Home>Articles>How Much Does 10 Feet Of 4 Inch Rigid Conduit Weights

Articles

How Much Does 10 Feet Of 4 Inch Rigid Conduit Weights

Modified: October 20, 2024

Find out the weight of 10 feet of 4 inch rigid conduit with our informative articles. Expertly written and accurate information to help with your electrical projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Conduit is an essential component in electrical and construction projects. It serves as a protective pathway for electrical cables, wiring, and other related components. There are various types of conduits available in the market, including rigid conduit. In this article, we will focus on 4-inch rigid conduit and explore its weight, specifically discussing how much 10 feet of it typically weighs.

Understanding the weight of conduit is crucial for several reasons. Firstly, it helps ensure that the appropriate equipment and manpower are allocated for its installation and handling. Additionally, knowing the weight of conduit is important for determining factors such as load-bearing capacity, transportation logistics, and overall project planning considerations.

In this article, we will delve into the specifics of 4-inch rigid conduit and examine the factors that influence its weight. By gaining a comprehensive understanding of these factors, you will be equipped with valuable insights to make informed decisions related to conduit selection and installation.

So, let’s dive in and explore the fascinating world of 4-inch rigid conduit and its weight!

Key Takeaways:

- Understanding conduit size is crucial for selecting the right conduit for your project. Consider factors such as electrical load, wiring type, and application requirements to ensure proper installation.

- The weight of 10 feet of 4-inch rigid conduit varies based on material, diameter, thickness, and other factors. Consider these elements for safe handling, transportation, and load-bearing capacity.

Read more: How Much Weight Can EMT Conduit Hold

What is Rigid Conduit?

