Articles

What Is A Self Priming Water Pump

Modified: January 8, 2024

"Discover the benefits and functionality of self-priming water pumps with our informative articles. Learn how they work and choose the right one for your needs."

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A self-priming water pump is an essential tool that provides a convenient and efficient way to move water from one location to another. Whether you need to drain a flooded basement, irrigate a field, or circulate water in a pool, a self-priming water pump can be a reliable and versatile solution.

Unlike traditional water pumps, a self-priming pump is designed to start pumping water without the need for external priming or filling the pump with water manually. This unique feature makes it a popular choice for various applications, both in residential and commercial settings.

In this article, we will explore the inner workings of a self-priming water pump, discuss the advantages of using one, explore the different applications where they are commonly used, and provide some insights on choosing the right pump for your specific needs. We will also cover the installation and maintenance requirements of these pumps, as well as common troubleshooting tips for any issues that may arise.

Key Takeaways:

- Self-priming water pumps offer convenience, reliability, and versatility for various applications, making them essential tools for efficient water transfer without the need for external priming.

- Proper installation, maintenance, and troubleshooting are crucial for maximizing the performance and longevity of self-priming water pumps, ensuring reliable operation for years to come.

Read more: How To Prime A Water Pump On A Well

How Does a Self Priming Water Pump Work?

A self-priming water pump operates using a combination of centrifugal force and air-water separation. The pump housing contains an impeller, which rotates at high speed when the pump is powered on. As the impeller spins, it creates a partial vacuum in the pump chamber, causing air to be drawn in through the intake port.

Once the air enters the pump chamber, it mixes with the water present in the casing. The rotating impeller then forcefully expels this mixture towards the discharge port, creating pressure within the pump. This pressure helps to push the air out of the system and prime the pump, allowing it to start pumping water efficiently.

Self-priming water pumps are equipped with a special chamber or reservoir that allows the air and water mixture to separate effectively. This ensures that only water is passed through the discharge port, without any air bubbles or cavitation that could affect the pump’s performance.

Advantages of Using a Self-Priming Water Pump

There are several distinct advantages to using a self-priming water pump:

- Convenience: With a self-priming pump, there is no need for manual priming or the use of external priming equipment. This saves time and effort, especially in situations where the pump needs to be started and stopped frequently.

- Reliability: Self-priming pumps are designed to handle air and water mixture, making them less susceptible to cavitation and damage. They can also handle small debris and solids without clogging, ensuring consistent and reliable performance.

- Versatility: Self-priming water pumps can handle a wide range of liquids, including clear water, muddy water, and liquids with varying viscosities. This versatility makes them suitable for various applications, from construction sites to agricultural operations.

- Efficiency: These pumps are engineered for optimal energy efficiency, delivering high flow rates and water pressure with minimal power consumption. This not only reduces operating costs but also minimizes the environmental impact.

Having covered the advantages, let’s move on to exploring the different applications where self-priming water pumps are commonly used.

Key Takeaways:

- Self-priming water pumps offer convenience, reliability, and versatility for various applications, making them essential tools for efficient water transfer without the need for external priming.

- Proper installation, maintenance, and troubleshooting are crucial for maximizing the performance and longevity of self-priming water pumps, ensuring reliable operation for years to come.

Read more: How To Prime A Water Pump On A Well

How Does a Self Priming Water Pump Work?

A self-priming water pump operates using a combination of centrifugal force and air-water separation. The pump housing contains an impeller, which rotates at high speed when the pump is powered on. As the impeller spins, it creates a partial vacuum in the pump chamber, causing air to be drawn in through the intake port.

Once the air enters the pump chamber, it mixes with the water present in the casing. The rotating impeller then forcefully expels this mixture towards the discharge port, creating pressure within the pump. This pressure helps to push the air out of the system and prime the pump, allowing it to start pumping water efficiently.

Self-priming water pumps are equipped with a special chamber or reservoir that allows the air and water mixture to separate effectively. This ensures that only water is passed through the discharge port, without any air bubbles or cavitation that could affect the pump’s performance.

