Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Stainless Steel Scratches

Tools & Equipment

What Grit Sandpaper For Stainless Steel Scratches

Published: December 20, 2023

Find out which grit sandpaper is best for removing scratches on stainless steel. Get expert advice and recommendations on tools and equipment for stainless steel repair.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Stainless steel is a popular material known for its durability, resistance to corrosion, and sleek appearance. Whether it’s in the form of appliances, cookware, or even jewelry, stainless steel holds a prominent place in many households and industries. However, even this resilient material is not completely immune to scratches and wear over time.

If you have stainless steel surfaces that have acquired scratches or signs of use, don’t worry! With the right tools and techniques, you can restore its original shine and smoothness. One indispensable tool in this process is grit sandpaper, which acts as a gentle abrasive to remove scratches and imperfections on stainless steel surfaces. In this article, we will delve into the world of grit sandpaper and guide you in choosing the right one for your stainless steel scratches.

Key Takeaways:

- Choose the right grit sandpaper based on the severity of scratches: 800-1200 for light scratches, 400-600 for moderate scratches, and 200-320 for deep scratches. Patience and proper technique are key to achieving a smooth, polished finish.

- Incorporate additional tips such as working in a well-lit area, using consistent pressure, and finishing with a polishing compound to ensure successful stainless steel scratch removal. By following these guidelines, you can effectively restore the luster of your stainless steel items.

Understanding Stainless Steel Scratches

Before diving into the world of grit sandpaper, it’s essential to understand the different types of scratches that can mar your stainless steel surfaces. Scratches on stainless steel can vary in depth and severity, ranging from light surface scratches to deep gouges. Understanding the nature of these scratches will help you determine the appropriate grit sandpaper to use for your specific needs.

Light surface scratches are shallow and primarily affect the top layer of the stainless steel. They are often caused by daily use, such as contact with utensils or cleaning materials. These scratches are generally less visible and can be easily remedied with the right sanding technique.

Moderate scratches, on the other hand, penetrate slightly deeper into the stainless steel surface and may be more noticeable. They can be caused by abrasive materials or accidental impacts. While they may require a bit more effort to remove than light scratches, they can still be effectively addressed with the proper sanding technique.

Deep scratches, as the name suggests, are more severe and extend further into the stainless steel surface. These scratches can be caused by heavy impacts or aggressive contact with abrasive materials. Removing deep scratches often requires a more comprehensive approach, as simply sanding the surface may not be enough to fully eliminate them.

By understanding the nature and severity of the scratches on your stainless steel, you can better assess the appropriate grit sandpaper to use for each specific scenario. Remember, the goal is to gradually smooth out the scratches without further damaging the stainless steel surface.

