Home>Technology>Smart Home Devices>What Do I Need For A Resin 3D Printer

Smart Home Devices

What Do I Need For A Resin 3D Printer

Modified: January 24, 2024

Discover the essential tools and accessories needed for a resin 3D printer to create high-quality smart home devices and prototypes. Explore the must-have items for successful resin printing.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Are you ready to embark on an exciting journey into the world of resin 3D printing? If so, you've come to the right place! In this comprehensive guide, we'll explore everything you need to know about setting up a resin 3D printing workspace. Whether you're a hobbyist, a DIY enthusiast, or a professional looking to expand your creative horizons, understanding the essential equipment, additional supplies, and workspace setup is crucial for achieving stunning results.

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP) printing, offers unparalleled precision and detail, making it a popular choice for creating intricate models, prototypes, and artistic designs. However, to unleash the full potential of this cutting-edge technology, it's essential to have the right tools and environment in place.

In the following sections, we'll delve into the basics of resin 3D printing, explore the essential equipment required for a successful setup, discuss additional supplies that can enhance your printing experience, and provide valuable insights into creating an optimal workspace. By the end of this guide, you'll be well-equipped to dive into the captivating world of resin 3D printing with confidence and enthusiasm.

So, let's roll up our sleeves and embark on this enlightening journey, where creativity meets technology, and imagination knows no bounds. Get ready to uncover the key components, essential knowledge, and practical tips that will empower you to bring your 3D printing dreams to life. It's time to unleash your creativity and embrace the endless possibilities offered by resin 3D printing!

**

Key Takeaways:

- Resin 3D printing requires essential equipment like resin, a 3D printer, UV light source, and protective gear for safety. Understanding the process and setting up a well-ventilated workspace are crucial for successful printing.

- In addition to essential equipment, cleaning tools, post-curing equipment, a reliable resin vat, and a well-designed build platform are necessary for optimal resin 3D printing. Prioritizing ventilation, lighting, and organization in the workspace is key for a successful printing experience.

Read more: What Do I Need For A 3D Printer

Resin 3D Printer Basics

**

Before diving into the intricate details of setting up a resin 3D printing workspace, it's essential to grasp the fundamental concepts behind this innovative technology. So, what exactly is a resin 3D printer, and how does it work?

What is a resin 3D printer?

A resin 3D printer, also known as a stereolithography (SLA) or digital light processing (DLP) printer, is a cutting-edge additive manufacturing device that utilizes liquid resin as the raw material to create three-dimensional objects with exceptional precision and detail. Unlike traditional filament-based 3D printers, which rely on layering molten plastic to build objects, resin 3D printers employ a photopolymer resin that solidifies when exposed to a specific wavelength of light, typically ultraviolet (UV) light.

These printers are renowned for their ability to produce high-resolution prints with smooth surfaces, intricate details, and fine features, making them ideal for applications that demand exceptional accuracy and aesthetic quality. Whether you're crafting miniature figurines, architectural models, jewelry prototypes, or intricate components, a resin 3D printer offers the precision and versatility to bring your designs to life with stunning realism.

How does a resin 3D printer work?

The operation of a resin 3D printer revolves around a process known as photopolymerization, where the liquid resin undergoes a transformation from a liquid state to a solid state under the influence of UV light. Here's a simplified overview of the key steps involved in the resin 3D printing process:

1. Preparation of the 3D Model:

Before initiating the printing process, a digital 3D model of the desired object is prepared using computer-aided design (CAD) software. This digital model serves as the blueprint for the physical object that will be created layer by layer.

2. Slicing the Model:

The digital model is sliced into thin horizontal layers using slicing software, which generates a series of 2D cross-sectional images representing the individual layers that will be printed sequentially.

