Home>Technology>Smart Home Devices>How To Use A Label Printer

Smart Home Devices

How To Use A Label Printer

Modified: August 17, 2024

Learn how to use a label printer for your smart home devices with our step-by-step guide. Organize and label your devices effortlessly.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

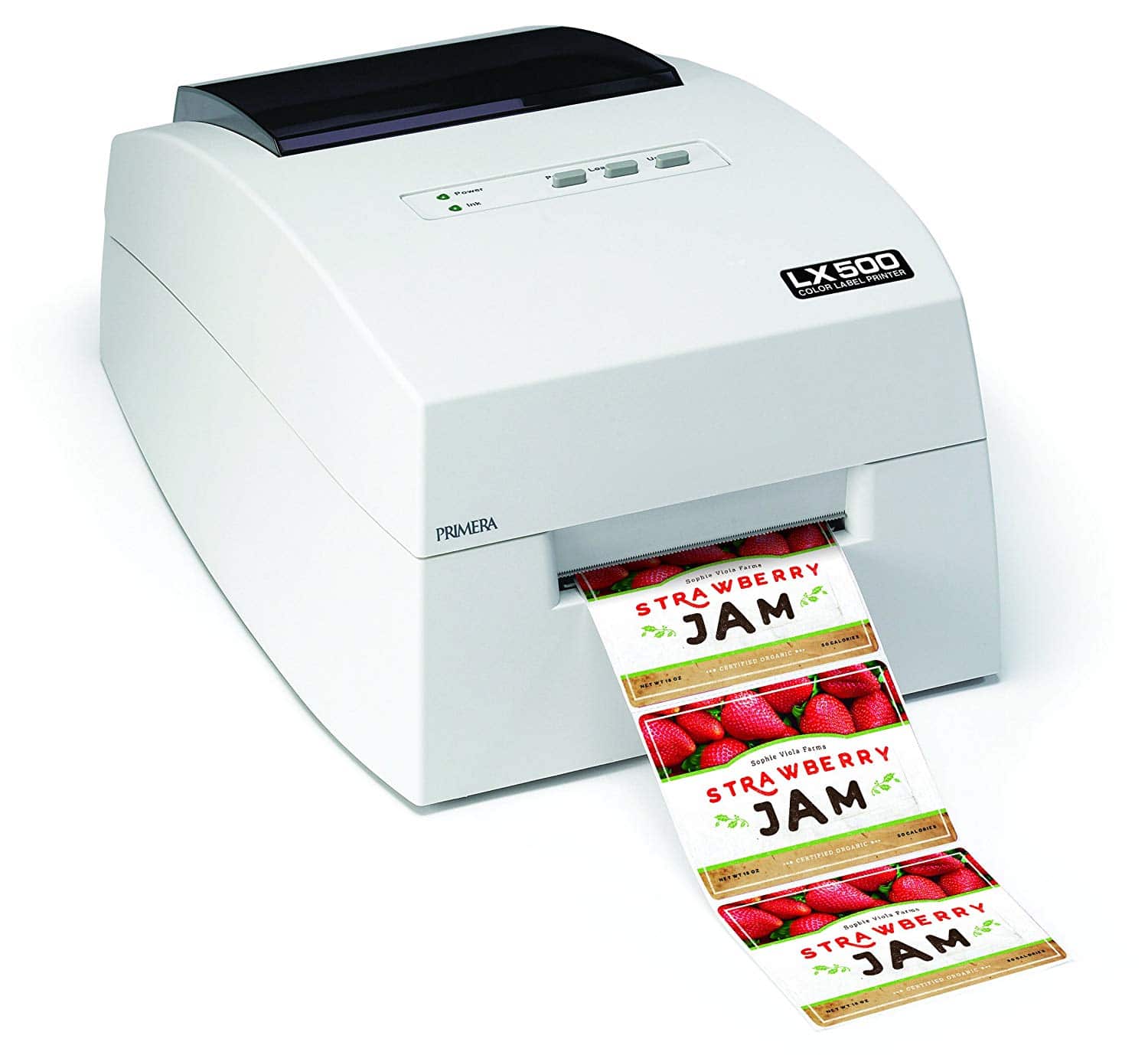

Are you tired of hand-labeling everything in your home or office? Do you want to streamline your organization process and give everything a polished, professional look? If so, a label printer might be just what you need. Label printers are versatile devices that can help you create custom labels for a wide range of applications, from organizing your pantry to labeling cables and wires in your smart home setup.