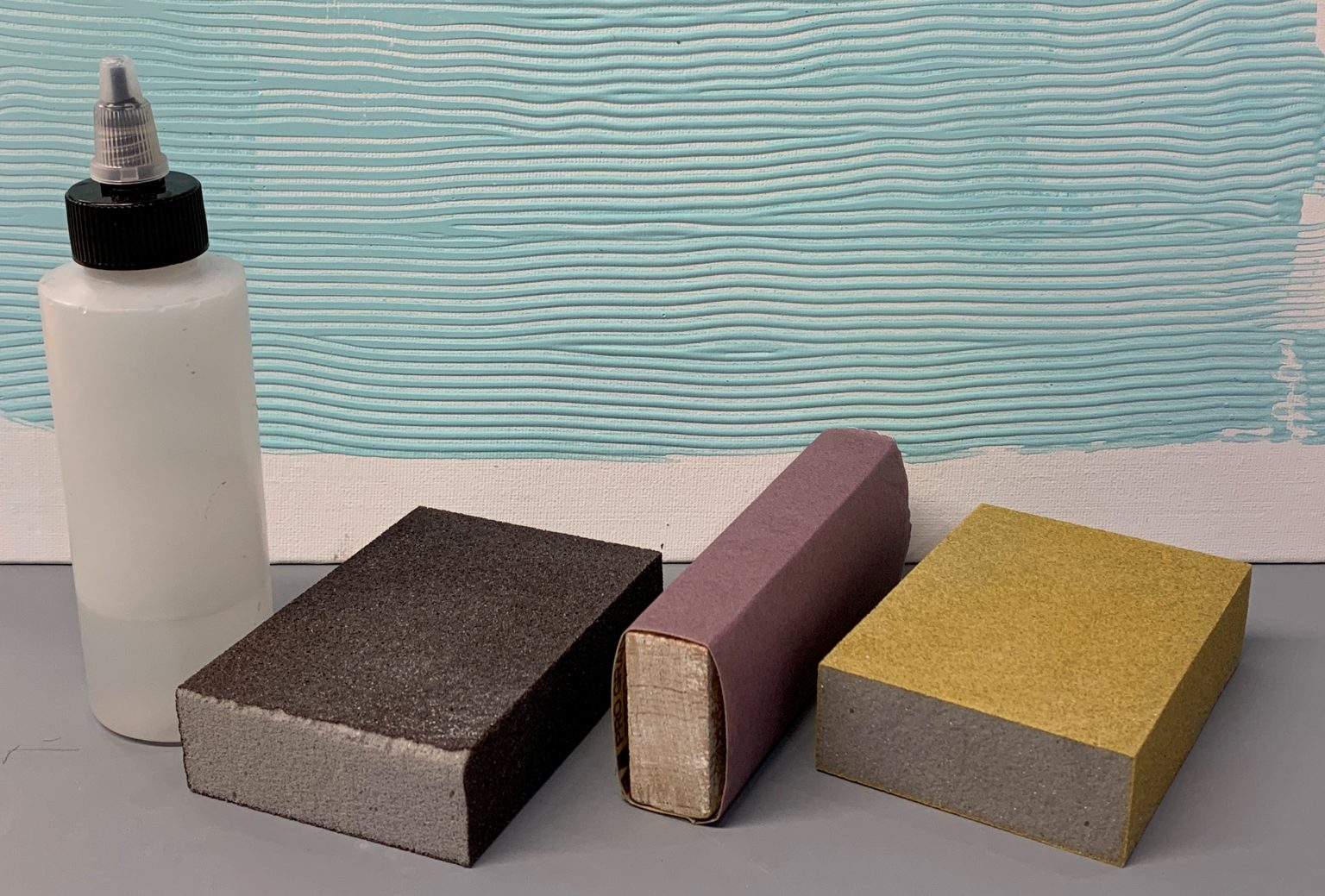

Importance of Grit Sandpaper

Grit sandpaper is a crucial tool in the process of removing scratches from stainless steel surfaces. It consists of a sheet of paper or fabric infused with abrasive particles, allowing you to gently abrade the surface and gradually remove imperfections. The different grit levels available in sandpaper determine the coarseness or fineness of the abrasive particles.

One of the key advantages of using grit sandpaper is its versatility. With the right grit sandpaper, you can effectively address scratches of varying depths, from light surface scratches to deeper gouges. The abrasiveness of the sandpaper helps to smooth out the surface by gradually wearing down the raised edges of the scratches, resulting in a more even and polished finish.

Grit sandpaper also offers a cost-effective solution for restoring stainless steel surfaces. Rather than completely replacing scratched surfaces, sanding allows you to repair and improve the appearance without incurring the expense of replacement. It gives you the opportunity to extend the life of your stainless steel items while maintaining their aesthetic appeal.

Furthermore, using the appropriate grit sandpaper ensures that you do not damage the stainless steel further. By selecting the right level of abrasiveness, you can effectively remove scratches without causing additional harm to the surrounding surface. This precision helps to maintain the integrity and original quality of the stainless steel.

Another benefit of using grit sandpaper is the convenience it offers. Sanding scratches from stainless steel surfaces can be done in the comfort of your own home, avoiding the need for professional assistance or expensive equipment. Grit sandpaper is readily available at hardware stores or online, making it easily accessible for your DIY projects.

In summary, grit sandpaper is an invaluable tool for removing scratches from stainless steel surfaces. Its versatility, cost-effectiveness, precision, and convenience make it an excellent choice for DIY enthusiasts looking to restore the appearance of their stainless steel items. By choosing the right grit sandpaper, you can effectively address scratches and bring back the lustrous shine of your beloved stainless steel possessions.

