Articles

How To Spray Foam Insulation

Modified: January 18, 2024

Discover articles on how to effectively use spray foam insulation for your projects. Learn the best techniques, tips, and tricks to ensure a successful installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of spray foam insulation! In this comprehensive guide, we will explore the ins and outs of spray foam insulation and provide you with valuable insights on how to properly install and maintain it. Whether you are a homeowner looking to improve the energy efficiency of your house or a contractor looking for information on the latest insulation trends, this article will serve as your go-to resource.

Spray foam insulation has gained popularity in recent years due to its remarkable thermal insulation properties and ability to create an airtight seal. It is a versatile material that can be used in a variety of applications, including walls, attics, crawl spaces, and even roofs.

So, what exactly is spray foam insulation? It is a two-component mixture that, when combined, creates a foam-like substance that expands and hardens within seconds. The foam adheres to the surfaces it is sprayed onto, forming a seamless barrier against air infiltration, moisture, and heat transfer.

Now that we understand the basics, let’s delve into the numerous benefits of spray foam insulation and explore why it is considered one of the most effective insulation methods available today.

Key Takeaways:

- Spray foam insulation offers superior thermal insulation, airtight sealing, and long-term energy efficiency benefits. Proper installation, maintenance, and care can significantly enhance indoor comfort and property value.

- Open-cell and closed-cell spray foam insulation types cater to different needs, with open-cell providing cost-effectiveness and sound dampening, and closed-cell offering high R-value and moisture resistance. Choose the type that best suits your specific requirements.

Read more: How To Spray Foam Insulation In An Attic

Benefits of Spray Foam Insulation

Spray foam insulation offers a range of benefits that make it a superior choice compared to traditional insulation materials. Here are some of the key advantages:

- Superior Thermal Insulation: Spray foam insulation has an incredibly high R-value, which is a measure of its thermal resistance. It provides excellent insulation and helps maintain a consistent indoor temperature, reducing the need for excessive heating or cooling.

- Airtight Seal: One of the standout features of spray foam insulation is its ability to create an airtight seal. Unlike other types of insulation, which can leave gaps and seams, spray foam expands to fill every crack and crevice, sealing off air leaks and preventing drafts.

- Moisture Barrier: Spray foam insulation acts as a moisture barrier, preventing the infiltration of water vapor into the walls and attic. This helps to prevent mold and mildew growth and protects the structural integrity of your home.

- Noise Reduction: The dense composition of spray foam helps to limit the transmission of sound. It can significantly reduce airborne noise, making your living spaces quieter and more peaceful.

- Energy Efficiency: By eliminating air leaks and providing superior insulation, spray foam helps to reduce energy consumption. This can lead to significant savings on heating and cooling costs throughout the year.

- Durability: Spray foam insulation is incredibly durable and long-lasting. Once it cures, it maintains its insulation properties for the life of the building, ensuring long-term energy efficiency and comfort.

- Improved Indoor Air Quality: Since spray foam creates an airtight seal, it prevents the entry of allergens, pollutants, and outdoor contaminants into your living spaces. This can lead to improved indoor air quality and a healthier living environment.

- Increased Property Value: Installing spray foam insulation is considered a valuable home improvement investment. It can increase the resale value of your property and make it more attractive to potential buyers.

These are just a few of the many benefits offered by spray foam insulation. Now that we understand its advantages, let’s explore the different types of spray foam insulation available on the market.

Types of Spray Foam Insulation

When it comes to spray foam insulation, there are two main types: open-cell and closed-cell foam. Each type offers unique features and benefits, making them suitable for different applications.

1. Open-Cell Foam:

Open-cell foam is a lightweight and flexible insulation material. It is called “open-cell” because the tiny cells within the foam are not completely closed, allowing air and moisture to penetrate to some extent. Open-cell foam is typically lower in density compared to closed-cell foam.

One of the main benefits of open-cell foam is its excellent sound dampening properties. It absorbs sound waves effectively, reducing noise transmission and creating a quieter indoor environment. It is commonly used in interior applications, such as walls and ceilings.

Another advantage of open-cell foam is its cost-effectiveness. It requires less material to cover a given area compared to closed-cell foam, making it a more affordable option for larger insulation projects.

However, open-cell foam has a lower R-value compared to closed-cell foam. It provides a lower level of insulation and is less effective at creating an air barrier. Therefore, it is not recommended for applications where a high level of insulation or moisture resistance is required.

2. Closed-Cell Foam:

Closed-cell foam is a denser and more rigid insulation material. The cells within the foam are completely closed, resulting in a higher level of insulation and better resistance to air and moisture infiltration.