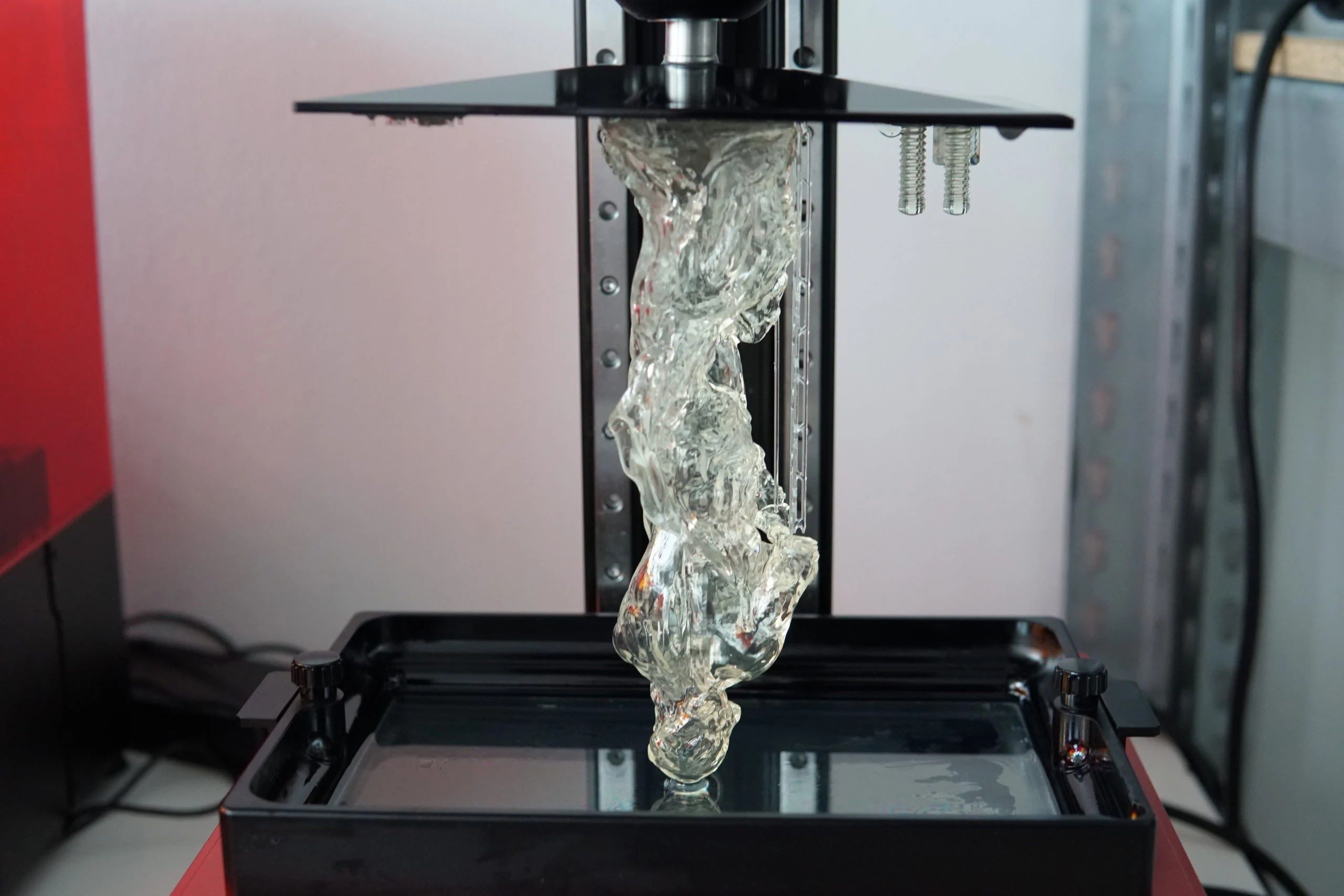

3. Printing the Layers:

Once the slicing process is complete, the resin 3D printer begins the printing operation. The build platform descends into the resin tank, and a UV light source selectively cures the resin in accordance with the cross-sectional image of the first layer. This process is repeated for each subsequent layer, gradually building the object from the bottom up.

4. Post-Processing:

After the printing is finished, the object is carefully removed from the build platform and undergoes post-processing steps such as cleaning, support removal, and post-curing to finalize its physical properties and surface finish.

By understanding the underlying principles of resin 3D printing and the intricate process through which objects are created, you'll gain a deeper appreciation for the technology and its potential to bring your creative visions to life with unparalleled precision and detail.

**

Essential Equipment

**

Now that we've delved into the foundational aspects of resin 3D printing, it's time to explore the essential equipment that forms the backbone of a successful resin printing setup. From the crucial raw material to the cutting-edge printing device and the protective gear that ensures safety, each component plays a pivotal role in achieving exceptional results.