In this comprehensive guide, we'll explore everything you need to know about using a label printer effectively. Whether you're a seasoned tech enthusiast or a novice looking to simplify your labeling tasks, this article will walk you through the process of choosing, setting up, and using a label printer to its full potential.

By the end of this guide, you'll have the knowledge and confidence to make the most of your label printer, ensuring that your labeling needs are met with efficiency and precision. Let's dive in and discover the world of label printing together!

Key Takeaways:

- Label printers are versatile tools that can streamline organization and add a professional touch to your home or office. Choosing the right printer, setting it up correctly, and maintaining it can ensure efficient and high-quality label printing.

- Designing and printing custom labels with a label printer offers endless possibilities for creativity and organization. By troubleshooting common issues and maintaining the printer, you can achieve exceptional results and maximize its value.

Read more: How To Change Printer Settings To Labels

Choosing the Right Label Printer

When it comes to selecting the right label printer for your needs, it’s essential to consider several key factors to ensure that you make the best choice. With a wide variety of label printers available on the market, each offering different features and capabilities, it’s important to assess your specific requirements before making a decision.

Here are some crucial considerations to keep in mind when choosing a label printer:

- Label Size and Type: Determine the sizes and types of labels you will need to print. Whether you require small, medium, or large labels, or if you need special label types such as weatherproof or heat-resistant labels, ensure that the printer you choose supports your desired label sizes and materials.

- Print Volume: Consider the volume of labels you anticipate printing on a regular basis. If you have high-volume labeling needs, opt for a printer designed to handle heavy usage without compromising on print quality or speed.

- Connectivity Options: Assess the connectivity options offered by the label printer. Whether you prefer a USB-connected printer for standalone use or a network-enabled printer for shared access across multiple devices, ensure that the printer’s connectivity aligns with your requirements.

- Print Resolution: Evaluate the print resolution capabilities of the label printer. Higher resolution results in sharper, more detailed labels, making it ideal for applications where precision and clarity are paramount.

- Additional Features: Explore additional features such as built-in label design software, automatic label cutting, and compatibility with barcode printing. These features can significantly enhance the versatility and functionality of the label printer.

Once you’ve identified your specific labeling needs and considered the factors mentioned above, you’ll be better equipped to narrow down your options and choose a label printer that aligns with your requirements. Whether you prioritize versatility, speed, or advanced features, selecting the right label printer is the first step toward efficient and professional label printing.

Setting Up Your Label Printer

After acquiring the ideal label printer for your needs, the next crucial step is setting it up for optimal performance. Whether you’ve chosen a compact desktop label printer or a network-enabled industrial model, the setup process typically involves several key steps to ensure seamless operation.

Here’s a step-by-step guide to setting up your label printer:

- Unboxing and Inspection: Carefully unpack your label printer and inspect it for any signs of damage that may have occurred during shipping. Ensure that all included components, such as power cords, labels, and ink ribbons, are present and undamaged.

- Power and Connectivity: Locate a suitable power outlet and connect the power cord to your label printer. If your printer supports USB or Ethernet connectivity, connect it to your computer or network using the appropriate cables.

- Driver Installation: If your label printer requires specific drivers to interface with your computer or network, install the necessary software by following the manufacturer’s instructions. Ensure that the drivers are compatible with your operating system.

- Calibration and Configuration: Follow the printer’s user manual to calibrate the print head and configure the settings according to your label specifications. This may involve adjusting the label gap sensor, print darkness, and label size settings to achieve optimal print quality.

- Testing the Printer: Load the printer with labels and ribbon, if applicable, and perform a test print to verify that the printer is functioning correctly. Use the test print to check for alignment, print quality, and any potential issues that may require adjustment.

- Network Setup (If Applicable): If you’re setting up a network-enabled label printer, configure the network settings as per the manufacturer’s instructions. Ensure that the printer is assigned an appropriate IP address and is accessible from other devices on the network.

By following these steps, you can ensure that your label printer is set up correctly and ready to fulfill your labeling needs with precision and efficiency. Whether you’re embarking on a small-scale labeling project or integrating the printer into a larger operational environment, proper setup is essential for maximizing the printer’s capabilities.

