Articles

What Is Seal Tight Conduit

Modified: February 17, 2024

Discover the benefits and uses of seal tight conduit in this comprehensive article. Learn how it can protect your electrical wiring and improve safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of Seal Tight Conduit! In today’s technologically advanced era, where the demand for various electrical and communication systems continues to rise, it is imperative to have a reliable method of protecting and organizing the wiring that powers these systems. That’s where Seal Tight Conduit comes into play.

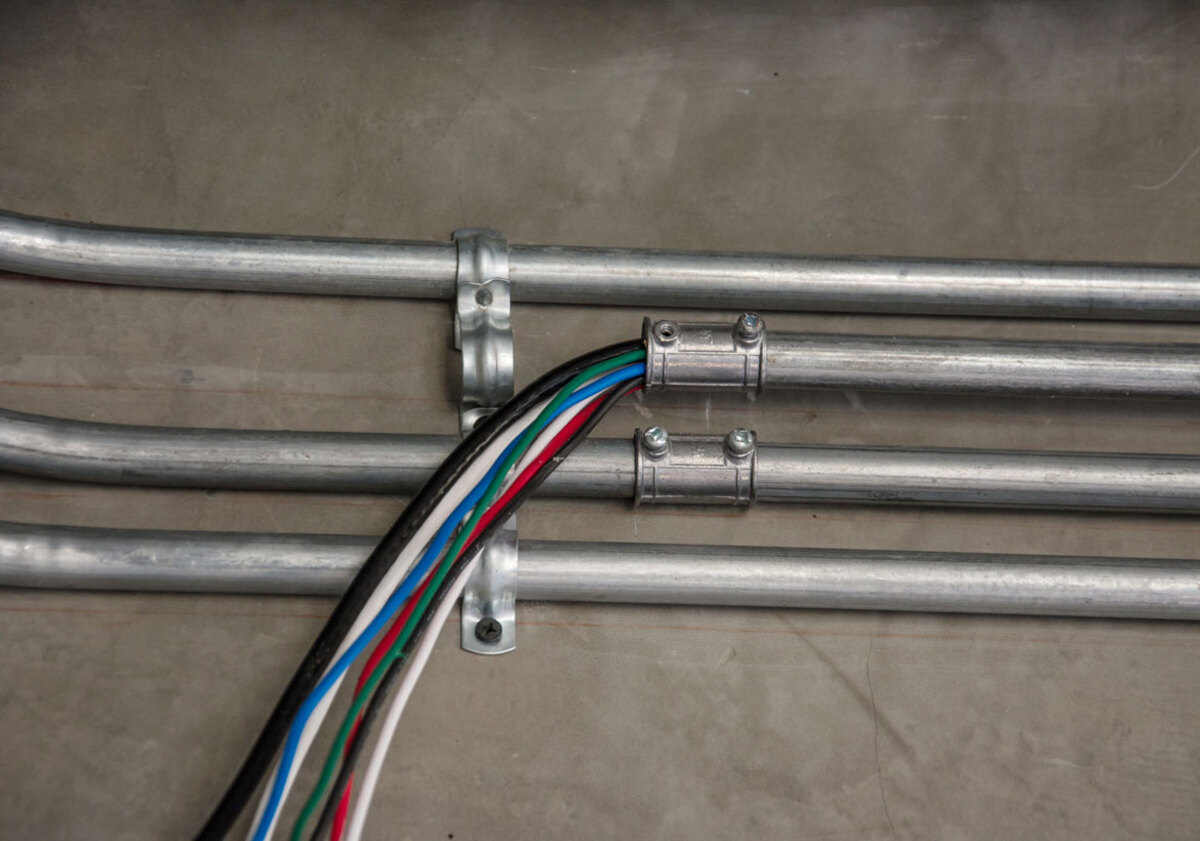

Seal Tight Conduit, also known as Liquid Tight Conduit, is a flexible and durable type of conduit designed to protect electrical wires, cables, and communication lines from moisture, dust, corrosion, and other environmental hazards. It’s a go-to solution for any project that requires a high level of protection and is commonly used in both residential and commercial applications.