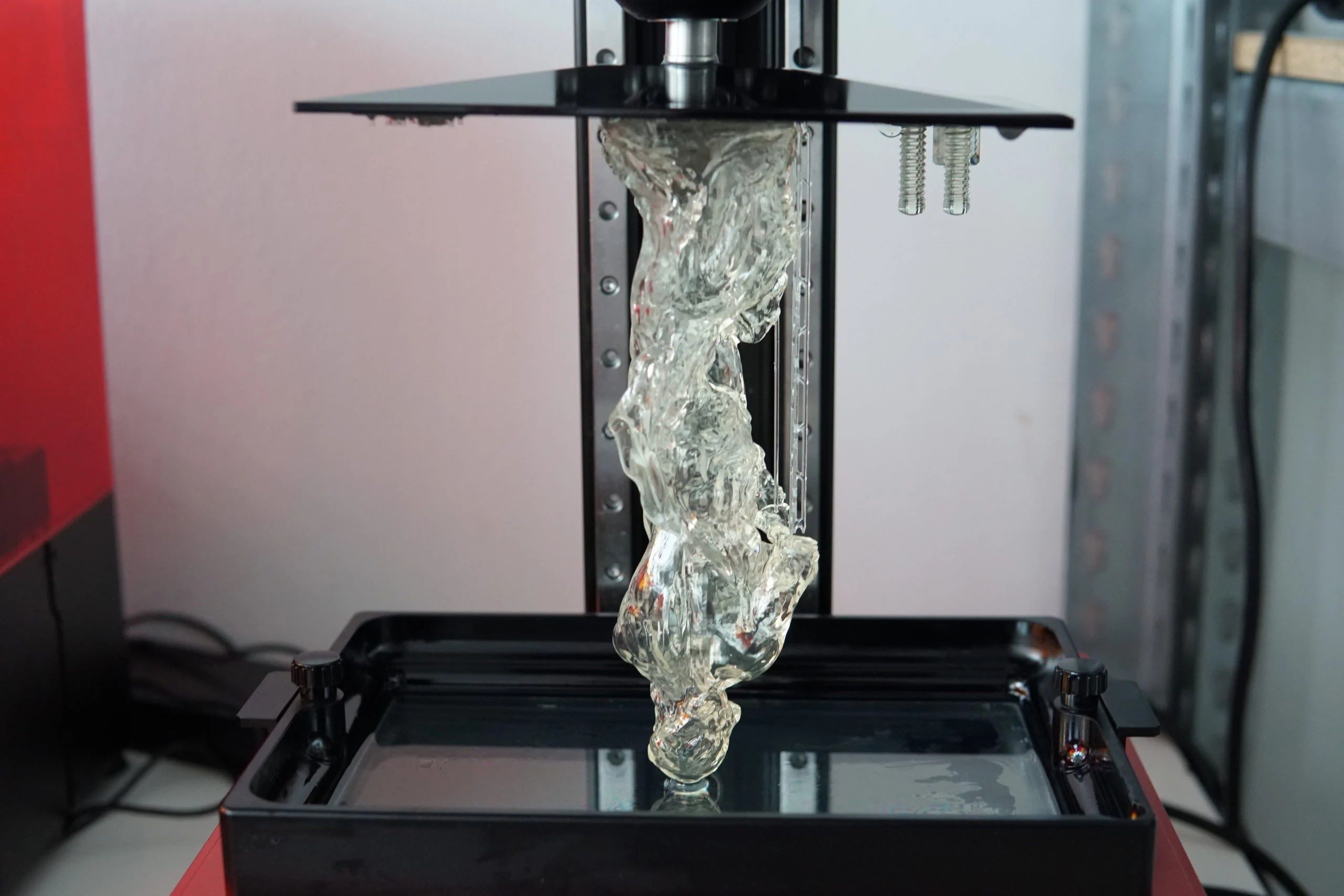

Resin:

At the heart of every resin 3D printing endeavor lies the resin itself. This photopolymer liquid serves as the raw material from which your three-dimensional creations will emerge. When selecting a resin, consider factors such as color, transparency, flexibility, and the specific properties required for your intended applications. Whether you opt for standard resins, castable resins for jewelry making, or specialized engineering resins with high durability, choosing the right resin is paramount for achieving the desired characteristics in your printed objects.