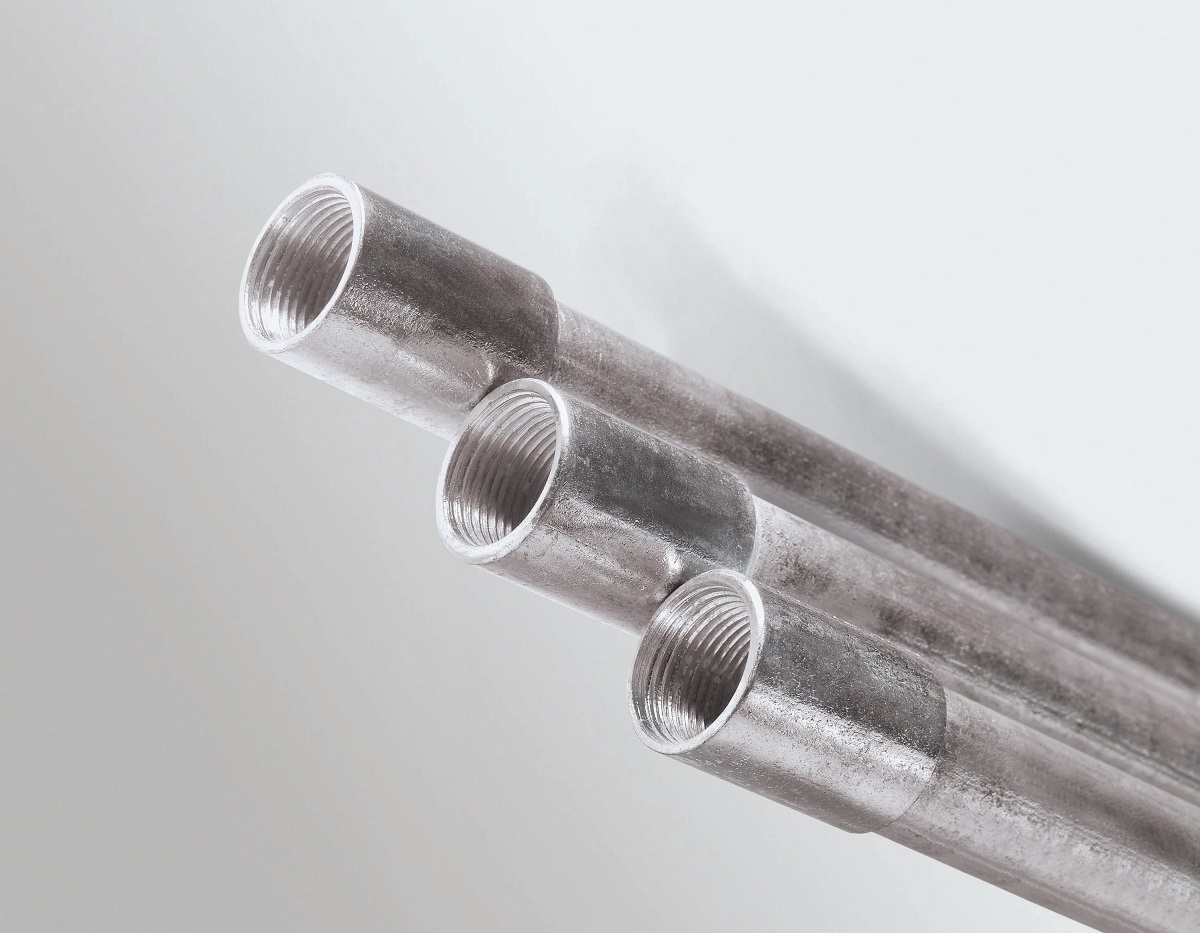

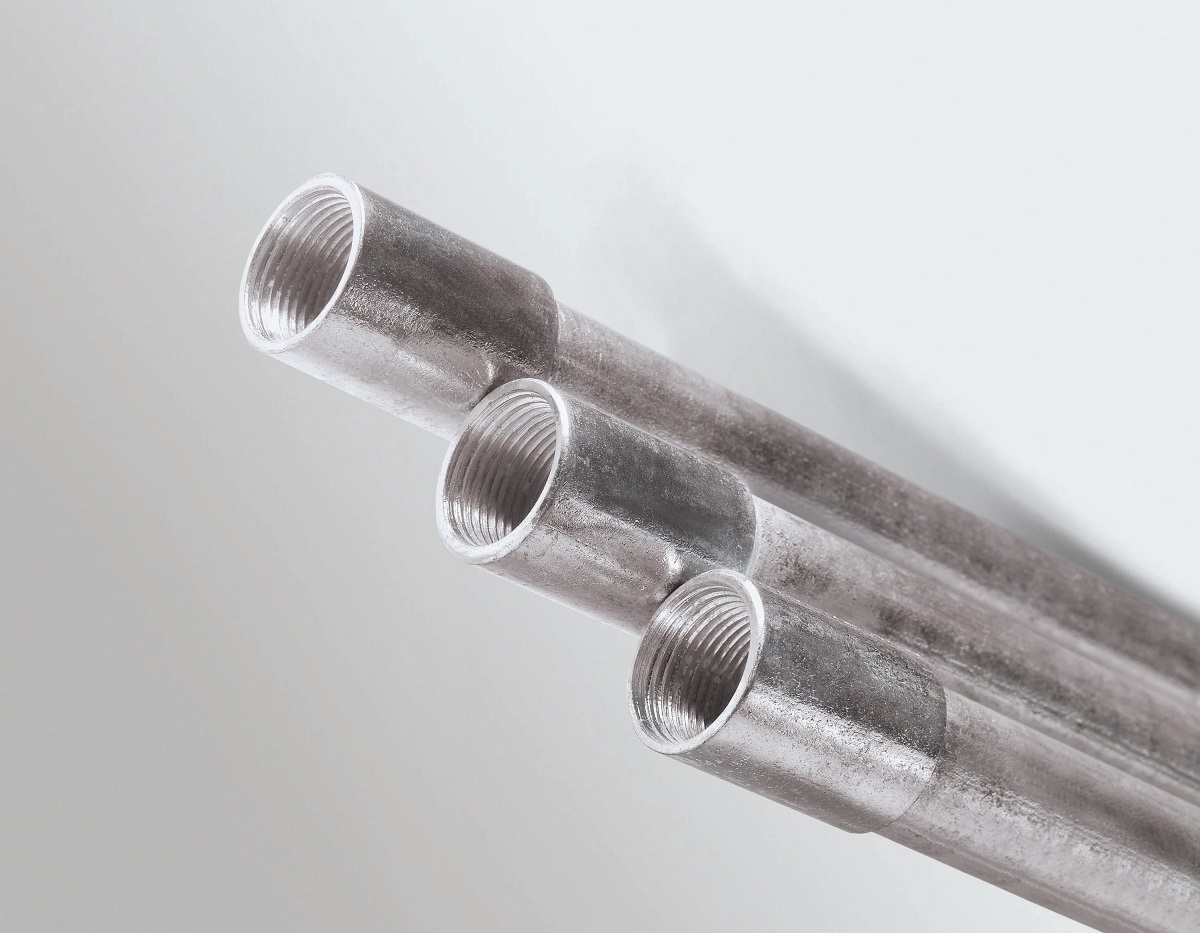

Rigid conduit, also known as rigid metal conduit (RMC), is a type of electrical conduit that is made from galvanized steel or aluminum. It is commonly used in commercial and industrial applications where a high level of protection for electrical wiring is required.

