Home>Technology>Smart Home Devices>Which Way Do You Put Labels Into Printer

Smart Home Devices

Which Way Do You Put Labels Into Printer

Modified: February 18, 2024

Discover the best way to insert labels into your printer for smart home devices. Learn the correct orientation for seamless printing and labeling.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the realm of printing, the placement of labels is a crucial consideration that can significantly impact the quality and efficiency of the printing process. Whether you're utilizing a traditional inkjet printer or a cutting-edge thermal label printer, understanding the optimal label placement is essential for achieving optimal results.

When it comes to label placement in printers, various factors come into play, including the type of printer being used and the specific requirements of the labeling task at hand. By delving into the nuances of label placement, we can uncover the best practices for ensuring seamless printing experiences and high-quality output.

In this comprehensive guide, we will explore the diverse types of printers commonly employed for label printing, delve into the intricacies of label placement within these devices, and elucidate the best practices for achieving optimal label placement. Whether you're a seasoned printing professional or a novice seeking to enhance your printing prowess, this guide is designed to equip you with the knowledge and insights needed to navigate the world of label placement in printers with confidence and proficiency.

Join us on this enlightening journey as we unravel the mysteries of label placement in printers, empowering you to harness the full potential of your printing endeavors.

Key Takeaways:

- Proper label placement in printers is crucial for achieving high-quality and professional-looking output. It involves aligning label stock correctly, inspecting for imperfections, and maintaining printer settings and components.

- By following best practices for label placement, such as proper alignment, inspection, and test printing, you can streamline operations and ensure consistent, visually appealing printed labels for various applications.

Types of Printers

Printers come in a variety of types, each offering unique functionalities and applications. When it comes to label printing, several types of printers are commonly utilized, each with its own set of advantages and considerations. Understanding the distinctions between these printer types is essential for determining the most suitable option for your specific labeling needs.