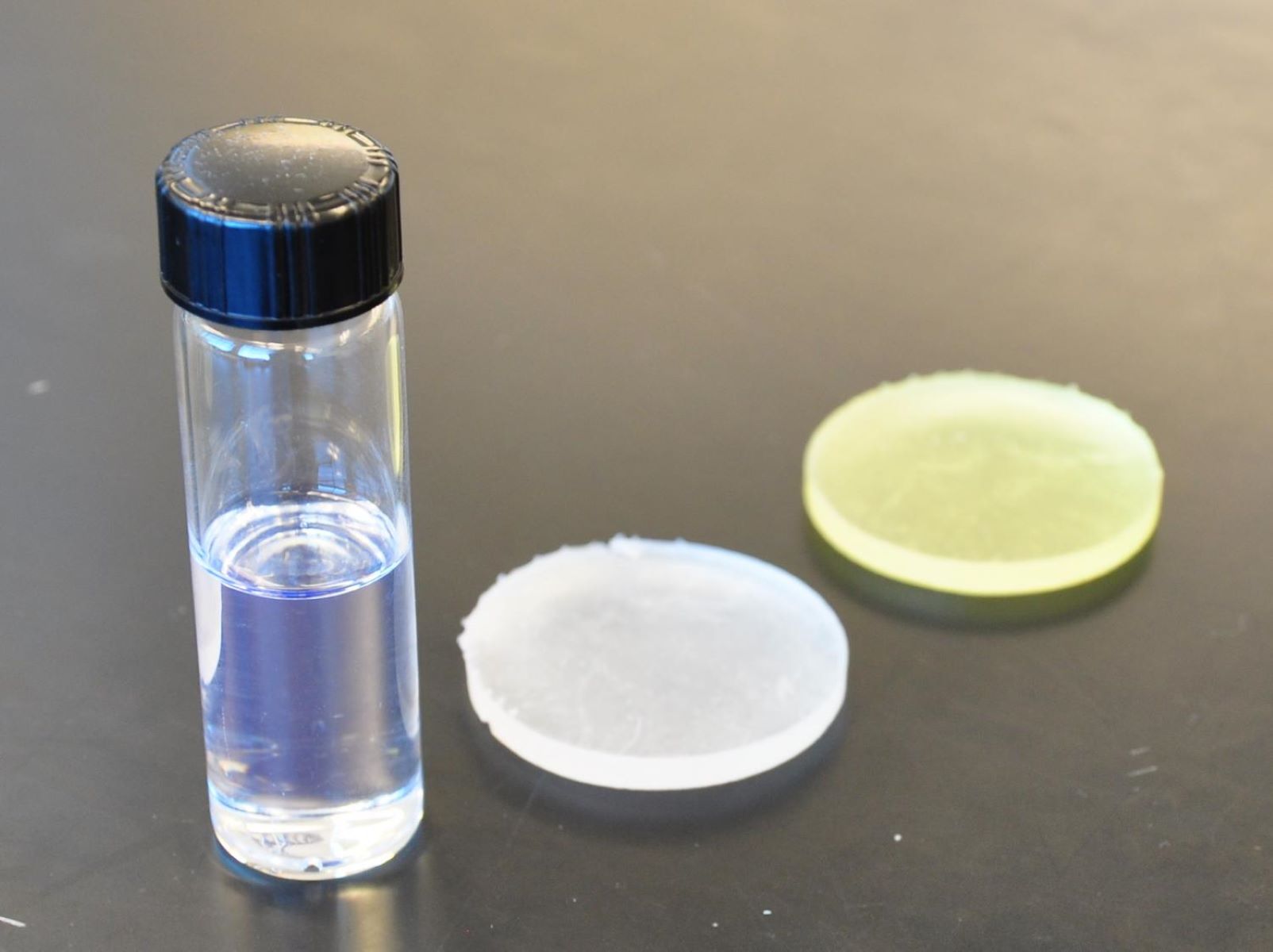

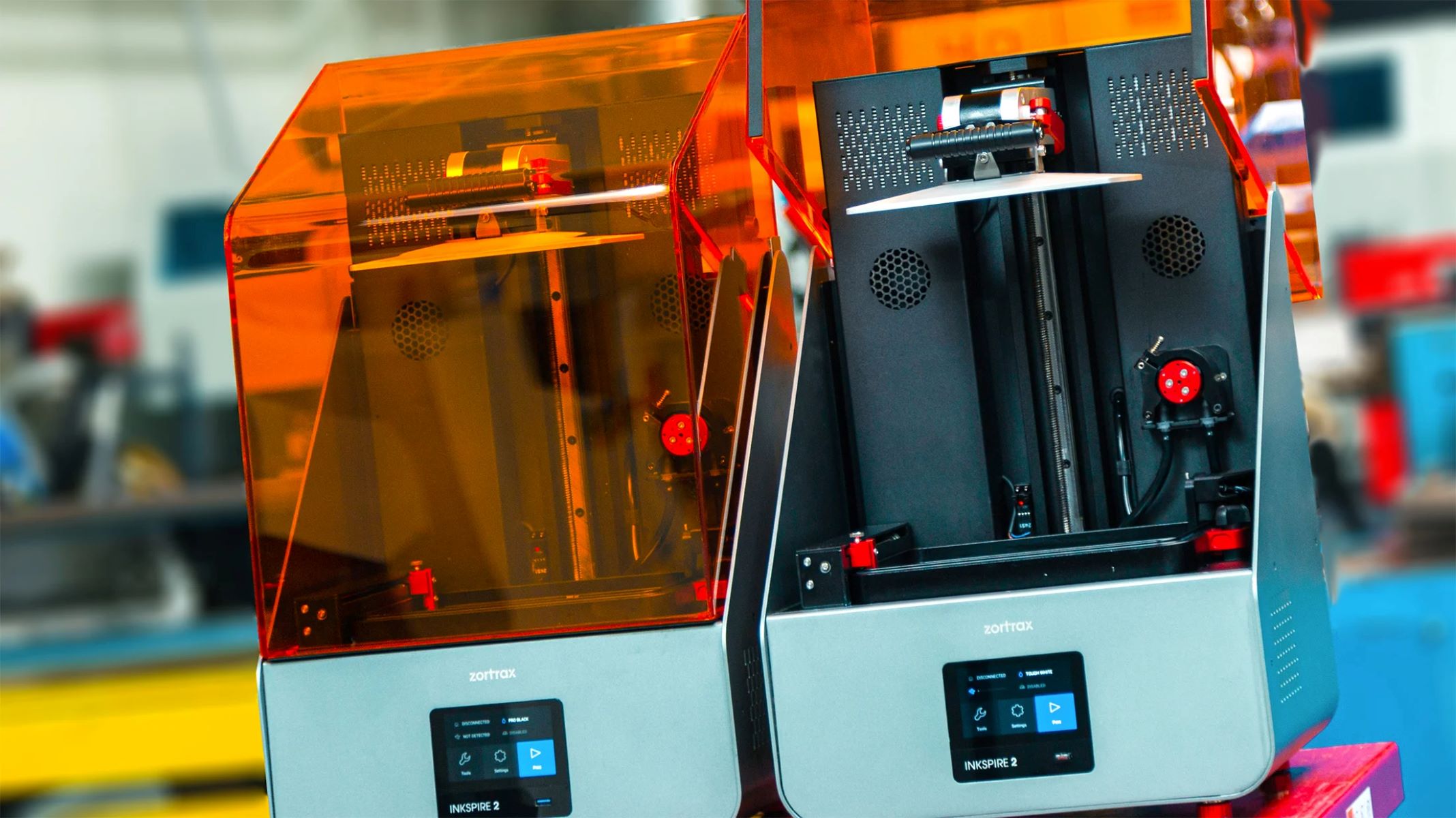

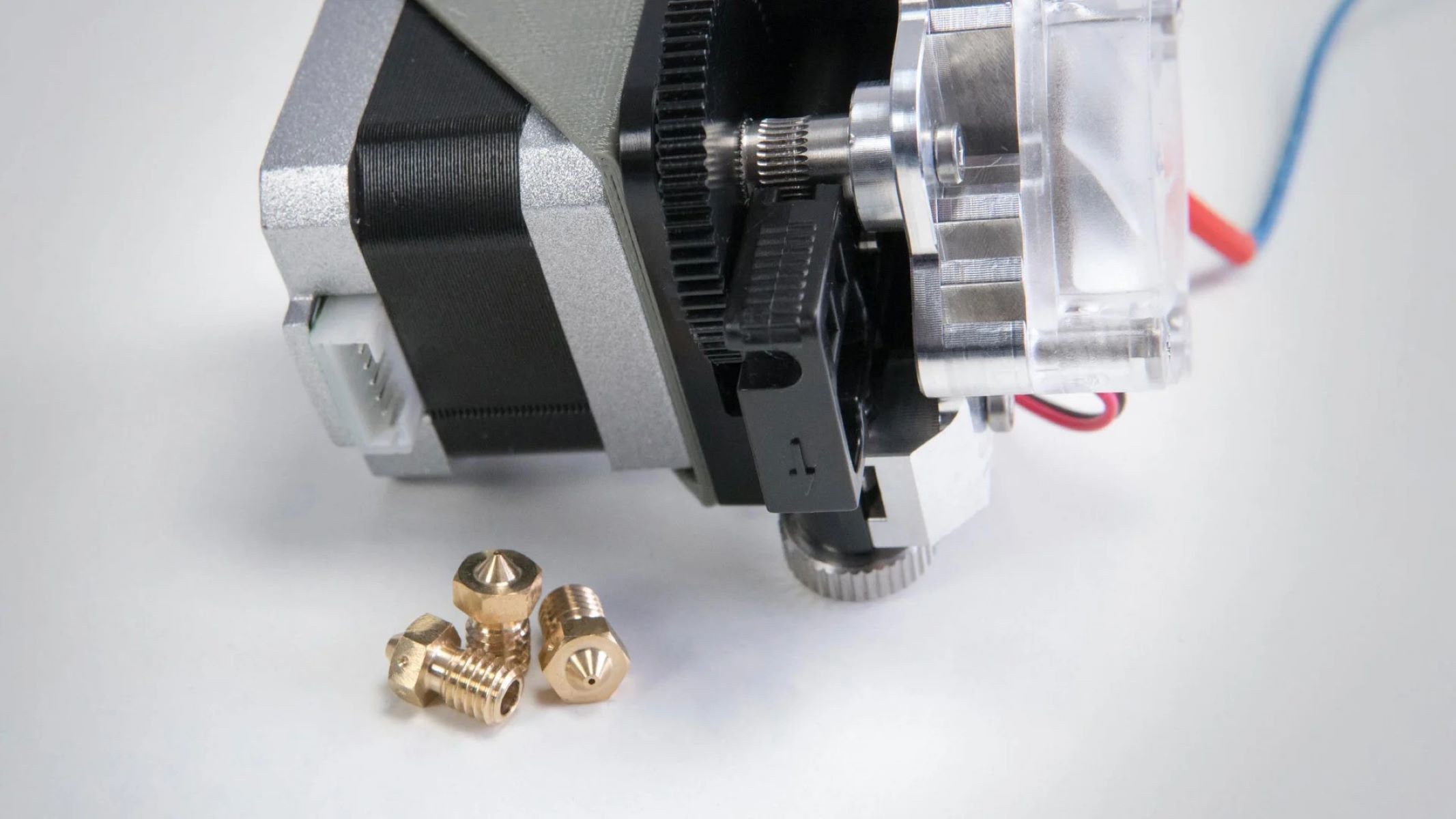

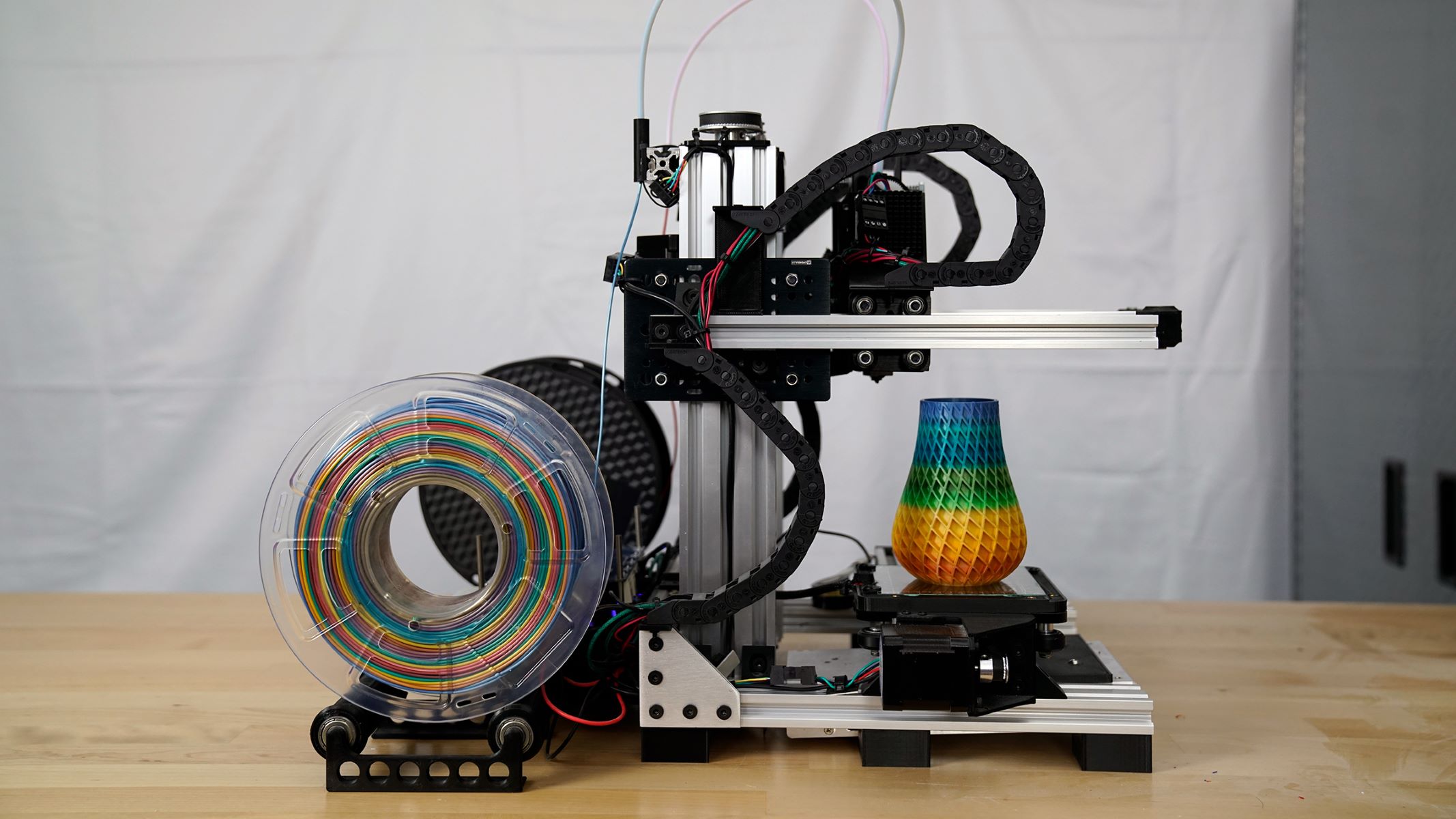

3D Printer:

The 3D printer itself is the central piece of hardware that brings your digital designs to life. When choosing a resin 3D printer, factors such as build volume, resolution, printing speed, and ease of use should be taken into account. Whether you opt for a compact desktop printer for small-scale projects or a professional-grade machine for larger, high-detail prints, selecting a 3D printer that aligns with your specific requirements is essential for achieving optimal results.

UV Light Source:

Since resin 3D printing relies on the selective curing of liquid resin using ultraviolet (UV) light, a reliable UV light source is indispensable for the printing process. Most resin printers are equipped with built-in UV light arrays or projectors that emit the specific wavelength of light required to solidify the resin. Ensuring that your printer's UV light source is functioning optimally and is calibrated for the specific resin being used is crucial for achieving consistent and accurate curing throughout the printing process.

