Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper To Polish Headlights

Tools & Equipment

What Grit Sandpaper To Polish Headlights

Published: December 20, 2023

Discover the best grit sandpaper for polishing headlights and get your tools and equipment ready for a flawless finish. Choose the right sandpaper for a professional-grade result.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to maintaining the appearance and functionality of your vehicle, ensuring that your headlights are in optimal condition is crucial. Over time, exposure to the elements can cause headlights to become cloudy or yellowed, diminishing their effectiveness and detracting from the overall aesthetic appeal of your car. However, with the right tools and techniques, restoring the clarity and brightness of your headlights is a manageable task.

One essential tool for this restoration process is grit sandpaper, which plays a pivotal role in smoothing and refining the surface of the headlight lens. Understanding the nuances of grit sandpaper and its application in headlight polishing is key to achieving professional-quality results. In this comprehensive guide, we will delve into the intricacies of grit sandpaper, explore the factors to consider when selecting the appropriate grit for headlight polishing, and provide recommendations to aid you in this endeavor.

By the end of this journey, you will be equipped with the knowledge and confidence to revitalize your headlights, elevating the overall appeal and safety of your vehicle. Let's embark on this illuminating exploration of grit sandpaper and its indispensable role in headlight restoration.

Key Takeaways:

- Choose the right grit sandpaper based on headlight condition and material. Start with 800 grit for deep scratches and oxidation, then progress to finer grits for a polished finish.

- Follow the recommended sequence of 800, 1500, 2000, and 3000 grit sandpaper for headlight restoration. Use wet sanding technique and patience for optimal results.