1. Inkjet Printers:

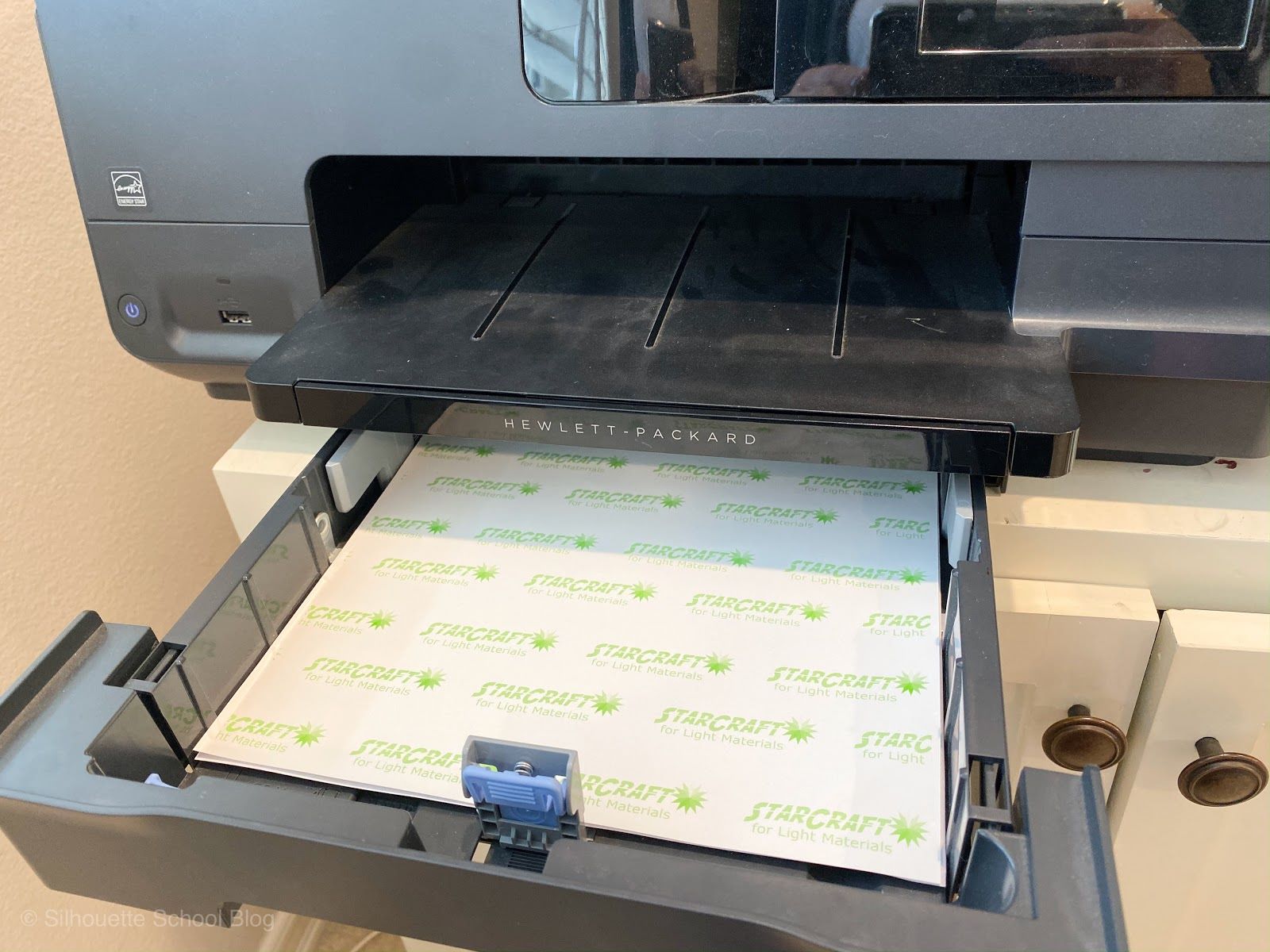

Inkjet printers are a popular choice for label printing due to their versatility and cost-effectiveness. These printers utilize droplets of ink to create precise and vibrant images on various types of media, including label sheets. Inkjet printers are ideal for producing high-quality labels with intricate designs and vivid colors, making them well-suited for applications such as product labeling and marketing materials.

2. Laser Printers:

Laser printers are known for their speed and efficiency, making them a preferred choice for high-volume label printing. By using a laser to fuse toner onto the label surface, these printers deliver crisp, smudge-resistant output, making them suitable for barcode labels, shipping labels, and other professional applications that demand durability and precision.