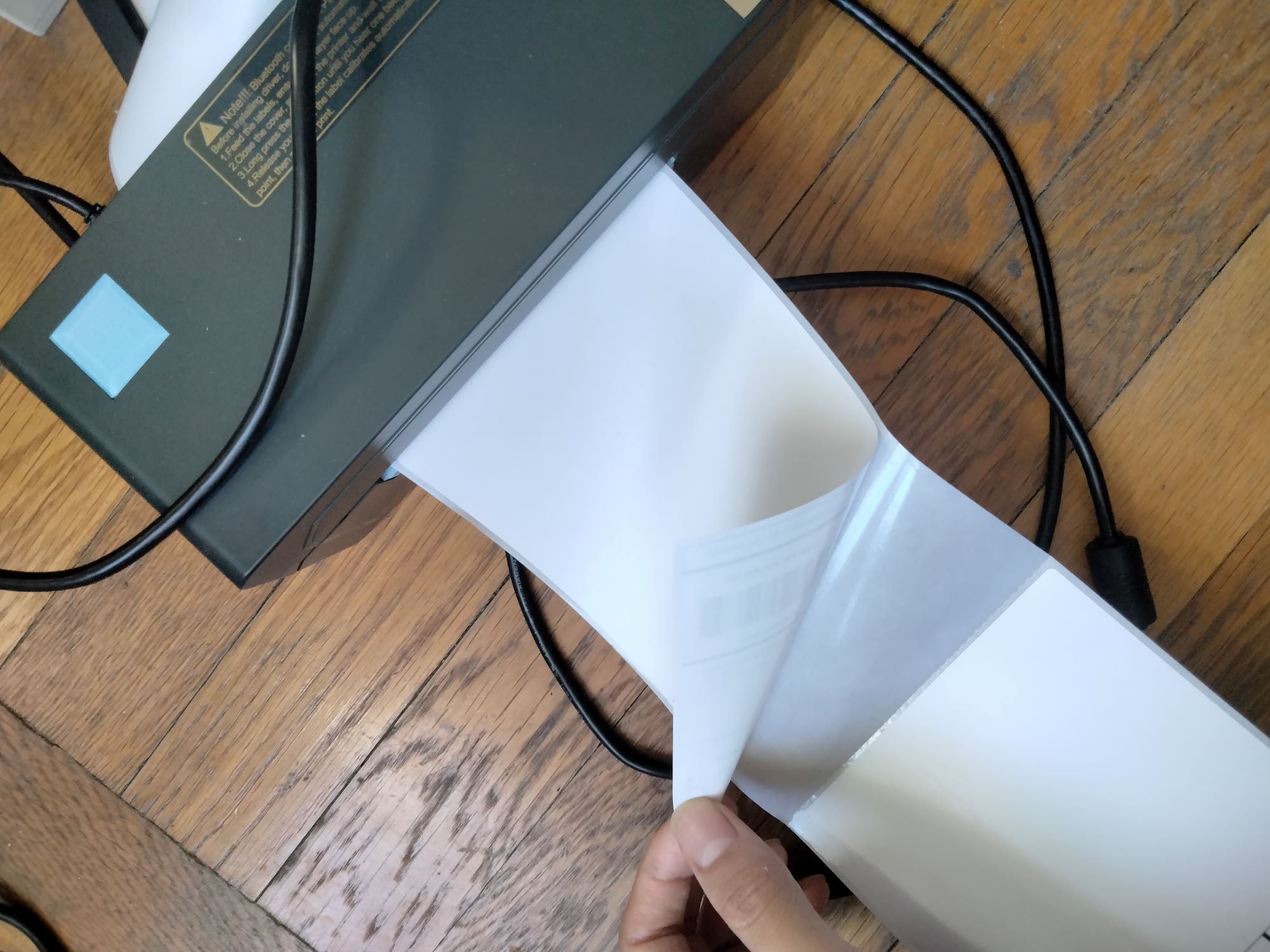

Loading Labels and Ribbons

Once your label printer is set up, the next essential task is loading it with labels and, if applicable, ink ribbons. Properly loading the labels and ribbons ensures smooth printing operations and optimal output quality. Whether you’re using direct thermal or thermal transfer printing technology, the loading process typically involves specific steps to follow for seamless label and ribbon insertion.

