Home>Articles>How Many #10 Current Carrying Conductors In A 3/4 Inch Conduit

Articles

How Many #10 Current Carrying Conductors In A 3/4 Inch Conduit

Modified: February 23, 2024

Find out how many #10 current carrying conductors can fit in a 3/4 conduit with this informative article. Learn more about electrical conduit sizing and installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our article on how many #10 current carrying conductors can fit in a 3/4″ conduit. When it comes to electrical installations, conduits play a crucial role in housing and protecting electrical wires. The size of the conduit and the number of conductors it can accommodate are important factors to consider for a safe and efficient electrical system.

In this article, we will dive into the details of conduits and conductors, specifically focusing on #10 current carrying conductors and the maximum fill capacity of a 3/4″ conduit. We’ll also discuss the factors to consider when determining the number of #10 conductors that can be installed in a 3/4″ conduit.

Whether you’re an electrician, a homeowner, or simply curious about electrical installations, this article will provide you with the knowledge you need to understand the limitations and capacity of a 3/4″ conduit.

So, let’s get started by exploring the basics of conduits and conductors.

Key Takeaways:

- A 3/4″ conduit can typically accommodate up to 4 #10 current carrying conductors, but factors like insulation thickness and grounding conductors must be considered. Adhering to NEC guidelines is crucial for safe and compliant installations.

- Calculating the number of #10 current carrying conductors in a 3/4″ conduit involves considering factors like conduit size, conductor size, insulation thickness, and pulling tension requirements. Professional consultation ensures accurate and code-compliant calculations.

Read more: How Many Wires In A 3/4 Inch Conduit

Understanding Conduits and Conductors

Before we delve into the specifics of #10 current carrying conductors and a 3/4″ conduit, let’s first understand what conduits and conductors are.

A conduit is a pipe or tube that is used to protect and route electrical wires. It provides a safe and organized pathway for the wires, protecting them from physical damage and preventing potential hazards. Conduits are typically made of materials such as PVC (polyvinyl chloride), aluminum, or steel.

On the other hand, conductors are the wires that carry electrical current. They are usually made of copper or aluminum and are measured by their gauge or thickness. The gauge number inversely represents the thickness of the conductor, meaning that a smaller gauge number indicates a thicker wire. In our case, we will be focusing on #10 current carrying conductors.

Conductors are available in different sizes or gauges to accommodate various electrical loads. The size of the conductor is determined by the amount of current it can safely carry without overheating. It’s crucial to select the appropriate conductor size to ensure the safety and efficiency of the electrical system.

Now that we have a basic understanding of conduits and conductors, let’s dive into the specifics of #10 current carrying conductors and their use in a 3/4″ conduit.

What is a #10 Current Carrying Conductor?

A #10 current carrying conductor refers to an electrical wire with a gauge size of #10 that is capable of carrying electrical current. The gauge size of a wire is determined by its diameter, with a smaller gauge number indicating a larger diameter and vice versa.

#10 current carrying conductors are commonly used in residential and commercial electrical installations. They can handle a maximum current load of 30 amperes, making them suitable for a range of electrical applications, such as lighting fixtures, outlets, and small appliances.

It’s important to note that the ampacity, or the maximum amount of current a wire can safely carry, of a #10 conductor is determined by various factors, including the ambient temperature, the type of insulation, and the length of the wire run. These factors need to be considered during electrical design and installation to ensure the proper sizing and protection of the wires.

When installing #10 current carrying conductors, it is essential to follow electrical codes and standards to ensure the safety and compliance of the electrical system. This includes proper insulation, grounding, and protection against overcurrent and short circuits.

Now that we understand what a #10 current carrying conductor is, let’s move on to discussing the types of conduits that can be used to house these conductors.

Types of Conduits

There are several types of conduits available for electrical installations, each with its own advantages and applications. Let’s explore some common types of conduits:

1. PVC Conduit: PVC (polyvinyl chloride) conduits are one of the most widely used types of conduits. They are lightweight, inexpensive, and easy to install. PVC conduits are resistant to moisture, corrosion, and many chemicals, making them suitable for both indoor and outdoor applications. They are available in various sizes and can be easily cut and joined using PVC fittings.

2. Rigid Metal Conduit (RMC): RMC conduits are made of galvanized steel and provide excellent mechanical and electrical protection. They are more rigid and durable than PVC conduits, making them suitable for industrial and heavy-duty applications. RMC conduits are typically used in areas where there is a high risk of physical damage or exposure to extreme conditions.

