Home>Articles>What Is The Appropriate Hole Saw Size For A 1 1/2 Inch Conduit

Articles

What Is The Appropriate Hole Saw Size For A 1 1/2 Inch Conduit

Modified: May 6, 2024

Find the right size hole saw for 1 1/2 conduit with our helpful article. Learn about the best options and get expert advice for your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on selecting the right hole saw size for 1 1/2″ conduit. Whether you are a professional electrician or a DIY enthusiast, choosing the correct hole saw size is crucial for successful conduit installations.

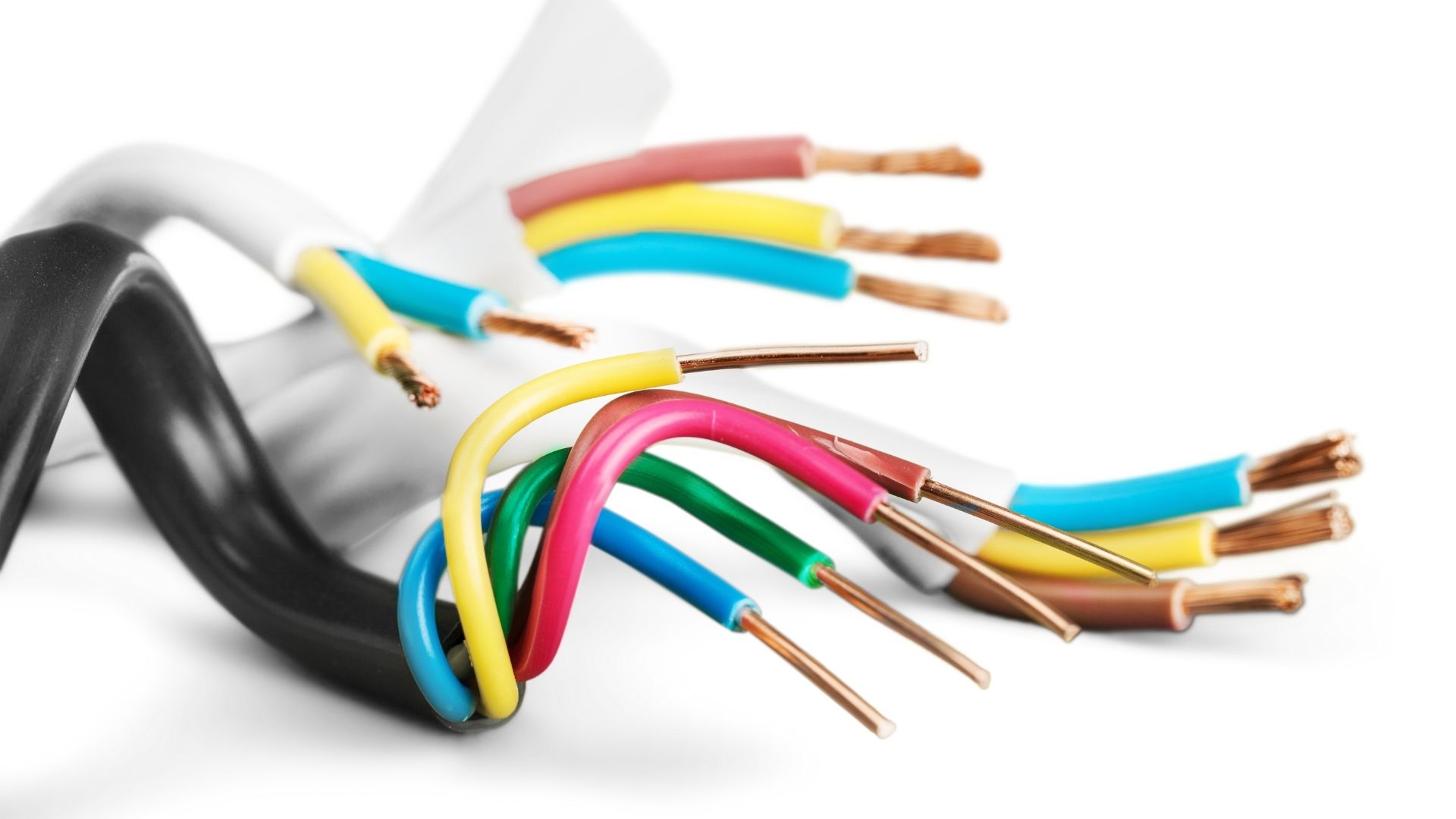

Conduits are widely used in electrical installations to protect and route electrical wires. They come in various sizes, and it’s essential to choose the right size hole saw to create openings for conduits in different materials such as wood, metal, or plastic.

