Articles

What Are Biscuits Used For In Woodworking

Modified: January 6, 2024

Learn all about the various uses of biscuits in woodworking with our informative articles. Master the art of joinery and enhance your woodworking skills.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

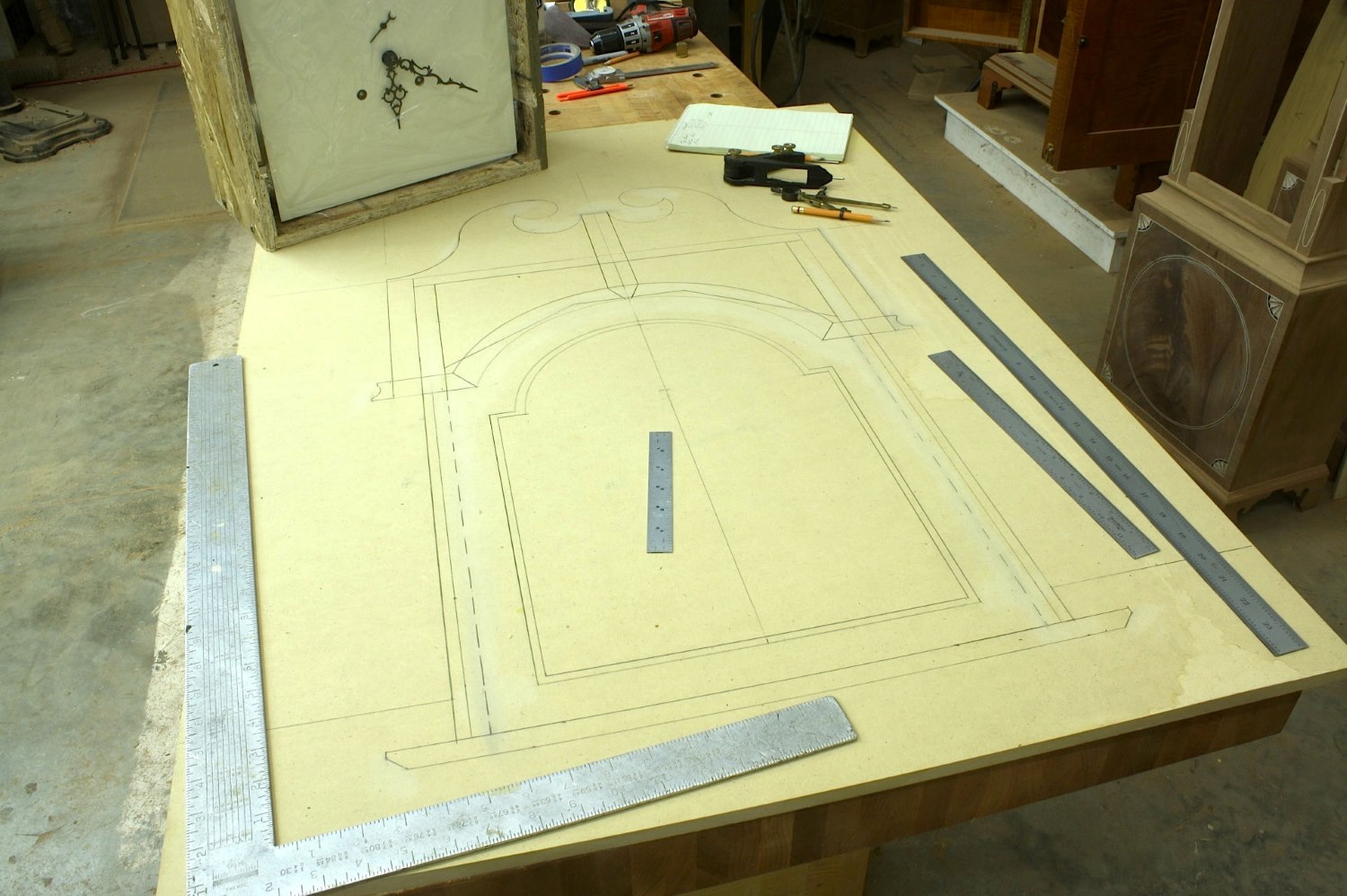

Woodworking is a timeless craft that requires precision and skill. From constructing furniture to creating intricate designs, woodworkers rely on various techniques and tools to bring their visions to life. One such technique that has gained popularity in recent years is the use of biscuits in woodworking.

