Articles

Where Not To Use Spray Foam Insulation

Modified: January 8, 2024

Discover the key areas where spray foam insulation should not be used. Explore our in-depth articles for expert advice and tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

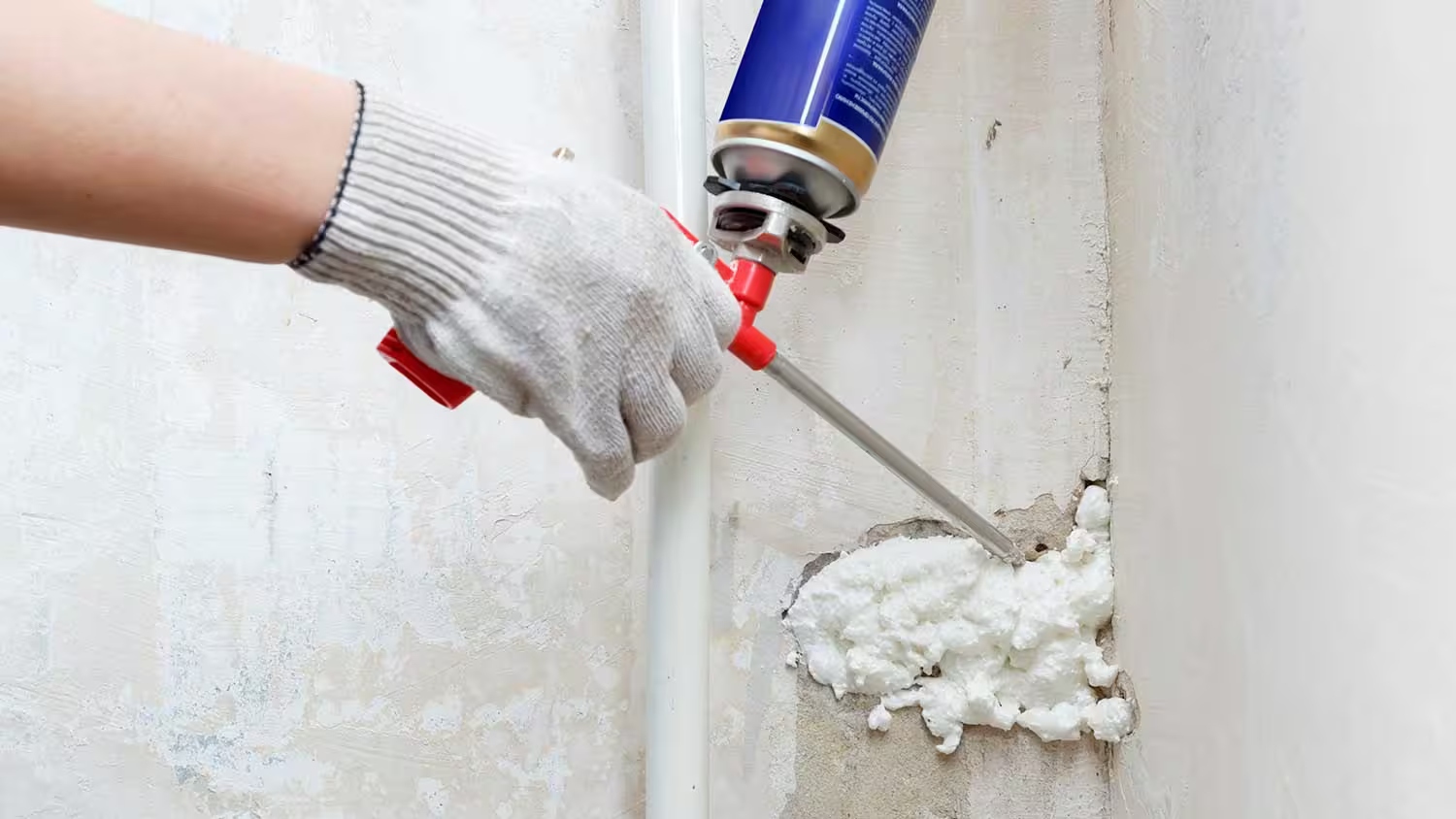

When it comes to insulating your home or building, spray foam insulation is a popular choice due to its excellent thermal performance and energy efficiency. It can provide a superior air barrier and help reduce energy costs by preventing the loss of conditioned air. However, there are certain situations where spray foam insulation may not be the ideal option. In this article, we will explore some of the scenarios where it is recommended to avoid using spray foam insulation.

It is important to note that spray foam insulation is not inherently bad or ineffective. It has numerous advantages and can be highly beneficial in many applications. However, there are certain circumstances where alternative insulation methods may be more appropriate or where special considerations need to be taken into account. By understanding these limitations, you can make an informed decision about the best insulation option for your particular situation.

