Home>Articles>What Are The Disadvantages Of Spray Foam Insulation

Articles

What Are The Disadvantages Of Spray Foam Insulation

Modified: December 7, 2023

Discover the drawbacks of spray foam insulation through informative articles. Learn about its downsides and make an informed decision for your next insulation project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

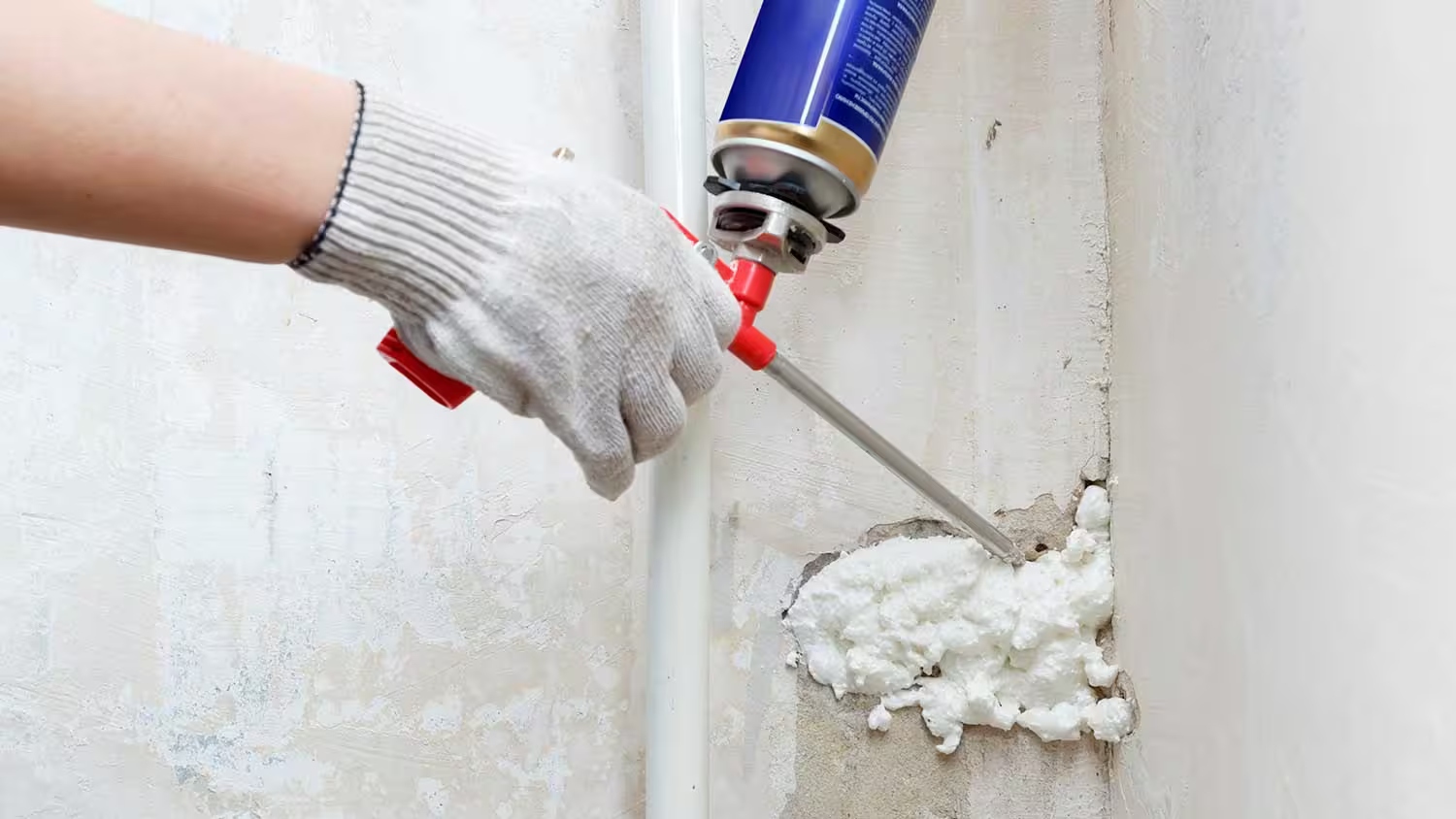

Spray foam insulation has gained popularity in recent years for its ability to provide superior insulation, energy efficiency, and air sealing. It is commonly used in residential and commercial buildings to create an airtight barrier, reducing energy consumption and enhancing comfort. However, like any other construction material, spray foam insulation also has its disadvantages that are worth considering before making a decision.

In this article, we will explore some of the major drawbacks of spray foam insulation. While it is important to weigh the pros and cons, it is crucial to highlight these limitations to ensure that homeowners and contractors make informed decisions.