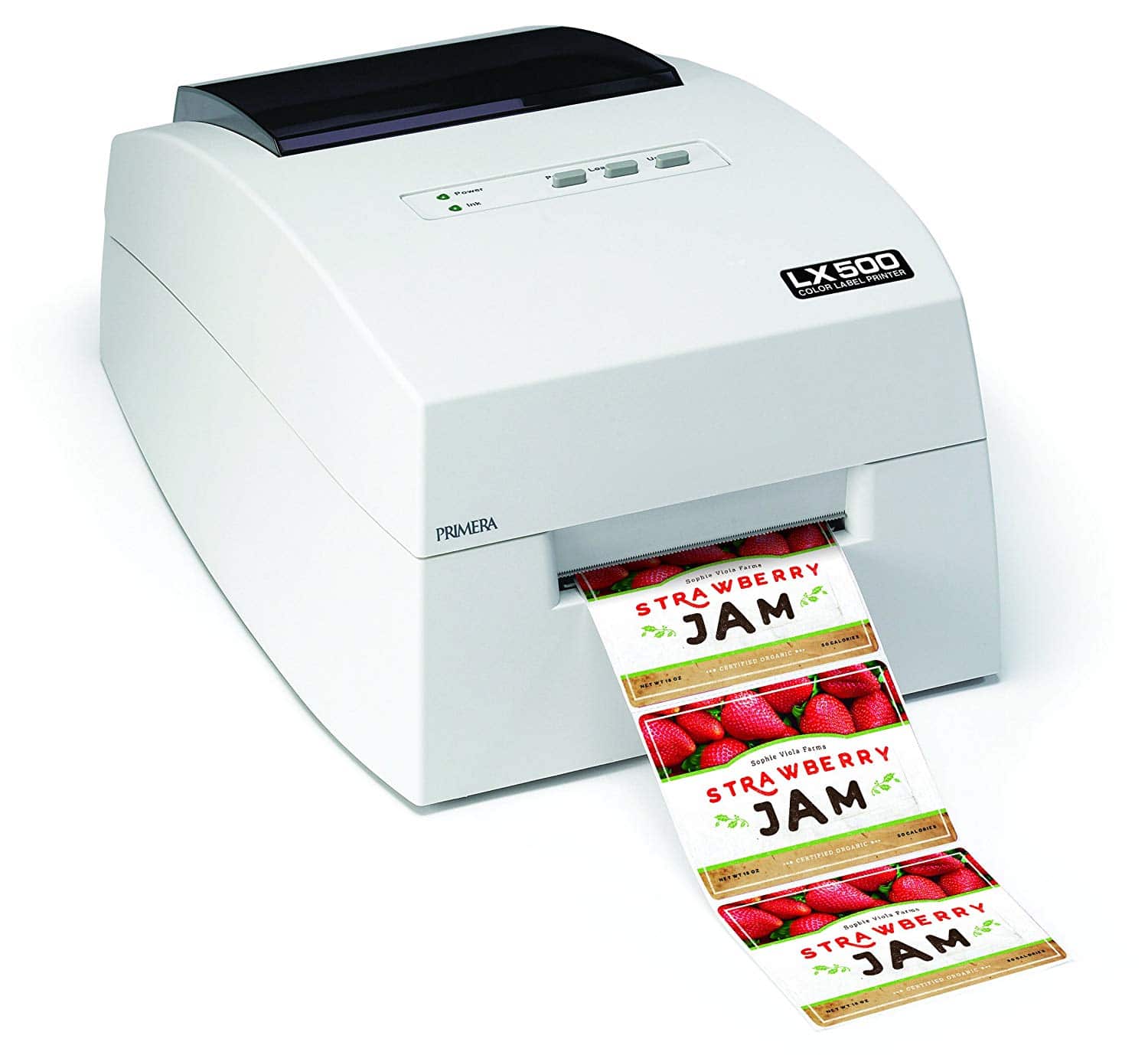

3. Thermal Label Printers:

Thermal label printers utilize heat to transfer ink onto label stock, eliminating the need for ink cartridges or toner. These printers are widely used in industries such as logistics, retail, and healthcare due to their reliability, speed, and low maintenance requirements. Thermal label printers are capable of producing high-resolution labels with exceptional clarity, making them an efficient choice for generating shipping labels, inventory tags, and compliance labels.

4. Dot Matrix Printers:

While less common in modern label printing applications, dot matrix printers use a matrix of pins to imprint characters and images onto label stock. These printers are valued for their ability to create multi-part forms and continuous labels, making them suitable for specialized applications such as industrial labeling and inventory management.

By understanding the unique capabilities and characteristics of each printer type, you can make informed decisions when selecting the most suitable device for your label printing needs. The next step in achieving optimal label placement involves exploring the specific considerations and best practices associated with each type of printer.

Label Placement in Printers

Once you’ve selected the appropriate type of printer for your label printing needs, the next crucial consideration is the precise placement of labels within the device. Proper label placement is essential for ensuring accurate printing, minimizing waste, and maintaining the integrity of the printed output. Whether you’re loading label sheets into an inkjet or laser printer or threading label rolls into a thermal label printer, understanding the nuances of label placement is paramount.

For inkjet and laser printers that utilize label sheets, it’s imperative to align the label stock within the printer’s paper tray to ensure that the labels feed through the device smoothly and consistently. Most printers feature adjustable paper guides that can be tailored to accommodate the dimensions of the label sheets, preventing misalignment and potential printing errors. Additionally, verifying that the label sheets are free of wrinkles, creases, or adhesive residue is crucial for preventing jams and maintaining print quality.

Thermal label printers, on the other hand, require the careful insertion of label rolls or fanfold label stock to facilitate seamless printing. Properly loading the label stock and adjusting the printer’s settings to match the label dimensions is essential for achieving precise label placement and preventing misprints. Many thermal label printers are equipped with intuitive mechanisms for adjusting label tension and alignment, allowing for effortless loading and accurate positioning of the labels during printing.

Regardless of the type of printer being used, ensuring that the labels are securely seated within the printer and that the print head or ink cartridges are properly aligned with the label stock is critical for achieving consistent and professional-looking output. Misaligned labels can result in skewed printing, smudged text or images, and wasted label stock, underscoring the importance of meticulous label placement.