In this article, we will explore the fundamentals of hole saws, provide an understanding of conduit sizes, and guide you in selecting the appropriate hole saw size for 1 1/2″ conduit. So, let’s dive in and learn how to make precise and efficient conduit openings with the right hole saw size.

Key Takeaways:

- Choosing the right hole saw size for 1 1/2″ conduit involves measuring the outer diameter, considering material type, and selecting a size slightly larger than the conduit for a secure fit.

- Recommended hole saw sizes for 1 1/2″ conduit include 2″, 2 1/8″, and 2 1/4″ options, catering to different preferences for a snug or flexible fit, ensuring professional and reliable electrical installations.

What is a Hole Saw?

A hole saw is a specialized cutting tool used to create circular holes in various materials. It consists of a cylindrical arbor with a central drill bit and a circular cutting saw blade attached to the outer edge. The saw blade is evenly spaced with sharp teeth that come in different sizes and configurations.

Hole saws are commonly used in construction, woodworking, plumbing, and electrical installations. They provide a quick and efficient method to create large-diameter holes compared to traditional drilling methods. The size of the hole saw depends on the diameter of the hole required and can range from small sizes, usually starting at 3/4″, up to several inches in diameter.

The advantage of using a hole saw is its ability to cut through various materials, including wood, metal, plastic, and even ceramic tiles. It can be used with a handheld drill or mounted on a drill press, depending on the complexity of the project.

The central drill bit of the hole saw acts as a guide and creates a small pilot hole. As the cutting saw blade rotates, it removes the material within the marked circle, resulting in a clean and precise hole. The removed material, or slug, typically remains trapped within the hole saw until it is manually pushed out or ejected.

It’s important to note that hole saws are not suitable for cutting through thick or dense materials such as concrete or stone. For such applications, specialized tools like diamond core drills or masonry bits are required.

Now that we have covered the basics of hole saws, let’s delve into the understanding of conduit sizes, which is vital for choosing the right hole saw size for your 1 1/2″ conduit installations.

Understanding Conduit Sizes

Before we dive into selecting the right hole saw size for 1 1/2″ conduit, it’s essential to have a clear understanding of conduit sizes and how they are measured.