Choosing the Right Grit Sandpaper for Stainless Steel Scratches

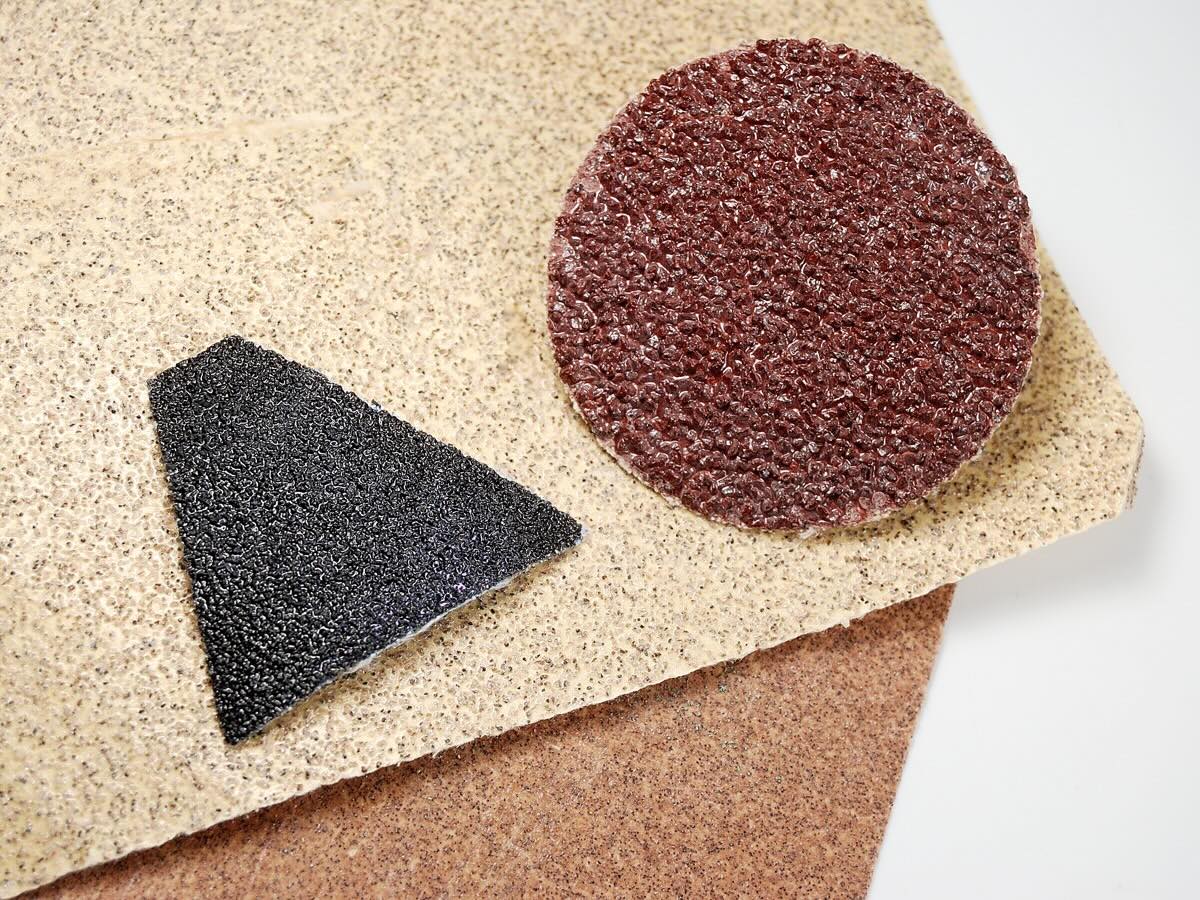

When it comes to selecting the right grit sandpaper for your stainless steel scratches, it’s essential to consider the severity of the scratches and the desired outcome. Each level of grit has its own purpose and application, allowing you to effectively address different types of scratches.

Typically, grit levels range from very coarse to very fine, with the coarser grits having larger abrasive particles and the finer grits having smaller particles. Here is a general guide to help you choose the right grit sandpaper for your stainless steel scratches:

- For light surface scratches: If you’re dealing with shallow, surface-level scratches, start with a finer grit sandpaper. Grit levels between 800 and 1200 are often suitable for this type of scratch. This finer grit helps to gently remove the imperfections without overly damaging the surrounding area.

- For moderate scratches: If the scratches are deeper and more noticeable, you may need to begin with a slightly coarser grit sandpaper. Grit levels between 400 and 600 can help effectively smooth out moderate scratches while still maintaining control over the sanding process.

- For deep scratches: Deeper gouges require more aggressive sanding to eliminate. In this case, you will want to start with a coarser grit, such as 200 or 320, to remove the majority of the scratch. Once you have leveled the surface, you can gradually transition to finer grit sandpaper to achieve a smooth finish.