Rigid conduit is known for its durability and strength. It is designed to withstand harsh environments, provide resistance to moisture, and protect the electrical wiring from physical damage. The rigid construction of this conduit makes it suitable for both indoor and outdoor applications.

One of the key features of rigid conduit is its ability to provide excellent mechanical protection to the electrical cables it houses. This is especially important in industrial settings where the conduit is likely to be exposed to heavy machinery, vibrations, or other mechanical stresses.

Rigid conduit is available in various sizes, ranging from ½ inch to 6 inches in diameter. The size is determined by the inner diameter of the conduit, and the outer diameter may be slightly larger due to the thickness of the conduit walls. The size of the conduit is an important factor to consider when determining the weight of a specific length of conduit.

Another advantage of using rigid conduit is its fire resistance properties. The galvanized steel or aluminum construction of the conduit provides additional protection against fire hazards, ensuring the safety of the electrical installation.

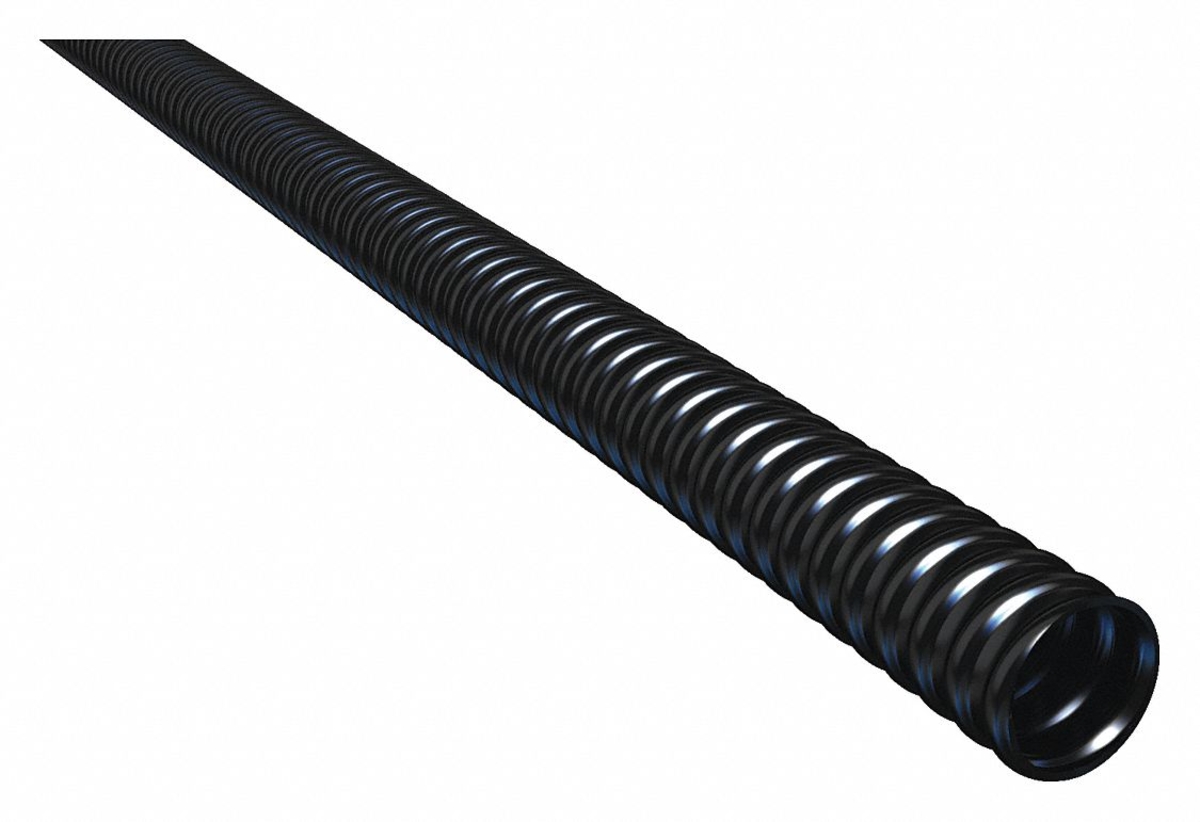

It is important to note that rigid conduit is different from other types of conduits, such as electrical metallic tubing (EMT) or electrical non-metallic tubing (ENT). While EMT is more lightweight and flexible, rigid conduit offers superior strength and durability, making it suitable for heavy-duty applications.