One of the key advantages of closed-cell foam is its high R-value. It provides superior thermal insulation, allowing you to achieve greater energy efficiency in your home or building. Closed-cell foam also offers excellent structural integrity, adding strength and stability to the walls and roofs where it is applied.

Due to its excellent moisture resistance, closed-cell foam is commonly used in areas prone to water damage, such as basements and crawl spaces. It acts as a vapor barrier, preventing the entry of moisture and reducing the risk of mold and mildew growth.

One drawback of closed-cell foam is its higher cost compared to open-cell foam. The denser composition and superior performance of closed-cell foam contribute to its higher price tag. However, the long-term energy savings and durability it offers make it a worthwhile investment.

Now that we’ve explored the different types of spray foam insulation, let’s move on to the essential steps involved in preparing the area for installation.

Preparing the Area for Spray Foam Insulation

Proper preparation of the area before applying spray foam insulation is crucial to ensure a successful installation. Here are the key steps to follow:

- Clean and Clear the Area: Before starting the insulation process, make sure the area is clean and free from any debris, dust, or loose materials. Remove any obstacles, furniture, or belongings that may hinder access to the surfaces where the spray foam will be applied.

- Protect the Surrounding Surfaces: Cover or mask off any surfaces or objects that you want to protect from overspray. Use plastic sheets, drop cloths, or tape to create a barrier around windows, doors, electrical outlets, and other sensitive areas.

- Seal Gaps and Cracks: Inspect the surfaces for any gaps, cracks, or openings that may need to be sealed prior to spraying the foam insulation. Use an appropriate sealant, like caulking or expanding foam, to fill in these gaps and ensure a tight seal.

- Ensure Proper Ventilation: Adequate ventilation is essential during the spray foam insulation process. Open windows or use fans to create a well-ventilated space. This will help dissipate any fumes emitted during the application and curing of the foam.

- Protect Yourself: Before starting the installation, ensure you are wearing appropriate personal protective equipment (PPE). This may include goggles, gloves, long-sleeved clothing, and a respirator, depending on the type of spray foam insulation being used.

- Consult Instructional Guidelines: If you are installing the spray foam insulation yourself, it is important to carefully read and understand the manufacturer’s instructions and safety guidelines. Follow the recommended application techniques, mixing ratios, and curing times provided by the manufacturer.

- Work in Sections: It is advisable to work in smaller sections at a time rather than trying to tackle the entire area at once. This will allow you to have better control over the application and ensure even coverage and thickness of the foam.

- Monitor Weather Conditions: Take into consideration the weather conditions when planning the installation. Extreme temperatures, humidity, or precipitation can affect the performance and curing process of the spray foam insulation. It is best to apply the insulation in moderate weather conditions for optimal results.

By following these preparation steps, you will create a suitable environment for the application of spray foam insulation. With the area ready, let’s move on to the next step – applying the spray foam insulation.