It’s worth noting that these guidelines are general recommendations, and you should always test on a small, inconspicuous area first to ensure that you achieve the desired results. Additionally, be mindful of the specific instructions provided by the manufacturer of your stainless steel item, as they may have specific recommendations for scratch removal.

Remember that the key is to start with a coarser grit sandpaper and gradually work your way to finer grits. This step-by-step approach allows you to achieve a smooth and polished finish while minimizing the chance of further damage to the stainless steel surface.

By choosing the right grit sandpaper for your stainless steel scratches, you can effectively and efficiently restore the appearance of your stainless steel surfaces. Whether you’re addressing light surface scratches or deep gouges, the appropriate grit sandpaper will be your trusty ally in the quest for a flawless stainless steel finish.

Best Grit Range for Light Scratches

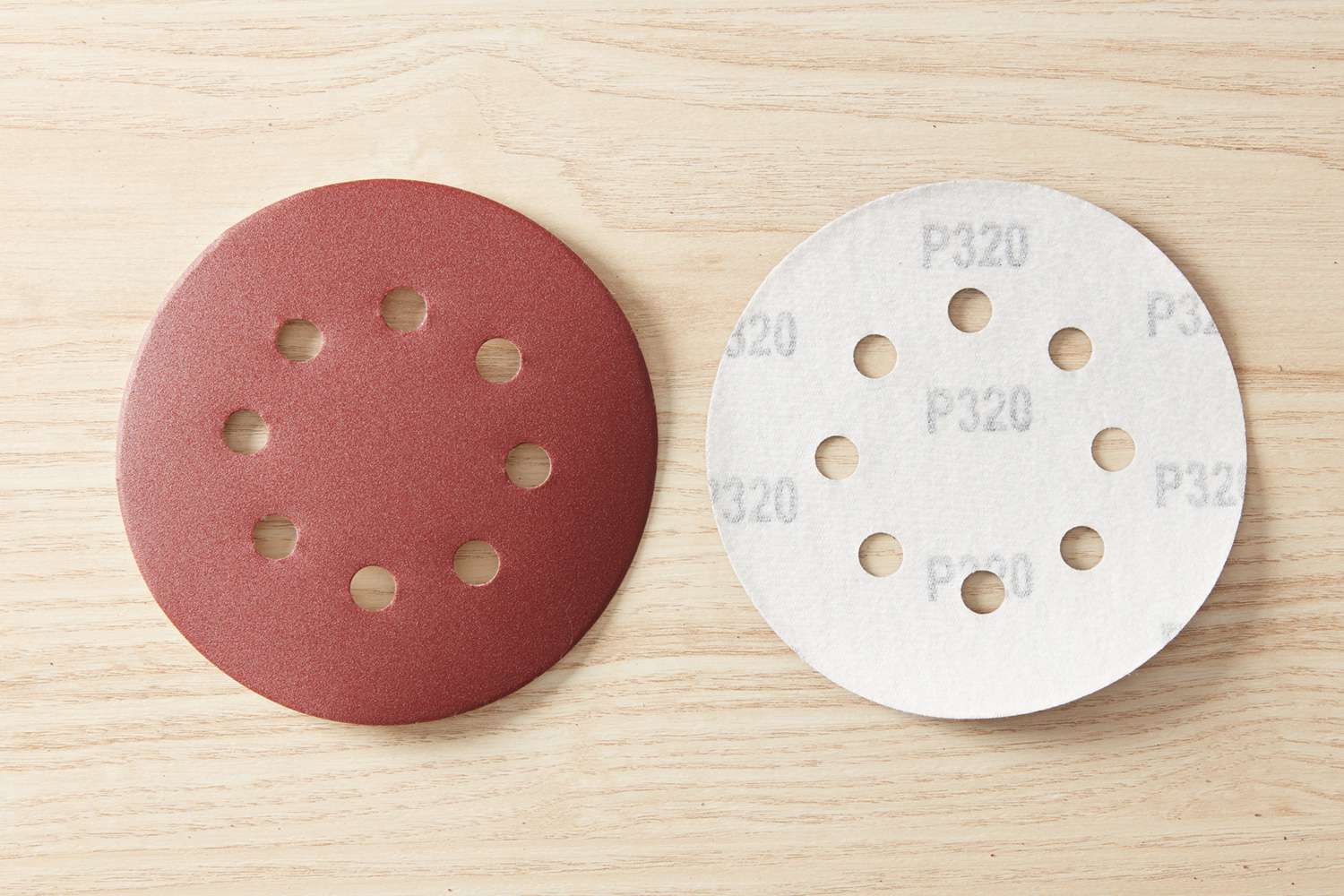

Light surface scratches on stainless steel surfaces can be easily remedied, and the key is to use a finer grit sandpaper to gently remove the imperfections without causing further damage. The best grit range for addressing light scratches typically falls between 800 and 1200.

