Home>Technology>Smart Home Devices>What Printer Do I Need To Make Shirts

Smart Home Devices

What Printer Do I Need To Make Shirts

Modified: March 14, 2024

Looking for the perfect printer for creating custom shirts? Discover the best options for smart home devices to bring your designs to life. Unlock the potential of your creativity today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Are you considering venturing into the world of custom shirt printing? Whether you're an aspiring entrepreneur or a creative individual looking to personalize your wardrobe, having the right printer is crucial for achieving high-quality results. In this comprehensive guide, we'll explore the various types of printers suitable for making shirts, delve into the essential factors to consider when choosing a printer, and provide valuable insights to help you make an informed decision. Let's embark on this exciting journey to uncover the perfect printing solution for your shirt-making endeavors!

**

Key Takeaways:

- Choose the right printer for shirt-making based on fabric compatibility, print quality, and production volume to unleash your creativity and bring your unique designs to life with confidence and efficiency.

- Consider factors such as printing technology, cost of operation, and user-friendliness when selecting a printer for shirt-making to ensure vibrant color reproduction, intricate design detailing, and high-speed production capabilities for your custom shirt projects.

Types of Printers for Making Shirts

**

When it comes to creating custom shirts, having the right printer can significantly impact the quality and durability of the prints. Here are some of the most popular types of printers used for making shirts:

1. Inkjet Printers:

Inkjet printers are widely used for shirt printing due to their versatility and ability to produce vibrant, detailed designs. These printers are capable of handling various types of specialty inks, including pigment and dye-based inks, making them suitable for different fabric materials. Additionally, inkjet printers are relatively affordable and can accommodate different shirt sizes, making them a popular choice for small-scale shirt printing projects.

2. Laser Printers:

Laser printers are known for their speed and precision, making them a preferred choice for high-volume shirt printing. While they are not as commonly used for fabric printing as inkjet printers, advancements in laser transfer technology have made it possible to use laser printers for creating durable and professional-looking shirt designs. Laser printers are ideal for producing intricate designs and detailed graphics on shirts, offering a level of crispness and clarity that is difficult to achieve with other printing methods.