So, what makes Seal Tight Conduit stand out from other types of conduits? One of the key features is its ability to provide a watertight and airtight seal, ensuring the longevity and safety of the enclosed wires. This makes it ideal for outdoor installations, underground wiring, and areas exposed to harsh weather conditions.

Not only does Seal Tight Conduit provide excellent protection against external elements, but it also offers flexibility for installation in tight spaces. Its bendable nature allows it to navigate through corners, bends, and obstacles easily, minimizing the need for additional fittings and reducing installation time.

Moreover, Seal Tight Conduit is resistant to UV rays, chemicals, and oils, ensuring durability even in demanding environments. This makes it suitable for a wide range of applications, including residential wiring, industrial facilities, outdoor lighting systems, communication networks, and more.

In this article, we will explore the uses, benefits, installation process, types, and maintenance of Seal Tight Conduit. Whether you’re a homeowner, electrician, or someone interested in learning more about electrical systems, this guide will provide you with valuable information to help you make informed decisions about using Seal Tight Conduit for your projects.

Key Takeaways:

- Seal Tight Conduit, also known as Liquid Tight Conduit, provides a watertight and airtight seal, making it ideal for outdoor, underground, and industrial applications. Its flexibility, durability, and resistance to environmental hazards ensure reliable protection for electrical systems.

- When choosing Seal Tight Conduit, consider factors such as environmental conditions, required level of protection, flexibility, compatibility, and compliance with safety standards. Proper maintenance and regular inspections are essential to ensure the longevity and reliability of Seal Tight Conduit.

Read more: How To Cut A Tight Conduit Seal

Definition of Seal Tight Conduit

Seal Tight Conduit, also known as Liquid Tight Conduit, is a type of flexible tubing used to protect electrical wiring, cables, and communication lines from moisture, dust, dirt, and other environmental hazards. It provides a secure and watertight seal, preventing any damage or deterioration to the enclosed wires.

The conduit is made from a high-quality thermoplastic material, typically PVC (Polyvinyl Chloride) or HDPE (High-Density Polyethylene), which is resistant to various chemicals, UV rays, and weathering. This ensures its durability and longevity, even in demanding applications.

Seal Tight Conduit is specifically designed for applications where the wiring is exposed to moisture or liquids. It effectively prevents water, oils, solvents, and other liquids from infiltrating the electrical system, thereby reducing the risk of short circuits, electrical failures, and potential hazards.

The conduit is available in various diameters, ranging from 1/4 inch to 4 inches, to accommodate different wire sizes and cable bundles. It is also available in different lengths, pre-cut or in rolls, providing flexibility for different installation requirements.

One of the notable features of Seal Tight Conduit is its flexibility. The conduit can be bent, twisted, and maneuvered easily, allowing it to navigate through tight spaces and complex routes without the need for additional fittings. This flexibility significantly simplifies installation and reduces labor time and costs.

In addition to its flexibility, the conduit is also flame retardant, providing an extra layer of safety. It adheres to industry standards, such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association), ensuring that it meets stringent quality and safety regulations.

