Articles

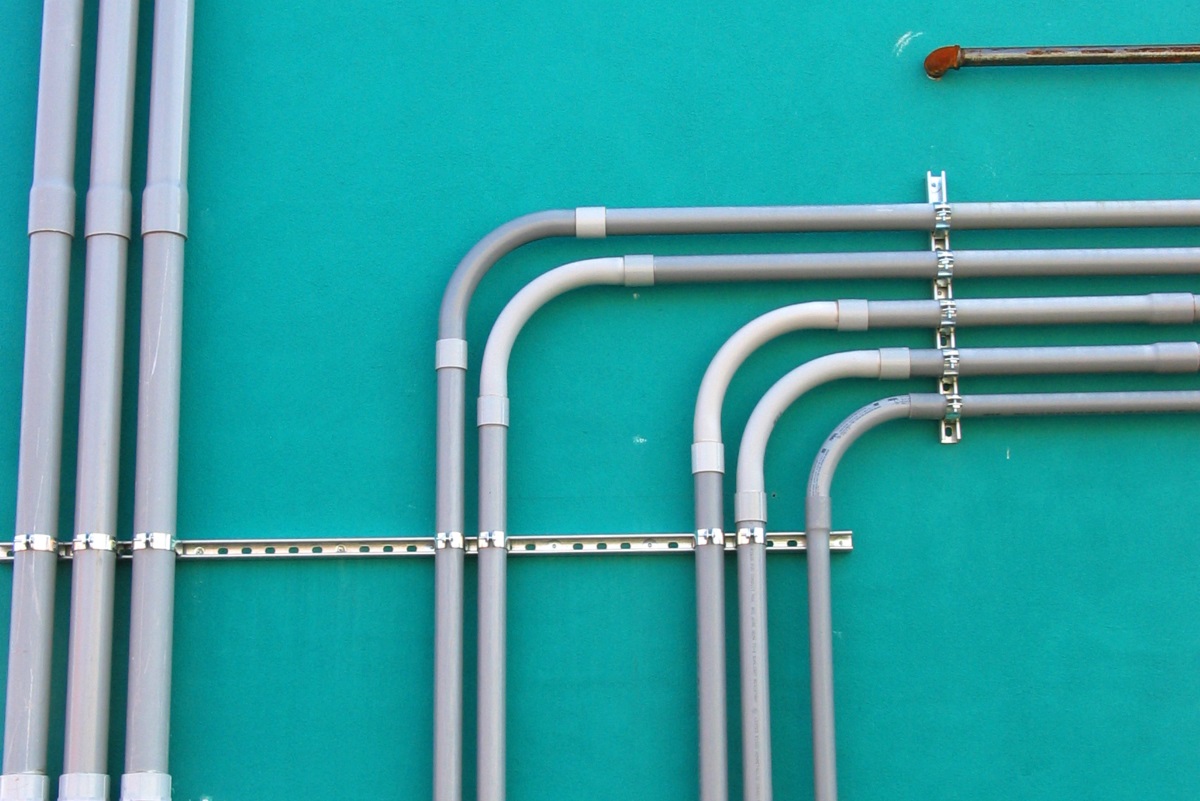

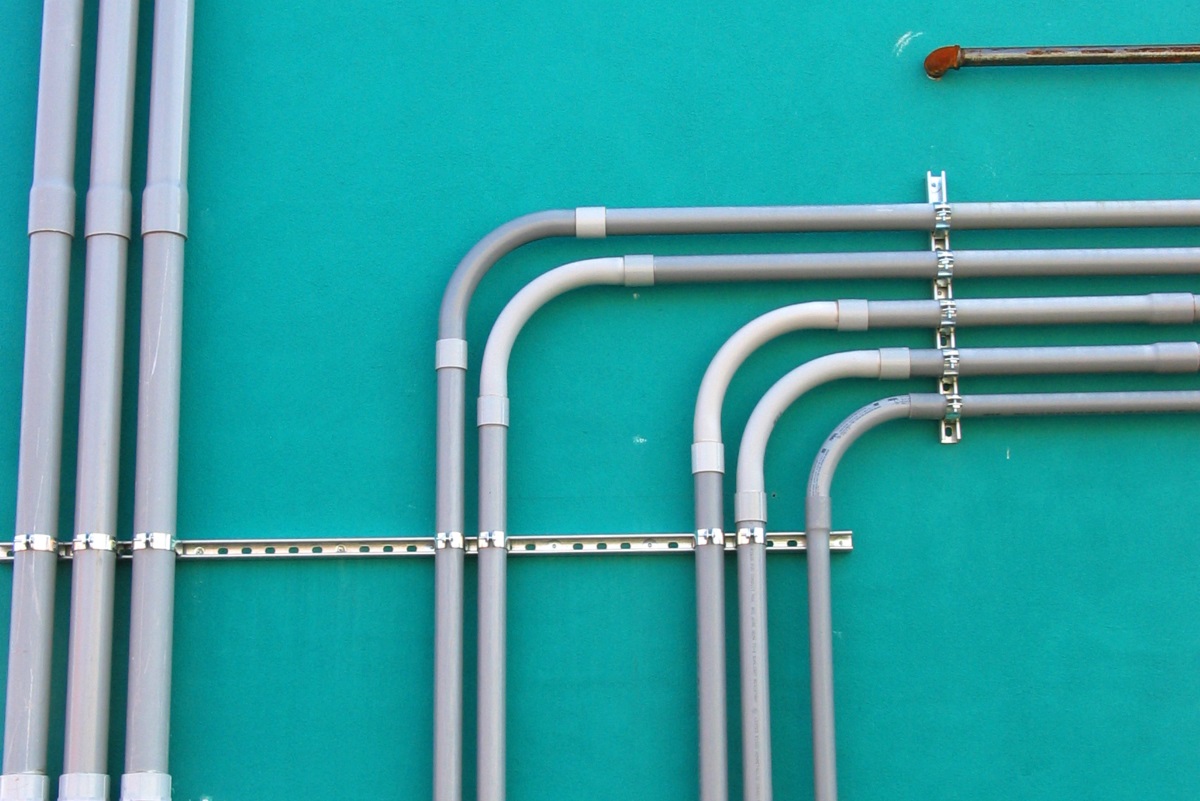

How To Bend Conduit Without A Bender

Modified: May 6, 2024

Learn how to bend conduit without a bender with these helpful articles. Find step-by-step instructions and tips for bending conduit easily and efficiently.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of conduit bending! Whether you’re a seasoned electrician or a do-it-yourself enthusiast, knowing how to bend conduit without a bender can be a valuable skill. Conduit bending is the process of shaping and curving metal pipes to run electrical wires and cables through walls, ceilings, and floors.

While using a dedicated conduit bender is the most efficient and accurate method, there are situations where you may not have access to one. Maybe you’re working on a small project at home and don’t want to invest in a specialized tool. Or perhaps you’re on a job site and the bender is unavailable. Whatever the reason, this article will guide you through alternative methods of bending conduit.

It’s important to note that bending conduit without a bender requires more skill and precision. You need to be cautious not to damage the conduit or compromise the integrity of the electrical installation. With the right technique and a few essential tools, you can achieve professional-looking bends without a bender.

In this article, we will walk you through understanding conduit bending, the materials and tools needed, preparing the conduit for bending, using alternative methods, and important tips for safety. By the end of this article, you’ll be ready to tackle conduit bending, even without a bender.

Key Takeaways:

- Bending conduit without a bender requires precision and alternative methods like the free-form technique or makeshift bending forms. It’s crucial to measure accurately, use the right tools, and prioritize safety for successful results.

- Understanding conduit bending basics, preparing the conduit, and following safety precautions are essential for bending without a bender. With practice and attention to detail, anyone can master this valuable skill.

Read more: How To Use Conduit Bender

