Home>Technology>Smart Home Devices>What Is The Fuser On A Printer

Smart Home Devices

What Is The Fuser On A Printer

Modified: August 17, 2024

Learn about the fuser on a printer and its role in printing. Discover how it works and its importance for smart home devices. Understand the function and maintenance of this essential printer component.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of printing, where cutting-edge technology meets everyday convenience. While we often marvel at the sleek design and advanced features of modern printers, there's a crucial component that quietly plays a pivotal role in the printing process: the fuser. In this article, we'll delve into the intricacies of this often-overlooked printer part, exploring its function, types, and significance in ensuring crisp, professional-quality prints.

Printers have become an indispensable tool in both professional and personal settings, seamlessly transforming digital files into tangible documents. However, the complex interplay of components within a printer is often taken for granted. Understanding the fuser, its operation, and its impact on the final output is essential for anyone seeking to gain a comprehensive understanding of the printing process.

So, let's embark on a journey to uncover the inner workings of this integral printer component. By the end of this article, you'll have a newfound appreciation for the crucial role that the fuser plays in the world of printing.

Key Takeaways:

- The fuser is a crucial part of a printer that uses heat and pressure to permanently fuse toner to paper, ensuring smudge-resistant, professional-quality prints.

- There are two main types of fusers: heat roller fusers and xenon flash fusers, each tailored to specific printing technologies and requirements.

Read more: What Is A Fuser In A Printer

What is a Fuser?