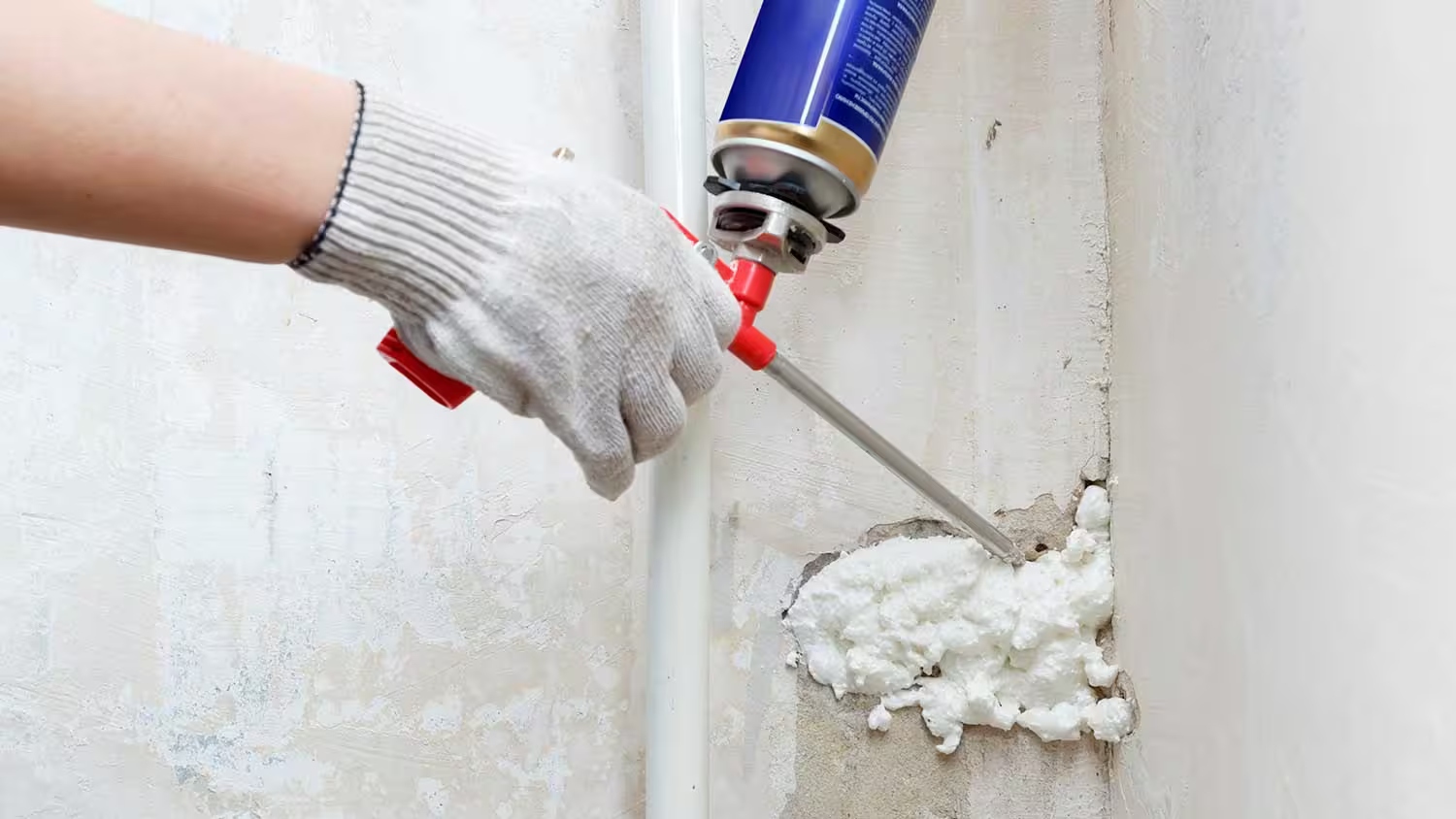

Applying Spray Foam Insulation

Applying spray foam insulation requires careful attention to detail and adherence to proper techniques. Follow these steps to ensure a successful application:

- Set Up the Equipment: Start by assembling and setting up the necessary equipment. This typically includes a spray foam insulation kit, a spray gun with hoses, and a compressor. Follow the manufacturer’s instructions for equipment setup and operation.

- Mix the Components: If you are using a two-component spray foam insulation, such as a closed-cell foam, properly mix the components according to the manufacturer’s recommended ratio. Use a mixing paddle or mechanical mixer to ensure thorough blending.

- Begin Spraying: Once the spray foam insulation mixture is properly mixed, begin spraying the foam onto the desired surfaces. Hold the spray gun at a consistent distance from the surface, usually around 12 to 18 inches, and maintain a steady sweeping motion to create an even layer of foam.

- Work in Layers: To achieve the desired insulation thickness, it is recommended to apply the spray foam insulation in multiple layers. Allow each layer to cure according to the manufacturer’s instructions before applying the next layer. This helps ensure proper adhesion and prevents sagging or uneven application.

- Pay Attention to Corners and Edges: Focus on applying the spray foam insulation to corners, edges, and hard-to-reach areas. These areas are prone to air leaks and require extra attention to ensure a complete air seal. Use a narrower spray nozzle to access tight spaces and achieve better coverage.

- Monitor Expansion: Spray foam insulation expands rapidly upon application, so it is crucial to monitor the foam’s expansion. Overfilling the space can lead to warping or distortion of the surfaces. Adjust the amount of foam you spray to achieve the desired thickness without causing any structural issues.

- Achieve a Smooth Surface: After each layer of foam is applied, use a foam trimsaw or a serrated knife to trim any excess foam and achieve a smooth and even surface. This will make it easier to install additional layers or for further construction or finishing work.

- Allow Proper Curing Time: Once the application is complete, allow the spray foam insulation to cure fully. This typically takes 24 to 48 hours, but curing times may vary depending on the type and brand of spray foam used. Avoid disturbing the foam during the curing process.

- Check for Proper Coverage: After the foam has cured, inspect the area for any missed spots, gaps, or uneven coverage. Address any deficiencies by applying additional foam to ensure a complete and effective insulation barrier.

By following these steps, you will be able to apply spray foam insulation effectively and achieve the desired level of insulation and air sealing. However, it is important to prioritize safety and follow all recommended precautions during the application process.