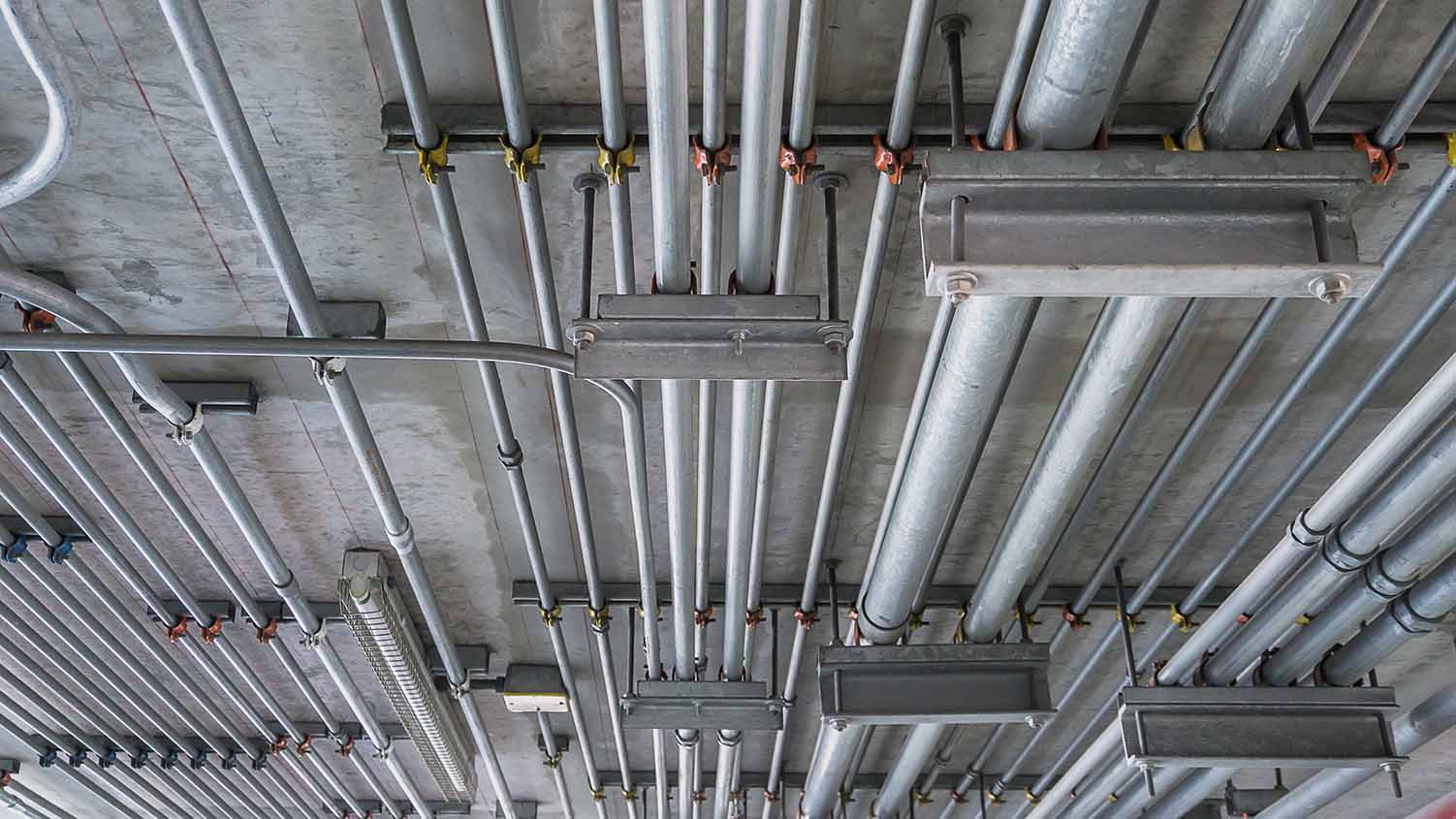

Seal Tight Conduit is commonly used in a wide range of applications, including outdoor lighting systems, underground wiring, industrial facilities, commercial buildings, telecommunications networks, marine applications, and residential installations. Its versatility, reliability, and durable construction make it an essential component in ensuring the proper functioning of electrical systems.

Now that we understand the definition of Seal Tight Conduit, let’s explore its uses and benefits in more detail.

Uses and Benefits of Seal Tight Conduit

Seal Tight Conduit offers a wide range of uses and benefits in various industries and applications. Let’s delve into some of the key uses and advantages of using this versatile conduit:

1. Outdoor Lighting Systems: Seal Tight Conduit is commonly used in outdoor lighting applications, such as landscape lighting, parking lot lighting, and street lighting. Its ability to withstand exposure to UV rays, moisture, and harsh weather conditions ensures reliable and long-lasting performance.