Read more: What Grit Sandpaper To Polish Metal

Understanding Grit Sandpaper

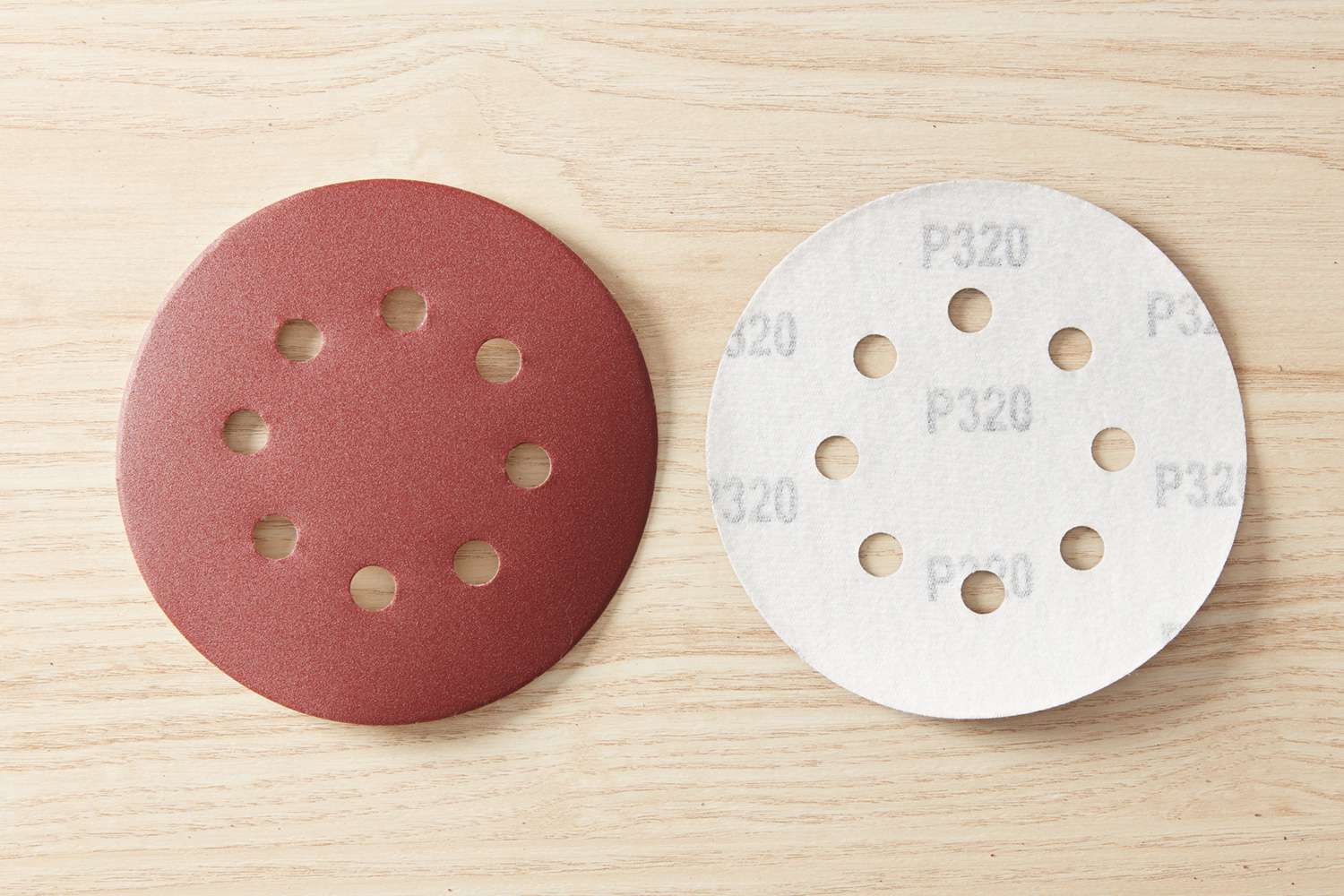

To comprehend the significance of grit sandpaper in headlight polishing, it is essential to grasp the fundamental characteristics and variations of this versatile abrasive material. Grit sandpaper is composed of abrasive particles adhered to a backing material, forming a coated abrasive that is utilized for smoothing surfaces through abrasion. The term “grit” refers to the coarseness or fineness of the abrasive particles, which determines the sandpaper’s aggressiveness and its suitability for specific applications.

The grit size of sandpaper is denoted by a numerical value, typically ranging from the coarsest at 24 grit to the finest at 3000 grit and beyond. Coarser grits feature larger abrasive particles, making them ideal for heavy material removal and surface leveling. Conversely, finer grits consist of smaller abrasive particles, facilitating precision sanding and the attainment of smooth, polished surfaces. Understanding the relationship between grit size and its impact on the sanding process is crucial for achieving the desired results.