Protective Gear:

When working with resin and operating a 3D printer, prioritizing safety is paramount. Protective gear such as nitrile gloves, safety goggles, and a lab coat or apron serves as a barrier against potential exposure to uncured resin and ensures a safe working environment. Additionally, having a well-ventilated workspace and following proper handling and disposal protocols for resin and cleaning solvents further enhances safety and minimizes health risks associated with resin 3D printing.

By equipping yourself with high-quality resin, a reliable 3D printer, a functional UV light source, and the necessary protective gear, you'll lay a solid foundation for a successful resin 3D printing setup. These essential components form the core infrastructure that empowers you to unleash your creativity and bring your designs to life with precision and finesse.

**

When using a resin 3D printer, make sure to have proper ventilation in the workspace to avoid inhaling fumes. Wear gloves and eye protection when handling resin to protect your skin and eyes.

Additional Supplies

**

While the essential equipment forms the cornerstone of a resin 3D printing setup, additional supplies play a vital role in enhancing the printing process, ensuring optimal print quality, and streamlining post-processing tasks. From cleaning tools that maintain the pristine condition of your printer to post-curing equipment that finalizes the physical properties of your prints, each supplementary item contributes to a seamless and efficient printing experience.

Cleaning Tools:

Keeping your resin 3D printer and its components clean is essential for consistent print quality and prolonged equipment lifespan. Cleaning tools such as isopropyl alcohol (IPA) for resin tank cleaning, lint-free cloths for wiping surfaces, and soft-bristled brushes for delicate cleaning tasks are indispensable for maintaining the cleanliness and functionality of your printer. Additionally, having a designated area for post-print cleaning and a well-organized cleaning kit streamlines the maintenance process and ensures that your printer remains in optimal condition.