2. Underground Wiring: Seal Tight Conduit provides excellent protection to electrical wiring in underground installations. It safeguards against water infiltration, corrosion, and physical damage, making it suitable for applications such as underground electrical distribution, utility projects, and irrigation systems.

3. Industrial Facilities: Seal Tight Conduit is widely used in industrial plants, factories, and manufacturing facilities, where the wiring is exposed to harsh environments, chemicals, and mechanical stress. It ensures the safety and reliability of electrical systems, preventing any potential disruptions or hazards.

4. Commercial Buildings: Seal Tight Conduit is an ideal choice for commercial buildings, such as offices, retail stores, and healthcare facilities. It provides a robust and secure solution for electrical wiring, meeting safety regulations and minimizing the risk of electrical failures or accidents.

5. Telecommunications Networks: Seal Tight Conduit is essential in telecommunications infrastructure, protecting communication lines and cables from moisture, dust, and physical damage. It ensures uninterrupted connectivity and reliable performance in telecommunication networks, including data centers, cellular towers, and fiber optic installations.

6. Marine Applications: Seal Tight Conduit is suitable for marine environments, where moisture, saltwater, and corrosive substances can damage electrical systems. It provides a watertight seal, preventing water infiltration and maintaining the integrity of electrical wiring on boats, yachts, and other marine vessels.

7. Residential Installations: Seal Tight Conduit is commonly used in residential wiring projects, offering protection and organization for electrical wires in homes. It ensures the safety of homeowners and their electrical systems, especially in areas prone to moisture or external hazards.

Now that we have explored some of the prevalent uses of Seal Tight Conduit, let’s delve into its benefits:

– Water and Moisture Resistance: The primary advantage of Seal Tight Conduit is its ability to provide a tight seal against water, moisture, and other liquids. By preventing water infiltration, it safeguards the enclosed wiring from damage, corrosion, and short circuits.

– Environmental Protection: Seal Tight Conduit offers excellent protection against dust, dirt, chemicals, and other environmental hazards. It ensures that the enclosed wires remain unaffected by external elements, resulting in improved reliability and longevity of the electrical system.

– Flexibility and Ease of Installation: Seal Tight Conduit’s flexibility allows for easy installation in tight spaces and complex routes. It can be bent and twisted without the need for additional fittings, reducing labor time and costs. This makes it a preferred choice for electricians and contractors.

– Durability and Longevity: The high-quality thermoplastic construction of Seal Tight Conduit ensures its durability and resistance to UV rays, chemicals, and weathering. It can withstand extreme conditions and maintains its performance over time, resulting in a longer lifespan for the electrical system.

– Compatibility with Various Wire Sizes and Cable Bundles: Seal Tight Conduit is available in different diameters, accommodating a wide range of wire sizes and cable bundles. This versatility allows for flexibility in design and ensures efficient installation of various electrical systems.

– Compliance with Safety Standards: Seal Tight Conduit adheres to industry safety standards, such as UL and CSA, ensuring that it meets specified quality and safety regulations. This provides peace of mind to users, knowing that the conduit has undergone rigorous testing and meets stringent requirements.

Overall, the uses and benefits of Seal Tight Conduit make it an indispensable component in ensuring the protection, reliability, and longevity of electrical systems in a wide range of applications. Now, let’s move on to understanding the installation process of Seal Tight Conduit.

Installation Process of Seal Tight Conduit

The installation process of Seal Tight Conduit is relatively straightforward, but it is essential to follow the correct steps to ensure a secure and effective installation. Here is a step-by-step guide on how to install Seal Tight Conduit:

Step 1: Planning and Preparation: Before starting the installation, carefully plan the route and layout of the conduit. Identify the starting and ending points, as well as any bends or obstacles along the way. Measure the required length of the conduit and prepare all necessary tools and materials.