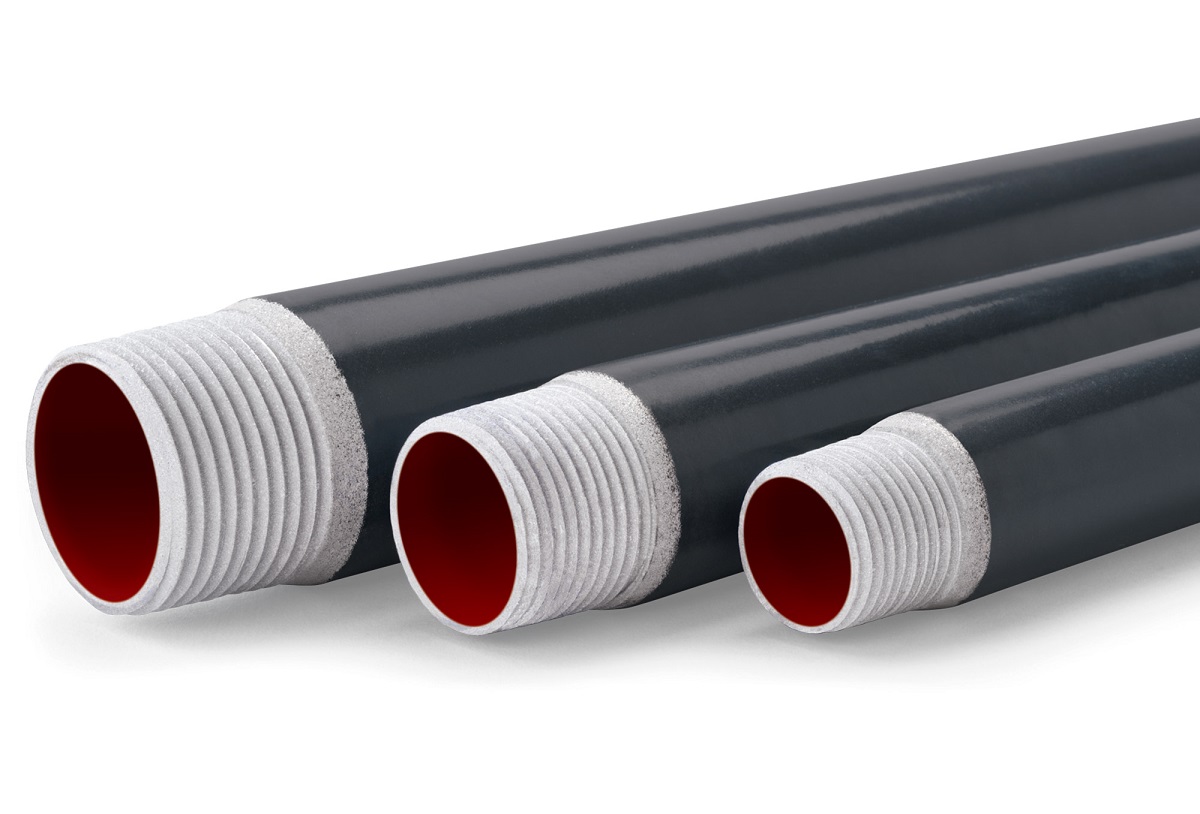

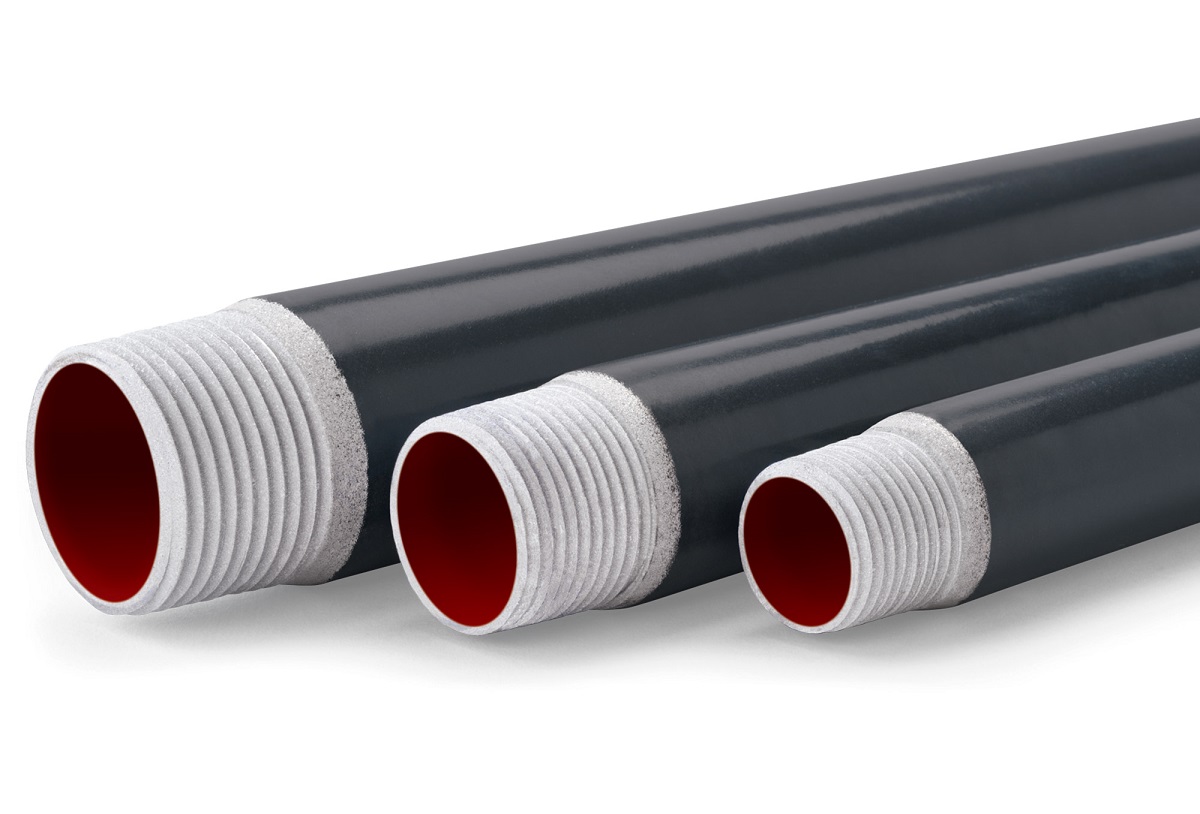

Conduits are hollow tubes used to protect and route electrical wires in various installations. They come in different sizes, typically measured by their inner diameter (ID) or outer diameter (OD). The size of the conduit is crucial as it determines the maximum number of wires that can fit inside and the level of protection provided.