Biscuits, also known as plate joiners, are small, oval-shaped wooden pieces that are inserted into slots cut in the surface of two pieces of wood. These slots are created using a biscuit joiner, a specialized power tool that cuts matching slots in the wood. Once the biscuits are inserted and glued, they create a strong and stable joint between the two pieces.

In this article, we will explore the different applications of biscuits in woodworking and their benefits. Whether you are a seasoned woodworker or just starting out, understanding how to use biscuits effectively can greatly enhance the quality and durability of your projects.

Next, we will delve into the various joinery applications of biscuits in woodworking.

Key Takeaways:

- Biscuits in woodworking offer enhanced joint strength, improved alignment, and simplified assembly. They provide versatility in creating various joint types and contribute to the overall durability and longevity of woodworking projects.

- When working with biscuits, attention to detail is crucial. Selecting the right biscuit size, accurately marking biscuit slot locations, and applying sufficient glue are essential for achieving seamless and visually appealing joints.

Read more: What Should Be Used When Using Hand Tools

Biscuits in Woodworking: An Overview

Biscuits are a versatile and practical tool in woodworking, offering a range of benefits that contribute to the overall strength and stability of a project. One of the primary uses of biscuits is in joinery.

When two pieces of wood need to be joined together, biscuits provide a simple yet effective solution. The biscuit joiner cuts a precise slot in each piece of wood, and a biscuit is inserted into each slot. The biscuits are then glued in place, creating a strong bond that holds the pieces together.

The size of the biscuit and the depth of the slot can be adjusted to suit the specific needs of the project. This flexibility allows woodworkers to create various joint types, including butt joints, miter joints, and T-joints. By using biscuits, woodworkers can create tight, seamless joints that are not only visually appealing but also structurally sound.

One of the key advantages of using biscuits in joinery is their ability to align and reinforce the joint. The biscuits act as alignment aids, ensuring that the two pieces of wood are perfectly positioned before the glue is applied. This helps to eliminate gaps and irregularities in the joint, resulting in a more professional finish.

Moreover, biscuits add stability and strength to the joint by increasing the gluing surface area. When the glue dries, it adheres not only to the surfaces of the wood but also to the biscuits, effectively creating a larger bonding area. This, in turn, enhances the overall strength and durability of the joint, minimizing the risk of failure or separation over time.

Another advantage of using biscuits in woodworking is their ability to compensate for wood movement. Wood naturally expands and contracts with changes in humidity and temperature. By incorporating biscuits into the joint, the wood is allowed to move within the slots, reducing the likelihood of cracks or warping.

In addition to their applications in joinery, biscuits are also valuable for edge joining and laminate work. When two boards need to be joined along their edges, biscuits can help align the pieces and improve the glue bond. Similarly, in laminate work, where thin sheets of veneer or laminate are applied to a substrate, biscuits assist in aligning the laminate layers and securing them in place.

Overall, the use of biscuits in woodworking provides numerous benefits in terms of joint strength, alignment, reinforcement, and compensation for wood movement. In the following sections, we will dive deeper into specific applications of biscuits in woodworking, as well as tips and techniques for working with them effectively.

Joinery Applications of Biscuits

Biscuits play a crucial role in various joinery applications in woodworking. They provide a secure and durable method for connecting two pieces of wood, allowing woodworkers to create strong and visually pleasing joints. Let’s explore some of the common joinery applications of biscuits:

1. Butt Joints: Butt joints are one of the simplest and most common forms of joinery. Two boards are joined together at their ends to create a right angle. Biscuits can be used to strengthen the joint by adding additional glue surface area and alignment assistance.

