Articles

How Many Wires In A 3/4 Inch Conduit

Modified: May 6, 2024

Find out how many wires can fit in a 3/4 conduit with this informative article. Learn about the wiring capacity and restrictions for a smooth electrical installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In any electrical installation, the proper routing and protection of wires is of utmost importance. Conduits serve as protective channels that house and safeguard electrical wires, ensuring their longevity and safety. However, it is essential to understand the capacity and limitations of conduits to determine the number of wires they can accommodate.

In this article, we will delve into the topic of wire capacity in conduits, specifically focusing on a 3/4″ conduit. We will explore the factors that influence the number of wires that can be installed, as well as important tips for proper wire installation.

Understanding the relationship between conduit size and wire capacity requires a basic understanding of conduit sizes and wire gauge. Let’s take a closer look.

Key Takeaways:

- Proper wire installation in conduits requires understanding conduit and wire sizes, considering factors affecting wire capacity, and following NEC guidelines for maximum fill percentages. Planning, using quality materials, and seeking professional assistance are crucial for a successful installation.

- When working with a 3/4″ conduit, it’s essential to consult NEC guidelines and consider factors like wire gauge, insulation type, and conduit material to determine the maximum number of wires allowed. Following fill ratio guidelines, avoiding sharp bends, and labeling wires for easy identification are key practices for safe and efficient wire installation.

Read more: How Many Wires In 1/2 Inch Conduit

Understanding Conduit and Wire Sizes

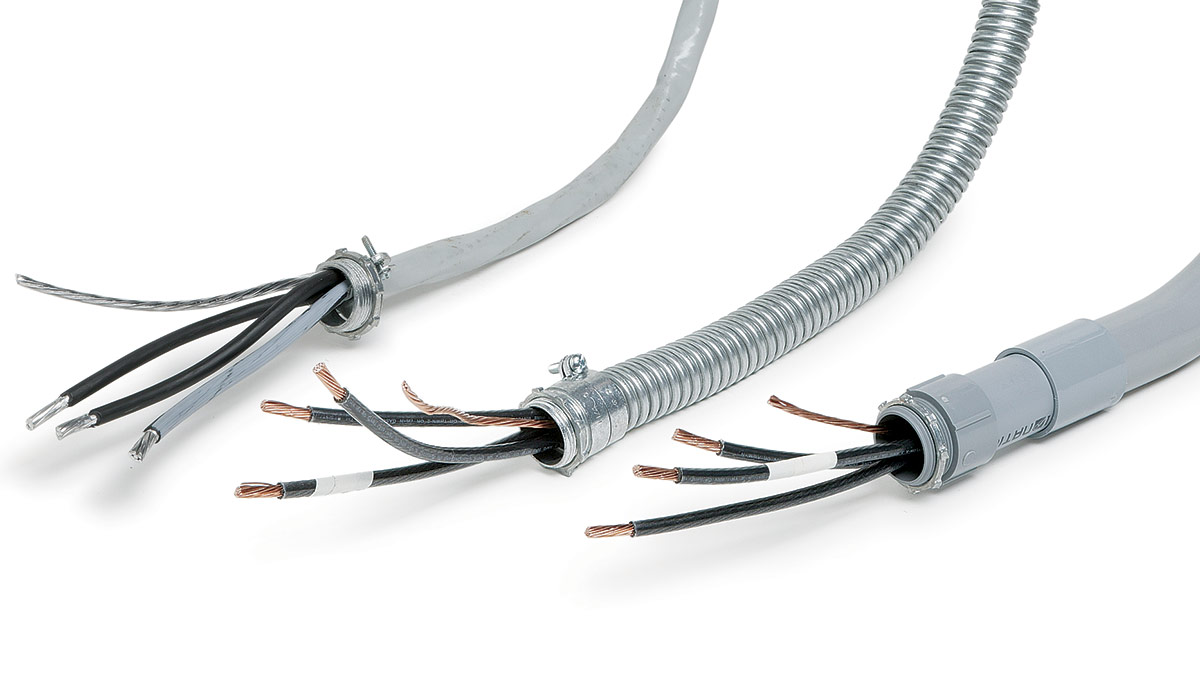

Conduits come in various sizes, typically measured in inches. The size refers to the diameter of the conduit and determines the maximum number of wires it can accommodate. Common conduit sizes include 1/2″, 3/4″, 1″, and 2″. In this article, our focus will be on a 3/4″ conduit.