Step 2: Gather Materials: Gather all the required materials, including the Seal Tight Conduit, appropriate connectors, fittings, and fasteners. Ensure that you have the correct size and type of conduit for your project.

Step 3: Mark the Path: Use a pencil or chalk to mark the path where the conduit will be installed. This will serve as a guide during the installation process.

Step 4: Make Openings: If necessary, make openings in walls, floors, or other surfaces to accommodate the conduit. Use appropriate tools, such as a drill or hole saw, to create the openings. Be careful to follow safety guidelines and avoid damaging any existing wiring or structures.

Step 5: Install Connectors: Install the appropriate connectors at the starting and ending points of the conduit. Connectors ensure a secure and watertight seal where the conduit meets junction boxes, electrical panels, or other enclosures.

Step 6: Thread the Conduit: Begin threading the Seal Tight Conduit through the designated path, starting at one end and working your way towards the other. Ensure that the conduit is aligned with the marked path and that it follows any bends or turns accurately.

Step 7: Secure the Conduit: Use appropriate fasteners, such as conduit straps or clamps, to secure the conduit in place at regular intervals. This helps to prevent excessive movement or sagging and ensures a neat and organized installation.

Step 8: Make Connections: Once the conduit is in place, make the necessary connections to the wires or cables inside. Follow industry-standard practices and guidelines for connecting and securing the wires within the conduit. Use appropriate connectors, fittings, and techniques to ensure reliable and safe connections.

Step 9: Seal the Conduit: If required, apply appropriate sealants or fittings to ensure a watertight seal at connections, junction boxes, or other points in the conduit. This further enhances the protection provided by Seal Tight Conduit and prevents water or moisture intrusion.

Step 10: Test and Inspect: Once the installation is complete, thoroughly test and inspect the electrical system to ensure its proper functioning. Check for any loose connections, faults, or abnormalities. Ensure that the conduit is properly secured and that there are no obstructions or damage along the path.

Always refer to the manufacturer’s instructions and industry best practices when installing Seal Tight Conduit. If you are unsure about any aspect of the installation process, consult a qualified electrician or professional for guidance.

Now that we are familiar with the installation process of Seal Tight Conduit, let’s explore the different types of Seal Tight Conduit available in the market.

Types of Seal Tight Conduit

Seal Tight Conduit comes in various types, each designed to meet specific requirements and applications. Here are some of the common types of Seal Tight Conduit available in the market:

1. PVC Seal Tight Conduit: PVC (Polyvinyl Chloride) Seal Tight Conduit is a popular choice for electrical and communication installations. It is lightweight, flexible, and offers excellent resistance to moisture, oil, chemicals, and abrasion. PVC Seal Tight Conduit is available in various sizes and is suitable for both indoor and outdoor applications.

2. LFNC (Liquidtight Flexible Nonmetallic Conduit): LFNC is a type of Seal Tight Conduit that is resistant to liquid, oil, sunlight, and temperature variations. It is commonly used in wet locations, such as basements, garages, and outdoor installations. LFNC provides superior protection against water ingress, making it suitable for underground and direct burial applications.

3. LFMC (Liquidtight Flexible Metal Conduit): LFMC combines the flexibility of Seal Tight Conduit with the added strength of a metal core. It is made with a spiral-wound steel core coated with PVC or other protective materials. LFMC offers enhanced crush resistance and is suitable for applications where additional mechanical protection is required.

4. LFNC-B (Liquidtight Flexible Nonmetallic Corrugated Conduit): LFN-CB is a corrugated version of Seal Tight Conduit that provides flexibility and protection against liquids, moisture, and mechanical damage. It is commonly used in outdoor applications, such as irrigation systems, outdoor lighting, and air conditioning installations.

5. HDPE (High-Density Polyethylene) Seal Tight Conduit: HDPE Seal Tight Conduit is known for its high durability and rugged construction. It offers excellent protection against moisture, sunlight, chemicals, and abrasion. HDPE Seal Tight Conduit is often used in industrial and outdoor applications where extreme conditions are present.