The efficiency and effectiveness of a self-priming water pump depend on several key components:

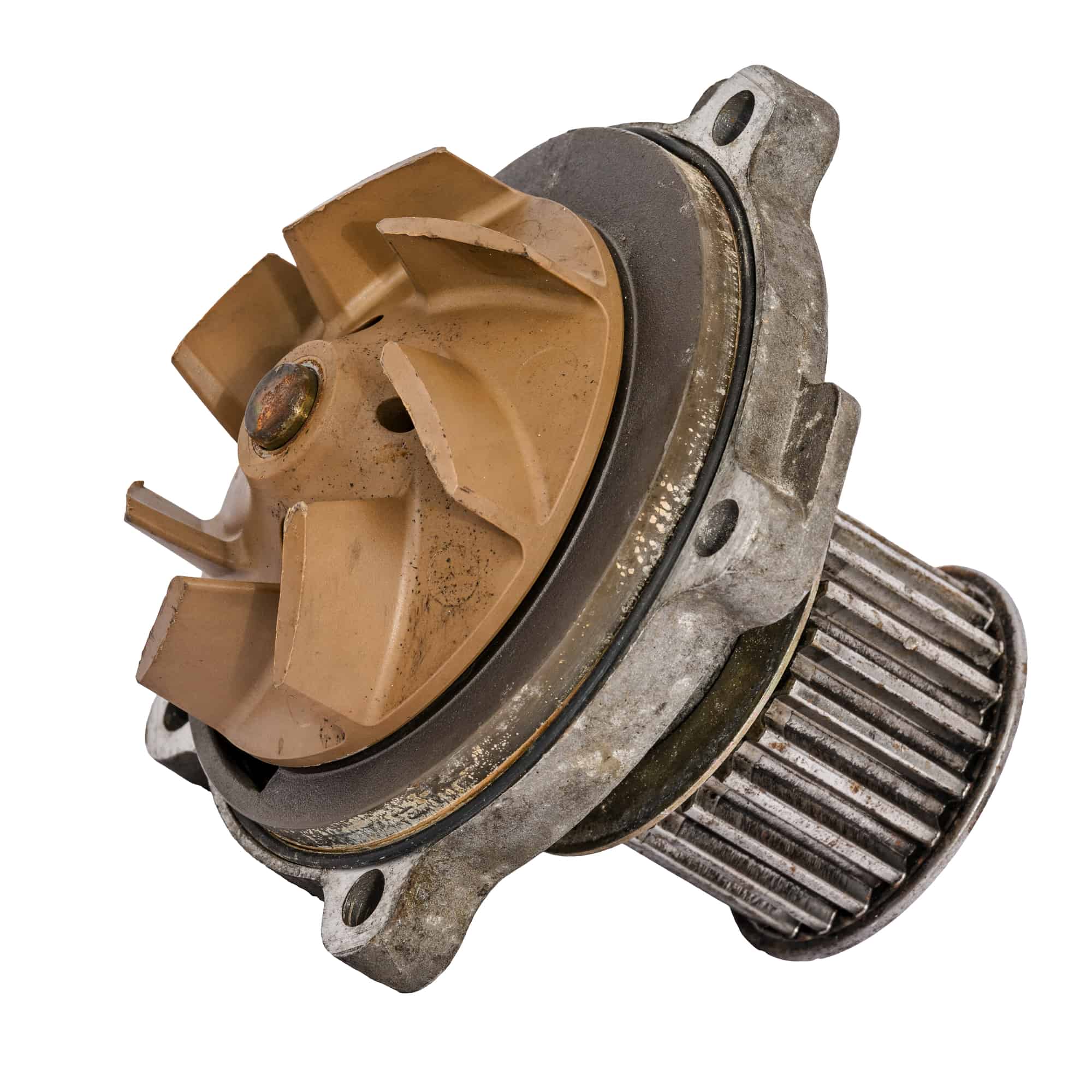

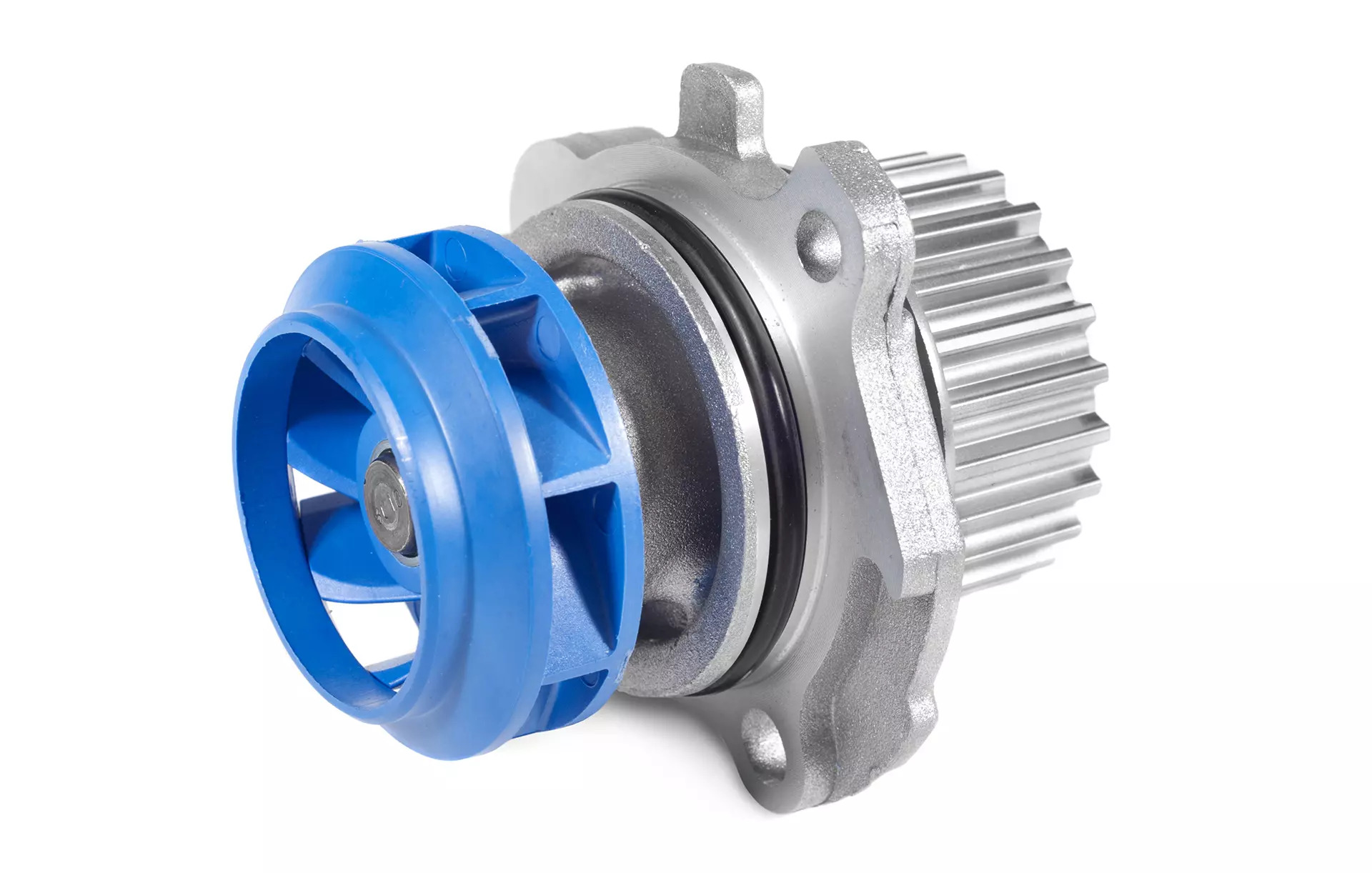

- Impeller: The impeller is the rotating component that draws in air and water and forces the mixture towards the discharge port. It is designed with curved blades that create centrifugal force, generating pressure and facilitating the separation of air and water.

- Check Valve: A check valve is located at the discharge port of the pump. It allows water to flow through in one direction, preventing backflow and maintaining the primed state of the pump even when it is not actively running.

- Priming Chamber: The priming chamber is an integral part of the pump housing, specifically designed to separate air and water. It allows the air to move to the top of the chamber, while the water collects at the bottom. This design prevents air from entering the discharge port during operation.

- Intake Port: The intake port is where the water initially enters the pump. It is typically located at the bottom of the pump housing and is connected to the water source through a suction hose or pipe.

When the self-priming water pump is turned on, the impeller creates the necessary suction to draw water into the pump through the intake port. As the impeller rotates, the trapped air is expelled through the discharge port, creating a vacuum that allows more water to enter. This process continues until the pump is fully primed, at which point it can start pumping water efficiently.

One important thing to note is that the initial priming process may take a bit longer compared to traditional water pumps. Since self-priming pumps have to separate air and water during the initial start-up, it may take a few minutes to establish a steady flow of water. However, once the pump is primed and operational, it will continue to deliver consistent and reliable performance.

In the next section, we will explore the advantages of using a self-priming water pump for various applications.

Advantages of Using a Self Priming Water Pump

There are several distinct advantages to using a self-priming water pump:

- Convenience: With a self-priming pump, there is no need for manual priming or the use of external priming equipment. This saves time and effort, especially in situations where the pump needs to be started and stopped frequently. Simply turning on the pump is all it takes to get it up and running.