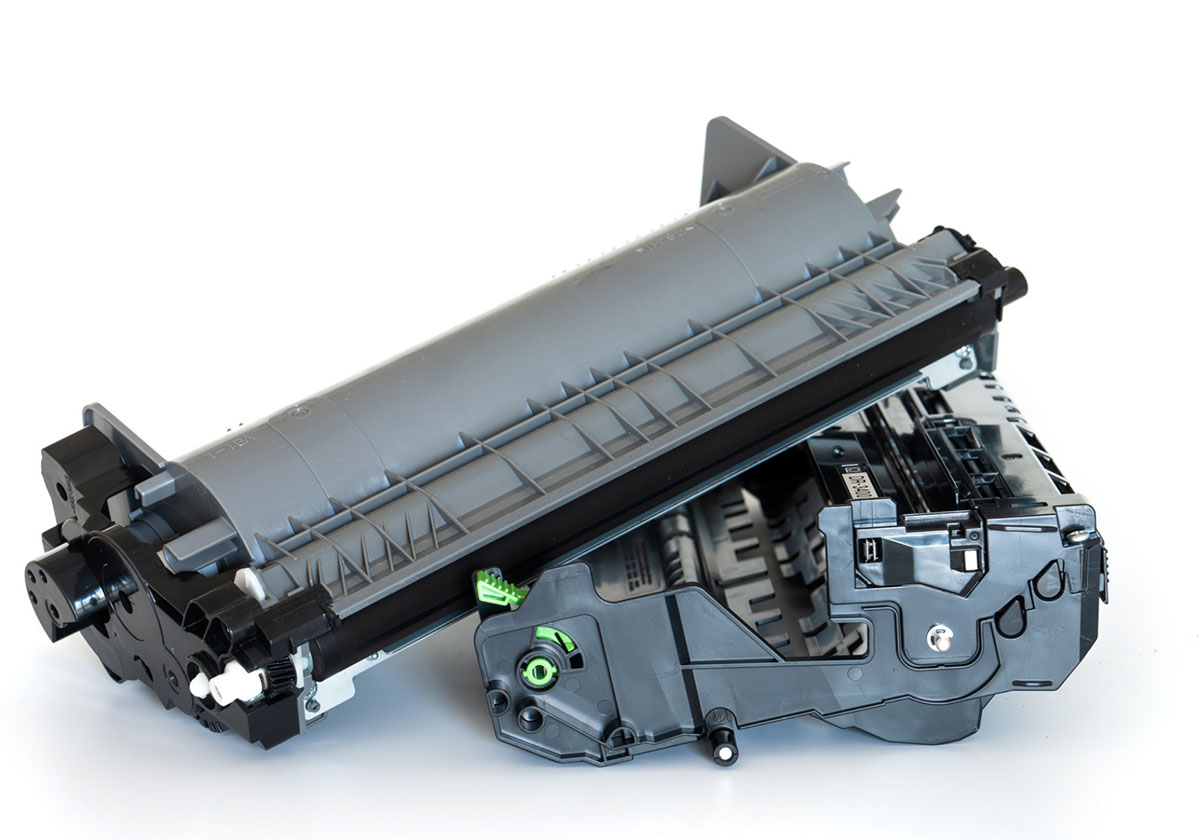

At the heart of every printer lies a remarkable component known as the fuser. This essential part is responsible for the final stage of the printing process, where the toner, or ink, is permanently fused to the paper, resulting in a durable, smudge-resistant print.

The fuser assembly typically consists of heated rollers that apply pressure to the paper as it passes through. These rollers work in tandem to melt the toner particles, ensuring that they adhere firmly to the paper fibers. As a result, the printed text and images become resistant to smudging and rubbing, providing a professional finish to every printout.

Whether it’s a laser printer or a copier, the fuser remains a critical element in the production of high-quality prints. Its ability to fuse toner to paper with precision and consistency is a testament to its indispensable role in the printing process.

Now that we’ve uncovered the basics of the fuser, let’s explore the intricate mechanisms behind its operation and understand how it brings your digital creations to life on paper.

How Does the Fuser Work?