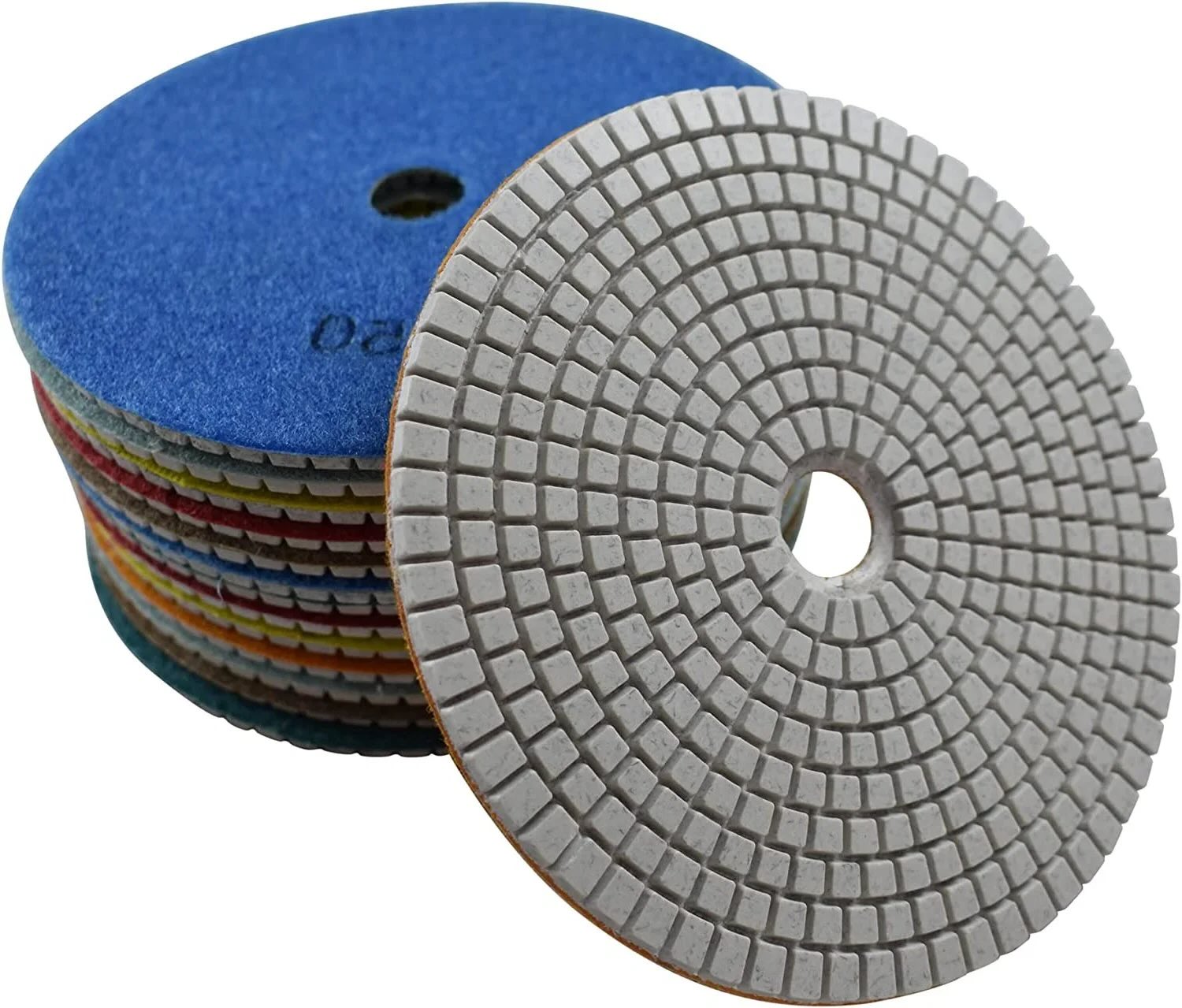

Furthermore, the backing material of grit sandpaper varies in composition, with options such as paper, cloth, or film. Each backing material offers distinct advantages in terms of flexibility, durability, and resistance to tearing, catering to different sanding requirements and techniques. Additionally, the bonding agent used to affix the abrasive particles to the backing material influences the sandpaper’s longevity and effectiveness during prolonged use.

As a key component in the headlight restoration process, grit sandpaper serves as the initial abrasive tool for removing the outer layer of the headlight lens, which may be marred by oxidation, scratches, or discoloration. This preparatory step sets the stage for subsequent polishing and buffing, ultimately yielding a crystal-clear and lustrous headlight surface. By comprehending the nuances of grit sandpaper, you can harness its potential to transform weathered and lackluster headlights into gleaming beacons of clarity.

Factors to Consider When Choosing Grit Sandpaper for Headlight Polishing

When embarking on the journey of headlight restoration, selecting the appropriate grit sandpaper is a pivotal decision that significantly influences the outcome of the polishing process. Several crucial factors should be taken into account to ensure that the chosen grit aligns with the condition of the headlights and the desired level of restoration.

- Extent of Damage: Assess the degree of wear, discoloration, and surface imperfections present on the headlights. Coarser grits, such as 800-1000, are suitable for addressing severe oxidation and deep scratches, while finer grits, like 2000-3000, excel in refining the surface and eliminating finer blemishes.

- Headlight Material: Consider the composition of the headlight lens, as different materials may respond differently to abrasive treatments. For plastic headlights, which are prevalent in modern vehicles, it is essential to utilize sandpaper specifically designed for plastic surfaces to prevent damage and ensure optimal results.

- Experience and Skill Level: Factor in your familiarity with sanding and polishing techniques. Novices may find it advantageous to begin with a less aggressive grit to avoid inadvertently compromising the integrity of the headlight lens, while experienced individuals can leverage coarser grits proficiently to expedite the restoration process.

- Complementary Polishing Stages: Envision the complete restoration process, including subsequent polishing and buffing stages. Selecting a range of grits that complement each other, such as starting with a coarser grit and progressively transitioning to finer grits, ensures a comprehensive and refined restoration outcome.