Post-Curing Equipment:

Post-curing, the process of exposing printed objects to additional UV light to finalize their physical properties and enhance their strength and durability, is a crucial step in resin 3D printing. Post-curing equipment, such as UV curing chambers or curing stations equipped with high-intensity UV light sources, facilitates the post-processing phase and ensures that your prints achieve the desired mechanical and aesthetic characteristics. By investing in reliable post-curing equipment, you can elevate the quality and performance of your printed objects, making them suitable for a wide range of applications.

Resin Vat:

The resin vat, also known as the resin tank or reservoir, is a key component of the 3D printer that holds the liquid resin during the printing process. A high-quality resin vat with a durable, optically clear bottom ensures consistent resin distribution, minimizes the risk of leaks or spills, and facilitates easy resin replacement and maintenance. Additionally, some resin vats feature innovative design elements, such as transparent windows for monitoring resin levels and integrated stirring mechanisms for optimal resin homogeneity, further enhancing the overall printing experience.

Build Platform:

The build platform, the surface on which prints are constructed layer by layer, plays a critical role in ensuring print adhesion, dimensional accuracy, and stability throughout the printing process. A well-designed build platform with adjustable leveling, robust adhesion mechanisms such as perforated build plates or textured surfaces, and compatibility with various print geometries and sizes is essential for achieving successful prints with minimal warping or detachment issues. Investing in a reliable build platform that aligns with your specific printing needs is integral to achieving consistent and high-quality results.

By incorporating essential cleaning tools, post-curing equipment, a reliable resin vat, and a well-engineered build platform into your resin 3D printing setup, you can optimize the printing process, maintain equipment integrity, and ensure that your printed objects meet the highest standards of quality and performance. These additional supplies complement the core equipment, elevating your resin printing endeavors to new levels of precision and excellence.