Understanding Conduit Bending

Before we delve into the practical aspects of bending conduit without a bender, let’s first understand the basics of conduit bending. Conduit bending involves shaping metal pipes to create bends of various angles to accommodate the layout of electrical wiring.

The most common types of conduit used in electrical installations are rigid metal conduit (RMC) and electrical metallic tubing (EMT). RMC is made of steel and provides superior protection for wires in industrial and outdoor applications. EMT, on the other hand, is made of lighter-weight steel or aluminum, making it suitable for commercial and residential applications.

Conduit bending is necessary when routing wires around corners, through walls, or across ceilings with a smooth and professional look. It is crucial to get the angle and the radius of the bends correct to ensure that the wires can easily pass through and that the electrical system functions optimally.

When bending conduit, there are a few essential terms you need to be familiar with:

- Stub-up: The straight portion of conduit that extends vertically from the ground or surface.

- Bend radius: The measurement of the distance from the centerline of the conduit to the point of the bend.

- Gain: The additional length added to the conduit to compensate for the take-up or shrinkage that occurs during the bending process.

- Back-to-back bend: A bend where two conduits are bent in opposite directions, allowing them to be joined together in a back-to-back configuration.

Now that you have a basic understanding of conduit bending and some key terminology, let’s move on to the materials and tools you’ll need for bending conduit without a bender.

Materials and Tools Needed

When it comes to bending conduit without a bender, having the right materials and tools is crucial to achieving accurate and professional bends. Here’s a list of what you’ll need:

- Conduit: Start by purchasing the appropriate type and size of conduit for your electrical installation. Make sure to choose either rigid metal conduit (RMC) or electrical metallic tubing (EMT), depending on your project requirements.