- Reliability: Self-priming pumps are designed to handle air and water mixture, making them less susceptible to cavitation and damage. They can also handle small debris and solids without clogging, ensuring consistent and reliable performance. This makes them ideal for applications where the water source may contain particles or where occasional air ingress is expected.

- Versatility: Self-priming water pumps can handle a wide range of liquids, including clear water, muddy water, and liquids with varying viscosities. This versatility makes them suitable for various applications, from construction sites to agricultural operations. They can also handle different suction depths, allowing you to pump water from shallow wells, ponds, or even underground sources.

- Efficiency: These pumps are engineered for optimal energy efficiency, delivering high flow rates and water pressure with minimal power consumption. This not only reduces operating costs but also minimizes the environmental impact. Their ability to prime themselves means that they waste minimal energy in the pumping process, making them an eco-friendly choice.

- Relatively Low Maintenance: Self-priming water pumps are designed to be low maintenance. They typically have fewer mechanical parts compared to other types of pumps, reducing the chances of failure or breakdown. Routine maintenance, such as checking for debris in the intake and regular inspection of the impeller and check valve, can help ensure optimal performance and longevity.

These advantages make self-priming water pumps a popular choice for a wide range of applications. They are commonly used in residential settings to drain pools, basements, and other flooded areas. In the commercial and industrial sectors, they are utilized for various purposes, including irrigation, construction dewatering, wastewater management, and firefighting.

Before selecting a self-priming water pump, it’s important to consider several factors, such as the required flow rate, total head, and the specific nature of the water being pumped. We will discuss these factors in more detail in the next section.

Now that we have explored the advantages of using a self-priming water pump, let’s move on to discussing the different applications where these pumps are commonly used.

Read more: How To Prime A Rv Water Pump

Applications of Self Priming Water Pumps

Self-priming water pumps are versatile tools that find application in various industries and settings. Their ability to handle air and water mixture, along with their convenience and reliability, makes them suitable for a wide range of applications. Here are some common applications of self-priming water pumps:

- Construction Sites: Self-priming water pumps are often used in construction sites to remove water accumulation in trenches, excavations, and foundation pits. Their ability to handle debris and solids makes them well-suited for such applications.

- Irrigation: Self-priming pumps are commonly used in irrigation systems to draw water from wells, lakes, or reservoirs and distribute it to fields, gardens, or agricultural areas. Their efficient priming capability and the ability to handle varying viscosities make them reliable for irrigation systems.

- Emergency Flood Control: In the event of heavy rain or flooding, self-priming water pumps are instrumental in controlling and removing excess water. They can quickly and effectively drain flooded basements, garages, and other low-lying areas, helping prevent water damage.

- Swimming Pool Maintenance: Self-priming pumps are commonly used to circulate and filter water in swimming pools. They help maintain water clarity and prevent stagnation by efficiently pumping water through the filtration system.

- Firefighting: Self-priming water pumps are crucial for firefighting operations, where immediate access to water is vital. They can quickly draw water from nearby sources, such as lakes or ponds, and provide the necessary water pressure to extinguish fires.

- Wastewater Management: Self-priming pumps are often used in sewage and wastewater treatment plants to pump wastewater between different treatment stages. They can handle both clean water and water with high solids content, making them ideal for wastewater management.

- Aquaculture: In fish farms and aquaculture facilities, self-priming water pumps are used to circulate and aerate water in ponds or tanks. They ensure proper oxygenation and water movement, creating a conducive environment for fish and other aquatic organisms to thrive.

These are just a few examples of the applications where self-priming water pumps excel. Their versatility, reliability, and ability to prime themselves make them indispensable tools in various industries, including construction, agriculture, water management, and more.

When selecting a self-priming water pump for a specific application, it’s essential to consider factors such as required flow rate, total head (vertical distance the water needs to be pumped), and the specific nature of the water being pumped (clean water, solids-laden water, viscous liquids, etc.). This will ensure that you choose a pump that matches your specific requirements.

In the next section, we will dive into the key factors to consider when choosing a self-priming water pump.

When using a self-priming water pump, ensure that the pump is placed close to the water source and that the suction pipe is free of air to facilitate the priming process.