Let’s dive into the various scenarios where using spray foam insulation may not be suitable:

Key Takeaways:

- Don’t overlook the importance of considering alternative insulation methods for specific scenarios such as exterior applications, areas with moisture issues, non-vented attics or crawlspaces, and historical structures to ensure long-term effectiveness and preservation.

- Prioritize safety and functionality by carefully considering insulation options for areas with potential fire hazards, HVAC systems and ducts, electrical boxes and wiring, and historical or architecturally significant structures. Consult with experts to make informed decisions.

Read more: Why Use Spray Foam Insulation

Exterior Applications

Spray foam insulation is typically not recommended for exterior applications, especially in areas where it will be directly exposed to sunlight and weather conditions. Over time, the UV rays from the sun can cause the foam to degrade and lose its insulating properties. Additionally, prolonged exposure to moisture can cause the foam to absorb water and lead to structural damage or mold growth.

For exterior insulation, alternative options such as rigid foam insulation or insulated sheathing are often preferred. These materials are designed to withstand the elements and provide efficient insulation for exterior walls, roofs, and foundations. They offer better durability and moisture resistance, making them a more suitable choice for protecting your home or building from the elements.

If you are considering insulation for your exterior walls or roofing, consult with a professional insulation contractor to determine the most appropriate insulation method for your specific climate and location.

Areas with Moisture Issues

While spray foam insulation is known for its ability to create an air-tight seal, it can also trap moisture if not properly applied or if there are existing moisture issues in the building. Moisture can seep into the walls or ceilings, leading to condensation and potential mold or mildew growth. This can be particularly problematic in areas with high humidity levels or chronic moisture problems.

Before applying spray foam insulation, it is crucial to address any underlying moisture issues and ensure proper ventilation and drainage. This may involve fixing leaks, repairing plumbing issues, or improving ventilation systems. If moisture problems persist, it is recommended to consult with a professional to identify and rectify the root cause before considering insulation options.

In situations where moisture cannot be adequately controlled, alternative insulation methods such as moisture-resistant fiberglass insulation or cellulose insulation may be more suitable. These materials are less prone to moisture-related issues and can provide effective insulation without the risk of trapping moisture.

Remember, it is important to prioritize moisture control to protect the integrity of your home or building and prevent potential health hazards associated with mold and mildew.

Non-vented Attics or Crawlspaces

In traditional building design, attics and crawlspaces were often vented to allow for proper air circulation and moisture control. However, with the advent of energy-efficient building practices, non-vented attics and crawlspaces have become more common. In these situations, spray foam insulation may not be the best choice.

Non-vented attics and crawlspaces rely on a sealed envelope to prevent air leakage and maintain consistent temperatures. Applying spray foam insulation to these areas can create a strong air barrier, which can disrupt the airflow dynamics and potentially cause moisture buildup. This can lead to condensation, rot, and other moisture-related problems.

When insulating non-vented attics or crawlspaces, it is recommended to use insulation materials that allow for proper moisture management, such as rigid foam insulation or fiberglass batts with a vapor barrier. These materials can provide effective insulation while allowing the structure to breathe and maintain proper humidity levels.

If you are unsure about the ventilation requirements or insulation options for your attic or crawlspace, consult with a professional insulation contractor or building specialist who can assess your specific situation and recommend the most appropriate insulation method.

Areas with Potential Fire Hazards

While spray foam insulation offers excellent thermal performance, it is important to consider its flammability in areas with potential fire hazards. Spray foam insulation is made from a combination of chemicals that can contribute to the spread of fire if not properly protected.

In areas such as furnace rooms, boiler rooms, or other spaces where there are open flames, hot surfaces, or electrical equipment, it is recommended to use fire-resistant insulation materials that can better withstand high temperatures and reduce the risk of fire spread.

There are insulation options available specifically designed for fire protection, such as mineral wool insulation or fire-rated batt insulation. These materials have a higher level of fire resistance and can provide added safety in areas where the risk of fire is elevated.

It is crucial to consult with local building codes and regulations to ensure compliance with fire safety requirements for insulation in these areas. Additionally, working with a professional insulation contractor who has experience with fire-resistant materials can provide reassurance and help mitigate potential risks.

By carefully considering the fire hazards in specific areas of your home or building, you can make informed decisions to prioritize safety and select the appropriate insulation materials.

Avoid using spray foam insulation in areas with high moisture levels, such as basements or crawl spaces, as it can trap moisture and lead to mold and mildew growth. Instead, consider using other insulation materials better suited for these environments.

Read more: Where Can I Buy Spray Foam Insulation

HVAC Systems and Ducts

When it comes to insulating HVAC systems and ductwork, spray foam insulation may not always be the best choice. While spray foam can provide excellent insulation and air sealing properties, it can also present challenges when it comes to HVAC system maintenance and repairs.

One concern with spray foam insulation is that it can create a barrier that makes it difficult to access and service the HVAC system or ductwork. If there is a need for repairs or maintenance, technicians may have to remove sections of the foam, leading to added time and cost.