Key Takeaways:

- Consider the cost, health risks, and environmental impact before opting for spray foam insulation. Proper installation, ventilation, and maintenance are crucial to maximize benefits and minimize drawbacks.

- While spray foam insulation offers superior performance, be mindful of its limitations. Consult professionals, weigh the pros and cons, and ensure proper planning for successful installation and use.

Read more: What Is The Best Spray Foam Insulation

Cost

One of the primary concerns with spray foam insulation is its cost. Compared to other insulation materials such as fiberglass batts or cellulose, spray foam insulation can be significantly more expensive.

There are several factors that contribute to the higher cost of spray foam insulation. First, the materials used in spray foam insulation, such as polyurethane, tend to be more expensive. Additionally, the installation process itself requires specialized equipment and trained professionals, which can further drive up the cost.

Furthermore, the cost of spray foam insulation can vary depending on the size and complexity of the project. Larger buildings or areas with irregular shapes and tight spaces may require more material and labor, leading to higher costs.

While spray foam insulation can provide long-term energy savings, it is important to consider the initial investment required. Homeowners should weigh the potential energy savings against the higher upfront costs to determine if spray foam insulation is a viable option for their budget.

Installation Process

The installation process of spray foam insulation requires professional expertise and specialized equipment. Unlike traditional insulation materials that can be easily installed by homeowners or general contractors, spray foam insulation should be handled by trained professionals.

One of the challenges in the installation process is achieving proper coverage and uniform thickness. Spray foam insulation needs to be sprayed evenly and in sufficient thickness to create an airtight seal. Inexperienced installers may struggle to achieve the desired results, resulting in air leaks or inadequate insulation.

Moreover, the installation process can be time-consuming and disruptive. The area to be insulated needs to be free from debris, dust, and potential moisture sources. This means that existing walls may need to be opened up or surfaces prepared before the insulation can be applied. This can be particularly challenging in retrofit or renovation projects where access to walls or attics may be limited.

It is important to note that the installation process can also be messy. The spray foam insulation expands rapidly upon application, and excess foam may need to be trimmed and cleaned up. Any overspray or spills can be difficult to remove and may require additional effort and expense to rectify.

Overall, the installation process of spray foam insulation requires specialized knowledge, careful attention to detail, and proper preparation. It is crucial to hire experienced professionals to ensure that the insulation is installed correctly and effectively.

Health Risks

While spray foam insulation is known for its excellent insulation properties, it is important to be aware of the potential health risks associated with its installation and use.

One of the main concerns is the release of volatile organic compounds (VOCs) during and after the installation process. VOCs are chemicals that can be emitted as gases from certain materials. Some of the chemicals used in spray foam insulation, such as isocyanates, can release VOCs that may cause eye, nose, and throat irritation, respiratory issues, and even allergic reactions. It is important for those who are sensitive or have respiratory conditions to take necessary precautions or consider alternative insulation options.

During the installation process, proper ventilation is crucial to minimize the exposure to VOCs. Installers should wear protective gear and ensure that the area being insulated is well-ventilated. Homeowners should also vacate the premises during installation and allow sufficient time for the foam to cure and VOC levels to dissipate before reoccupying the space.

In addition to VOCs, spray foam insulation can pose a fire hazard. Although properly installed and cured foam is generally resistant to flames, it can release toxic fumes when exposed to high temperatures. It is important to follow local building codes and fire safety regulations to minimize the risk of fire and ensure adequate fire protection measures are in place.

Furthermore, some individuals may be more sensitive or allergic to the chemicals used in spray foam insulation. It is important to consult with a medical professional if you have a history of allergies or respiratory issues before considering spray foam insulation for your home.

In summary, while spray foam insulation offers numerous benefits, it is important to be aware of the potential health risks associated with it. Proper ventilation, following safety guidelines, and taking necessary precautions can help minimize these risks and ensure a safe indoor environment.

Environmental Impact

While spray foam insulation provides excellent insulation performance, it is not without its environmental impact. It is important to consider the potential consequences of using spray foam insulation on the environment.

One of the primary concerns is the carbon footprint associated with the production of spray foam insulation materials. The manufacturing process of the materials used in spray foam insulation, such as polyurethane, can emit greenhouse gases and contribute to climate change. Additionally, the chemicals used in the production and installation of spray foam insulation may have harmful effects on the environment, including air and water pollution.

Furthermore, the disposal of spray foam insulation can be problematic. Once installed, spray foam insulation is not easily removable or recyclable. In the event that insulation needs to be replaced or removed, it can be challenging to dispose of properly. Improper disposal can result in the release of harmful substances into the environment and contribute to landfill waste.

Another environmental concern is the depletion of non-renewable resources. Some insulation materials, such as fiberglass or cellulose, are made from renewable or recycled materials. In contrast, spray foam insulation typically requires the use of non-renewable resources, such as petroleum-based chemicals.