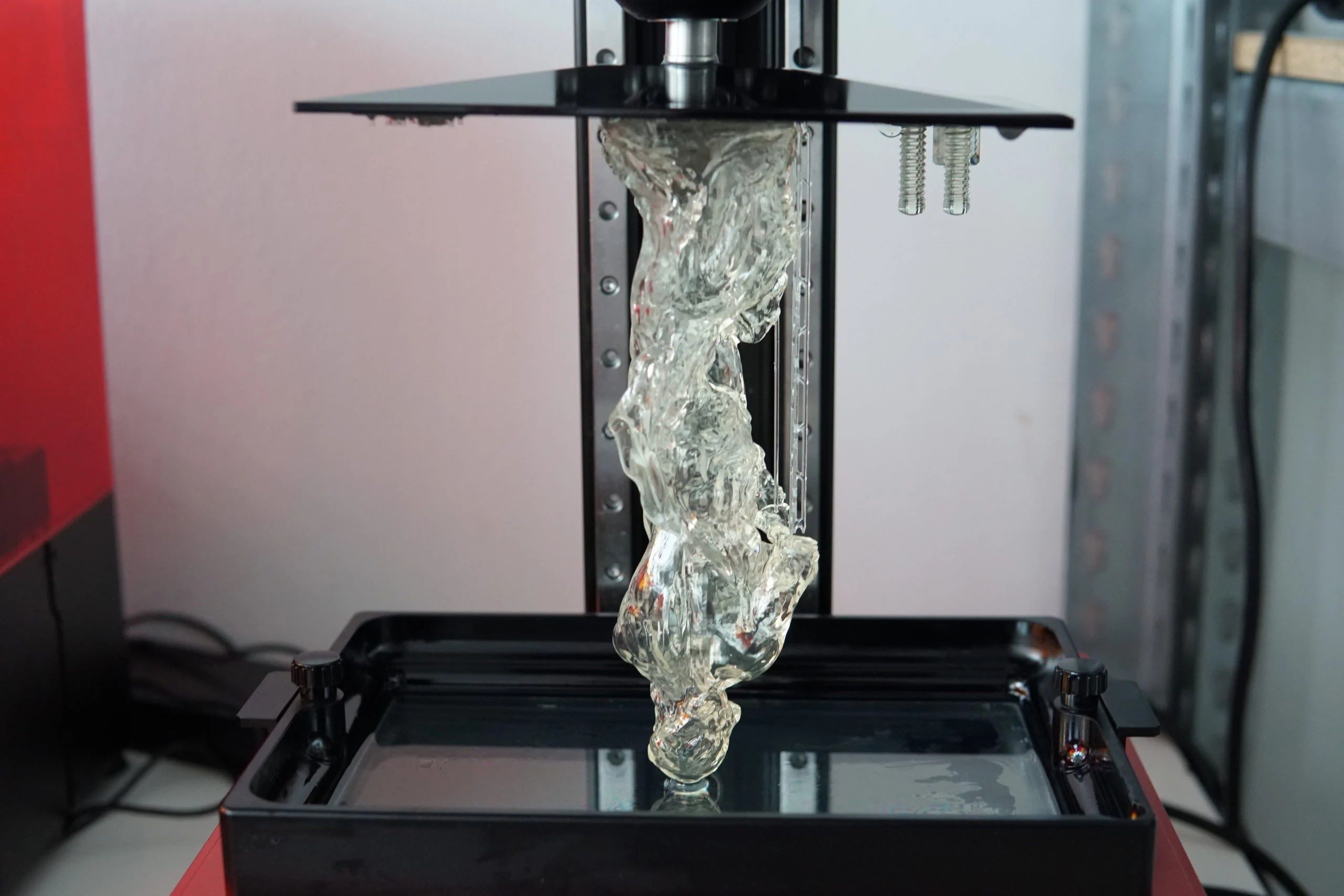

3. Dye Sublimation Printers:

Dye sublimation printers are specifically designed for transferring designs onto fabrics, making them an excellent choice for shirt printing. These printers use heat to transfer dye onto the fabric, resulting in vibrant and long-lasting prints. Dye sublimation printing is known for its ability to produce photo-quality images and intricate designs, making it a popular option for creating custom shirts with high-definition graphics and vivid colors.

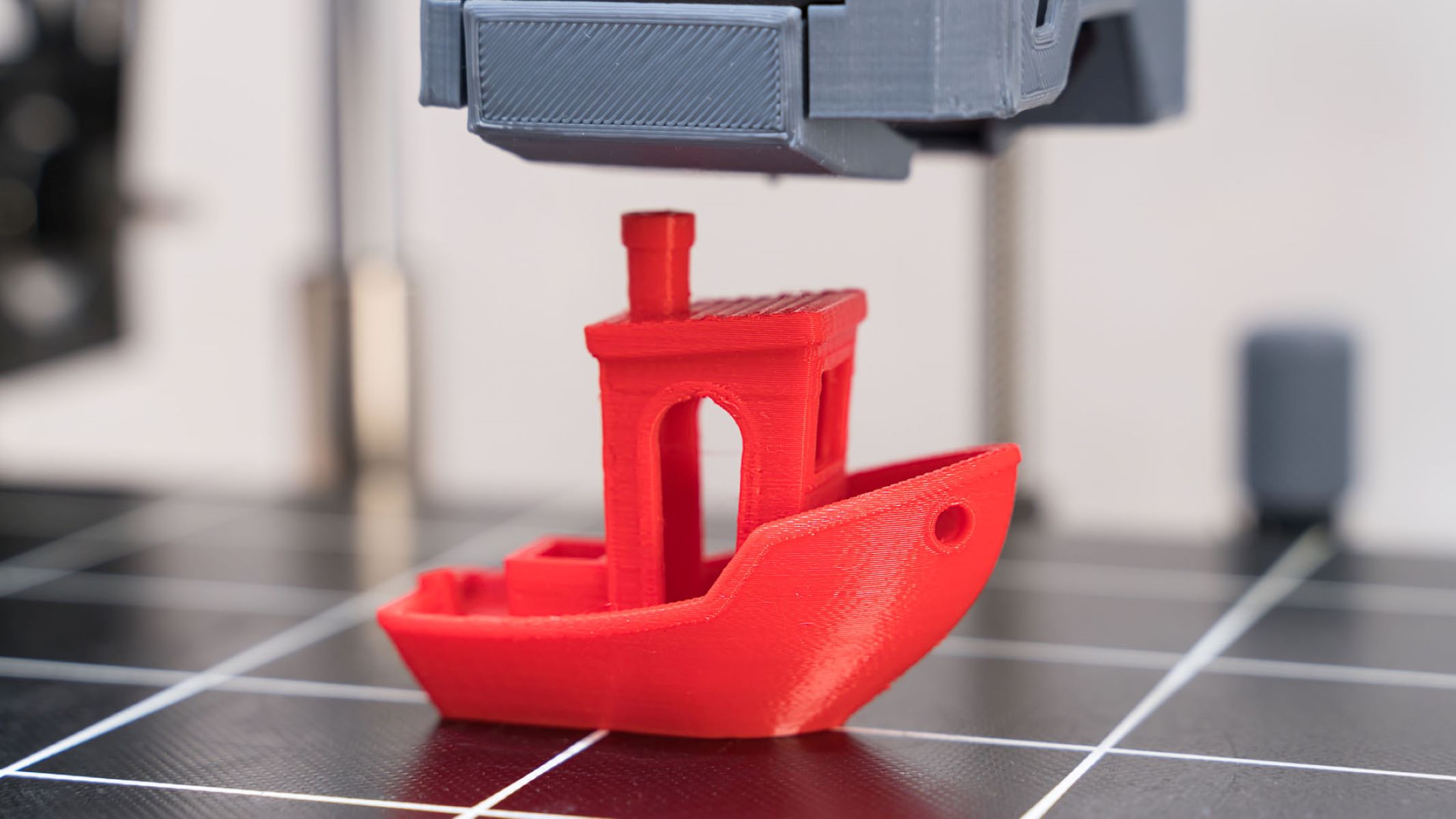

4. Direct-to-Garment (DTG) Printers:

DTG printers are designed to print directly onto garments, including shirts, using specialized textile inks. These printers are capable of producing detailed and multicolored designs with exceptional precision, making them an ideal choice for creating custom shirts with complex artwork and vibrant color gradients. DTG printing is known for its ability to produce soft, breathable prints that seamlessly integrate with the fabric, resulting in a comfortable and long-lasting finish.