2. Miter Joints: Miter joints are widely used in woodworking projects that require seamless corners, such as picture frames or box construction. Biscuits help to align the mitered pieces, ensuring a tight and precise joint. They also add strength and stability to the joint, preventing it from pulling apart.

3. T-Joints: T-joints are formed when one piece of wood is joined to the edge of another, forming the shape of a “T.” Biscuits can be used to reinforce these joints, providing additional gluing surface area and improving the overall strength and stability of the connection.

4. Corner Blocks: In larger woodworking projects, such as cabinets or bookshelves, corner blocks are often used to strengthen the corners. Biscuits can be inserted into the corner blocks to reinforce the joint and prevent the corners from separating or weakening over time.

5. Dowel Joinery Alternatives: Biscuits can act as alternatives to traditional dowel joinery. While dowels require precise drilling and can be time-consuming, biscuits offer a quicker and easier solution. The biscuit joiner cuts the slots in a fraction of the time, and the biscuits can be easily inserted and glued, providing a strong and reliable joint.

6. Panel Assembly: When joining panels together to create larger surfaces, such as tabletops or cabinet doors, biscuits aid in keeping the panels aligned and flat. They prevent the boards from shifting during the glue-up process, resulting in a flat and seamless surface.

These are just a few examples of the joinery applications where biscuits shine in woodworking projects. By incorporating biscuits into these joints, woodworkers can ensure strong and reliable connections that withstand the test of time. In the next section, we will explore how biscuits can strengthen and reinforce various woodworking joints.

Strengthening and Reinforcement with Biscuits

Biscuits are not only useful for joining two pieces of wood together, but they also serve as a means of strengthening and reinforcing various woodworking joints. By incorporating biscuits into the joint, woodworkers can create connections that are more stable, durable, and resistant to stress. Let’s explore how biscuits contribute to the strengthening and reinforcement of woodworking joints:

1. Increased Glue Surface Area: When a biscuit is inserted into a joint, it creates additional gluing surface area for the adhesive to bond with. This increased surface area enhances the strength and stability of the joint, reducing the risk of failure. The glue adheres to both the surfaces of the wood and the biscuit, creating a strong bond that reinforces the connection.

2. Prevention of Joint Separation: Woodworking joints are susceptible to stress and movement over time, which can lead to joint separation. Biscuits help to prevent this by distributing the stress evenly across the joint, making it less likely to separate or weaken. The added reinforcement provided by the biscuits ensures that the joint remains intact, even under heavy use or external forces.

3. Load Distribution: In load-bearing structures or furniture pieces, the distribution of weight and load is crucial for the longevity and durability of the joint. Biscuits aid in evenly distributing the load across the joint, reducing the strain on individual areas and minimizing the risk of failure. This is particularly important in projects such as table legs or chair frames, where the joints experience constant pressure.

4. Joint Alignment: One of the key factors in the strength of a joint is its alignment. Misaligned joints can result in weaker connections and compromised stability. Biscuits act as alignment aids, ensuring that the pieces of wood are perfectly aligned before the glue is applied. This helps to eliminate gaps and irregularities, resulting in a stronger and more secure joint.

5. Reinforcement for Weak Points: In some woodworking projects, certain joints or areas may be prone to weakness or vulnerability. For example, long-grain-to-long-grain connections are generally weaker than other joints. By incorporating biscuits into these weak points, woodworkers can strengthen and reinforce them, increasing their overall strength and durability.

6. Resistance to Shear and Torsion Forces: Biscuits provide a considerable amount of resistance against shear and torsion forces, which can threaten the integrity of a joint. The additional gluing surface area created by the biscuits helps to distribute and absorb these forces, preventing the joint from failing under pressure.

By using biscuits for strengthening and reinforcement purposes, woodworkers can ensure that their projects are built to last. The added stability and durability provided by biscuits contribute to the overall quality and longevity of woodworking joints. In the next section, we will explore how biscuits aid in the alignment and assembly of wood pieces.