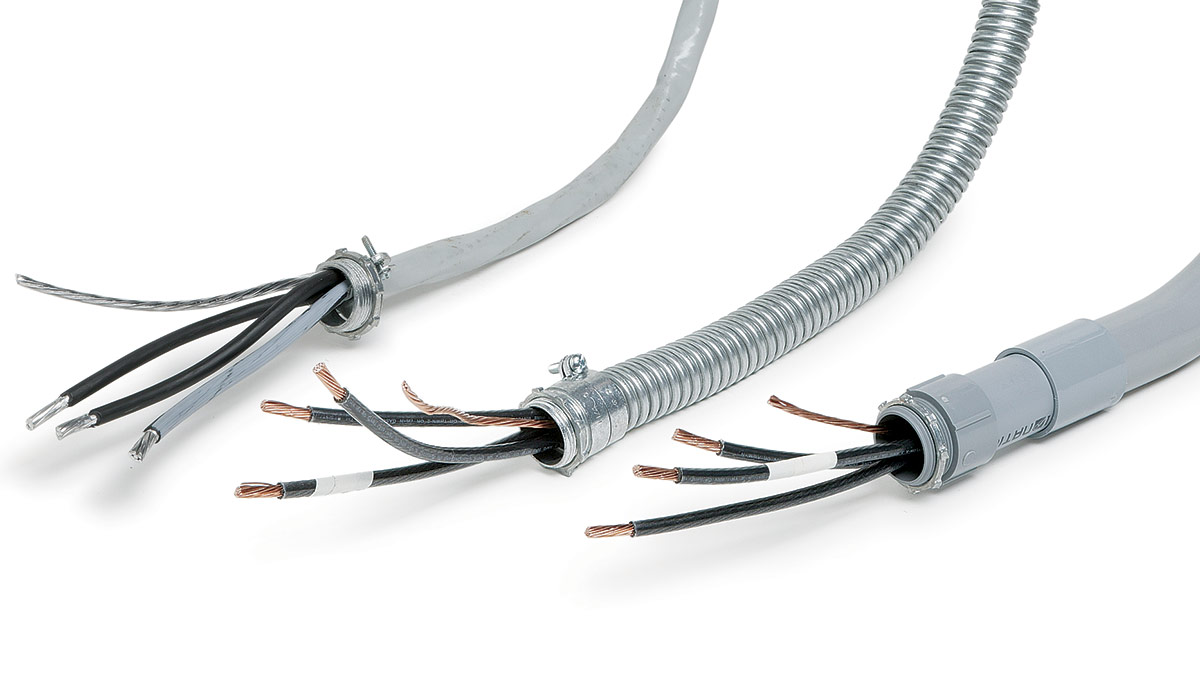

3. Electrical Metallic Tubing (EMT): EMT conduits are made of thin-walled galvanized steel or aluminum. They are lightweight, easy to bend, and cost-effective. EMT conduits are commonly used in residential and commercial applications where flexibility and ease of installation are important factors.

4. Flexible Conduit: Flexible conduits, as the name suggests, are designed to be flexible and easily maneuverable. They are made of materials such as PVC, metal, or liquid-tight materials. Flexible conduits are ideal for installations that require bends, twists, or movement, such as in machinery or outdoor applications.

These are just a few examples of the types of conduits available. It’s important to select the appropriate conduit based on factors such as the environment, installation requirements, and the types of conductors being used.

Now that we have explored the different types of conduits, let’s move on to discussing the maximum fill capacity of a 3/4″ conduit.

When determining the number of #10 current carrying conductors in a 3/4 conduit, you can use the NEC ampacity tables to find the maximum allowable ampacity for the conductors and then divide the total allowable ampacity by the ampacity of the #10 conductor to find the maximum number of conductors allowed.

Maximum Fill Capacity of a 3/4″ Conduit

When it comes to conduits, it’s essential to consider their maximum fill capacity to ensure proper wire installation and compliance with electrical codes. The maximum fill capacity refers to the maximum number and size of conductors that can be safely housed within a conduit without exceeding its capacity.

In the case of a 3/4″ conduit, the maximum fill capacity depends on the type and size of the conductors being used. Different conductor sizes have different diameters, which directly impact how many can fit within the conduit.

In general, a 3/4″ conduit can accommodate up to 4 #10 current carrying conductors. However, it’s important to note that this is a general guideline and can vary depending on other factors such as the type of conduit being used, the insulation thickness of the conductors, and the presence of ground wires.

It’s crucial to always consult the National Electrical Code (NEC) and any local electrical regulations to determine the specific fill capacity requirements for the project at hand. The NEC provides tables and guidelines that detail the maximum fill capacities for different types and sizes of conduits.

Exceeding the maximum fill capacity of a conduit can lead to several issues. Overcrowding the conduit can cause excessive heat buildup, which can damage the insulation of the conductors and increase the risk of electrical fires. It can also make it challenging to properly pull or remove wires in the future, hindering maintenance and repairs.

Now that we understand the maximum fill capacity of a 3/4″ conduit, let’s explore the factors to consider when determining the number of #10 current carrying conductors that can be installed.