- Conduit Pipe Cutter: A conduit pipe cutter is an essential tool for cutting the conduit to the desired length. It provides clean and precise cuts, ensuring a solid and secure fit when assembling the bends.

- Hacksaw: In the absence of a conduit pipe cutter, a hacksaw can be used to cut the conduit. However, be sure to use a metal-cutting blade and take your time to make clean and accurate cuts.

- Deburring Tool: After cutting the conduit, use a deburring tool or a file to remove any sharp or rough edges. This step is important to prevent damage to wires and ensure smooth passage through the conduit.

- Conduit Bender App (Optional): In the age of smartphones, there are several mobile apps available that can help you calculate and visualize the measurements and angles for bending conduit. While not necessary, these apps can be a handy resource for accurate bending.

- Measuring Tape: A measuring tape is essential for taking precise measurements and determining the length and position of the bends.

- Marker or Chalk: Use a marker or chalk to mark the desired bending points on the conduit. This will help you maintain accuracy and consistency throughout the bending process.

- Heat Source: Depending on the type of conduit being used, a heat source may be required for certain bending methods. This could be a propane torch or a heat gun, which helps soften the conduit before bending.

- Gloves and Safety Glasses: Safety should always be a priority when working with tools and materials. Wear gloves and safety glasses to protect your hands and eyes from any potential hazards.

Having the right materials and tools at hand will make the process of bending conduit without a bender much smoother and more efficient. With these essentials ready, you’re now well-prepared to move on to preparing the conduit for bending.

Preparing the Conduit for Bending

Before you can start bending conduit, it’s important to properly prepare the conduit to ensure accurate and precise bends. The steps below will guide you through the process:

- Measure and Mark: Begin by measuring the length of conduit required for your installation. Use a measuring tape to determine the distance and mark the points where the bends will be made.

- Cut the Conduit: Once you have marked the bending points, use a conduit pipe cutter or a hacksaw to cut the conduit to the desired length. Make sure to cut the conduit squarely to ensure proper alignment.

- Deburring: After cutting the conduit, use a deburring tool or a file to remove any burrs or sharp edges. This step is crucial to prevent damage to wires and ensure a smooth passage through the conduit.

- Consider the Bend Radius: The bend radius refers to the measurement from the centerline of the conduit to the point of the bend. It is important to calculate and consider the appropriate bend radius for the conduit size to avoid kinks or damage to the conduit walls.

- Pre-Bending Prep (For Heat Bending): If you’re using heat to bend the conduit, it’s necessary to soften the metal first. Use a heat source such as a propane torch or heat gun to warm up the section of the conduit where the bend will be made. This will make the metal more pliable and easier to bend.

- Bending Techniques: Depending on the method you choose, there are different techniques for bending conduit without a bender. Some common methods include the “free-form” method, where you manually bend the conduit using leverage and careful manipulation, or using a makeshift bending form or a vice.

- Cooling and Inspecting: After making the bend, it’s important to allow the conduit to cool down before handling. This will prevent the metal from warping or losing its shape. Once cooled, inspect the bend to ensure it matches the desired angle and radius.

By following these steps, you’ll be able to prepare the conduit correctly and set the stage for successful and accurate bending. Now that you’re prepared, let’s explore some alternative methods for bending conduit without a bender in the next section.

When bending conduit without a bender, use a spring bender or fill the conduit with sand before bending to prevent kinking. Bend slowly and carefully to avoid damaging the conduit.

Using Alternative Methods for Bending Conduit

While using a dedicated conduit bender is the most efficient and accurate method, there are alternative methods you can employ to bend conduit when a bender is not available. Here are a few techniques you can try:

- The Free-Form Method: This method involves manually bending the conduit using your hands and leverage. Start by gripping the conduit tightly near the bending point and slowly apply pressure to bend it to the desired angle. You can use your body weight and the leverage of your arms to assist in the bending process. It’s important to be patient and make small adjustments to achieve the desired bend gradually.

- Makeshift Bending Form: If you need to make multiple bends that require consistent angles, you can create a makeshift bending form. Use a piece of sturdy wood or metal and shape it to match the desired bend radius. Secure the conduit to the bending form and use leverage to bend the conduit around the form. This method allows for more precise and consistent bends.

- Vice Method: If you have access to a vice, you can utilize it to bend conduit. Simply secure one end of the conduit in the vice, leaving the portion to be bent free. Apply pressure to the free end of the conduit to achieve the desired bend. Make sure to support the conduit near the bending point to prevent it from collapsing or deforming.

- Hot Box Method: This method is suitable for bending PVC conduit. Place the PVC conduit inside a hot box or a homemade heating enclosure. Heat the conduit evenly until it becomes malleable. Carefully remove the conduit from the hot box and use gloved hands or bending tools to shape it according to the desired angle. Be cautious while working with heated materials and ensure adequate ventilation.