In summary, rigid conduit is a robust and reliable electrical conduit that provides excellent mechanical protection and fire resistance for electrical wiring. Its strength, durability, and ability to withstand harsh environments make it a preferred choice in industrial and commercial settings. Understanding the characteristics and properties of rigid conduit is crucial for selecting the appropriate conduit for your specific project requirements.

Understanding Conduit Size

Conduit size refers to the diameter of the inner space within the conduit, and it plays a vital role in determining the capacity and suitability of the conduit for specific wiring applications. Understanding conduit size is crucial for selecting the right conduit for your project and ensuring proper installation.

Conduit sizes are typically measured in inches and range from ½ inch to 6 inches in diameter. The size of the conduit is determined by the inner diameter, while the outer diameter may be slightly larger due to the thickness of the conduit walls. It is important to note that the actual dimensions of the conduit may vary slightly depending on the manufacturer.

The size of the conduit directly affects the amount and type of wiring that can be installed inside it. Larger conduit sizes are capable of accommodating more wires and cables, while smaller conduit sizes may have limitations in terms of the number and size of wires that can be installed.

To determine the appropriate conduit size for your project, you need to consider several factors. First and foremost, you should assess the electrical load of the installation. This includes factors such as the number and type of circuits, the voltage of the system, and the amount of current flowing through the wires.

Another important consideration is the type of wiring being used. Different types of wiring have varying diameters, and you need to ensure that the conduit size is adequate to accommodate the specific wiring you intend to use. It is crucial to consult the manufacturer’s specifications or consult with electrical professionals to determine the correct conduit size for your specific wiring requirements.

Furthermore, the application and environment in which the conduit will be installed should also be taken into account. For example, if the conduit will be exposed to high levels of moisture or corrosive substances, you may need to choose a conduit made from corrosion-resistant materials or consider additional protective measures.

In summary, understanding conduit size is essential for selecting the right conduit for your electrical installation. By considering factors such as electrical load, wiring type, and application requirements, you can ensure that the chosen conduit size is appropriate for the specific project. Consulting with electrical professionals and adhering to industry standards and codes will help guarantee a safe and successful installation.

The weight of 10 feet of 4 inch rigid conduit can be calculated by using the formula: Weight = (3.14 x (4/12)^2) x 10 x 490. The 490 is the weight per cubic foot of steel.

How Much Does 10 Feet of 4-Inch Rigid Conduit Weigh?

The weight of 10 feet of 4-inch rigid conduit can vary depending on several factors, including the material of the conduit and its thickness. Let’s explore some common weight ranges for 10 feet of 4-inch rigid conduit made from galvanized steel and aluminum.

Galvanized Steel Conduit:

In general, galvanized steel conduit is heavier than its aluminum counterpart. For 10 feet of 4-inch galvanized steel rigid conduit, the weight can range from approximately 75 pounds to 100 pounds. The weight can vary based on the thickness of the conduit walls, which can range from 0.104 inches to 0.226 inches.

Aluminum Conduit:

Aluminum conduit is lighter than galvanized steel conduit, making it a preferred choice for applications where weight is a consideration. For 10 feet of 4-inch aluminum rigid conduit, the weight can range from approximately 25 pounds to 50 pounds. The thickness of the conduit walls can vary from 0.065 inches to 0.125 inches.

It’s important to note that these weight ranges are approximate and can vary based on the specific manufacturer and the tolerances allowed. It’s always best to consult the manufacturer’s specifications or contact the supplier to get accurate weight information for the specific brand or type of conduit you plan to use.

Factors such as the material, thickness, and even the manufacturing process can influence the weight of the conduit. Additionally, any accessories or fittings attached to the conduit can add to the overall weight.

When planning your project and handling the conduit, it is crucial to consider its weight to ensure appropriate equipment and manpower are allocated for installation, transportation, and any load-bearing requirements. Additionally, it’s important to adhere to safety guidelines and follow proper lifting techniques when handling heavy conduit to prevent injuries or accidents.