Factors to Consider When Choosing a Self Priming Water Pump

Choosing the right self-priming water pump requires careful consideration of several factors. These factors will ensure that the pump you select is suitable for your specific application and can deliver the desired performance. Here are the key factors to keep in mind when choosing a self-priming water pump:

- Flow Rate: The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of water the pump can move within a given time. It is essential to determine the required flow rate based on the specific application. Consider factors such as the size of the area to be drained or irrigated and the desired water turnover rate.

- Total Head: Total head refers to the vertical distance the water needs to be pumped. It takes into account both the suction lift (vertical distance from the water source to the pump) and the discharge head (vertical height to which the water needs to be pumped). Understanding the total head helps determine the pump’s ability to overcome resistance and deliver water to the desired location.

- Power Source: Consider the power source available for the pump. Self-priming water pumps are typically powered by electricity, gasoline, or diesel. Choose a pump that matches the available power source and ensures reliable operation.

- Priming Time: The priming time refers to the duration it takes for the pump to establish a steady flow of water after it is initially powered on. Some self-priming pumps may have longer priming times compared to others. Evaluate the priming time based on your specific needs and the time it takes for the pump to reach optimal performance.

- Pump Material: Consider the material used to construct the pump. Common materials include cast iron, stainless steel, and thermoplastic. The choice of material should be based on the compatibility with the water being pumped (e.g., corrosive or abrasive liquids) and the durability required for the application.

- Portability and Mobility: Depending on the application, portability and mobility may be important factors to consider. Evaluate the pump’s weight, size, and available handles or wheels for easy transportation and maneuverability.

- Manufacturer Reputation: Research the reputation of the pump manufacturer. Look for well-established brands with a track record of producing high-quality pumps and providing reliable customer support. Reading customer reviews and seeking recommendations can help you make an informed decision.

By considering these factors, you can narrow down your options and choose a self-priming water pump that aligns with your specific requirements. It is important to remember that different applications may have different pump needs, so selecting the right pump is crucial to ensure optimal performance and longevity.

After choosing the appropriate self-priming water pump, the next step is to install it correctly and perform regular maintenance to ensure its efficient operation. In the next section, we will discuss the installation and maintenance requirements of self-priming water pumps.

Installation and Maintenance of Self Priming Water Pumps

Proper installation and regular maintenance are essential to ensure the efficient and long-lasting operation of a self-priming water pump. By following these guidelines, you can maximize the performance and reliability of the pump. Here are the key steps for installation and maintenance:

Installation:

- Location: Choose a suitable location for the pump that allows easy access for maintenance and operation. The pump should be positioned on a stable and level surface to prevent vibrations and ensure optimal performance.

- Intake and Discharge: Connect the intake port of the pump to the water source using a suction hose or pipe. Ensure that the connection is secure and free from any leaks. Connect the discharge port to the desired outlet or plumbing system.

- Check Valve: Install a check valve at the discharge port to prevent backflow and maintain prime between start-ups. This will ensure efficient and immediate operation when the pump is powered on.

- Power Connection: Follow the manufacturer’s guidelines for connecting the pump to a power source. Ensure that the electrical supply matches the required voltage and amperage of the pump.

- Priming: Before starting the pump, ensure that the priming chamber or reservoir is filled with water to facilitate the self-priming process. This will optimize the pump’s ability to draw in water and deliver it efficiently.

- Startup and Testing: Once the pump is properly installed and primed, power it on and observe its performance. Check for any abnormal noises, vibrations, or leaks. Ensure that water is being discharged adequately and consistently.

Read more: What Is A Water Pump

Maintenance:

- Cleaning and Inspection: Regularly inspect the intake port, impeller, and check valve for any debris or obstructions. Clean or remove any blockages to ensure optimal performance. Clean the pump housing and surrounding area to prevent dirt or dust accumulation.

- Check for Leaks: Inspect all connections and seals for any signs of leaks. Replace or repair any damaged parts immediately to prevent water loss or damage to the pump.

- Impeller and Check Valve Maintenance: Periodically inspect the impeller for any signs of wear or damage. Replace the impeller if necessary. Check the check valve for proper operation and replace it if it is not functioning effectively.

- Priming Chamber Maintenance: Clean and flush the priming chamber regularly to remove any accumulated debris or sediment. Ensure that the air and water separation functions efficiently to maintain optimal pump performance.

- Motor Maintenance: If the pump is powered by an electric motor, follow the manufacturer’s instructions for motor maintenance. This may include lubrication, checking electrical connections, and inspecting for any signs of wear or damage.

- Routine Service: Schedule regular service and maintenance checks for the pump. This may include professional inspections, lubrication of moving parts, and replacement of worn or damaged components.