**

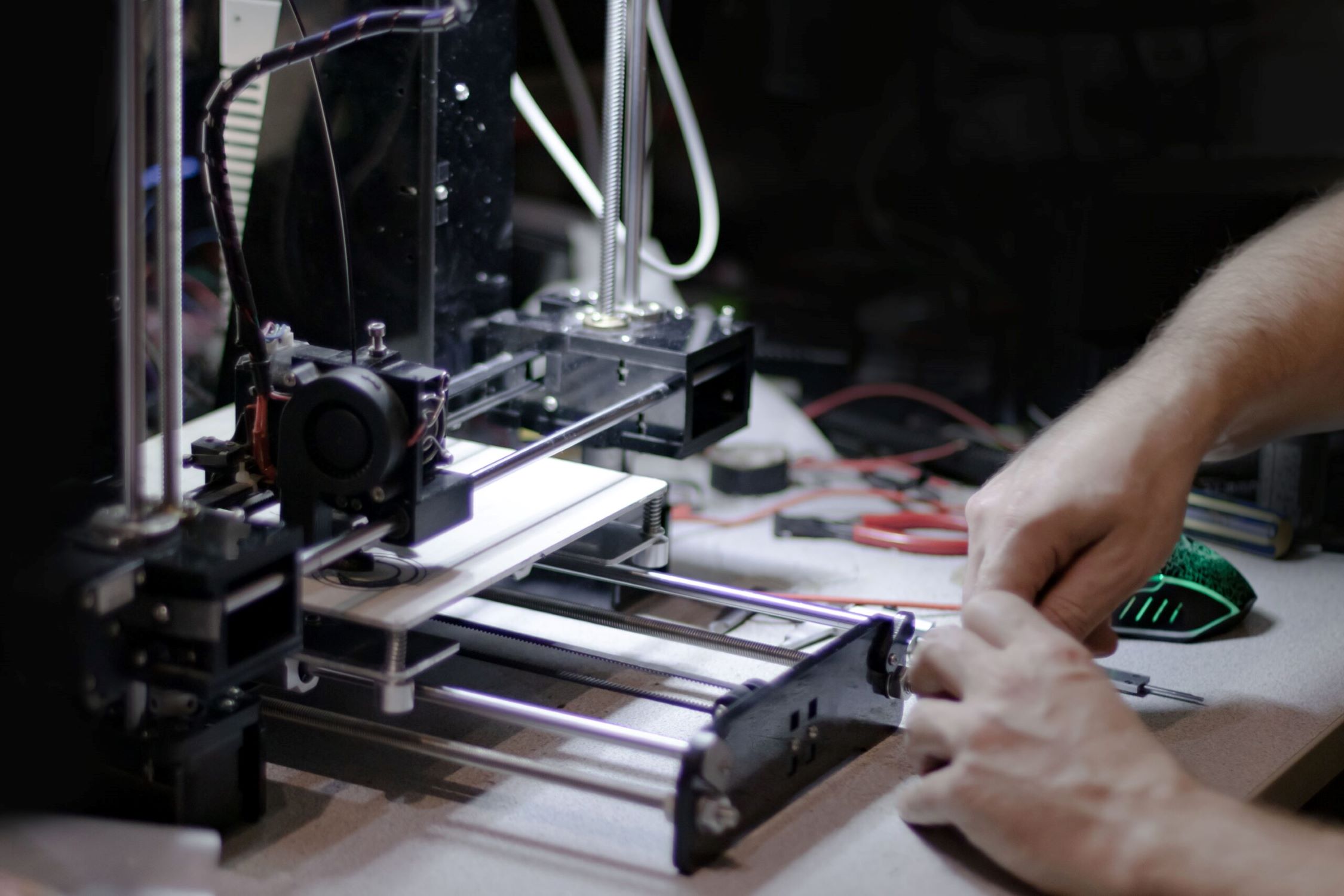

Workspace Setup

**

Creating an optimal workspace for resin 3D printing is essential for ensuring safety, efficiency, and the overall quality of your printing endeavors. From adequate ventilation that mitigates resin fumes to well-planned lighting and organized storage solutions, each aspect of the workspace contributes to a conducive environment for successful resin printing.

Ventilation:

Proper ventilation is a critical consideration when setting up a resin 3D printing workspace. Since resin printing involves the use of liquid resin and the potential release of fumes during the printing and post-curing processes, ensuring adequate ventilation is essential for maintaining air quality and minimizing exposure to potentially harmful airborne particles. Setting up the workspace in a well-ventilated area, using dedicated ventilation systems such as fume extractors or air purifiers with activated carbon filters, and adhering to recommended safety protocols for handling resin and cleaning solvents are essential for creating a safe and healthy working environment.

Lighting:

Effective lighting is crucial for maintaining visibility, precision, and overall comfort within the resin printing workspace. Adequate ambient lighting, supplemented by task lighting focused on the 3D printer and post-processing areas, ensures that intricate details are clearly visible during printing, inspection, and post-curing tasks. Additionally, positioning lighting sources to minimize glare on resin tanks and printed objects, as well as incorporating adjustable lighting options for different stages of the printing process, enhances the overall functionality and visual clarity within the workspace.

Storage:

Organized storage solutions are essential for maintaining a tidy, efficient, and safe resin 3D printing workspace. Proper storage of resin bottles, cleaning solvents, spare parts, tools, and consumables not only minimizes clutter but also reduces the risk of accidents and ensures that essential items are readily accessible. Utilizing storage containers, shelving units, and labeling systems for different categories of supplies and equipment streamlines workflow, facilitates inventory management, and promotes a well-structured and productive workspace environment.

By prioritizing adequate ventilation, effective lighting, and organized storage within your resin 3D printing workspace, you can create an environment that fosters safety, efficiency, and productivity. These foundational elements form the framework for a workspace that supports the intricate processes of resin printing, post-processing, and maintenance, ultimately enhancing the overall printing experience and the quality of your printed creations.

**

Read more: What Is A Resin 3D Printer

Conclusion

**

As we conclude this comprehensive guide to setting up a resin 3D printing workspace, it’s evident that the world of resin 3D printing is a captivating realm where creativity, technology, and craftsmanship converge to bring innovative designs to life. By exploring the resin 3D printer basics, essential equipment, additional supplies, and workspace setup, we’ve gained valuable insights into the key components and considerations that form the foundation of a successful resin printing endeavor.

From understanding the intricate process through which resin 3D printers bring digital designs to physical reality to equipping ourselves with essential tools, protective gear, and supplementary supplies, we’ve uncovered the essential elements that contribute to a seamless and rewarding resin printing experience. Whether you’re a hobbyist seeking to unleash your creative visions, an entrepreneur exploring rapid prototyping solutions, or an artist pushing the boundaries of design, the knowledge and practical tips shared in this guide empower you to embark on your resin 3D printing journey with confidence and enthusiasm.

By embracing the principles of safety, precision, and innovation, and by cultivating a workspace that prioritizes ventilation, lighting, and organization, you’re poised to unlock the full potential of resin 3D printing. The fusion of cutting-edge technology, meticulous craftsmanship, and boundless creativity awaits as you embark on this remarkable venture, where each print embodies the culmination of your vision and expertise.

As you set out to establish your resin 3D printing workspace, remember that the journey is as enriching as the destination. Embrace the learning process, celebrate the moments of discovery, and revel in the transformative power of bringing digital designs to life in three-dimensional form. With each print, you’re not merely creating objects; you’re sculpting possibilities, shaping innovations, and crafting narratives that transcend the boundaries of imagination.

So, as you prepare to embark on this enlightening journey, armed with knowledge, passion, and a steadfast commitment to excellence, remember that the world of resin 3D printing beckons with endless opportunities for creativity, ingenuity, and exploration. Seize the moment, unleash your imagination, and let the resin 3D printer be the conduit through which your visions materialize into tangible works of art, innovation, and inspiration.

Now, with the essential knowledge and insights at your fingertips, it’s time to step into the realm of resin 3D printing and witness the extraordinary transformations that await. Embrace the journey, cherish the process, and revel in the remarkable creations that emerge from the synergy of technology, artistry, and boundless imagination.

Frequently Asked Questions about What Do I Need For A Resin 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Do I Need For A Resin 3D Printer”