Grit levels in this range are relatively fine and provide enough abrasiveness to smooth out the scratches while still being gentle on the stainless steel surface. It’s important to note that the exact grit level you choose within this range may depend on the severity and depth of the scratches, as well as personal preference.

Start by assessing the scratches and determining their depth. If the scratches are very shallow and barely noticeable, you may opt for a finer grit sandpaper in the range of 1000 to 1200. These higher grit levels will provide a smoother finish without overly removing the surrounding stainless steel material.

However, if the light scratches are slightly more noticeable or have some depth to them, it may be advisable to start with a coarser grit in the range of 800 to 1000. This will allow you to effectively refine the surface and gradually blend in the scratches for a polished finish.

Remember to use a light touch and moderate pressure when sanding the stainless steel surface. You want to gently abrade the scratches rather than aggressively removing layers of metal. It’s also important to keep the sandpaper in constant motion and avoid staying in one spot for too long, as this can create uneven results or further damage the surface.

After sanding with the chosen grit sandpaper, inspect the surface to evaluate the progress. If the scratches are still visible but have improved, you can continue to use finer grit sandpaper in the same range to refine the surface further.

Keep in mind that patience is key when dealing with light scratches. It may take several rounds of sanding with progressively finer grit sandpaper to achieve the desired results. Take your time, exercise caution, and always test on a small, inconspicuous area before proceeding to the larger scratched areas.

By utilizing the best grit range for light scratches and employing the proper sanding technique, you can successfully restore the appearance of your stainless steel surfaces and make those light scratches a thing of the past.

Use 320-400 grit sandpaper for light scratches on stainless steel. For deeper scratches, start with 120-180 grit and gradually move to finer grits for a smooth finish. Always sand in the direction of the grain.

Best Grit Range for Moderate Scratches

Moderate scratches on stainless steel surfaces require slightly more aggressive sanding compared to light surface scratches. The best grit range for addressing moderate scratches typically falls between 400 and 600.

Grit levels within this range provide a balance between abrasiveness and control, allowing you to effectively smooth out deeper scratches while minimizing the risk of further damage to the surrounding stainless steel surface.

When dealing with moderate scratches, it’s important to start with a coarser grit sandpaper, such as 400 or 500, to remove the majority of the scratch. The coarser grit helps to level the surface and gradually wear down the raised edges of the scratch.

Apply moderate pressure and use a back-and-forth motion while sanding the surface, keeping the sandpaper in constant motion to ensure even results. As you progress, periodically check the surface to assess the progress and determine if further sanding is required. If the scratches are still visible but have improved, you can then transition to a finer grit sandpaper within the range of 500 to 600.

The finer grit sandpaper will help to refine the surface further, gradually blending in the scratch and smoothing out any remaining imperfections. Always remember to exercise caution and avoid excessive sanding, as this can result in unwanted removal of the stainless steel material.

As with light scratches, it’s important to be patient when dealing with moderate scratches. Achieving the desired results may take several rounds of sanding with progressively finer grit sandpaper. Take your time, regularly inspect the surface, and adjust your approach as needed to meet your specific goals.

It’s worth noting that the specific grit level within the 400 to 600 range may vary depending on the depth and severity of the scratches, as well as personal preference. Prioritize thorough surface preparation and consistent sanding techniques to ensure the best possible outcome.

By choosing the best grit range for moderate scratches and employing proper sanding techniques, you can effectively address these deeper imperfections and restore the smoothness and luster to your stainless steel surfaces.

Best Grit Range for Deep Scratches

Deep scratches on stainless steel surfaces require more intensive sanding to effectively remove them. The best grit range for addressing deep scratches typically falls between 200 and 320.

Grit levels within this range are coarser and more abrasive, allowing you to remove the majority of the deep scratch and level the surrounding surface. It’s important to note that when dealing with deep scratches, it’s crucial to start with a coarser grit to effectively address the severity of the imperfection.