Speaking of safety, let’s discuss some essential safety precautions to keep in mind when working with spray foam insulation.

When applying spray foam insulation, make sure to wear protective gear such as goggles, gloves, and a mask to avoid skin and respiratory irritation.

Read more: How To Spray Foam Insulation In Attic

Safety Precautions

Working with spray foam insulation requires caution and adherence to proper safety measures. Here are some essential safety precautions to follow:

- Protective Gear: Always wear appropriate personal protective equipment (PPE) when working with spray foam insulation. This includes safety goggles, gloves, a respirator, and clothing that covers your skin. These protective measures help prevent direct contact with the insulation and any potential allergic reactions.

- Ventilation: Ensure proper ventilation while applying spray foam insulation. Open windows, use fans, or set up exhaust systems to remove fumes and maintain fresh air circulation. Proper ventilation helps dissipate any off-gassing or odors associated with the curing process of the foam.

- Fire Safety: Spray foam insulation is highly flammable during the application and curing process. Avoid open flames, smoking, or any potential sources of ignition in the vicinity. Ensure that fire extinguishers are readily available in case of emergencies.

- Chemical Exposure: Follow the manufacturer’s instructions on handling and disposing of spray foam insulation chemicals. Avoid prolonged or direct skin contact with the foam and the uncured materials. In case of accidental contact, rinse the affected area with water and seek medical attention if necessary.

- Working at Heights: If you are working in elevated areas such as attics or roofs, take precautions to prevent falls. Use appropriate safety harnesses, ladders, and scaffolding to ensure stability and minimize the risk of accidents or injuries.

- Working in Confined Spaces: If the spray foam insulation application requires working in confined spaces, ensure proper ventilation and comply with confined space entry requirements and safety protocols. Monitor the oxygen levels, beware of potential hazards, and have a safety plan in place.

- Storage and Disposal: Store spray foam insulation materials in a cool, dry, and well-ventilated area according to the manufacturer’s instructions. Dispose of any excess foam or unused chemicals responsibly, following local regulations and guidelines.

- Training and Certification: Properly trained and certified professionals should handle complex spray foam insulation projects. If you are not experienced in installing spray foam insulation, consider hiring a professional contractor to ensure a safe and effective installation.

Remember, the safety of yourself, your team, and the occupants of the building should always be a top priority. Following these safety precautions will help minimize risks and ensure a smooth and secure application process.

Now that we’ve covered safety precautions, let’s move on to discussing the recommended tools and equipment needed for spray foam insulation installation.

Recommended Tools and Equipment

Having the right tools and equipment is essential for a successful spray foam insulation installation. Here are some recommended tools and equipment:

- Spray Foam Insulation Kit: Start by choosing a high-quality spray foam insulation kit that suits your specific needs. These kits typically include the necessary components, such as the foam mixture, spray gun, hoses, and nozzles.

- Spray Gun and Hoses: Ensure you have a reliable and durable spray gun and compatible hoses. The spray gun should have adjustable settings for controlling the foam flow and pattern, allowing for precise application.

- Compressor: A reliable compressor is necessary to provide the air pressure required to spray the foam insulation. Consider the recommended air pressure range for the specific type of spray foam you are using and choose a compressor that meets those requirements.

- Personal Protective Equipment (PPE): Always prioritize safety by wearing proper PPE. This includes safety goggles, gloves, a respirator, and clothing that covers your skin. Invest in high-quality PPE to protect yourself from potential exposure to chemicals and ensure maximum safety.

- Measuring Tools: Accurate measurements are crucial for efficient insulation application. Have a tape measure, ruler, or laser measuring device on hand to measure the areas where the spray foam insulation will be applied. This will help calculate the required amount of foam and ensure even coverage.

- Sealant and Caulking Gun: Before applying the spray foam insulation, it is essential to seal any gaps or cracks in the surfaces. A caulking gun and a high-quality sealant or expanding foam will help you fill in these gaps effectively, ensuring a tight seal and preventing air leakage.

- Trim Saw or Serrated Knife: After the spray foam insulation has cured, use a foam trimsaw or a serrated knife to trim any excess foam and achieve a smooth and even surface. These tools will help you shape and prepare the foam for further construction or finishing work.

- Extension Cords and Power Supply: Make sure you have adequate extension cords and a reliable power supply to operate your equipment. Ensure the power supply can handle the compressor’s power requirements and that the extension cords are in good condition to avoid any electrical hazards.

- Cleaning Supplies: Spray foam insulation can be messy, so it’s important to have cleaning supplies on hand. This includes rags, towels, and cleaning solvents specifically designed for removing uncured foam in case of accidental spills or mistakes.