Furthermore, understanding the specific requirements of your label design and content is essential for optimizing label placement. Whether you’re printing address labels, product labels, or barcode labels, taking into account factors such as label orientation, margins, and content placement can contribute to the overall effectiveness and visual appeal of the printed labels.

By mastering the art of label placement in printers, you can harness the full potential of your chosen printing device, ensuring seamless operation and professional-quality output for all your labeling needs.

Make sure to check the printer manual or manufacturer’s website for specific instructions on how to load labels into your printer. Most printers have a diagram or markings inside the printer to show the correct orientation for the labels.

Best Practices for Label Placement

Optimizing label placement in printers entails adhering to best practices that promote efficiency, accuracy, and high-quality output. By implementing the following guidelines, you can elevate your label printing endeavors and achieve consistent, professional results.

1. Proper Alignment: Ensure that the label stock is aligned correctly within the printer, taking care to adjust paper guides and settings to accommodate the dimensions of the labels. This prevents misalignment and ensures smooth feeding of the labels during printing.

2. Inspection and Preparation: Thoroughly inspect label sheets or rolls for wrinkles, creases, or adhesive residue before loading them into the printer. Preparing the label stock ensures that the printing process is free from obstructions and potential issues that could compromise print quality.

3. Calibration and Settings: For thermal label printers, calibrate the printer settings to match the dimensions of the label stock being used. Adjust label tension and alignment mechanisms as needed to facilitate accurate label placement and prevent misprints.

4. Print Head Maintenance: Regularly maintain the print head or ink cartridges of the printer to ensure proper alignment with the label stock. Clean the print head and perform any necessary maintenance procedures to prevent smudging and ensure consistent print quality.

5. Content Considerations: When designing label content, consider factors such as label orientation, margins, and content placement to optimize label placement within the printer. This ensures that the printed labels convey information effectively and appear visually appealing.

6. Test Printing: Before embarking on large-scale label printing, conduct test prints to verify label placement and print quality. This allows for adjustments to be made if necessary, preventing potential waste of label stock and ensuring optimal printing results.

7. Label Orientation: Pay attention to the orientation of the label stock when loading it into the printer, particularly for designs that require specific orientation, such as landscape or portrait layouts. Proper label orientation contributes to the clarity and readability of the printed labels.

By incorporating these best practices into your label printing processes, you can streamline operations, minimize errors, and achieve consistent, professional-quality output. Whether you’re producing shipping labels, product tags, or organizational labels, mastering the art of label placement in printers is essential for maximizing the effectiveness and visual appeal of your printed labels.

Conclusion

As we conclude our exploration of label placement in printers, it becomes evident that meticulous attention to detail and adherence to best practices are integral to achieving optimal results in label printing. Whether you’re utilizing inkjet, laser, thermal, or dot matrix printers, the precise placement of labels within these devices directly impacts print quality, efficiency, and overall effectiveness.

By understanding the unique considerations associated with each type of printer and implementing best practices for label placement, you can elevate your label printing endeavors and unlock the full potential of your chosen printing device. Proper alignment, thorough inspection and preparation of label stock, calibration of printer settings, and regular maintenance of print heads are essential elements of achieving seamless label placement and consistent, professional-quality output.

Furthermore, taking into account label orientation, content considerations, and conducting test prints are crucial steps in optimizing label placement and ensuring that the printed labels effectively convey information and exhibit visual appeal.

Whether you’re producing labels for shipping, inventory management, product identification, or organizational purposes, mastering the art of label placement in printers empowers you to deliver clear, accurate, and visually compelling labels that meet the demands of diverse applications.

As you embark on your label printing journey, may the insights and best practices shared in this guide serve as valuable tools in your quest for excellence in label placement. By harnessing the knowledge and applying the principles outlined herein, you can navigate the intricacies of label placement with confidence and precision, achieving outstanding results that reflect the dedication and expertise invested in your label printing endeavors.

Embrace the art of label placement in printers as a cornerstone of your commitment to delivering exceptional printed labels, and let your passion for precision and quality shine through in every label you produce.

Frequently Asked Questions about Which Way Do You Put Labels Into Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Way Do You Put Labels Into Printer”