surface Imperfections: The extent of surface imperfections, such as pitting, warping, or corrosion, dictates the initial grit selection. Coarser grits are effective for addressing pronounced imperfections, while finer grits contribute to refining the surface and achieving the desired smoothness.

- Engine Requirements: Understanding the specific performance requirements of the engine is essential. High-performance engines may necessitate exceptionally smooth and precisely machined surfaces, warranting the use of finer grit sandpaper to achieve the desired level of precision and sealing integrity.

- Sealing Interface: The quality of the sealing interface between the cylinder head and engine block is paramount. The chosen grit sandpaper should facilitate the creation of a uniform and smooth mating surface, ensuring optimal sealing and preventing issues such as leaks and loss of compression.

- Tool Compatibility: Considering the equipment and tools used for head resurfacing is crucial. Ensuring that the selected grit sandpaper is compatible with the resurfacing machinery, such as a cylinder head resurfacing machine, is essential for seamless and effective operations.

By carefully evaluating these factors, you can make informed decisions when selecting the appropriate grit sandpaper for head resurfacing, ultimately contributing to the overall performance and longevity of the engine.

**

Conclusion

**

Head resurfacing is a meticulous process that demands precision and attention to detail. The selection of grit sandpaper plays a pivotal role in achieving the desired surface finish and ensuring optimal functionality of the cylinder head within the engine assembly. By understanding the intricacies of grit levels, considering the specific requirements of the cylinder head, and evaluating critical factors, you can make informed decisions to enhance the resurfacing process.

From the initial preparation with coarse grits to the intermediate stages and final finishing with finer abrasives, the progression of grit levels is instrumental in transforming the surface of the cylinder head. Whether addressing material composition, surface imperfections, engine specifications, or the sealing interface, each factor contributes to the overall resurfacing outcome.

Ultimately, the careful selection of grit sandpaper for head resurfacing can contribute to the longevity, performance, and reliability of the engine. A properly resurfaced cylinder head with a meticulously prepared sealing interface ensures optimal compression, combustion, and overall engine functionality.

As you embark on head resurfacing endeavors, remember that the journey from coarser to finer grits is not merely a technical progression but a transformative process that culminates in the restoration and refinement of critical engine components. Embrace the artistry and precision of head resurfacing, and let the selection of the right grit sandpaper be your guide in achieving exceptional results.

With a deep understanding of grit levels and a keen eye for the factors that influence grit sandpaper selection, you are well-equipped to elevate the resurfacing of cylinder heads to a level of excellence, ensuring the continued performance and reliability of automotive and machinery engines.

Curious about achieving even smoother surfaces? Our next article delves into selecting ultra-fine abrasives for those meticulous projects. Whether you're a hobbyist or a professional, understanding variations in sandpaper grit can significantly impact your results. Don't miss out on learning how to choose just the right texture for your next endeavor.

Frequently Asked Questions about What Grit Sandpaper To Resurface Heads

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper To Resurface Heads”