Alignment and Assembly Using Biscuits

Alignment and precise assembly are crucial aspects of woodworking, as they directly impact the quality and strength of the final product. Biscuits play a significant role in ensuring accurate alignment and seamless assembly of wood pieces. Let’s explore how biscuits aid in alignment and assembly in woodworking:

1. Alignment Assistance: Biscuits act as alignment aids, helping woodworkers achieve precise alignment between two pieces of wood. When the biscuit joiner cuts slots in the wood, it creates reference points that guide the positioning of the pieces. The biscuits fit snugly into these slots, ensuring that the wood pieces are aligned correctly before applying glue and clamping them together.

2. Elimination of Gaps: The tight fit of biscuits within the slots helps eliminate gaps between the wood pieces. Gaps can compromise the overall strength and stability of the joint, as they create weak points that are susceptible to future failure. Biscuits help ensure a seamless connection by pulling the wood pieces closer together, resulting in a joint that is both visually appealing and structurally sound.

3. Ease of Assembly: Biscuits simplify the assembly process by providing easy insertion and alignment points for the wood pieces. The slots cut by the biscuit joiner serve as guides, allowing for quick and accurate insertion of the biscuits. This saves time and effort during the assembly phase, streamlining the overall woodworking process.

4. Clamping Efficiency: When using biscuits, the wood pieces can be clamped together more efficiently. The biscuits aid in holding the joint in place, making it easier to align and secure the pieces with clamps. This ensures a consistent and even distribution of pressure across the joint, promoting a stronger and more secure bond.

5. Accurate Joinery: Biscuits contribute to accurate joinery by providing a standardized method for aligning and connecting pieces of wood. The slots created by the biscuit joiner are consistently sized, allowing for precise fitting of the biscuits. This standardized approach helps woodworkers achieve repeatable results and ensures that the joints are aligned correctly every time.

6. Complex Assembly: In projects that involve complex assembly, such as cabinetry or furniture with multiple components, biscuits simplify the process. They assist in aligning and joining various parts, ensuring that the pieces fit together seamlessly. This is particularly useful when working with large or intricate projects that require precise alignment and a high level of craftsmanship.

Overall, biscuits enhance the alignment and assembly process in woodworking by providing reference points, eliminating gaps, simplifying clamping, and aiding in accurate joinery. Their contribution to precise alignment ensures that woodworking projects are assembled with accuracy and attention to detail. In the next section, we will delve into how biscuits are used for edge joining and laminate work.

Read more: How To Use Biscuit Dough In A Waffle Iron

Biscuits for Edge Joining and Laminate Work

Biscuits are not only valuable for traditional joinery applications, but they also have a significant role in edge joining and laminate work. These applications involve the joining of thin boards or the application of veneers or laminates to a substrate. Let’s explore how biscuits are used in edge joining and laminate work in woodworking:

1. Edge Joining: When two boards need to be joined along their edges to create a wider surface, biscuits play a crucial role in achieving a strong and seamless joint. The biscuit joiner is used to cut matching slots in the edges of the boards, and biscuits are then inserted into the slots. The biscuits aid in aligning the edges, ensuring a tight fit, and provide additional reinforcement through the glue bond.

2. Alignment and Stability: Edge joining can be challenging, as it requires precise alignment of the boards to create a smooth and even surface. Biscuits act as alignment aids, guiding the positioning of the boards and ensuring that they are perfectly flush. The biscuits also add stability to the joint, preventing the boards from shifting or separating over time.

3. Laminate Work: Biscuits are beneficial in laminate work, where thin sheets of veneer or laminate are applied to a substrate to create decorative or functional surfaces. Biscuits are used to align the laminate layers and secure them in place, creating a smooth and cohesive finish. The biscuits help ensure accurate placement of the laminate and prevent shifting or bubbling during the adhesive curing process.

4. Strengthening and Reinforcement: In edge joining and laminate work, biscuits provide additional strength and reinforcement to the joint or the laminated surface. They increase the gluing surface area and distribute the stress more evenly, creating a more durable and long-lasting bond. Biscuits help prevent the edges of the boards from warping or separating and add stability to the laminate layers, reducing the risk of delamination.