In the case of 1 1/2″ conduit, the measurement refers to the trade size of the conduit, which corresponds to its nominal or approximate size. However, it’s important to note that the actual outer diameter (OD) of a conduit may slightly differ from its nominal size due to manufacturing tolerances.

Conduits are available in various materials, including PVC (polyvinyl chloride), galvanized steel, aluminum, and flexible conduit made of plastic or metal. Each material has its specific applications and advantages, such as durability, flexibility, and resistance to corrosion.

It’s important to determine the appropriate conduit size based on the number and type of wires to be installed. National Electrical Code (NEC) guidelines provide specific requirements for conduit sizing to ensure safe and efficient electrical installations.

When selecting a conduit for a project, consider the following factors:

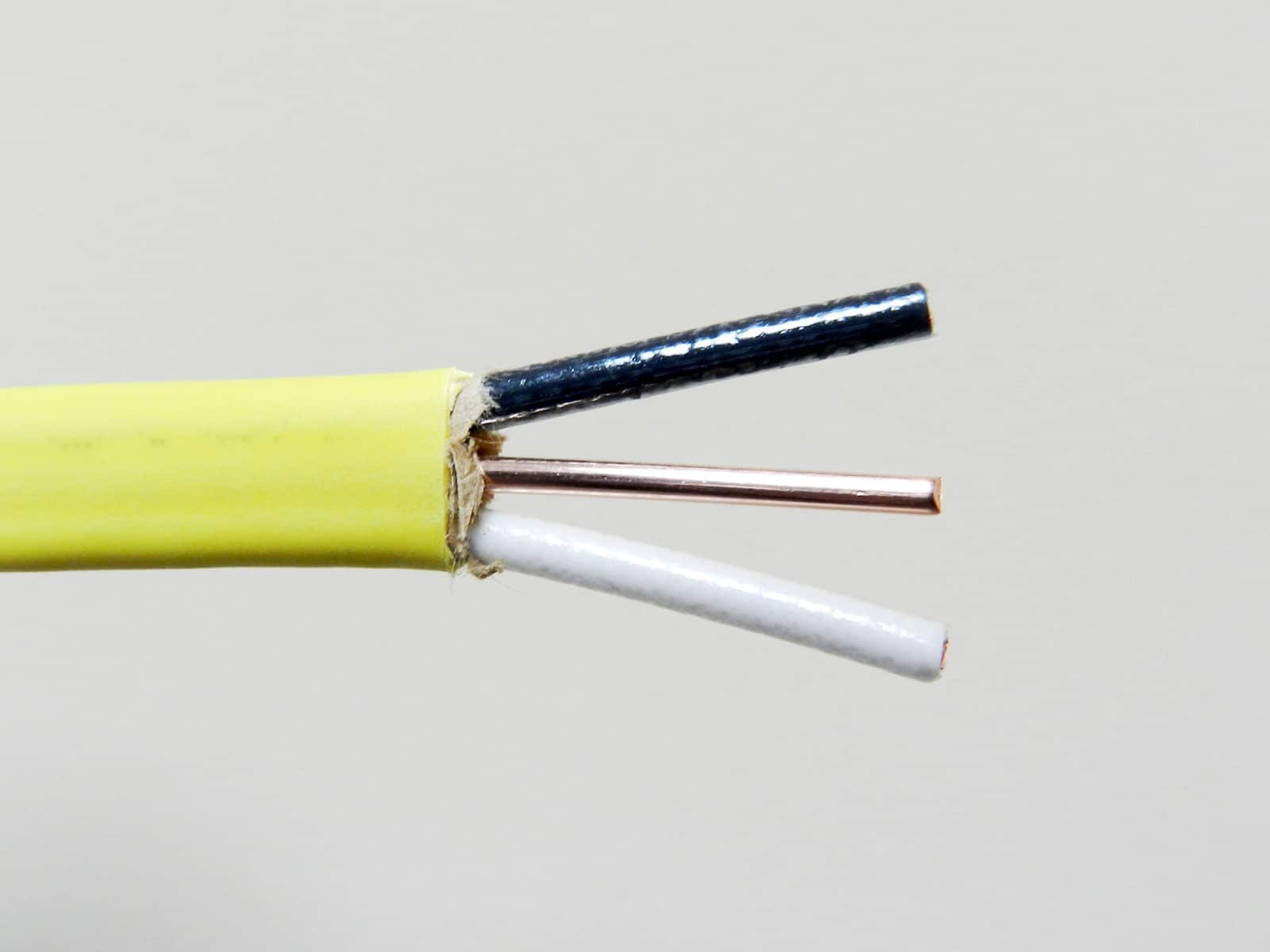

1. Wire Size: The size of the wires to be installed plays a significant role in determining the conduit size. Larger wire sizes require larger conduits to accommodate them.