Wires, on the other hand, are measured using American Wire Gauge (AWG), which assigns a specific numerical value to each wire size. The lower the AWG number, the larger the wire diameter. For example, a 12 AWG wire is larger than a 14 AWG wire.

The size of the wires and the corresponding conduit size are crucial in ensuring proper wire installation. If the conduit is too small for the wires, it can lead to overcrowding, which increases the risk of overheating and potential fire hazards. On the other hand, if the conduit is too large for the wires, they may not be adequately secured and protected.

Next, let’s discuss how to determine the appropriate conduit size based on the wire capacity.

Determining the Size of Conduit

To determine the size of conduit required for a specific number of wires, you need to consider the wire gauge and the maximum fill capacity of the conduit. The National Electrical Code (NEC) provides guidelines for calculating the fill capacity, which is expressed as a percentage of the total conduit area.

The fill capacity depends on a few factors, such as the insulation type of the wires, the conduit material, and the installation method. Different types of insulation materials have varying outside diameters, which can affect the overall fill capacity. It is essential to consult the NEC or a professional electrician to ensure compliance with local electrical codes.

The NEC provides a table that lists the maximum allowable fill percentages for different conduit sizes and wire combinations. It is crucial to refer to this table when determining the appropriate conduit size for a specific wiring application. Keep in mind that going above the maximum fill capacity can lead to overheating and potential safety hazards.

Additionally, it is important to consider factors such as bends, junctions, and accessibility when determining the size of the conduit. These elements can impact the ease of wire installation and maintenance. A larger conduit size may be necessary to accommodate these factors.

Now that we understand how to determine the size of conduit based on wire capacity, let’s explore the specific limitations for a 3/4″ conduit.

Factors Affecting Wire Capacity in Conduits

There are several factors that can affect the wire capacity in conduits. Understanding these factors is essential for proper wire installation and to avoid overfilling the conduit, which can pose safety risks. Let’s take a look at some of the key factors:

1. Wire Diameter: The diameter of the wires being installed plays a significant role in determining the number of wires that can fit inside a conduit. Smaller diameter wires take up less space, allowing for more wires to be installed. Conversely, larger diameter wires require more space and may limit the number of wires that can fit within the conduit.

2. Conduit Material: The material of the conduit can also influence the wire capacity. Different materials have varying inner diameters and thicknesses, affecting the available space for wire installation. It is important to consider the specific material of the conduit when determining wire capacity.

3. Wire Insulation: The type of insulation on the wires can impact their outer diameter. Different insulation materials have different thicknesses, which can affect the overall space required within the conduit. It is crucial to account for the outer diameter of the insulated wires when calculating wire capacity.

4. Conduit Fill Percentage: As mentioned earlier, the National Electrical Code provides guidelines on the maximum fill percentage for conduits. It is crucial to adhere to these guidelines to prevent overcrowding and ensure proper airflow, reducing the risk of overheating. Exceeding the maximum fill percentage can lead to safety hazards and code violations.

Considering these factors when determining wire capacity in conduits is essential to maintain electrical safety and compliance. Now, let’s examine the maximum number of wires allowed in a 3/4″ conduit.

When determining how many wires can fit in a 3/4 conduit, the general rule is that you can have up to 9 conductors for a single phase system and up to 18 conductors for a three phase system. Always consult local electrical codes for specific regulations.

Maximum Number of Wires Allowed in a 3/4″ Conduit

When it comes to a 3/4″ conduit, the maximum number of wires that can be installed depends on several factors, including wire gauge, insulation type, conduit material, and maximum fill percentage. It’s crucial to refer to the NEC guidelines and consult a professional electrician for accurate calculations based on your specific installation requirements.

For example, considering a standard scenario where the wires are using THHN/THWN insulation and the conduit is PVC, the NEC provides a general rule of thumb for a 3/4″ conduit. It states that the maximum number of 12 AWG wires is 6, while for 14 AWG wires, it is 9. These values are based on a 40% fill ratio, which provides sufficient space for proper wire installation and potential future modifications.

It’s important to note that these values may vary depending on insulation types, conduit materials, installation methods, and local electrical codes. Additionally, other factors like bends and junctions within the conduit may further limit the number of wires that can be installed.