Here’s a detailed guide on loading labels and ribbons into your printer:

- Label Roll Installation: Open the printer’s cover or access panel to reveal the label roll compartment. Insert the roll of labels onto the label holder spindle, ensuring that the labels unwind from the bottom of the roll. Follow any included diagrams or instructions for proper label orientation.

- Adjusting Label Guides: If your printer features adjustable label guides, position them to match the width of your labels. This helps prevent label misalignment and ensures that the labels feed through the printer smoothly during printing.

- Ribbon Installation (For Thermal Transfer Printers): If your printer utilizes thermal transfer technology, install the ink ribbon by following the manufacturer’s guidelines. Ensure that the ribbon is threaded correctly through the print head and that it is taut without being overly stretched.

- Label Path Alignment: Verify that the labels and ribbon (if applicable) are threaded through the printer’s designated paths according to the provided instructions. Proper label path alignment is crucial for consistent and accurate printing without jams or misfeeds.

- Tension Adjustment: If your printer allows for tension adjustment of the label and ribbon, ensure that the tension is set to the recommended level. Correct tension prevents label and ribbon slippage during printing, contributing to clean and precise output.

- Test Printing: After loading the labels and ribbons, perform a test print to confirm that the printer is feeding and printing the labels correctly. Use the test print to check for any issues such as misalignment, smudging, or incomplete printing.

By following these steps, you can effectively load your label printer with labels and ribbons, setting the stage for consistent and high-quality label printing. Proper loading not only ensures reliable performance but also minimizes the risk of printing errors, ultimately contributing to professional-looking labels for your various applications.

When using a label printer, make sure to select the correct label size and type in the printer settings to avoid any printing errors. Also, always check the alignment and print preview before printing to ensure the labels come out correctly.