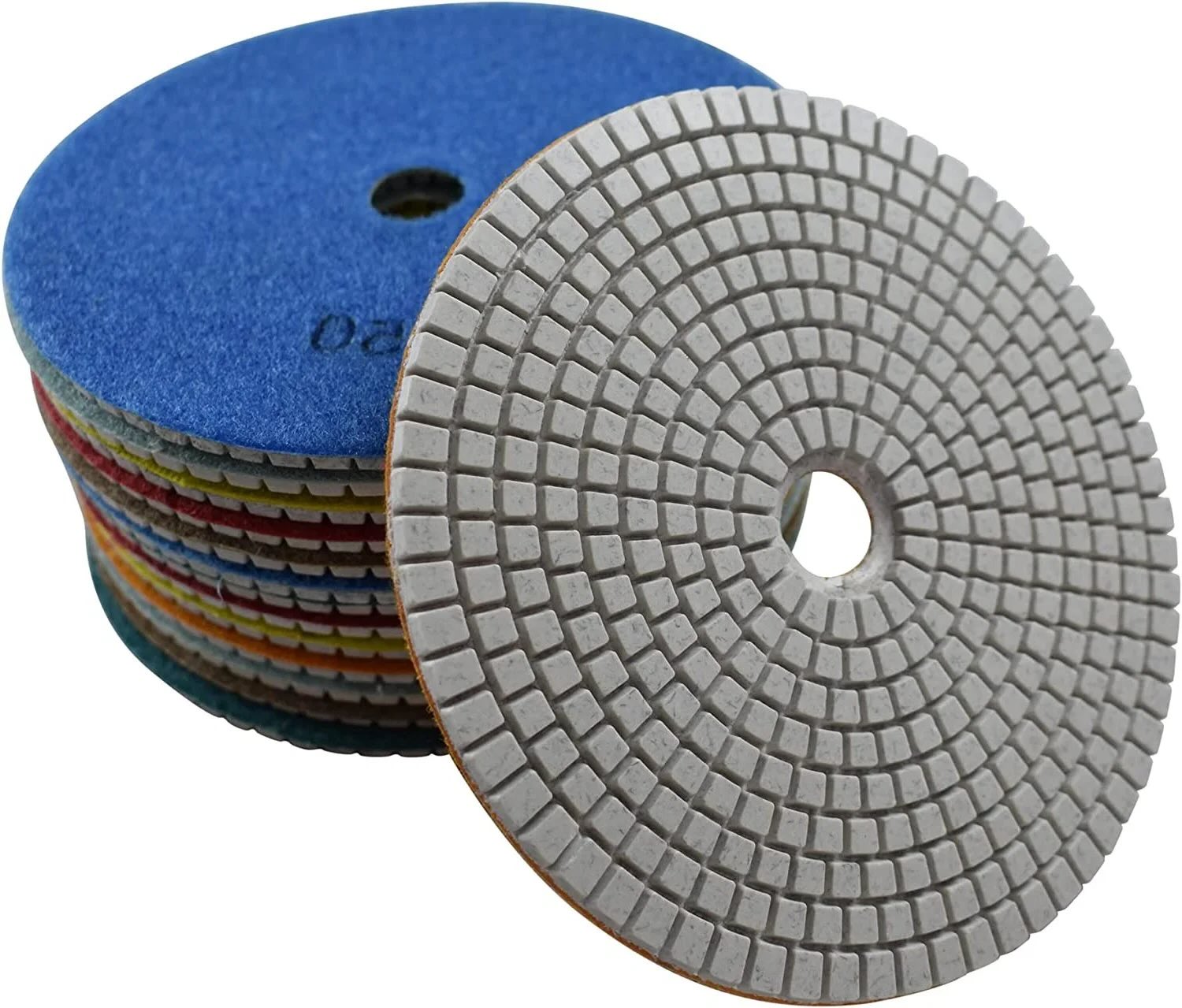

Begin with a grit sandpaper in the range of 200 or 240 to tackle the deep scratch. Apply moderate pressure and use a back-and-forth motion to work the sandpaper across the surface, focusing on the area of the deep scratch. Keep the sandpaper in constant motion to ensure even results and avoid excessive removal of the stainless steel material.

Once you have leveled the surface and significantly reduced the depth of the deep scratch, you can gradually transition to a finer grit sandpaper within the range of 280 to 320. The finer grit will help to refine the surface and blend in any remaining imperfections for a smoother finish.