5. Screen Printing Equipment:

While not a traditional printer, screen printing equipment is widely used for creating custom shirts in bulk. This method involves using a stencil or screen to transfer ink onto the fabric, resulting in durable and vibrant prints. Screen printing is particularly suitable for large-scale shirt production and is often chosen for creating designs that require opaque or metallic inks, as well as for achieving a textured or raised effect on the printed designs.

Each type of printer offers unique capabilities and advantages, allowing you to choose the most suitable option based on your specific shirt printing requirements. Whether you prioritize speed, color vibrancy, or intricate design reproduction, there is a printer type tailored to meet your custom shirt printing needs.

**

You will need a heat transfer or sublimation printer to make shirts. These printers can transfer designs onto fabric using heat and special ink.

Factors to Consider When Choosing a Printer

**

When selecting a printer for making shirts, several crucial factors should be taken into account to ensure that the chosen printer aligns with your specific printing needs. Here are the key considerations to keep in mind:

1. Printing Technology:

Understand the printing technology employed by the printer, whether it utilizes inkjet, laser, dye sublimation, or direct-to-garment (DTG) printing. Each technology offers distinct advantages in terms of color vibrancy, print durability, and suitability for different fabric types.

2. Print Quality and Durability:

Evaluate the print quality and durability offered by the printer. Look for printers capable of producing high-resolution prints with vibrant colors and excellent wash-fastness, ensuring that your custom shirts maintain their visual appeal after multiple wash cycles.

3. Fabric Compatibility:

Consider the types of fabrics the printer can accommodate. Some printers are optimized for cotton blends, while others are suitable for a wider range of materials, including synthetic fabrics and blends. Ensure that the printer can handle the specific fabric types you intend to use for your custom shirts.

4. Production Volume:

Determine the production volume you anticipate for your shirt printing projects. If you plan to produce shirts in large quantities, a printer capable of high-speed and high-capacity printing would be essential to meet your production demands efficiently.

5. Cost of Operation:

Consider the overall cost of operation, including ink or toner expenses, maintenance requirements, and energy consumption. Opt for a printer that strikes a balance between initial investment and long-term operational costs, ensuring cost-effectiveness over time.

6. Software and Compatibility:

Assess the compatibility of the printer with design software and operating systems. Ensure that the printer seamlessly integrates with your preferred design applications and supports the file formats commonly used for creating custom shirt designs.

7. User-Friendliness and Support:

Evaluate the user-friendliness of the printer, including its interface, setup process, and maintenance procedures. Additionally, consider the availability of technical support, warranty coverage, and access to resources such as online tutorials or user communities for troubleshooting and guidance.

8. Space and Setup Requirements:

Take into account the physical footprint and setup requirements of the printer. Depending on your available space and workspace configuration, choose a printer that fits comfortably within your production environment and aligns with your setup preferences.

By carefully considering these factors, you can make an informed decision when choosing a printer for making shirts, ensuring that the selected printer meets your specific printing goals and delivers the quality and performance required for your custom shirt projects.

**

Conclusion

**

Embarking on the journey of creating custom shirts is an exciting endeavor, and selecting the right printer is a pivotal step towards achieving stunning and durable shirt designs. Whether you aspire to launch a shirt printing business or simply want to unleash your creativity through personalized shirt creations, the diverse range of printers available offers a multitude of options to cater to your unique printing needs.

From the versatility of inkjet printers to the precision of laser printers, the photo-quality output of dye sublimation printers, the intricate detailing of direct-to-garment (DTG) printers, and the efficiency of screen printing equipment, there is a printer type suited for every printing requirement and preference.

When choosing a printer for making shirts, it’s essential to consider factors such as printing technology, print quality and durability, fabric compatibility, production volume, cost of operation, software compatibility, user-friendliness, and space requirements. By carefully evaluating these factors, you can make an informed decision that aligns with your specific printing goals and budget.

Ultimately, the chosen printer should empower you to unleash your creativity, produce visually captivating shirt designs, and bring your custom shirt projects to life with confidence and efficiency. Whether you prioritize vibrant color reproduction, intricate design detailing, or high-speed production capabilities, the right printer will serve as a valuable tool in transforming your shirt printing visions into tangible and impressive creations.

As you embark on your custom shirt printing journey, may the insights shared in this guide empower you to make a well-informed decision, leading you to the perfect printer that elevates the quality and creativity of your shirt-making endeavors. Embrace the artistry of shirt printing, and let your chosen printer be the catalyst for bringing your unique shirt designs to fruition with excellence and distinction.

Frequently Asked Questions about What Printer Do I Need To Make Shirts

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Printer Do I Need To Make Shirts”