Read more: How Many #4 Wires In A 1 Inch Conduit

Factors to Consider in Conduit Filling

When determining the number of #10 current carrying conductors that can be installed in a 3/4″ conduit, there are several factors to consider. These factors help ensure proper conduit filling and adherence to electrical codes and standards. Let’s explore the key factors:

1. Conductor Size and Type: The size and type of conductors play a crucial role in conduit filling. Different gauge sizes and types of conductors have varying outer diameters, which directly impact how many can fit within a given conduit. It’s important to accurately measure the diameter of the conductors to determine the available space within the conduit.

2. Insulation Thickness: The insulation thickness of the conductors also affects the available space within the conduit. Thicker insulation can reduce the available fill capacity and may require adjustments in the calculations. It’s essential to consider the insulation thickness when determining the number of conductors that can fit in the conduit.

3. Grounding Conductors: Grounding conductors, such as grounding wires, need to be taken into account when calculating conduit filling. These conductors provide a path for electrical faults and are typically larger in size than the current carrying conductors. The presence of grounding conductors may reduce the available space for other conductors within the conduit.

4. Bend Radius and Pulling Tension: Conduit filling should also consider the bend radius and pulling tension requirements. Overfilling a conduit can make it challenging to properly pull wires through or place excessive strain on the conductors during installation or future maintenance. It’s crucial to maintain proper bend radius and ensure that pulling tension remains within acceptable limits.

5. Regulatory Codes: Adhering to the National Electrical Code (NEC) and any local electrical regulations is of utmost importance. These codes provide specific guidelines and requirements for conduit fill capacity based on the type of conduit, conductor size, and insulation types. It’s essential to consult the applicable codes to ensure compliance and safe installation.

By taking these factors into consideration, you can determine the maximum number of #10 current carrying conductors that can be safely installed in a 3/4″ conduit while maintaining compliance with electrical codes.

Now, let’s move on to discussing how to calculate the number of #10 current carrying conductors in a 3/4″ conduit.

Calculating the Number of #10 Current Carrying Conductors in a 3/4″ Conduit

To determine the number of #10 current carrying conductors that can fit in a 3/4″ conduit, you need to consider the factors we discussed earlier. Here’s a step-by-step guide to calculating conduit fill:

1. Determine the Conduit Size: Identify the size of the conduit you’re working with. In this case, we have a 3/4″ conduit.

2. Identify the Conductor Size: As we’re specifically dealing with #10 current carrying conductors, the conductor size is already established. Make sure to measure the diameter or outer dimensions of the conductor accurately to account for any variations.

3. Check the Conduit Fill Capacity Chart: Refer to the conduit fill capacity chart provided by the NEC or other regulatory codes. This chart offers guidance on the maximum number and size of conductors that can be installed in a specific type and size of conduit.

4. Consider conductor insulation and grounding conductors: Take into account the thickness of the conductor insulation and any additional grounding conductors that need to be installed. These factors may reduce the available fill capacity within the conduit.

5. Calculate the Number of Conductors: Based on the conduit fill capacity chart and the factors mentioned above, determine the maximum number of #10 current carrying conductors that the 3/4″ conduit can accommodate. Remember to consider any applicable local or regional codes that may impose additional requirements.

It’s important to note that the calculations may vary depending on the specific circumstances and installation requirements. Professional electricians and engineers often use specialized software or online calculators to accurately determine conduit fill capacities.

By following these steps and considering the relevant factors, you can ensure that the number of #10 current carrying conductors installed in a 3/4″ conduit meets safety standards and electrical code requirements.

Now that we’ve discussed how to calculate the number of conductors in a 3/4″ conduit, let’s conclude our article.

Conclusion

In conclusion, understanding the capacity and limitations of conduits is essential for safe and efficient electrical installations. In this article, we explored the topic of how many #10 current carrying conductors can fit in a 3/4″ conduit.

We began by discussing the basics of conduits and conductors, highlighting the importance of selecting the appropriate size of conductors to handle electrical loads safely. We then delved into the different types of conduits available, such as PVC, RMC, EMT, and flexible conduits, each with its own advantages and applications.

Next, we explored the maximum fill capacity of a 3/4″ conduit, which depends on factors like conductor size, insulation thickness, and the presence of grounding conductors. Adhering to electrical codes, such as the NEC, is crucial for determining the specific fill capacity requirements.

To accurately calculate the number of #10 current carrying conductors in a 3/4″ conduit, it is necessary to consider factors like conduit size, conductor size, insulation thickness, grounding conductors, and pulling tension requirements. By following the steps outlined in our article, you can ensure that the conduit is filled within safe limits.

Remember, it’s always best to consult with a professional electrician or engineer for accurate calculations and to ensure compliance with local electrical codes and regulations.

In summary, understanding conduit capacity and properly calculating the number of conductors is vital for a safe and reliable electrical system. We hope this article has provided valuable insights and guidance for your electrical installations.

Thank you for reading, and may your future electrical projects be successful and secure.

Frequently Asked Questions about How Many #10 Current Carrying Conductors In A 3/4 Inch Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many #10 Current Carrying Conductors In A 3/4 Inch Conduit”