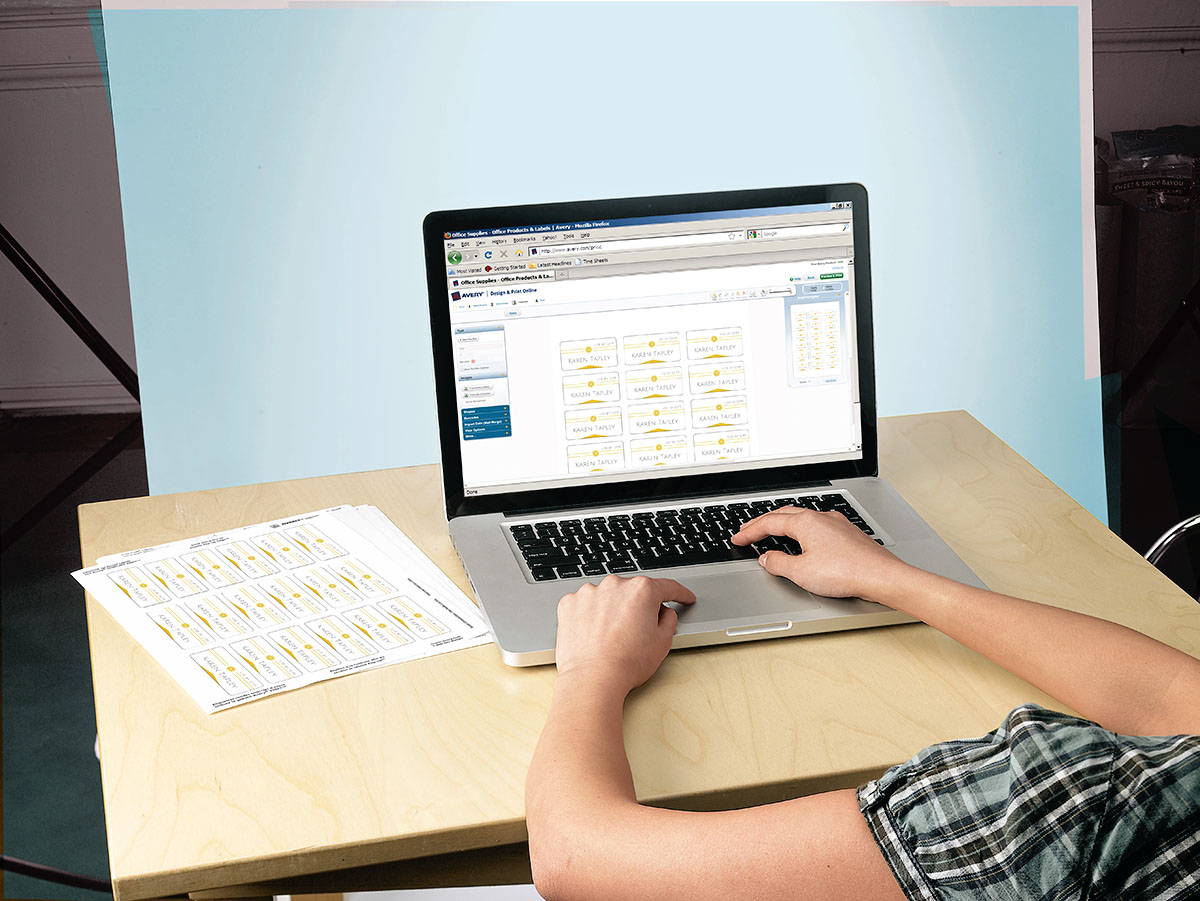

Designing and Printing Labels

Once your label printer is set up and loaded with labels and ribbons, you’re ready to embark on the creative process of designing and printing your custom labels. Whether you’re organizing storage containers, creating shipping labels, or adding identification tags to your smart home devices, the ability to design and print personalized labels offers endless possibilities for customization and organization.

Here’s a comprehensive overview of the process of designing and printing labels using your label printer:

- Label Design Software: Utilize the label design software provided with your printer or use compatible third-party software to create custom label designs. These programs offer a range of design tools, including text, images, shapes, and barcode generation, allowing you to tailor your labels to specific requirements.

- Template Selection: If you’re new to label design, consider starting with pre-designed templates that align with common labeling needs. Templates can expedite the design process and provide a framework for creating professional-looking labels with minimal effort.

- Customization and Branding: Tailor your labels to reflect your personal or brand identity by incorporating custom logos, color schemes, and fonts. Consistent branding across your labels can enhance recognition and convey a cohesive visual identity.

- Variable Data Printing: Leverage the capability of variable data printing to include unique information on each label, such as sequential numbering, batch codes, or individualized content. This feature is particularly valuable for applications requiring serialized labels or personalized data.

- Print Settings Adjustment: Prior to printing, review and adjust print settings such as print density, speed, and label size to achieve the desired output quality. Fine-tuning these settings can optimize print clarity and durability, especially when using specialty label materials.

- Printing Process: Initiate the printing process through the label design software, ensuring that the printer is adequately stocked with labels and ribbons. Monitor the printing operation to address any issues promptly and to confirm that the labels are being printed accurately and consistently.

By following these steps, you can unleash the full potential of your label printer by designing and printing custom labels tailored to your specific needs. Whether you’re creating informative labels for your smart home devices or adding a personal touch to your organizational systems, the ability to design and print labels empowers you to bring creativity and functionality together in a single, impactful output.

Read more: How To Add A Dymo Label Printer

Troubleshooting Common Issues

While label printers are invaluable tools for creating professional and customized labels, occasional issues may arise during operation. Understanding how to troubleshoot common problems can help you address issues swiftly and resume smooth label printing without significant downtime. By familiarizing yourself with potential challenges and their solutions, you can minimize disruptions and maintain consistent printing performance.

Here are some common issues you may encounter when using a label printer, along with effective troubleshooting steps:

- Label Misalignment: If labels are printing off-center or skewed, ensure that the label guides are correctly adjusted to match the label width. Additionally, inspect the label path for any obstructions or debris that may be affecting the label alignment.

- Print Quality Issues: If the printed labels exhibit smudging, fading, or incomplete printing, consider adjusting the print density and speed settings to achieve optimal print quality. Additionally, verify that the print head and label path are clean and free from debris that could impact print clarity.

- Label Jams or Misfeeds: Address label jams or misfeeds by checking the label path for any adhesive residue or debris that may be impeding the smooth movement of labels through the printer. Adjust the label tension and ensure that the labels are loaded correctly to prevent jams.

- Communication Errors: If the printer fails to respond to print commands or exhibits connectivity issues, verify the cable connections and ensure that the printer is properly recognized by the computer or network. Restarting the printer and computer may resolve temporary communication errors.

- Ribbon Wrinkling (Thermal Transfer Printers): When using a thermal transfer printer, address ribbon wrinkling by confirming that the ribbon is loaded correctly and is not excessively tensioned. Adjust the ribbon tension as needed to prevent wrinkling during printing.