However, it is worth noting that spray foam insulation can contribute to energy efficiency and reduce overall energy consumption in buildings. By creating an airtight seal, spray foam insulation helps to reduce heat loss or gain, resulting in lower energy bills and reduced reliance on heating and cooling systems. This can ultimately lead to a decrease in greenhouse gas emissions associated with energy production.

It is important to weigh the environmental impact of spray foam insulation against its energy-saving benefits. There are also alternative insulation materials available that are more environmentally friendly, such as natural fiber insulation or recycled insulation materials.

In summary, while spray foam insulation offers excellent insulation performance, it is important to consider its environmental impact. Exploring alternative insulation materials and practices can help to minimize the negative effects on the environment.

When using spray foam insulation, be aware that it can be more expensive than other insulation options and may require professional installation to ensure proper application and safety. Additionally, it can be difficult to remove or reapply once installed.

Read more: How To Spray Foam Insulation

Limited Application Areas

Spray foam insulation may not be suitable for all areas or types of construction projects. There are certain limitations to where and how spray foam insulation can be effectively used.

Firstly, spray foam insulation is ideal for new construction or major renovation projects where walls, attics, or other surfaces are accessible. It is difficult to retrofit existing buildings with spray foam insulation, especially if there are limited access points or obstacles in the way. In such cases, alternative insulation methods may be more suitable.

Secondly, spray foam insulation is not suitable for areas with high moisture levels. The moisture can interfere with the adhesive properties of the foam and can result in poor adhesion, which can compromise the effectiveness of the insulation. In areas prone to frequent water intrusion or high humidity, alternative moisture-resistant insulation materials may be a better choice.

In addition, spray foam insulation may not be recommended for certain building materials. For example, some types of foam can emit chemicals that can degrade or react with certain plastics or materials. It is important to consult with professionals to determine the compatibility of spray foam insulation with specific materials used in a building.

Moreover, spray foam insulation should be applied within specific temperature ranges. Extreme temperatures can affect the curing process and overall performance of the insulation. Installers need to consider the climate conditions during the installation process and follow the manufacturer’s guidelines for proper application.

Lastly, there may be building code restrictions or requirements that limit the use of spray foam insulation in certain areas. Local regulations may specify the types of insulation materials allowed and their fire safety ratings. It is crucial to consult with local authorities or building officials to ensure compliance with applicable codes and regulations.

While spray foam insulation can be highly effective in the right circumstances, it is important to assess the compatibility, accessibility, and environmental conditions of the project before deciding on its application.

Potential for Moisture and Mold Issues

One of the potential drawbacks of spray foam insulation is its susceptibility to moisture-related issues, including the growth of mold and mildew. While spray foam insulation is known for its air sealing properties, its impermeable nature can trap moisture within the building envelope if not properly installed or if there are underlying moisture issues.

If moisture becomes trapped between the spray foam insulation and the substrate, it can create an environment conducive to the growth of mold and mildew. Mold can not only cause structural damage but also poses health risks to occupants, especially those with allergies or respiratory conditions.

It is crucial to address any existing moisture issues before installing spray foam insulation. This includes fixing any leaks, addressing water intrusion, and ensuring proper ventilation and moisture control measures are in place. Proper installation techniques, such as sealing all gaps and cracks, are also essential to prevent moisture from entering and becoming trapped within the insulation.

Furthermore, in the event that moisture issues do occur, it can be challenging to detect and remediate the problem. The impermeability of spray foam insulation makes it difficult to visually inspect for moisture or mold growth. Infrared cameras or moisture meters may be needed to identify potential problem areas. If mold growth is found, it may require professional remediation and potentially the removal of the affected insulation, which can be costly and time-consuming.

It is important to note that not all spray foam insulation materials or formulations are created equal when it comes to moisture resistance. Some types of spray foam insulation have better moisture management properties than others. Consulting with professionals who are experienced in spray foam insulation can help in selecting the appropriate type of insulation and ensuring proper installation techniques are followed to minimize the risk of moisture-related issues.

In summary, while spray foam insulation can provide excellent insulation and air sealing properties, there is a potential for moisture-related issues if not installed or maintained properly. Addressing existing moisture issues, ensuring proper ventilation, and selecting the right type of spray foam insulation can help mitigate these risks and maintain a healthy and dry indoor environment.

Difficulties in Renovation or Repair

One of the challenges associated with spray foam insulation is the difficulty of renovation or repair work in areas where it has been installed. Unlike other types of insulation materials that can be easily removed and replaced, spray foam insulation can present obstacles when it comes to making changes or repairs to a building.

One issue is the permanence of spray foam insulation. Once it is applied and has cured, it becomes a solid and rigid material that cannot be easily removed or altered. This can make it challenging to access underlying structures, plumbing, or electrical systems for maintenance or repairs.