It’s important to note that deep scratches may require more time and effort to fully remove, as the deeper the scratch, the more material needs to be gradually removed to achieve a smooth surface. Regularly inspect the surface while sanding to assess the progress and make sure you are achieving the desired results.

Take your time and exercise caution when dealing with deep scratches. Maintain a consistent sanding technique, avoid excessive pressure, and periodically test the surface to ensure that you are achieving the desired level of smoothness.

It’s worth mentioning that deep scratches may require additional steps beyond sanding, such as using a polishing compound or stainless steel cleaner, to fully restore the original appearance. These additional steps can help further refine the surface and enhance its shine.

By utilizing the best grit range for deep scratches and employing the proper sanding techniques, you can effectively reduce the depth of the scratches and restore the smoothness and finish of your stainless steel surfaces.

Additional Tips for Sanding Stainless Steel Scratches

When it comes to sanding stainless steel scratches, there are several additional tips and techniques that can help you achieve the best results. Consider the following tips to ensure a successful sanding process:

- Use the right sandpaper: Select the appropriate grit sandpaper based on the severity of the scratches. Starting with a coarser grit and gradually transitioning to finer grits will help you achieve a smooth and polished finish.

- Work in a well-lit area: Adequate lighting will ensure that you can clearly see the scratches and monitor your progress as you sand. This will help to ensure even results and prevent over-sanding.

- Protect the surrounding surfaces: When sanding stainless steel, it’s important to protect adjacent surfaces from accidental damage. Use masking tape or protective film to cover areas that you don’t want to sand or scratch.

- Use consistent pressure: Apply moderate pressure while sanding, but avoid using excessive force as it can result in uneven removal of the stainless steel material.

- Maintain a steady motion: Keep the sandpaper in constant motion, using a back-and-forth or circular motion, to achieve even and consistent results. Avoid staying in one spot for too long to prevent over-sanding.

- Work on small areas at a time: Focus on a specific area or scratch at a time, ensuring thorough sanding before moving on to the next section. This approach allows you to maintain control and accurately gauge your progress.

- Regularly check your work: Periodically inspect the sanded area to assess your progress and determine if further sanding is necessary. This will help you achieve the desired level of smoothness and remove any remaining imperfections.

- Follow manufacturer instructions: If you are working on a specific stainless steel item, such as an appliance or piece of cookware, refer to the manufacturer’s instructions for any specific recommendations on scratch removal techniques or products.

- Finish with a polishing compound: After sanding, consider using a polishing compound specifically designed for stainless steel to further refine the surface and restore its shine. Follow the instructions provided with the polishing compound for the best results.

By incorporating these additional tips into your sanding process, you can ensure a smoother and more successful experience when tackling stainless steel scratches. Remember to take your time, be patient, and periodically evaluate your progress to achieve the best possible outcome.

Conclusion

Sanding stainless steel scratches can be a simple and effective way to restore the appearance of your stainless steel surfaces. By understanding the nature of the scratches and selecting the appropriate grit sandpaper, you can achieve impressive results and bring back the smoothness and luster of your stainless steel items.

For light surface scratches, using grit sandpaper in the range of 800 to 1200 will help gently remove imperfections and restore the polished finish. Moderate scratches may require a slightly coarser grit range of 400 to 600 to effectively smooth out deeper imperfections. Deep scratches necessitate the use of coarser grit levels, such as 200 to 320, to significantly reduce the depth of the scratch and level the surrounding surface.

Throughout the sanding process, it’s essential to work in a well-lit area, apply consistent pressure, and maintain a steady motion to achieve even results. Protecting surrounding surfaces and regularly checking your work are also important steps to ensure that you stay on track and achieve desired outcomes.

Remember to exercise patience when sanding stainless steel scratches. It may take multiple rounds of sanding with progressively finer grits to achieve the desired results. By following manufacturer instructions, using appropriate sanding techniques, and considering the use of a polishing compound, you can further refine the surface and restore its original shine.

With these tips and techniques in mind, you can confidently tackle stainless steel scratches and restore the beauty of your cherished stainless steel items. Enjoy the process of bringing back their pristine condition and revel in the renewed shine and smoothness that grit sandpaper can provide.

Frequently Asked Questions about What Grit Sandpaper For Stainless Steel Scratches

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Stainless Steel Scratches”