5. Versatile Applications: Biscuits can be used in a variety of edge joining and laminate work scenarios. Whether it’s joining wide panels to create tabletops or countertops, edge joining small boards to create a panel, or applying laminates to curved surfaces, biscuits provide flexibility and versatility. They can be adjusted in size to accommodate different thicknesses of materials and are effective in various wood types, as well as other materials like plywood and MDF.

By incorporating biscuits into edge joining and laminate work, woodworkers can achieve seamless and stable results. The alignment assistance, reinforcement, and versatility of biscuits make them an invaluable tool in these applications. In the next section, we will explore the benefits of using biscuits in woodworking.

When using biscuits in woodworking, be sure to apply glue to both the biscuit and the slot for a strong bond. Also, consider the size of the biscuit in relation to the thickness of the wood for best results.

Benefits of Using Biscuits in Woodworking

The utilization of biscuits in woodworking offers several benefits that contribute to the overall quality, stability, and efficiency of projects. From enhancing joint strength to simplifying assembly processes, biscuits have become a valuable tool in the woodworking industry. Let’s explore the advantages of using biscuits:

1. Enhanced Joint Strength: Biscuits significantly contribute to the strength of woodworking joints. By providing additional gluing surface area, they increase the bond’s overall strength and durability. The biscuits, when inserted and glued into the slots, effectively reinforce the joint, reducing the risk of separation or failure under stress or movement.

2. Improved Alignment: Biscuits act as alignment aids in woodworking, assisting in achieving accurate and seamless joint alignment. The slots created by the biscuit joiner guide the placement of the wood pieces, ensuring precise positioning before gluing. This results in tight and flush joints, eliminating unsightly gaps and promoting a professional finish.

3. Simplified Assembly: The use of biscuits simplifies the assembly process in woodworking projects. With the aid of biscuits, woodworkers can easily align and connect the wood pieces before clamping and gluing. This saves time and effort while maintaining accurate joint alignment, making the assembly process more efficient and streamlined.

4. Versatile Joint Options: Biscuits offer versatility in creating various joint types. Depending on the project requirements, biscuits can be used to create butt joints, miter joints, T-joints, and more. This versatility allows woodworkers to choose the most suitable joint type for their specific needs, ensuring both visual appeal and strength.

5. Compensation for Wood Movement: Wood naturally expands and contracts with changes in humidity and temperature. Biscuits allow for slight movement within the slots, enabling the wood to expand and contract without compromising the joint’s integrity. This compensation for wood movement reduces the likelihood of cracks, warping, or other damage that may occur over time.

6. Precision and Consistency: Biscuits aid in achieving precision and consistency in woodworking projects. The use of a biscuit joiner ensures that the slots are cut accurately and consistently on both wood pieces. This standardized approach results in repeatable and reliable joints, regardless of the number of connections made throughout the project.

7. Accessibility and Ease of Use: Biscuits are readily available in various sizes and shapes, making them accessible to woodworkers of all levels. The biscuit joiner is relatively easy to use and offers straightforward adjustments for slot depth and cutting angles. This accessibility and ease of use make biscuits a practical choice for woodworkers of all skill levels.

Whether you are a professional woodworker or a hobbyist, incorporating biscuits into your woodworking projects brings numerous benefits. The enhanced joint strength, improved alignment, simplified assembly, and versatility that biscuits offer contribute to the overall quality and durability of your woodworking creations. In the next section, we will explore the different types of biscuit joiners and accessories available to enhance your woodworking experience.

Types of Biscuit Joiners and Accessories

When it comes to using biscuits in woodworking, having the right tools and accessories is essential. Biscuit joiners, also known as plate joiners, come in different types and offer various features to suit different woodworking needs. Let’s explore the types of biscuit joiners and accessories commonly used in woodworking:

1. Handheld Biscuit Joiners: Handheld biscuit joiners are the most common type of joiner used in woodworking. These portable tools are versatile and easy to maneuver, making them suitable for both small-scale and large-scale projects. Handheld biscuit joiners typically offer adjustable depth settings, allowing for precise and consistent biscuit slot cuts.