6. Halogen-Free Seal Tight Conduit: Halogen-Free Seal Tight Conduit is designed to minimize the emission of harmful halogen gases in the event of a fire. It is commonly used in applications where safety is a top priority, such as hospitals, schools, and public buildings.

7. FMC (Flexible Metal Conduit): FMC is a type of Seal Tight Conduit that consists of a spiral-wound metal core with a PVC or other protective coating. It provides excellent physical protection and flexibility for electrical wiring. FMC is commonly used in industrial and commercial applications where resistance to mechanical stress is important.

It is important to choose the appropriate type of Seal Tight Conduit based on the specific needs of your project. Consider factors such as the environment, temperature, moisture exposure, and level of mechanical protection required to ensure a successful installation.

Now that we have explored the various types of Seal Tight Conduit, let’s compare it to other types of conduit to understand its unique advantages.

Seal tight conduit is a flexible, non-metallic conduit used to protect electrical wiring from moisture, chemicals, and physical damage. It is commonly used in outdoor and wet locations.

Read also: 11 Best Liquid Tight Conduit for 2024

Comparison of Seal Tight Conduit with other Conduit Types

When it comes to selecting the right conduit for your electrical and communication installations, it’s essential to consider the unique features and benefits of each type. Here, we compare Seal Tight Conduit with other commonly used conduit types to help you make an informed decision:

1. Rigid Metal Conduit (RMC): RMC is a traditional conduit option made of steel or aluminum. It provides the highest level of protection against physical damage and is suitable for heavy-duty applications. However, RMC is rigid and less flexible compared to Seal Tight Conduit, making it challenging to install in tight spaces or areas where bending is required.

2. Electrical Metallic Tubing (EMT): EMT is another popular conduit option made of thin-wall galvanized steel. It offers moderate protection and is commonly used in commercial and residential applications. While EMT is relatively flexible, it is not as versatile as Seal Tight Conduit and may not provide the same level of resistance to moisture and environmental hazards.

3. Electrical Nonmetallic Tubing (ENT): ENT is a plastic conduit option made of PVC or other nonmetallic materials. It is lightweight and easy to work with, but it may not offer the same level of durability and protection as Seal Tight Conduit. ENT is commonly used in residential applications where moisture resistance is not a significant concern.

4. Flexible Metal Conduit (FMC): FMC consists of a metal core surrounded by a protective coating, typically PVC. It provides flexibility and moderate protection for electrical wiring. However, FMC may not offer the same level of resistance to moisture, oils, and other environmental hazards as Seal Tight Conduit. Moreover, FMC may require additional fittings and connectors to ensure a watertight seal.

5. PVC Conduit: PVC conduit is a popular choice for both indoor and outdoor applications. It is lightweight, cost-effective, and offers good protection against physical damage. However, PVC conduit may lack the watertight and airtight seal provided by Seal Tight Conduit, making it less suitable for applications exposed to moisture, oils, or other liquids.

6. Liquidtight Flexible Metal Conduit (LFMC): LFMC combines the flexibility of Seal Tight Conduit with the added strength of a metal core. It provides excellent protection against physical damage and is suitable for applications that require enhanced mechanical protection. However, LFMC may still fall short in terms of the watertight seal and resistance to moisture offered by Seal Tight Conduit.

Overall, Seal Tight Conduit stands out due to its unique ability to provide a watertight and airtight seal, making it particularly suited for applications that require protection against moisture, liquids, and environmental hazards. Its flexibility, durability, and resistance to UV rays and chemicals make it an excellent choice for outdoor installations, underground wiring, and industrial facilities.

Consider the specific needs and requirements of your project when selecting a conduit type. If moisture resistance and maximum protection are crucial, Seal Tight Conduit is the optimal choice.