In addition, spray foam insulation is not recommended for use directly on HVAC units or in areas where the foam may come into direct contact with heat sources. The heat generated by HVAC units can cause the foam to melt or emit harmful fumes, posing a potential fire hazard.

Instead, for insulating HVAC systems and ductwork, it is advisable to use specialized insulation materials designed for this purpose. These materials, such as duct insulation wraps or HVAC duct liners, provide effective insulation while allowing for easy access and maintenance of the system. They are also designed to withstand the temperatures generated by the HVAC system without compromising safety.

Consulting with HVAC professionals or insulation specialists can help determine the most appropriate insulation method for your specific HVAC system and ductwork, ensuring both optimal performance and ease of maintenance.

Electrical Boxes and Wiring

When it comes to insulating around electrical boxes and wiring, spray foam insulation should be used with caution. While it can provide effective insulation in many areas of a building, applying spray foam insulation directly around electrical boxes or onto electrical wiring can pose potential risks and may violate building safety codes.

One concern is that the expanding nature of spray foam insulation can put pressure on electrical boxes, leading to potential damage or loosening of connections. This can create safety hazards, such as electrical arcing or short circuits.

Additionally, applying spray foam insulation directly onto electrical wiring can make it difficult to identify and address any future electrical issues or perform proper repairs. The foam can act as a barrier, hindering access to the wiring and making it more challenging for electricians to work on the system.

When insulating around electrical boxes and wiring, it is recommended to use non-expanding insulation materials, such as fiberglass insulation or foam boards, to maintain proper access and ensure electrical safety. These materials can provide effective insulation while allowing for easy inspection, maintenance, and repair of the electrical system.

It is important to consult with an electrician or building professional to ensure compliance with electrical codes and regulations when insulating around electrical boxes and wiring. Their expertise will help ensure the safety and functionality of your electrical system while providing the necessary insulation.

Historical or Architecturally Significant Structures

When it comes to insulating historical or architecturally significant structures, it is important to approach the insulation process with careful consideration. While spray foam insulation offers many benefits, it may not be the best choice for these types of buildings due to their unique construction and preservation requirements.

Historical structures often have specific architectural features, such as ornate moldings, intricate woodwork, or original masonry, that contribute to their historical significance and aesthetic value. Applying spray foam insulation directly onto these surfaces can be detrimental, as it can cover or damage these intricate details, altering the original character of the building.

In addition, historical structures may require special considerations for moisture management, ventilation, and air circulation. The application of spray foam insulation, which creates a complete air barrier, can impede proper airflow and moisture control, potentially leading to moisture-related issues and damage to the building’s integrity.

When insulating historical or architecturally significant structures, it is best to consult with preservation specialists, architects, or conservationists who have expertise in the restoration and preservation of these buildings. They can guide you in selecting insulation methods that are sensitive to the unique needs of the structure while providing the necessary thermal performance.

In some cases, alternative insulation options such as blown-in cellulose insulation or rigid foam insulation placed in discreet locations may be more suitable. These options allow for easy removal or adjustments in the future without causing irreversible damage to the structure.

Preserving the historical and architectural integrity of these structures is of utmost importance. Thus, it is crucial to approach insulation decisions with careful consideration and expert guidance to ensure the long-term preservation and appreciation of these valuable buildings.

Conclusion

Spray foam insulation is a versatile and effective insulation option for many homes and buildings. Its ability to provide excellent thermal performance and air sealing has made it a popular choice among homeowners and construction professionals alike. However, it is essential to understand that there are certain scenarios where spray foam insulation may not be the most suitable option.

When considering insulation options, it is crucial to assess the specific needs and requirements of your project. Exterior applications, areas with moisture issues, non-vented attics or crawlspaces, areas with potential fire hazards, HVAC systems and ducts, electrical boxes and wiring, and historical or architecturally significant structures all warrant careful consideration when deciding on insulation methods.

In such situations, alternative insulation options may be more appropriate. Rigid foam insulation, moisture-resistant fiberglass insulation, fire-resistant insulation materials, specialized insulation for HVAC systems and ductwork, or insulation methods that preserve the historical integrity of a building can be considered. To make the best choice, it is advisable to consult with insulation professionals, preservation specialists, or building experts who can assess your specific needs and provide the most suitable recommendations.

By understanding the limitations and considering the unique circumstances of each project, you can make informed decisions that not only provide effective insulation but also ensure the safety, durability, and preservation of your home or building.

Remember, insulation is not a one-size-fits-all solution, and each application requires careful consideration. By weighing the pros and cons, understanding local building codes and regulations, and seeking expert guidance, you can optimize insulation choices for the best long-term results.

Frequently Asked Questions about Where Not To Use Spray Foam Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Where Not To Use Spray Foam Insulation”