In some cases, removal of spray foam insulation may be necessary to address specific issues or accommodate renovations. However, removing spray foam insulation can be a difficult and labor-intensive process. It often requires the use of specialized tools and the expertise of professionals experienced in the removal process.

Another difficulty arises when additional insulation or upgrades are desired. Since spray foam insulation creates a tight and complete seal, it can be challenging to add new insulation or make changes without compromising the integrity of the existing insulation. This can limit the options for future insulation upgrades or modifications.

Additionally, the presence of spray foam insulation can impact the accessibility of pipes, plumbing, and electrical wiring. For example, in the event of a leak or issue with these systems, accessing them for repairs or maintenance can require extensive cutting or removal of the insulation, which can be time-consuming and costly.

It is important for homeowners and contractors to consider these potential challenges when planning renovations or repairs in buildings with spray foam insulation. Proper planning and coordination with experienced professionals can help ensure that any necessary work is carried out effectively and without compromising the performance of the insulation.

Overall, while spray foam insulation can offer significant benefits in terms of insulation and energy efficiency, its permanence and potential obstacles in renovation or repair work should be taken into account when considering its use in a building.

Difficulties in Removal

Removing spray foam insulation can be a challenging and complex process. Unlike other types of insulation that can be easily removed or replaced, spray foam insulation adheres tightly to surfaces and forms a strong, continuous barrier that can be difficult to remove without causing damage.

One of the main difficulties in removing spray foam insulation is its adhesive properties. It adheres firmly to the substrate, making it hard to detach without causing significant damage to the surrounding surfaces, such as walls, ceilings, or floors. The removal process may involve scraping, sanding, or using chemicals, which can be time-consuming, labor-intensive, and may require specialized tools or equipment.

Another challenge is the potential health risks associated with the removal process. The process of removing spray foam insulation can release fine particles into the air, including dust and fibers, which may contain chemicals used in the insulation material. These particles can be hazardous if inhaled or come into contact with the skin. Protective gear, such as masks, gloves, and goggles, should be worn during the removal process to minimize exposure.

In some cases, the removal of spray foam insulation may require the assistance of professionals who have experience and expertise in handling such tasks. They have the knowledge, equipment, and protective measures in place to ensure the safe and effective removal of the insulation without causing further damage or posing health risks.

Additionally, the cost of removing spray foam insulation can be significant. The labor-intensive nature of the process, coupled with the potential for damage to the surrounding structures, can result in high removal costs. It is important for homeowners or building owners to be aware of the potential expenses associated with removing spray foam insulation before deciding to install it.

It is worth mentioning that proper planning and careful consideration should be taken before deciding to remove spray foam insulation. In some cases, it may be more cost-effective to address any issues or concerns by encapsulating or covering the existing insulation rather than removing it entirely.

In summary, the difficult and complex process of removing spray foam insulation, coupled with the potential health risks and high costs involved, should be taken into consideration before deciding to install it in a building. It is important to explore alternative options and consult with professionals to make informed decisions about insulation choices.

Read more: Where Not To Use Spray Foam Insulation

Conclusion

Spray foam insulation offers numerous advantages in terms of insulation performance, energy efficiency, and air sealing. However, it is important to consider the disadvantages and potential drawbacks before making a decision to install it in a building.

The cost of spray foam insulation, along with the specialized equipment and expertise required for installation, can be a significant barrier for some homeowners or contractors. Additionally, the potential health risks associated with volatile organic compounds (VOCs) and the need for proper ventilation during installation should not be overlooked.

The environmental impact of spray foam insulation, particularly in terms of greenhouse gas emissions and disposal challenges, should also be considered. Alternative insulation materials may provide more environmentally friendly options.

There are limitations to where and how spray foam insulation can be effectively used, such as in retrofit projects, areas with high moisture levels, or certain building materials. The permanence and difficulties in renovation or repair, as well as the challenges in removal, can pose significant obstacles for future modifications or updates.

However, it is important to note that if these disadvantages are carefully considered and addressed, spray foam insulation can still be a viable choice for certain projects. It offers superior insulation and air sealing performance, which can result in energy savings and improved comfort.

To mitigate the potential drawbacks and ensure successful installation and use of spray foam insulation, it is crucial to work with experienced professionals who have the knowledge and expertise in handling the material. Following best practices, maintaining proper ventilation, and addressing any moisture-related issues are essential for maximizing the benefits and minimizing the risks.

In conclusion, while spray foam insulation has its disadvantages, it remains a popular and effective choice in many building projects. By weighing the pros and cons, considering the specific needs of the project, and taking necessary precautions, homeowners and contractors can make informed decisions about whether spray foam insulation is the right choice for their insulation needs.

Frequently Asked Questions about What Are The Disadvantages Of Spray Foam Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The Disadvantages Of Spray Foam Insulation”