- Barcode Scanning Issues: If printing barcodes, ensure that the barcode symbology and dimensions are compatible with the scanning equipment. Adjust the barcode settings in the label design software to generate barcodes that align with the requirements of your scanning system.

By proactively addressing these common issues and implementing the recommended troubleshooting steps, you can maintain the optimal performance of your label printer and swiftly resolve any challenges that may arise. Regular maintenance and attentive troubleshooting contribute to consistent and reliable label printing, ensuring that your labeling tasks proceed with efficiency and precision.

Maintenance and Care of Your Label Printer

Ensuring the ongoing performance and longevity of your label printer requires regular maintenance and attentive care. By implementing a structured maintenance regimen and observing best practices for printer care, you can optimize the reliability and output quality of your label printer, extending its service life and minimizing the risk of operational issues.

Here are essential maintenance tasks and care guidelines to keep your label printer in peak condition:

- Clean the Print Head: Regularly clean the print head using a specialized cleaning pen or solution recommended by the printer manufacturer. Removing debris and residue from the print head helps maintain print quality and prevents potential damage to the printing mechanism.

- Inspect and Clean Label Path: Periodically inspect the label path for accumulated adhesive residue, dust, or debris that may hinder label movement or affect print quality. Use a lint-free cloth and approved cleaning solution to gently clean the label path and rollers.

- Replace Worn Components: Monitor the condition of critical components such as the print head, platen roller, and label guides. If signs of wear or damage are observed, follow the manufacturer’s guidelines to replace these components to ensure consistent performance.

- Use High-Quality Labels and Ribbons: Opt for high-quality labels and ribbons that are compatible with your printer’s specifications. Using substandard consumables can lead to premature wear on the print head and other printer components, impacting print quality and reliability.

- Regular Calibration and Testing: Periodically calibrate the printer and perform test prints to verify print quality and alignment. Calibration helps maintain accurate label positioning and print consistency, while test prints allow you to identify and address any emerging issues promptly.

- Maintain Optimal Environmental Conditions: Store and operate the label printer in a clean, dust-free environment with moderate temperature and humidity levels. Extreme environmental conditions can impact printer performance and contribute to premature component wear.

- Follow Manufacturer’s Maintenance Guidelines: Adhere to the maintenance recommendations outlined in the printer’s user manual. These guidelines may include specific cleaning procedures, lubrication requirements, and scheduled component inspections to uphold optimal printer functionality.

By integrating these maintenance practices into your label printer care routine, you can safeguard the printer’s performance and prolong its operational lifespan. Consistent maintenance not only preserves print quality and reliability but also minimizes the likelihood of unexpected downtime due to preventable issues.

Conclusion

Congratulations on delving into the world of label printing and equipping yourself with the knowledge to maximize the potential of your label printer. With the insights gained from this guide, you are well-prepared to embark on a seamless and efficient label printing journey, enhancing organization, professionalism, and personalization across various applications.

By carefully selecting the right label printer to suit your needs, setting it up with precision, and mastering the art of loading labels and ribbons, you’ve laid a solid foundation for consistent and high-quality label printing. Furthermore, understanding the design and printing process, troubleshooting common issues, and implementing proactive maintenance practices empowers you to maintain peak performance from your label printer over the long term.

As you venture into the realm of label printing, remember that creativity and functionality go hand in hand. Whether you’re labeling smart home devices, organizing storage spaces, or streamlining your business operations, your label printer is a versatile tool that enables you to bring order and personalization to every label you create.

Embrace the flexibility and customization offered by your label printer, and don’t hesitate to explore new label design ideas that reflect your unique style and branding. As you continue to refine your label printing skills and leverage the full capabilities of your printer, you’ll discover endless opportunities to elevate your labeling endeavors.

With a commitment to ongoing learning and attentive care for your label printer, you are poised to achieve exceptional results and derive maximum value from this indispensable device. Embrace the journey ahead, and let your label printer be the catalyst for efficiency, creativity, and organization in all aspects of your personal and professional endeavors.

Here’s to a future filled with impeccably designed, precisely printed labels that elevate your surroundings and streamline your operations. Happy labeling!

Frequently Asked Questions about How To Use A Label Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use A Label Printer”