2. Stationary Biscuit Joiners: Stationary biscuit joiners are larger, more powerful tools that are often used in professional woodworking shops. These heavy-duty joiners are designed for heavy use and can handle larger boards and thicker materials. Stationary joiners are commonly used for commercial or industrial woodworking projects that require speed and efficiency.

3. Fence and Depth Stop Accessories: Many biscuit joiners come with fence and depth stop accessories. These accessories allow for consistent biscuit slot cutting by providing a guide for the joiner’s base plate and controlling the depth of the slot. The fence and depth stop accessories are adjustable, enabling woodworkers to customize the size and position of the biscuit slots.

4. Dust Collection Attachments: Biscuit joiners can generate a significant amount of dust during operation. Dust collection attachments help to minimize dust and debris by capturing it directly at the point of cutting. This not only keeps the workspace cleaner but also improves visibility and prevents dust from interfering with the adhesive bond during the gluing process.

5. Different Sizes and Types of Biscuits: Biscuits come in various sizes, typically categorized by numbers such as #0, #10, #20, etc. The biscuit size and type depend on the application and the thickness of the materials being joined. It is important to select the appropriate biscuit size to ensure a proper fit and a strong joint.

6. Glue and Clamping Accessories: While not specific to biscuit joiners, glue and clamping accessories are essential for using biscuits effectively. Woodworkers can choose from a variety of woodworking adhesives suitable for their specific project requirements. Additionally, adopting proper clamping techniques and using clamps of appropriate size and pressure ensure that the joint remains secure during the curing process.

It is important to select a biscuit joiner and accessories that align with your specific woodworking needs. Consider the scale of your projects, the materials you work with, and the level of precision and customization required. By having the right tools and accessories, you can unleash the full potential of biscuits in your woodworking endeavors. In the following section, we will explore some useful tips and techniques for working with biscuits effectively.

Tips and Techniques for Working with Biscuits

Working with biscuits in woodworking requires precision and attention to detail to achieve optimal results. Here are some useful tips and techniques to help you work with biscuits effectively:

1. Select the Right Biscuit Size: Choose the appropriate biscuit size based on the thickness and type of wood you are working with. The size should allow for a snug fit without causing the wood to split or deform.

2. Test Cuts and Fit: Before making the final biscuit cuts, perform test cuts on scrap wood to ensure the biscuit joins fit tightly and securely. This allows you to make any necessary adjustments before cutting into your actual project pieces.

3. Mark Biscuit Locations: Measure and mark the locations for the biscuit slots on both wood pieces. This ensures accurate alignment and prevents mistakes during the cutting process.

4. Use a Biscuit Joiner Guide: A biscuit joiner guide, also known as a fence or jig, helps maintain consistency in the depth and position of the biscuit slot cuts. This ensures a precise and flush joint.

5. Consider Grain Direction: When placing biscuit slots, take into account the direction of the wood grain. Align the biscuit slots perpendicular to the grain for added joint strength and stability.

6. Apply the Right Amount of Glue: Apply an even layer of woodworking adhesive to the biscuit slots, ensuring sufficient coverage for a strong bond. Avoid over-applying glue, as excess glue can cause a messy joint and weaken the bond.

7. Align and Clamp Immediately: Once the biscuits are inserted into the slots and glued, quickly align the wood pieces and clamp them together. This prevents the glue from drying prematurely and ensures a tight and secure joint.

8. Remove Excess Glue: Wipe off any excess glue that squeezes out from the joint immediately. This will prevent hardened glue from interfering with future sanding, staining, or finishing processes.

9. Allow Sufficient Drying Time: Follow the manufacturer’s instructions for the recommended drying time for the adhesive used. Avoid rushing the process as this can compromise the integrity of the joint.

10. Sand and Finish with Care: After the glue has fully dried, sand the joint area to achieve a smooth and seamless finish. Pay attention to blending the joint with the surrounding wood surface. Apply the desired finish or stain to match the overall project.