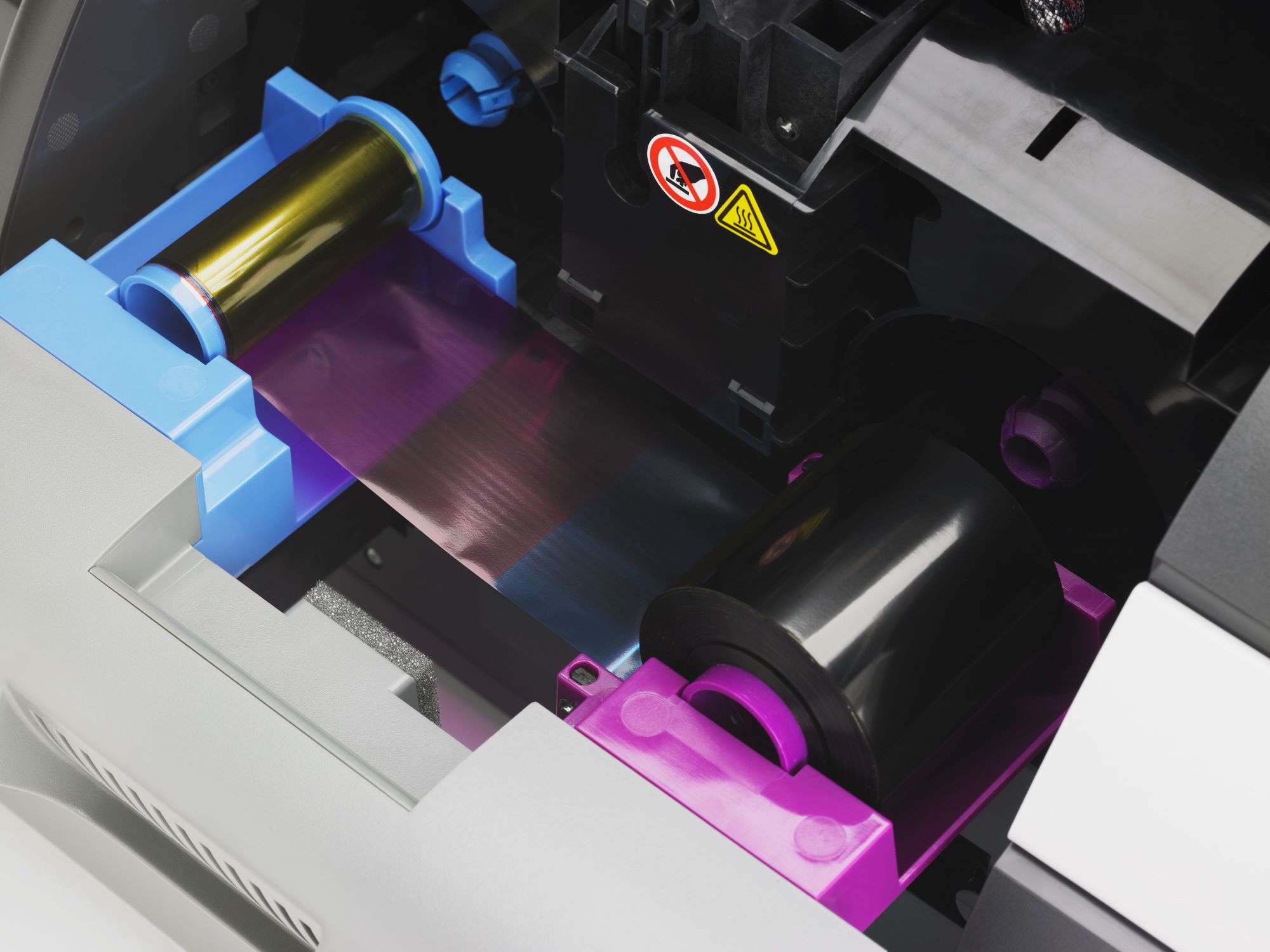

The fuser’s operation is a carefully orchestrated dance of heat, pressure, and precision. Once the paper, carrying the toner image, exits the printer’s imaging unit, it enters the fuser assembly. Here, the paper is guided between the fuser rollers, which are heated to a precise temperature.

As the paper passes through the fuser rollers, the heat softens the toner particles, allowing them to fuse with the paper fibers. The pressure exerted by the rollers ensures that the toner is firmly bonded to the paper, resulting in a permanent, smudge-resistant print.

It’s important to note that the fuser’s temperature must be carefully regulated to achieve optimal results. If the temperature is too low, the toner may not fuse properly, leading to smudging and poor print quality. Conversely, excessive heat can cause the paper to wrinkle or the toner to become glossy, compromising the integrity of the printout.

Modern printers are equipped with advanced sensors and heating elements that maintain the fuser at the ideal temperature for various paper types and print settings. This dynamic control ensures that the fuser adapts to different printing conditions, delivering consistent, high-quality results with every print job.

By understanding the inner workings of the fuser, we gain a deeper appreciation for the precision and engineering that goes into producing flawless prints. Now, let’s explore the different types of fusers that printers utilize to bring your documents and images to life.

Types of Fusers

Printers employ different types of fusers, each tailored to specific printing technologies and requirements. The two primary fuser types are heat roller fusers and xenon flash fusers.

Heat Roller Fusers: This type of fuser is commonly found in laser printers and copiers. It consists of a heated fuser roller and a pressure roller. As the paper carrying the toner passes between these rollers, the heat softens the toner particles, allowing them to adhere to the paper fibers. The pressure roller ensures that the toner is firmly fused to the paper, resulting in durable, high-quality prints. Heat roller fusers are known for their reliability and ability to produce consistent results across a wide range of print jobs.

Xenon Flash Fusers: Typically used in high-speed, production-grade printers, xenon flash fusers utilize intense bursts of light to fuse the toner to the paper. Unlike heat roller fusers, which rely on prolonged exposure to heat, xenon flash fusers rapidly heat the toner, achieving quick fusion without compromising print speed. This technology is favored for its efficiency in high-volume printing environments, where speed and precision are paramount.

While these are the primary types of fusers, advancements in printing technology continue to drive innovation in fuser design and performance. Manufacturers are constantly refining fuser technology to enhance print quality, energy efficiency, and overall printer reliability.

Understanding the different fuser types provides insight into the diverse mechanisms that power the printing industry. Now, let’s delve into the significance of the fuser in ensuring the exceptional quality of printed materials.

The fuser on a printer is a component that uses heat and pressure to permanently bond the toner to the paper, ensuring that the printout is smudge-proof and durable. If you’re experiencing print quality issues, the fuser may need to be replaced.

Importance of the Fuser in Printing

The fuser’s role in the printing process cannot be overstated. It serves as the final gateway through which every print job must pass, exerting a profound impact on the quality and durability of the output. Here are several key reasons why the fuser is indispensable in the world of printing:

- Quality Output: The fuser is instrumental in ensuring that the toner is securely fused to the paper, resulting in sharp, smudge-resistant prints with professional-grade clarity and detail. Without a properly functioning fuser, printouts may exhibit smudging, toner flaking, or poor adhesion, detracting from the overall quality.