It is crucial to consider all these factors and consult the appropriate guidelines to ensure compliance and safety during wire installation in a 3/4″ conduit or any other conduit size.

Now that we understand the wire capacity limitations in a 3/4″ conduit, let’s explore some tips for properly installing wires in conduits.

Read more: How Many #4 Wires In A 1 Inch Conduit

Tips for Properly Installing Wires in Conduits

Proper installation of wires in conduits is essential to ensure electrical safety and prevent any potential hazards. Here are some helpful tips to consider when installing wires in conduits:

1. Plan the Installation: Before starting the installation, carefully plan the layout and routing of the wires. Consider factors such as the distance between outlets, bends, junctions, and accessibility for maintenance or future modifications. The proper planning will help ensure an efficient and organized wire installation.

2. Choose the Right Conduit Size: Determine the appropriate conduit size based on the number and size of wires that need to be accommodated. Refer to the NEC guidelines and consult with an electrician to ensure compliance with local codes. Using a conduit that is too small can lead to overcrowding, while using one that is too large may not provide adequate protection.

3. Follow the Fill Ratio Guidelines: Adhere to the maximum fill ratio guidelines provided by the NEC. Overfilling the conduit can lead to poor airflow, increased heat buildup, and potential safety hazards. Maintain a fill ratio that allows for proper wire installation and potential future modifications.

4. Use Quality Materials: Invest in high-quality conduit materials and wires to ensure durability and long-lasting performance. Inferior materials can lead to premature degradation, compromising the safety and effectiveness of the electrical installation.

5. Properly Secure the Wires: Use appropriate clamps, straps, or hangers to secure the wires within the conduit. Secure them at regular intervals to prevent excessive movement, which can lead to wire damage or disconnections. Avoid using excessive force when securing the wires to prevent potential damage.

6. Avoid Sharp Bends: When routing the wires, minimize the number of sharp bends or turns. Excessive bending can cause strain or damage to the wires, leading to potential issues with conductivity or insulation integrity. Use appropriate bend radius guides to ensure smooth and gradual bends.

7. Label and Document: Properly label the wires and document their location and purpose for easy identification and troubleshooting in the future. This saves time and effort during maintenance or repairs and ensures a smooth operation of the electrical system.

8. Seek Professional Assistance: If you are uncertain about any aspects of the wire installation process, it’s always best to consult with a professional electrician. They can provide guidance, ensure compliance with local codes, and address any specific requirements or concerns.

By following these tips, you can ensure a safe and efficient wire installation in conduits. Now, let’s summarize what we’ve discussed in this article.

Conclusion

Properly installing wires in conduits is crucial to ensure electrical safety, longevity, and efficiency. Understanding the relationship between conduit size and wire capacity is essential for a successful installation. We discussed some key points to keep in mind when working with a 3/4″ conduit.

First, it’s important to understand conduit and wire sizes. Conduits come in various sizes, and wires are measured in AWG. Choosing the right conduit size that can accommodate the wires is crucial for a secure and efficient installation.

Several factors affect wire capacity in conduits, including wire diameter, conduit material, wire insulation, and maximum fill percentage. Considering these factors ensures proper wire installation and prevents potential hazards.

In the case of a 3/4″ conduit, the maximum number of wires that can be installed varies depending on factors such as wire gauge and insulation type. Consulting NEC guidelines and considering other variables like bends and junctions within the conduit is essential for accurate calculations.

Lastly, we provided some tips for properly installing wires in conduits. Planning the installation, following fill ratio guidelines, using quality materials, properly securing the wires, avoiding sharp bends, labeling and documenting, and seeking professional assistance when needed are all important practices to ensure a successful wire installation.

Remember, electrical installations should always be carried out by trained professionals or individuals with adequate knowledge and experience in the field. Safety is paramount when working with electrical systems.

By adhering to these guidelines and seeking professional advice when necessary, you can ensure a safe, efficient, and code-compliant wire installation in conduits.

Excited to tackle more DIY electrical projects? Our latest guides have just what you need to get started. Learn the practical steps for running overhead electrical wiring to your garage, ensuring a safe and efficient setup. Plus, don’t miss our exclusive roundup of the top 10 electrical wires 12 gauge for 2024. These insights will help you make informed decisions for all your home wiring projects, keeping safety and quality as top priorities.

Frequently Asked Questions about How Many Wires In A 3/4 Inch Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many Wires In A 3/4 Inch Conduit”