Remember to take your time and make gradual adjustments when using alternative bending methods. It may require some trial and error to achieve the desired bends, especially if you’re new to conduit bending. Practice on scrap pieces of conduit before attempting bends on the actual installation.

Each method has its own benefits and challenges, so choose the one that best suits your needs and the specific requirements of your project. Don’t forget to measure and mark the bending points accurately before attempting any bends.

Now that you have explored alternative bending methods, it’s important to keep some tips and safety precautions in mind. Let’s discuss these in the next section.

Read more: How To Measure Conduit Bending

Tips and Safety Precautions

Bending conduit without a bender requires careful attention to detail and adherence to safety guidelines. Here are some important tips and safety precautions to consider:

- Measure Twice, Cut Once: Before cutting the conduit, double-check your measurements to ensure accuracy. This will save you from wasting material or having to redo bends.

- Use the Right Conduit Type and Size: Make sure you’re using the appropriate type and size of conduit for your project. Rigid metal conduit (RMC) and electrical metallic tubing (EMT) have different bending characteristics, so choose the one that suits your needs.

- Wear Protective Gear: Whenever working with tools or materials, be sure to wear safety glasses and gloves to protect your eyes and hands from potential hazards.

- Take Breaks If Necessary: Bending conduit can be physically demanding. If you find yourself fatigued, take regular breaks to avoid injuries and maintain focus while bending.

- Practice on Scrap Conduit: If you’re new to conduit bending or using alternative methods, practice on scrap conduit first to get a feel for the process and familiarize yourself with the technique.

- Inspect Bends Carefully: After bending conduit, inspect the bends thoroughly for any cracks, kinks, or deformations. Replace any damaged sections before continuing with the installation.

- Work in a Well-Ventilated Area: If using heat to bend conduit, ensure that you’re working in a well-ventilated area to prevent the accumulation of fumes and the risk of inhaling hazardous chemicals.

- Seek Professional Help When Needed: If you’re uncertain about any aspect of bending conduit or feel that the job is beyond your skill level, don’t hesitate to seek help from a professional electrician.

By following these tips and safety precautions, you can ensure a smooth and safe bending process. Bending conduit without a bender requires patience, practice, and a focus on precision. Remember, it’s always better to take your time and achieve accurate bends rather than rush through the process and end up with subpar results.

Now that you’ve learned the techniques, tips, and safety precautions for bending conduit without a bender, you’re ready to embark on your bending journey. With practice and experience, you’ll become proficient in this valuable skill and be able to tackle a wide range of electrical installations with confidence.

Best of luck with your conduit bending endeavors!

Conclusion

Conduit bending without a bender may require more skill and patience, but it is a valuable skill to have in your repertoire as an electrician or DIY enthusiast. By understanding the basics of conduit bending, preparing the conduit properly, and utilizing alternative methods, you can achieve accurate and professional bends even without a bender.

Throughout this article, we discussed the importance of understanding conduit bending and the terminology associated with it. We also explored the materials and tools needed for bending conduit without a bender, such as conduit pipe cutters, deburring tools, and measuring tapes.

We then moved on to the steps involved in preparing the conduit for bending, including measuring and marking the bending points, cutting the conduit to the desired length, and ensuring a smooth and burr-free surface. It’s crucial to consider the bend radius and, if using heat for bending, to soften the conduit appropriately.

We also looked at various alternative methods for bending conduit without a bender, such as the free-form method, makeshift bending forms, the vice method, and the hot box method for PVC conduit. Each method has its own benefits and challenges, so choose the one that suits your project needs best.

Finally, we provided some essential tips and safety precautions to keep in mind while bending conduit without a bender. These tips include measuring twice, wearing protective gear, practicing on scrap conduit, and seeking professional help if needed.

By following the techniques, tips, and safety precautions outlined in this article, you can successfully bend conduit without a bender and achieve professional-looking results. Remember, practice makes perfect, so don’t be discouraged if your first attempts aren’t flawless. With time and experience, you’ll become proficient in bending conduit without a bender.

Now it’s time to put your knowledge to the test and start bending conduit like a pro. So grab your materials, tools, and safety gear, and get ready to tackle your next electrical installation with confidence!

Now that you've mastered bending conduit without a bender, don't miss our next guide on seamless conduit setup inside walls. Perfecting the installation process can save you both time and headaches in future projects. Whether you're a seasoned handyperson or just starting, knowing how to professionally install conduit ensures your home improvements look great and meet safety standards. Get ready to tackle this next challenge with confidence!

Frequently Asked Questions about How To Bend Conduit Without A Bender

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Bend Conduit Without A Bender”