2. Fill Capacity: Conduits have a maximum fill capacity, which refers to the number and size of wires that can be safely installed inside. NEC provides guidelines and tables to determine the fill capacity based on wire size and conduit diameter.

3. Environmental Factors: Consider the environmental conditions in which the conduit will be installed. For outdoor or corrosive environments, choose a conduit material that offers suitable protection and longevity.

Now that we have a solid understanding of conduit sizes, let’s explore how to choose the right hole saw size for 1 1/2″ conduit installations.

Selecting the Right Hole Saw Size

When it comes to selecting the right hole saw size for 1 1/2″ conduit, there are several factors to consider. Choosing the correct size ensures that the hole created is precise, allowing the conduit to fit snugly without any gaps.

1. Conduit Outer Diameter: Begin by measuring the outer diameter (OD) of the 1 1/2″ conduit you will be using. This measurement is crucial as it determines the size of the hole needed to accommodate the conduit. Typically, the OD of 1 1/2″ conduit is around 1.90″ to 1.94″.

2. Hole Saw Diameter: To create a hole with the appropriate size, select a hole saw with a diameter slightly larger than the outer diameter of the conduit. This additional space ensures a proper fit and allows for easy installation.

3. Cutting Depth: Consider the cutting depth of the hole saw. This refers to the length of the cutting blade and determines the depth of the hole created. Make sure the cutting depth is sufficient to accommodate the length of the conduit.

4. Material: Take into account the type of material you will be cutting. Different materials require different types of hole saws. For cutting through metal conduits, such as galvanized steel, use a hole saw designed specifically for metal cutting. For PVC or plastic conduits, a general-purpose hole saw should suffice.

5. Pilot Bit: Check if the hole saw comes with a pilot bit. The pilot bit acts as a guide and helps create a precise hole. Ensure that the size of the pilot bit matches the drill chuck size of your power drill.

6. Quality and Durability: Choose a hole saw of good quality and durability. This ensures smooth and precise cutting and longevity of the tool. Read reviews and consider reputable brands that are known for manufacturing reliable hole saws.

Always follow the manufacturer’s instructions and guidelines for proper installation and usage of the hole saw. Take safety precautions, such as wearing protective eyewear and gloves, while operating power tools.

By considering these factors and selecting the appropriate hole saw size, you can achieve clean and accurate holes for your 1 1/2″ conduit installations. Now, let’s explore the recommended hole saw sizes for 1 1/2″ conduit to make your selection even easier.

When using a hole saw for 1 1/2″ conduit, use a hole saw with a diameter slightly larger than the conduit size, such as a 2″ hole saw, to allow for easy installation and movement of the conduit.

Factors to Consider

When selecting the right hole saw size for 1 1/2″ conduit, it’s important to take into account several factors to ensure successful installation. These factors include:

1. Conduit Material: Consider the material of the conduit you will be working with. Different materials require different cutting techniques and tools. For example, metal conduits like galvanized steel may require specialized hole saws designed for cutting through metal, while PVC conduits can typically be cut using standard hole saws.

2. Desired Fit: Think about the fit you want to achieve between the conduit and the hole. If you prefer a snug fit, choose a hole saw size that is slightly larger than the outer diameter of the conduit. This will allow the conduit to fit tightly in the hole. If you want a looser fit or need some space for insulation or fillers, you can opt for a slightly larger hole saw size.

3. Cutting Speed: Consider the speed at which you want to complete the cutting process. Larger hole saw sizes may require more time and effort to cut through the material. If you need to make multiple holes or have a large number of conduit installations, you might prefer a smaller hole saw size for quicker and more efficient cutting.

4. Material Thickness: Take into consideration the thickness of the material you will be cutting. Thicker materials may require larger hole saw sizes to create a hole that is wide enough to accommodate the conduit.