Now that we have compared Seal Tight Conduit with other conduit types, let’s explore the factors to consider before choosing Seal Tight Conduit for your project.

Factors to Consider Before Choosing Seal Tight Conduit

Before selecting Seal Tight Conduit for your electrical or communication project, it’s important to consider several factors to ensure it meets your specific requirements. Here are some key factors to keep in mind:

1. Environmental Conditions: Assess the environmental conditions in which the conduit will be installed. Consider factors such as moisture, UV exposure, temperature fluctuations, and the presence of chemicals or corrosive substances. Seal Tight Conduit is designed to provide excellent protection in harsh environments, making it suitable for outdoor, underground, and industrial applications.

2. Degree of Protection Required: Evaluate the level of protection needed for your wiring and cables. If your project requires a watertight and airtight seal to prevent moisture, dust, or other liquids from entering the conduit, Seal Tight Conduit is an ideal choice. It offers superior protection against external elements that can cause damage or deterioration to electrical systems.

3. Flexibility and Ease of Installation: Consider the flexibility and ease of installation provided by Seal Tight Conduit. Its bendable nature allows for easy maneuverability and installation in tight spaces or complex routes without the need for additional fittings. This can reduce labor costs and save time during the installation process.

4. Wire Size and Cable Bundle: Determine the size of your wires and cable bundles to choose the correct diameter of Seal Tight Conduit. Ensure that the conduit can comfortably accommodate the number and thickness of wires you intend to install. Consider the future expansion or modification of your electrical system to leave room for additional wiring.

5. Compliance with Standards: Check whether the Seal Tight Conduit you are considering meets industry standards and regulations, such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association). Compliance with these standards ensures that the conduit has undergone rigorous testing and meets safety and quality requirements.

6. Durability and Longevity: Assess the durability and longevity of Seal Tight Conduit. Look for conduit made from high-quality materials, such as PVC or HDPE, that are resistant to UV rays, chemicals, oils, and weathering. A durable conduit will provide long-lasting protection and withstand the demands of your application.

7. Cost and Budget: Consider your budget and the overall cost-effectiveness of Seal Tight Conduit. Evaluate the upfront cost of the conduit, as well as any additional fittings or accessories required for installation. Also, factor in long-term savings, such as reduced maintenance and repair costs, that can result from using high-quality conduit.

8. Compatibility with Other System Components: Ensure that Seal Tight Conduit is compatible with other system components, such as connectors, fittings, and junction boxes. Verify that the conduit and its accessories provide a secure and reliable connection, ensuring optimal performance and safety.

By considering these factors, you can choose the most suitable Seal Tight Conduit for your project, ensuring the protection and integrity of your electrical or communication system.

Now that we have explored the factors to consider, let’s move on to understanding the maintenance and repair of Seal Tight Conduit.

Maintenance and Repair of Seal Tight Conduit

Maintaining and regularly inspecting your Seal Tight Conduit is crucial to ensure its proper functioning and longevity. While Seal Tight Conduit is designed to be durable and resistant to various environmental hazards, it’s essential to perform routine maintenance and address any issues promptly. Here are some key maintenance and repair considerations for Seal Tight Conduit:

1. Regular Inspection: Conduct periodic inspections of the conduit to check for any signs of damage, wear, or degradation. Inspect the entire length of the conduit, paying particular attention to areas prone to moisture exposure or physical stress. Look for cracks, breaks, loose fittings, or signs of corrosion.

2. Cleanliness: Keep the Seal Tight Conduit clean and free from dirt, dust, and debris. Regularly remove any accumulated dirt or foreign particles that may obstruct the conduit or compromise its performance. Use a soft cloth or brush to gently clean the exterior surface of the conduit. Avoid using abrasive materials that can cause damage.

3. Repairs: If any damage or defects are detected during the inspection, prompt repairs are essential. Depending on the nature and severity of the damage, repairs may include replacing damaged sections of the conduit, repairing or replacing fittings, or sealing any cracks or gaps to ensure a watertight and airtight seal. Consult a qualified electrician or professional to assess and perform repairs if necessary.