In summary, the weight of 10 feet of 4-inch rigid conduit can range from approximately 75 pounds to 100 pounds for galvanized steel conduit, and from approximately 25 pounds to 50 pounds for aluminum conduit. The weight can vary based on the material, thickness, and other factors. Consult the manufacturer or supplier for accurate weight information for the specific conduit you plan to use.

Factors Affecting Conduit Weight

The weight of conduit is influenced by several factors that play a role in determining the overall weight and load-bearing capacity. Understanding these factors is crucial for selecting the appropriate conduit for your project and ensuring its safe and efficient installation. Let’s explore some key factors that can affect conduit weight:

1. Material:

The material of the conduit is a significant factor in determining its weight. Common materials used for conduit include galvanized steel, aluminum, and PVC (polyvinyl chloride). Galvanized steel conduit is typically heavier than aluminum or PVC conduit. The density and thickness of the material contribute to the overall weight of the conduit.

2. Diameter and Thickness:

The diameter and thickness of the conduit walls directly impact its weight. Conduits with larger diameters and thicker walls will generally be heavier. Thicker walls provide increased strength and durability but also add to the overall weight of the conduit.

3. Length:

The length of the conduit also affects its weight. Longer lengths of conduit will weigh more compared to shorter lengths of the same diameter. It’s important to consider the weight of the conduit when handling, transporting, and installing it, as longer lengths can be more challenging to maneuver.

4. Accessories and Fittings:

Accessories and fittings, such as connectors, couplings, and bends, can add to the overall weight of the conduit. These additional components must be considered when calculating the total weight of the conduit system.