- Durability: By permanently bonding the toner to the paper, the fuser enhances the durability of printed materials, allowing them to withstand handling, filing, and long-term storage without compromising the integrity of the prints.

- Consistency: A well-maintained fuser ensures consistent print quality across various print jobs, regardless of the paper type or print settings. This uniformity is essential for professional documents, marketing materials, and other printed materials that demand a polished, consistent appearance.

- Efficiency: The fuser’s ability to swiftly and reliably fuse toner to paper contributes to the overall efficiency of the printing process, allowing for rapid production of high-quality prints without sacrificing speed or accuracy.

- Professionalism: In business and professional settings, the fuser plays a critical role in upholding the professional image of printed materials. Whether it’s a client proposal, a marketing brochure, or a financial report, the fuser ensures that every printout reflects a level of quality befitting the intended audience.

By understanding the pivotal role of the fuser in printing, we gain a profound appreciation for the meticulous engineering and precision that underpin the production of every printed document. Now, let’s address some common fuser problems and explore effective solutions to ensure seamless printing operations.

Common Fuser Problems and Solutions

While the fuser is a stalwart component in the printing process, it is not immune to occasional issues that can impact print quality and overall performance. Here are some common fuser problems and effective solutions to address them:

- Smudging or Toner Flaking: If printouts exhibit smudging or toner flaking, it may indicate that the fuser is not reaching the optimal temperature. This can be resolved by allowing the printer to warm up before initiating print jobs, ensuring that the fuser reaches the required temperature for proper toner fusion.

- Wrinkled or Warped Paper: Excessive fuser heat or pressure can cause paper wrinkling or warping. Adjusting the printer settings to align with the paper type being used can alleviate this issue, ensuring that the fuser operates within the recommended parameters for the specific paper stock.

- Poor Adhesion: Inconsistent toner adhesion to the paper may result from a worn fuser roller. Replacing the fuser assembly, including the fuser roller, can restore proper toner fusion and improve print quality.

- Streaks or Lines on Prints: Streaks or lines on prints can indicate a damaged or dirty fuser roller. Regularly cleaning the fuser roller and ensuring that it is free from debris can help eliminate these imperfections, resulting in clean, flawless prints.

- Fuser Error Messages: If the printer displays fuser-related error messages, such as “Fuser Error” or “Replace Fuser,” it is advisable to follow the manufacturer’s recommendations for troubleshooting or replacing the fuser assembly. This ensures that the printer operates reliably and maintains print quality.

By promptly addressing these common fuser issues and implementing the corresponding solutions, users can optimize their printing experience and maintain consistent, high-quality output. Now, armed with a deeper understanding of the fuser’s significance and troubleshooting techniques, let’s conclude our exploration of this vital printing component.

Conclusion

As we conclude our journey into the realm of printing technology, we’ve gained a newfound appreciation for the unassuming yet indispensable fuser. This unassuming component, with its heated rollers and precision engineering, plays a pivotal role in ensuring that every printout emerges with clarity, durability, and professionalism.

The fuser’s ability to fuse toner to paper with unwavering precision and consistency is a testament to the intricate mechanisms that underpin the printing process. Whether it’s producing vital business documents, captivating marketing materials, or cherished personal creations, the fuser stands as the final arbiter of print quality, durability, and reliability.

By understanding the significance of the fuser and recognizing the common challenges that can arise, users can navigate the world of printing with confidence, armed with the knowledge to address issues and optimize their printing experience.

As printing technology continues to evolve, the fuser remains a steadfast cornerstone, ensuring that every print job meets the highest standards of quality and professionalism. So, the next time you marvel at a crisp, flawless printout, take a moment to acknowledge the unsung hero behind the scenes: the fuser.

With this newfound insight into the fuser’s role and operation, we invite you to embark on your printing endeavors with a deeper understanding of the meticulous processes that transform digital creations into tangible, lasting documents. Happy printing!

Frequently Asked Questions about What Is The Fuser On A Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Fuser On A Printer”