5. Power Drill Compatibility: Ensure that the hole saw size you choose is compatible with your power drill’s chuck size. Most hole saws have standard-sized shanks that fit common power drills, but it’s important to double-check to avoid any compatibility issues.

6. Project Requirements: Assess the specific requirements of your project. Consider aspects such as budget, time constraints, and the overall scope of the installation. These factors may influence your choice of hole saw size.

Remember, it’s always a good practice to test the selected hole saw size on a scrap piece of material before proceeding with the actual installation. This will give you an opportunity to check the fit and make any necessary adjustments before working with the conduit itself.

By considering these factors, you can make an informed decision when selecting the right hole saw size for your 1 1/2″ conduit installation. Now, let’s move on to the recommended hole saw sizes for 1 1/2″ conduit to further assist you in your selection process.

Recommended Hole Saw Sizes for 1 1/2″ Conduit

When it comes to selecting the right hole saw size for 1 1/2″ conduit, there are several recommended options to consider. The specific size that will work best for your project may depend on factors such as the conduit material and the desired fit. Here are a few recommended hole saw sizes for 1 1/2″ conduit:

1. 2″ Hole Saw: A 2″ hole saw is a commonly used size for 1 1/2″ conduit installations. This size allows for a snug fit, with some room for adjustment. It provides enough space for the conduit to maneuver through the hole, ensuring a secure and stable installation.

2. 2 1/8″ Hole Saw: If you prefer a slightly looser fit or need room for insulation or fillers, a 2 1/8″ hole saw may be suitable for your 1 1/2″ conduit installations. This size allows for a bit more flexibility while still providing a secure fit.

3. 2 1/4″ Hole Saw: Another option to consider is a 2 1/4″ hole saw. This size offers a slightly larger opening, which can be beneficial if you anticipate the need for additional wires or cables in the conduit.

It’s important to note that these hole saw sizes are recommendations based on general industry practices. However, it’s always advisable to measure the actual outer diameter (OD) of your specific conduit to ensure an accurate fit. Depending on the manufacturing tolerances or brand-specific variations, the outer diameter of your conduit may slightly differ from the nominal size.

Furthermore, it’s worth mentioning that the selection of the hole saw size also depends on the material you are working with and the specific requirements of your project. Different materials may require slightly larger or smaller hole saw sizes to achieve the desired results.

Always refer to the manufacturer’s guidelines and follow best practices when using hole saws. Remember to use proper safety equipment, such as goggles and gloves, and be cautious when operating power tools.

By considering these recommended hole saw sizes and taking into account the specific factors of your project, you can confidently select the right hole saw size for your 1 1/2″ conduit installations. Now, let’s wrap up our guide with a concluding note.

Conclusion

Selecting the right hole saw size for 1 1/2″ conduit is crucial for precise and efficient installations. By understanding the basics of hole saws, conduit sizes, and the factors to consider, you can make an informed decision and achieve professional results.

Start by measuring the outer diameter (OD) of your 1 1/2″ conduit and select a hole saw size that provides a proper fit. Consider factors such as the material you are working with, the desired fit, cutting speed, and project requirements. It’s also important to ensure compatibility with your power drill and test the selected hole saw size on a scrap piece of material before proceeding with the actual installation.

Recommended hole saw sizes for 1 1/2″ conduit include 2″, 2 1/8″, and 2 1/4″ options. These sizes cater to different preferences, providing a secure fit or allowing for room for insulation or additional wires.

Always follow manufacturer’s guidelines, use safety equipment, and take necessary precautions when working with hole saws. Check for any specific variations in conduit sizes due to manufacturing tolerances to ensure an accurate fit.

Remember, the goal is to create clean and precise openings for your 1 1/2″ conduit, allowing for seamless wire routing and protection. By choosing the right hole saw size, you will ensure a professional and reliable electrical installation.

We hope this comprehensive guide has provided you with the knowledge and confidence to select the appropriate hole saw size for your 1 1/2″ conduit projects. Happy cutting and successful installations!

Now that you've got the hang of choosing hole saw sizes for conduits, why not expand your know-how with our next guide? Whether you're upgrading your toolkit or handling a new project, knowing about the top conduit fittings will prove invaluable. Dive into our detailed review to find out which options will suit your needs best.

Frequently Asked Questions about What Is The Appropriate Hole Saw Size For A 1 1/2 Inch Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Appropriate Hole Saw Size For A 1 1/2 Inch Conduit”