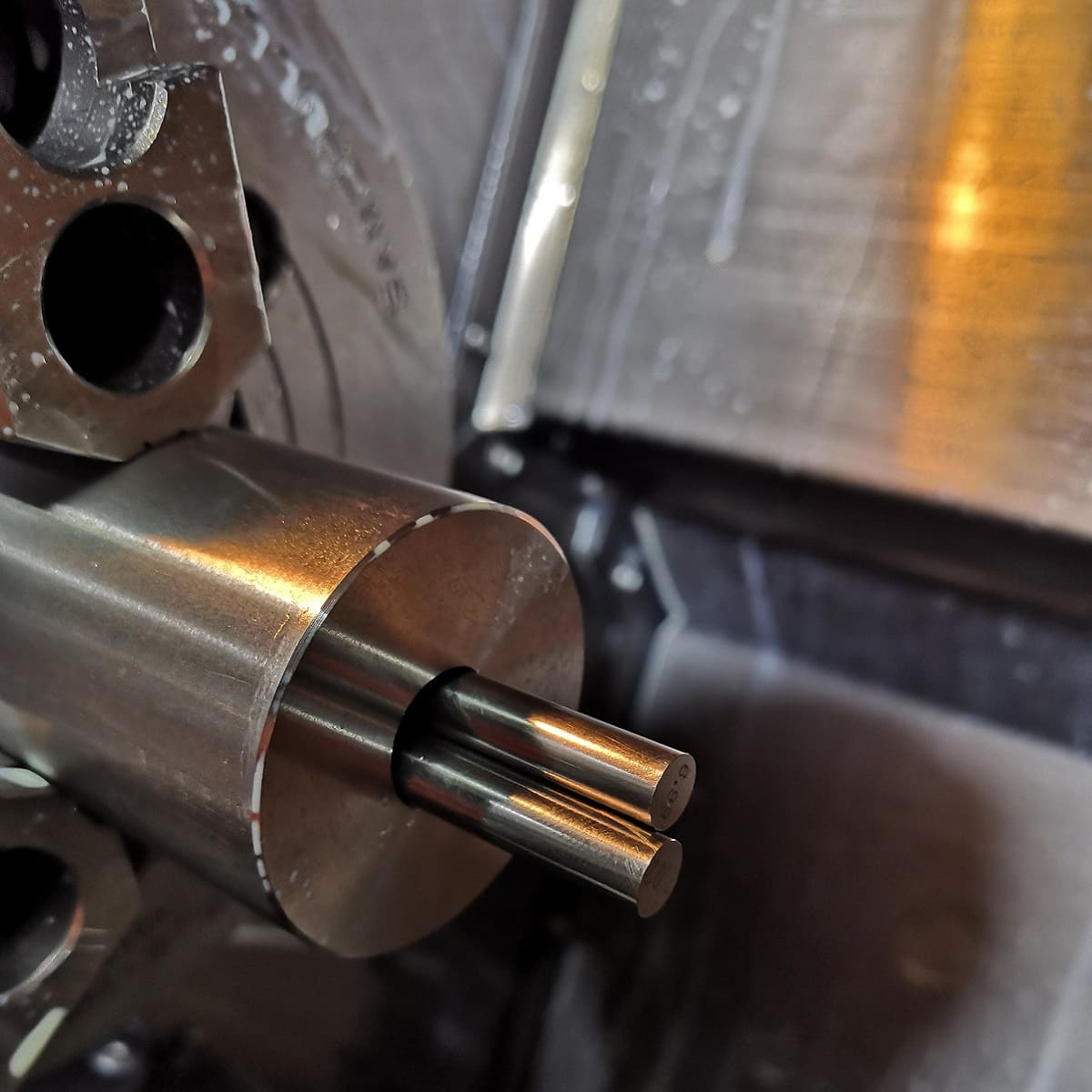

5. Manufacturing Variations:

Conduit weight can vary due to manufacturing variations and tolerances. Even within the same material and diameter, conduits from different manufacturers may have slight differences in weight. It is essential to consult the manufacturer’s specifications or contact the supplier for accurate weight information for the specific conduit you plan to use.

6. Corrosion Protection:

In some cases, corrosion protection coatings or treatments on conduit can add weight. Galvanized steel conduit, for example, has a layer of zinc coating for corrosion resistance, which adds to its weight compared to non-galvanized conduit.

7. Conduit Fill:

The number and size of wires or cables inside the conduit, known as conduit fill, can also affect its weight. A conduit filled with a greater number or thicker wires will weigh more than an empty or less-filled conduit.

By considering these factors, you can make informed decisions when selecting and installing conduit for your specific project requirements. It’s important to consult the manufacturer’s specifications, industry standards, and local building codes to ensure compliance and safety.

In summary, several factors affect the weight of conduit, including the material, diameter, thickness, length, accessories, manufacturing variations, corrosion protection, and conduit fill. Understanding these factors enables you to choose the right conduit for your project, ensure proper load-bearing, and maintain safety standards throughout the installation process.

Read more: How Many Wires In A 3/4 Inch Conduit

Conclusion

Choosing the right conduit for your electrical projects involves considering various factors, including conduit size and weight. In this article, we explored the weight of 10 feet of 4-inch rigid conduit, as well as the factors that can affect conduit weight.

Understanding conduit size is essential for determining the capacity and suitability of the conduit for specific wiring applications. The size of the conduit affects the amount and type of wiring that can be installed inside. It’s crucial to consider factors such as electrical load, wiring type, and application requirements to select the appropriate conduit size.

When it comes to the weight of 10 feet of 4-inch rigid conduit, it is influenced by factors such as the material (galvanized steel or aluminum), diameter, thickness, length, accessories, manufacturing variations, and conduit fill. Galvanized steel conduit tends to be heavier than aluminum conduit, and the weight can vary based on the specific specifications and tolerances of the manufacturer.

Considering conduit weight is crucial for proper planning, installation, and transportation. It ensures that the necessary equipment and manpower are allocated for handling the conduit safely. Additionally, understanding conduit weight helps in determining load-bearing capacity, adhering to safety guidelines, and complying with industry standards.

It’s important to consult the manufacturer’s specifications, industry standards, and local building codes when selecting and installing conduit. This ensures that your project meets safety requirements and is in compliance with applicable regulations.

In conclusion, understanding conduit size and weight is essential for successful electrical projects. By considering factors such as conduit size, material, and weight, you can make informed decisions to ensure the proper installation and functionality of your electrical systems. Investing time in understanding these factors will contribute to the efficiency, safety, and longevity of your electrical installations.

Curious about the ins and outs of conduit materials? Dive into our detailed article on rigid metal conduit to grasp its essentials and benefits for your projects. If you're planning on a DIY upgrade or a new installation, our step-by-step guide on conduit installation in walls will surely simplify your task. Both pieces are packed with practical tips to ensure your work not only meets but exceeds expectations. Ready to learn more? Check out these must-read articles for all your home improvement needs.

Frequently Asked Questions about How Much Does 10 Feet Of 4 Inch Rigid Conduit Weights

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does 10 Feet Of 4 Inch Rigid Conduit Weights”