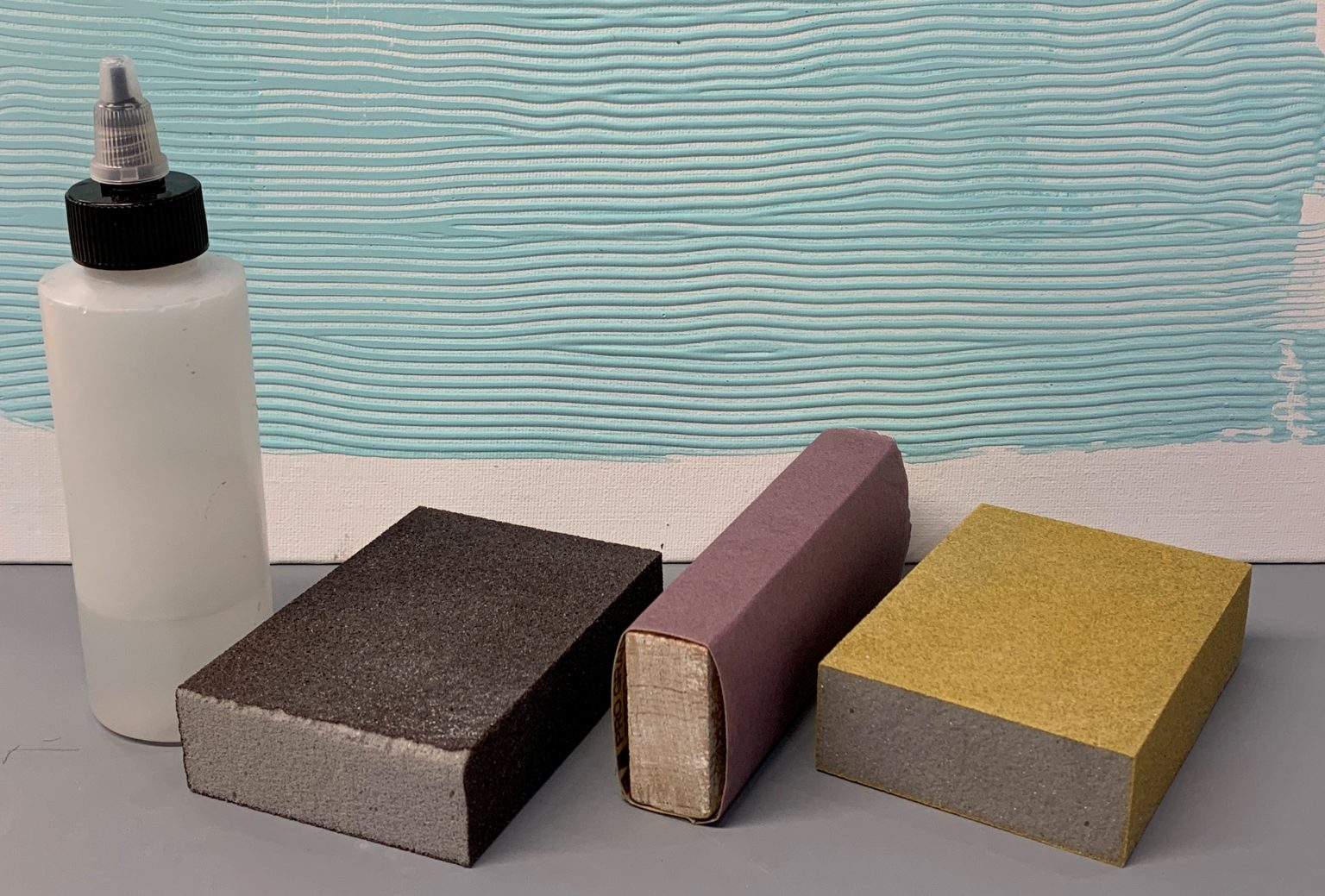

- Equipment and Safety Measures: Evaluate the availability of sanding tools and safety equipment, such as sanding blocks, water sprays, and protective gear. Different grits may necessitate specific sanding implements and techniques, and adhering to safety protocols is imperative to prevent injury and damage to the vehicle.