By following these installation and maintenance guidelines, you can ensure the efficient operation and longevity of your self-priming water pump. Regular maintenance and prompt repairs will help prevent breakdowns and ensure that the pump continues to deliver reliable performance when you need it.

In the next section, we will explore common issues that may occur with self-priming water pumps and provide troubleshooting tips to address them.

Troubleshooting Common Issues with Self Priming Water Pumps

While self-priming water pumps are known for their reliability, occasional issues may arise. Understanding common problems and knowing how to troubleshoot them can help you quickly resolve any issues and get your pump back in operation. Here are some common issues with self-priming water pumps and troubleshooting tips:

- Poor or No Priming: If the pump is having difficulty priming or is not self-priming at all, check the following:

- Ensure that the intake hose or pipe is not clogged or blocked. Remove any obstructions to enable water flow into the pump.

- Check the impeller for any damage or blockage. Clean or replace the impeller if necessary to improve its performance.

- Inspect the check valve for proper functioning. Clean or replace the check valve if it is faulty or obstructed.

- Verify that the priming chamber is filled with water and there are no air leaks in the system. Ensure all connections are tight and sealed properly.

- Insufficient Water Flow: If the pump is running but not delivering adequate water flow, consider the following:

- Check for any leakage or air suction along the intake line. Repair any leaks and ensure the intake line is airtight.

- Inspect the impeller for wear or damage. Replace it if necessary to improve pump performance.

- Ensure that the pump is properly sized for the application. If the flow rate is consistently insufficient, consider upgrading to a higher capacity pump.

- Check the power supply to ensure that the pump is receiving adequate voltage and amperage for optimal performance.

- Excessive Noise or Vibration: If the pump is making unusual noises or exhibiting excessive vibration, consider the following:

- Inspect the impeller for any debris or obstructions. Clean or remove any foreign objects that may be causing the noise or vibration.

- Check the motor or engine mounts to ensure they are secure and in good condition. Loose mounts can cause increased noise and vibration.

- Verify that the pump is properly aligned and sitting on a stable, level surface. Uneven surfaces or misalignment can cause excessive vibrations.

- Inspect the pump housing and impeller for signs of damage. Replace any worn or damaged parts that may be causing the noise or vibration.

- Failure to Start: If the pump fails to start when powered on, consider the following:

- Check the power supply and ensure that the pump is receiving the correct voltage and amperage.

- Inspect the circuit breaker or fuse. Reset or replace as necessary.

- Verify that the on/off switch is in the correct position and functioning properly.

- Inspect the motor or engine for any signs of damage or obstruction. Clean or repair as needed.

If you encounter any issues with your self-priming water pump that you are unable to resolve, consult the pump’s user manual or seek assistance from a qualified technician. Regular maintenance and prompt troubleshooting can help keep your self-priming water pump operating smoothly and effectively.

With proper troubleshooting and maintenance, your self-priming water pump will continue to serve you reliably for a long time. In the final section, we will conclude our discussion on self-priming water pumps.

Conclusion

Self-priming water pumps are versatile, reliable, and convenient tools that provide efficient water transfer in various applications. These pumps are designed to start pumping water without the need for external priming, making them a popular choice for both residential and commercial settings.

In this article, we have explored how self-priming water pumps work, the advantages they offer, and the different applications where they excel. We discussed the importance of considering factors such as flow rate, total head, power source, and pump material when choosing the right pump for your specific needs.

We also covered the installation and maintenance requirements of self-priming water pumps, highlighting the significance of proper positioning, priming, and routine maintenance to ensure efficient and reliable operation. By following the recommended installation and maintenance steps, you can maximize the performance and lifespan of your self-priming water pump.

Furthermore, we discussed common issues that may occur with self-priming water pumps and provided troubleshooting tips to address these problems. Understanding and addressing these issues promptly can help maintain the pump’s performance and minimize downtime.

Whether you need to remove water from flooded areas, irrigate fields, maintain swimming pools, or handle emergency situations, a self-priming water pump is a valuable tool that provides convenience, reliability, and efficiency.

In conclusion, self-priming water pumps are essential tools for any water transfer needs. Their ability to prime themselves, handle various liquids, and deliver reliable performance make them a versatile choice for a wide range of applications. By selecting the right pump, following proper installation and maintenance procedures, and troubleshooting any issues that arise, you can ensure that your self-priming water pump continues to serve you effectively for years to come.

Frequently Asked Questions about What Is A Self Priming Water Pump

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Self Priming Water Pump”