By implementing these tips and techniques, you can maximize the effectiveness of biscuits in your woodworking projects. Remember to practice proper safety precautions when using power tools and always follow the manufacturer’s instructions for your specific biscuit joiner. Now, we will explore some common mistakes made when working with biscuits and how to avoid them in the next section.

Read more: What Hand Tools To Use For Etching

Common Mistakes and How to Avoid Them

Working with biscuits in woodworking can yield outstanding results, but it is important to be aware of common mistakes that can compromise the quality of your joints. Here are some common mistakes and tips on how to avoid them:

1. Incorrect Biscuit Size: Using the wrong biscuit size can weaken the joint or lead to poor alignment. Ensure that you choose the appropriate biscuit size based on the thickness and type of wood being joined.

2. Improper Slot Depth: Cutting biscuit slots too shallow or too deep can affect the joint’s strength and stability. Always adjust the biscuit joiner’s depth setting to achieve the correct slot depth for the chosen biscuit size.

3. Inaccurate Alignment: Failing to accurately mark the biscuit slot locations or misaligning the wood pieces during assembly can result in gaps or misaligned joints. Take the time to measure and mark the biscuit positions accurately and use alignment aids such as clamps or jigs to ensure precise alignment.

4. Insufficient Glue Application: Applying too little glue or unevenly distributing the glue on the biscuit slots can weaken the bond. Apply an even layer of adhesive, ensuring complete coverage on both the biscuits and the wood surfaces.

5. Rushing the Clamping Process: Clamping the joint too quickly after applying the glue can result in misalignment or incomplete bonding. Take the time to accurately align the wood pieces before clamping and allow sufficient time for the glue to dry according to the manufacturer’s instructions.

6. Ignoring Wood Grain Direction: Failing to align the biscuit slots perpendicular to the wood grain can compromise the joint’s strength. Ensure that the biscuit slots are placed in alignment with the grain for optimal stability.

7. Neglecting to Sand and Finish: Skipping the necessary sanding and finishing steps after the joint is complete can result in a rough or unfinished appearance. Take the time to properly sand the joint area and apply the desired finish or stain to match the overall project.

8. Overlooking Safety Precautions: Accidents can occur if proper safety precautions are not followed when working with power tools. Always wear appropriate safety gear, such as goggles and ear protection, and ensure that the biscuit joiner is used in accordance with safety guidelines.

By being mindful of these common mistakes, you can avoid potential pitfalls and achieve strong, precise, and visually appealing joints when using biscuits in your woodworking projects. Take the time to plan, measure, and execute each step carefully to achieve the best results.

Conclusion

Biscuits have become a valuable tool in woodworking, offering a range of benefits for joining, aligning, and reinforcing wood pieces. From their ability to enhance joint strength to their assistance in alignment and assembly, biscuits have revolutionized the way woodworkers approach their projects.

By using biscuits, woodworkers can create stronger, more stable joints that withstand the test of time. The increased gluing surface area, alignment assistance, and compensation for wood movement contribute to the overall durability and longevity of the joints.

Furthermore, biscuits simplify the assembly process, allowing for accurate alignment and efficient clamping. They are versatile tools that can be used in a variety of joinery applications, such as butt joints, miter joints, T-joints, and corner blocks.

When working with biscuits, it is crucial to select the right biscuit size, accurately mark biscuit slot locations, and apply sufficient glue for a strong bond. Attention to detail in alignment, clamping, and finishing will ensure seamless and visually appealing joints.

Additionally, woodworkers should be aware of common mistakes such as using incorrect biscuit sizes, improper slot depth, and neglecting wood grain direction. By taking the time to avoid these errors, woodworkers can maximize the effectiveness of biscuits in their projects.

In conclusion, biscuits offer a practical and efficient solution for joinery and assembly in woodworking. Incorporating biscuits into your projects will not only enhance the strength and stability of your joints, but also streamline the woodworking process, resulting in professional-quality results. So, don’t hesitate to explore the world of biscuits and discover how they can elevate your woodworking skills and craftsmanship.

Frequently Asked Questions about What Are Biscuits Used For In Woodworking

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Biscuits Used For In Woodworking”