By carefully considering these factors, you can tailor your grit sandpaper selection to suit the unique characteristics of your headlights and your proficiency in executing the restoration process. This thoughtful approach maximizes the efficacy of the sanding phase and sets the stage for achieving impeccably restored headlights that exude brilliance and clarity.

Use 800-1000 grit sandpaper to remove oxidation and yellowing from headlights. Follow up with 2000-3000 grit for a smooth finish.

Recommended Grit Sandpaper for Headlight Polishing

Choosing the optimal grit sandpaper for headlight polishing is a nuanced endeavor that hinges on the specific condition of the headlights and the desired level of restoration. To guide you in this selection process, we present a recommended sequence of grits tailored to address various degrees of headlight wear and imperfections, culminating in a resplendent and rejuvenated appearance.

- 800 Grit: Commence the restoration journey with 800 grit sandpaper to effectively eliminate stubborn oxidation, deep scratches, and ingrained blemishes on the headlight surface. This coarse grit initiates the smoothing and leveling process, preparing the lens for subsequent refinement.

- 1500 Grit: Transition to 1500 grit sandpaper to further refine the surface, smoothing out the abrasions left by the previous coarse grit. This intermediate step facilitates the gradual elimination of imperfections, bringing the headlight closer to its original clarity and luster.

- 2000 Grit: As the restoration progresses, 2000 grit sandpaper becomes instrumental in achieving a notably smoother and more polished surface. This fine grit effectively diminishes residual blemishes and prepares the headlight for the final stages of the polishing process.

- 3000 Grit: The ultimate refinement is accomplished with 3000 grit sandpaper, which imparts a luxurious and pristine finish to the headlight lens. This ultra-fine grit ensures that all surface imperfections are eradicated, culminating in a brilliantly clear and reflective headlight surface.

It is imperative to employ a wet sanding technique during the utilization of these grits, utilizing a constant water spray to lubricate the sandpaper and prevent the accumulation of debris, resulting in a smoother sanding process and enhanced surface finish. Additionally, exercising patience and precision during each grit transition is pivotal, as it contributes to the seamless progression toward achieving impeccably restored headlights.

By adhering to this recommended sequence of grit sandpaper, you can navigate the headlight restoration process with confidence and precision, revitalizing your headlights to exude a radiance that enhances both the aesthetic allure and safety of your vehicle.

Conclusion

Embarking on the endeavor of headlight restoration through the utilization of grit sandpaper is a transformative journey that rejuvenates the appearance and functionality of your vehicle’s headlights. By comprehending the nuances of grit sandpaper and its pivotal role in the restoration process, you have gained invaluable insight into the art of achieving pristine and luminous headlights.

As you venture forth, armed with the knowledge of grit sandpaper’s coarseness and its impact on the sanding process, you are empowered to navigate the intricate facets of headlight polishing with finesse and precision. The careful consideration of factors such as the extent of damage, headlight material, and complementary polishing stages enables you to tailor your grit sandpaper selection to suit the unique characteristics of your headlights, ensuring a comprehensive and refined restoration outcome.

Guided by the recommended sequence of grits, including 800, 1500, 2000, and 3000 grit sandpaper, you are equipped to orchestrate a symphony of restoration, gradually transforming weathered and lackluster headlights into gleaming beacons of clarity. By embracing the wet sanding technique and exercising patience during each grit transition, you can elevate the restoration process to an art form, culminating in impeccably restored headlights that exude brilliance and clarity.

Ultimately, the revitalization of your headlights transcends mere aesthetics, bolstering the safety and visibility of your vehicle, especially during low-light conditions. The resplendent radiance emanating from your rejuvenated headlights not only enhances the allure of your vehicle but also underscores your commitment to meticulous maintenance and care.

As you embark on this illuminating journey of headlight restoration, may the transformative power of grit sandpaper and the artistry of precision sanding guide you toward the realization of impeccably restored headlights, illuminating the path ahead with unparalleled clarity and brilliance.

Frequently Asked Questions about What Grit Sandpaper To Polish Headlights

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper To Polish Headlights”