4. Seal Integrity: Verify the integrity of the seals and fittings along the length of the conduit. Ensure that the seals are undamaged and properly installed, maintaining the watertight and airtight properties of the conduit. If any seals appear compromised, reseal the affected areas using compatible sealants or fittings recommended by the manufacturer.

5. Protection from External Factors: Take precautions to protect the Seal Tight Conduit from potential external damage. This can include installing conduit straps or clamps at appropriate intervals to secure the conduit and prevent excessive movement or strain. Additionally, avoid exposing the conduit to harsh chemicals, extreme temperatures, or other substances that could compromise its integrity.

6. Documentation and Recordkeeping: Maintain records of the installation, maintenance, and repairs performed on the Seal Tight Conduit. This documentation can provide a comprehensive history of the conduit’s maintenance and help with troubleshooting or future maintenance efforts. Keep a record of any repairs or replacements made, including dates and details.

7. Regular Testing: Test the electrical system connected to the Seal Tight Conduit periodically to verify its proper operation. Check for any irregularities, such as flickering lights or voltage fluctuations, that may indicate an issue with the conduit or the enclosed wiring. Consult a qualified electrician if any abnormalities are detected.

8. Professional Assistance: If you are unsure about any aspect of the maintenance or repair process, consult a qualified electrician or professional. They can provide guidance, perform inspections, and address any issues related to the Seal Tight Conduit.

By following these maintenance and repair practices, you can help ensure the optimal performance and longevity of your Seal Tight Conduit. Regular inspections, prompt repairs, and proper protection from environmental factors will contribute to the reliability and safety of your electrical or communication system.

Now that we have discussed the maintenance and repair of Seal Tight Conduit, let’s conclude our article.

Conclusion

Seal Tight Conduit, also known as Liquid Tight Conduit, is a versatile and reliable solution for protecting electrical wiring, cables, and communication lines from moisture, dust, and other environmental hazards. Its ability to provide a watertight and airtight seal sets it apart from other types of conduit.

Throughout this article, we have explored the uses and benefits of Seal Tight Conduit in various applications, including outdoor lighting systems, underground wiring, industrial facilities, and residential installations. Its flexibility, durability, and resistance to UV rays, chemicals, and weathering make it an indispensable component in ensuring the proper functioning of electrical systems.

The installation process of Seal Tight Conduit involves careful planning, gathering of materials, marking the path, threading the conduit, making connections, and testing the system for proper functionality. Following the correct installation procedures ensures a secure and effective installation.

When choosing Seal Tight Conduit, consider factors such as environmental conditions, required level of protection, flexibility, compatibility, and compliance with safety standards. These considerations will help you select the most suitable conduit for your specific project requirements.

Proper maintenance and regular inspections are essential to ensure the longevity and reliability of Seal Tight Conduit. By conducting routine checks, keeping the conduit clean, addressing any damage or defects promptly, and protecting it from external factors, you can extend its lifespan and maintain optimal performance.

In conclusion, Seal Tight Conduit offers a range of advantages, including superior protection against moisture, flexibility for easy installation, compatibility with various wire sizes, and compliance with safety standards. By choosing Seal Tight Conduit and following proper maintenance practices, you can safeguard your electrical system and ensure its efficient and safe operation for years to come.

Remember, if you are unsure about any aspect of working with Seal Tight Conduit, it’s always best to seek the guidance of a qualified electrician or professional. They can provide expertise and ensure that the installation and maintenance processes are carried out correctly.

We hope this comprehensive guide has provided valuable insights into Seal Tight Conduit and its various aspects. Whether you’re a homeowner, electrician, or someone interested in learning more about electrical systems, this article serves as a valuable resource to help you make informed decisions about using Seal Tight Conduit for your projects.

Frequently Asked Questions about What Is Seal Tight Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Seal Tight Conduit”