- Appropriate Lighting: Working in well-lit areas is essential for proper application and to identify any missed spots or areas that require additional foam. Use adequate lighting sources, such as portable work lights or headlamps, to ensure visibility during the installation process.

Investing in high-quality tools and equipment will make the spray foam insulation installation process more efficient and ensure accurate and effective results. Remember to regularly maintain and inspect your tools to ensure their optimal functionality.

With the tools and equipment sorted, let’s move on to discussing the maintenance and care of spray foam insulation.

Maintenance and Care of Spray Foam Insulation

To ensure the longevity and effectiveness of spray foam insulation, it is important to implement proper maintenance and care practices. Here are some key maintenance tips to keep your spray foam insulation in optimal condition:

- Regular Inspections: Periodically inspect your spray foam insulation to identify any signs of damage, wear, or deterioration. Look for cracks, gaps, or areas where the foam may have pulled away from surfaces. Promptly address any issues to maintain the insulation’s performance.

- Keep the Area Clean: Maintain a clean environment around the spray foam insulation. Regularly remove dust, debris, or any organic materials that could attract pests or cause moisture buildup. This will help preserve the integrity of the insulation and prevent potential issues.

- Prevent Moisture Accumulation: Moisture can compromise the effectiveness of spray foam insulation. Address any sources of water leakage or excess humidity promptly. Ensure proper ventilation and use dehumidifiers when necessary to maintain a dry and healthy indoor environment.

- Avoid Physical Damage: Take precautions to prevent any physical damage to the spray foam insulation. Avoid puncturing or tearing the foam by accident. If the insulation is in an exposed or vulnerable area, consider adding a protective layer or covering to shield it from potential damage.

- Seal Gaps and Cracks: Monitor the condition of seals and caulking around windows, doors, and other openings. Repair or replace any damaged or worn-out seals to maintain the airtightness and insulation effectiveness of the foam.

- Address Pest Infestation: Spray foam insulation can act as a deterrent for pests, but it is not entirely immune to their activity. Regularly inspect for any pest infestations, such as rodents or insects, and take appropriate measures to eradicate them. Consult a pest control professional if necessary.

- Consult Professional Help: If you notice significant damage or issues with your spray foam insulation, it is best to consult a professional insulation contractor. They can assess the situation, provide recommendations, and perform any necessary repairs or maintenance to ensure the insulation’s optimal performance.

- Follow Manufacturer’s Recommendations: Lastly, always refer to the manufacturer’s guidelines and recommendations for the specific type of spray foam insulation you have installed. They may provide specific maintenance instructions or additional care tips tailored to their product.

By implementing these maintenance practices, you can prolong the lifespan and effectiveness of your spray foam insulation, ensuring optimal energy efficiency and comfort in your home or building.

Now that we have discussed maintenance, let’s summarize the key points covered in this article.

Conclusion

Spray foam insulation is an exceptional choice for enhancing energy efficiency, improving indoor comfort, and creating airtight seals in residential and commercial buildings. Throughout this comprehensive guide, we have explored the benefits of spray foam insulation, the different types available, and the essential steps for its installation.

We have discussed how spray foam insulation provides superior thermal insulation, acts as a moisture barrier, reduces noise transmission, and enhances energy efficiency. Whether you choose open-cell or closed-cell spray foam insulation depends on your specific needs and priorities.

To ensure a successful application, we have emphasized the importance of thorough preparation, including cleaning and clearing the area, sealing gaps, and ensuring proper ventilation. Applying spray foam insulation requires attention to detail, working in layers, and achieving even coverage to maximize effectiveness.

We have also emphasized the significance of safety precautions, including wearing appropriate personal protective equipment, ensuring proper ventilation, and following fire safety protocols. Additionally, we recommended using the right tools and equipment, such as a spray foam insulation kit, spray gun, compressor, and measuring tools, to achieve the best results.

Proper maintenance and care are essential to preserve the performance and longevity of spray foam insulation. Regular inspections, keeping the area clean, and addressing moisture buildup or physical damage are crucial for maintaining optimal insulation effectiveness.

Remember to consult professional help when needed, follow manufacturer’s recommendations, and address any pest infestations promptly. By following these guidelines, you can enjoy the benefits of spray foam insulation for years to come.

In conclusion, spray foam insulation is a game-changer in the world of insulation, providing superior thermal performance, exceptional air sealing, and long-lasting energy efficiency benefits. With proper installation, maintenance, and care, spray foam insulation can significantly improve the comfort, energy efficiency, and value of your home or building.

Frequently Asked Questions about How To Spray Foam Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Spray Foam Insulation”